A Forming Method for Improving the Microstructure and Properties of Rare Earth Magnesium Alloy Conical Cylindrical Parts

A technology of microstructure and properties, rare earth magnesium, applied in metal extrusion dies, metal processing equipment, forging/pressing/hammering machinery, etc. The use of warhead cones and other issues can improve mechanical properties, reduce heating times, and ensure high performance and high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

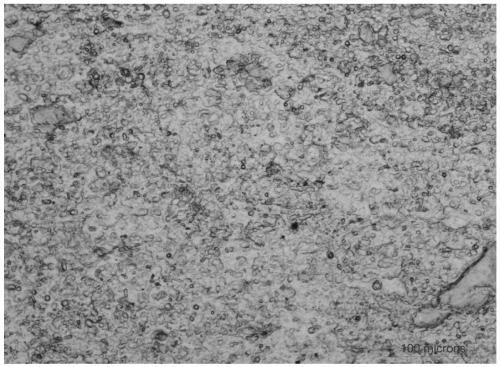

Embodiment 1

[0054] A forming method for improving the structure and performance of a rare earth magnesium alloy tapered cylindrical part, the forming method includes:

[0055] (1) Homogenize the Mg-9Gd-3RE rare earth magnesium alloy ingot, the homogenization temperature is 500 ℃, the homogenization temperature, keep for 8 hours, and cool to room temperature naturally after the keep warm;

[0056] (2) After homogenization, the ingot is subjected to extrusion deformation treatment. Before extrusion, the mold is first heated, the mold heating temperature is 300°C, the extrusion ratio is 7, and the extruded bar is obtained after extrusion;

