Forming method for improving structure performance of rare-earth magnesium alloy conical cylindrical part

A technology of microstructure and properties, rare earth magnesium, applied in metal processing equipment, metal extrusion dies, manufacturing tools, etc., can solve the problem of microstructure grain size growth, poor heating ability of rare earth magnesium alloy, affecting the use of warhead conical parts and other problems to achieve the effect of reducing heating times, improving mechanical properties, ensuring high performance and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

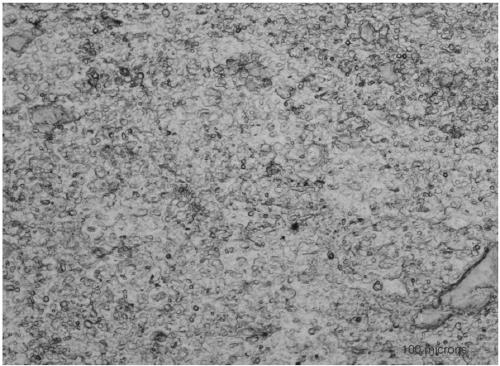

[0054] A forming method for improving the microstructure and performance of a rare earth magnesium alloy conical cylindrical part, the forming method comprising:

[0055] (1) Homogenize the Mg-9Gd-3RE rare earth magnesium alloy ingot, the homogenization treatment temperature is 500°C, the homogenization temperature is kept for 8 hours, and naturally cooled to room temperature after the heat preservation is completed;

[0056] (2) After the homogenization treatment, the ingot is subjected to extrusion deformation treatment, and the mold is first heated before extrusion, the mold heating temperature is 300 ° C, the extrusion ratio is 7, and the extruded bar is obtained after extrusion;

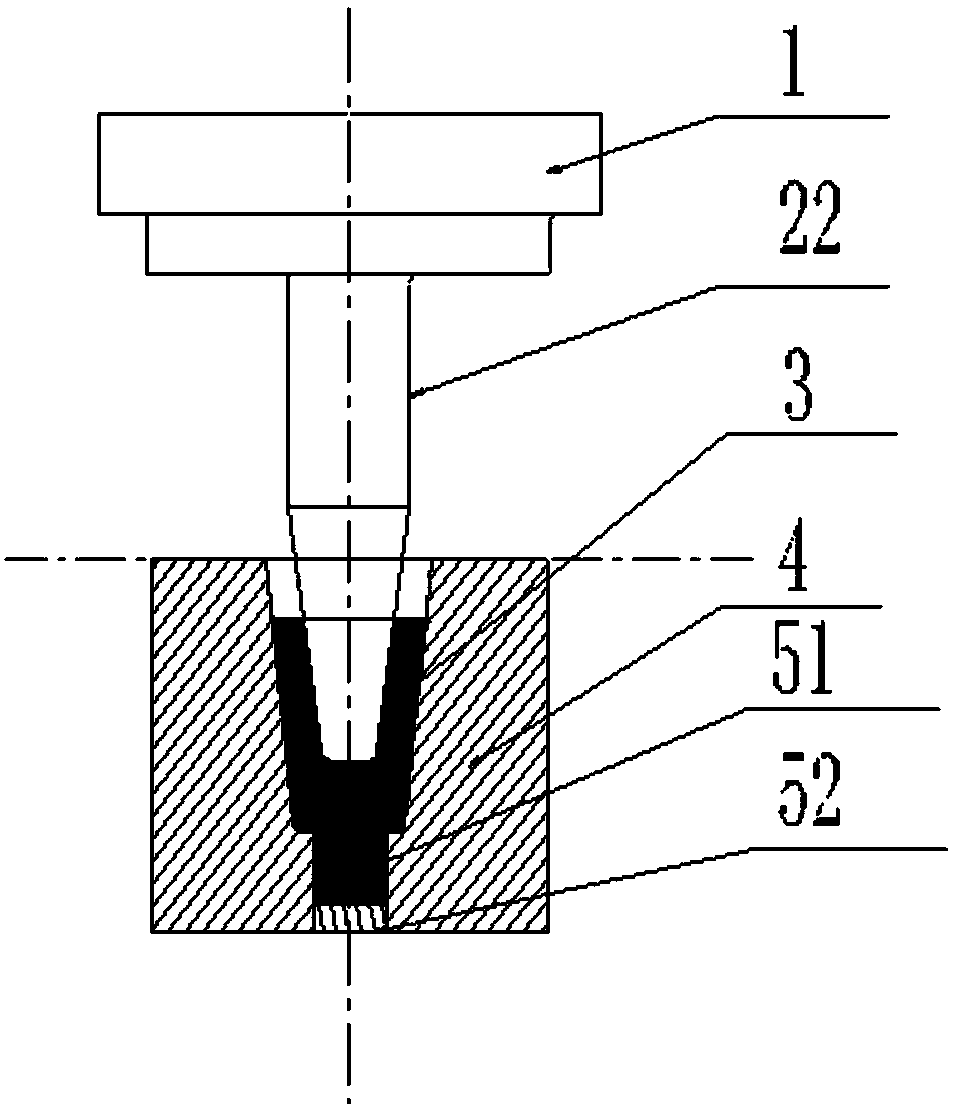

[0057] (3) Carry out upsetting deformation to the extruded rod obtained in step (2), the amount of upsetting deformation is 40%; the first punch 2, concave film 4 and top block 5 of the upsetting deformation mold, the heating temperature is 280 ℃ , keep warm for 0.5-2h; extrude the bar at a heat...

Embodiment 2

[0064] A forming method for improving the microstructure and performance of a rare earth magnesium alloy conical cylindrical part, the forming method comprising:

[0065] (1) Homogenize the Mg-9Gd-3RE rare earth magnesium alloy ingot, the homogenization treatment temperature is 500°C, the homogenization temperature is kept for 8 hours, and naturally cooled to room temperature after the heat preservation is completed;

[0066] (2) After the homogenization treatment, the ingot is subjected to extrusion deformation treatment, and the mold is first heated before extrusion, the mold heating temperature is 300 ° C, the extrusion ratio is 7, and the extruded bar is obtained after extrusion;

[0067] (3) Carry out upsetting deformation to the extruded rod obtained in step (2), the amount of upsetting deformation is 40%; the first punch 2, concave film 4 and top block 5 of the upsetting deformation mold, the heating temperature is 280 ℃ , heat preservation 0.5 ~ 2h; extruded bar heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com