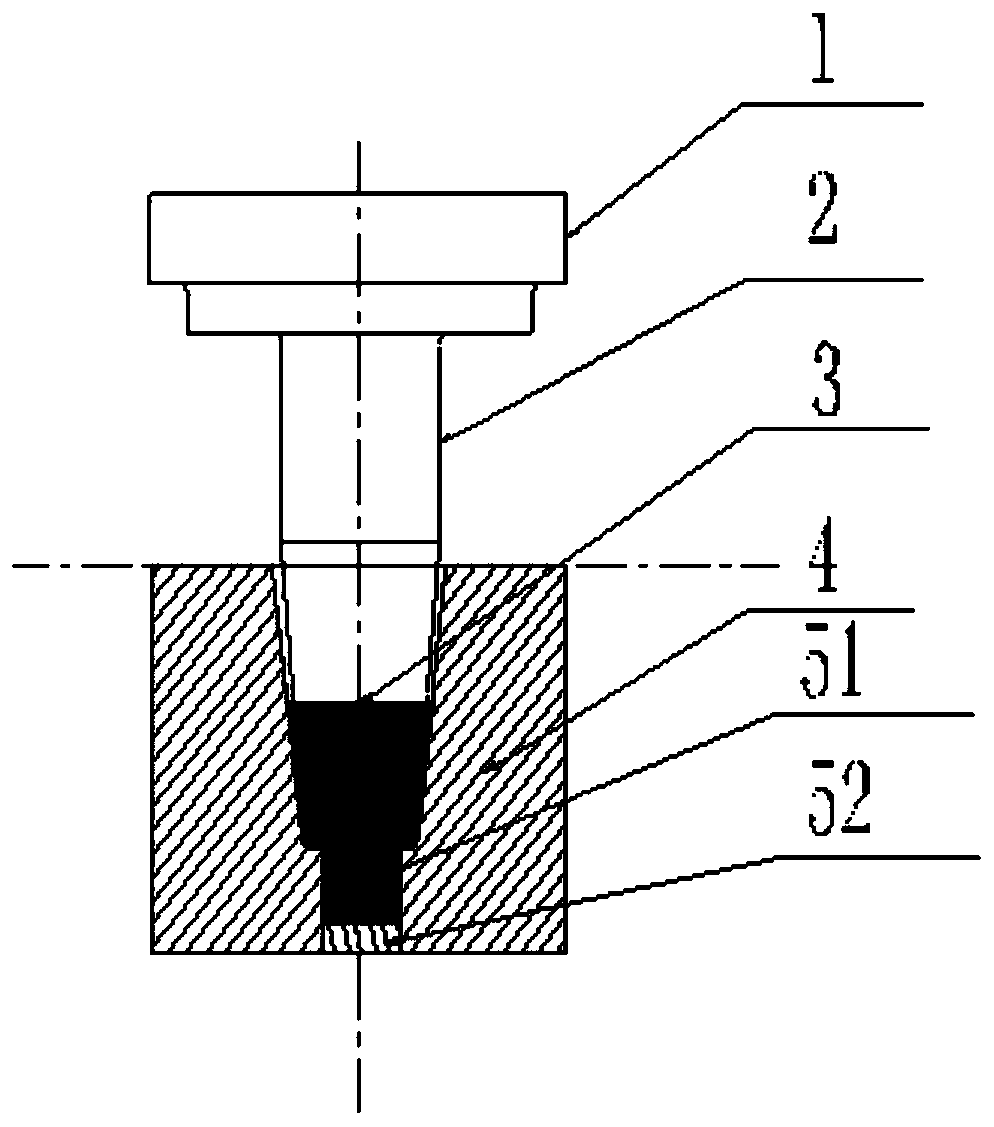

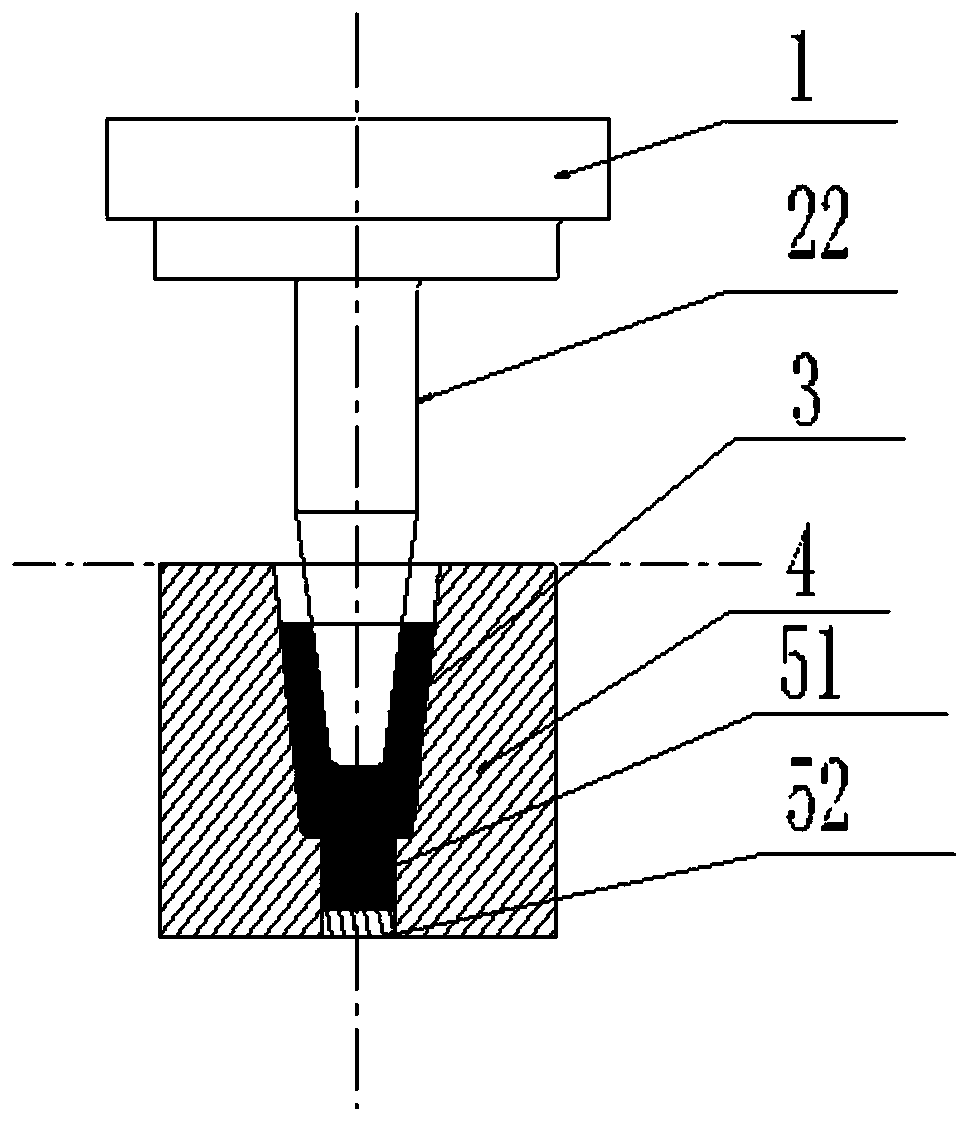

[0057] (3) Perform upsetting deformation on the extruded bar obtained in step (2), the upsetting deformation amount is 40%; the first punch 2, the concave film 4 and the top block 5 of the upsetting deformation die, the heating temperature is 280℃ , Heat preservation for 0.5~2h; heating temperature of the extruded bar is 350℃, heat preservation for 1h; obtain th...

Embodiment 2

[0064] A forming method for improving the structure and performance of a rare earth magnesium alloy tapered cylindrical part, the forming method includes:

[0065] (1) Homogenize the Mg-9Gd-3RE rare earth magnesium alloy ingot, the homogenization temperature is 500 ℃, the homogenization temperature, keep for 8 hours, and cool to room temperature naturally after the keep warm;

[0066] (2) After homogenization, the ingot is subjected to extrusion deformation treatment. Before extrusion, the mold is first heated, the mold heating temperature is 300°C, the extrusion ratio is 7, and the extruded bar is obtained after extrusion;

[0067] (3) Perform upsetting deformation on the extruded bar obtained in step (2), the upsetting deformation amount is 40%; the first punch 2, the concave film 4 and the top block 5 of the upsetting deformation die, the heating temperature is 280℃ , Heat preservation for 0.5~2h; heating temperature of the extruded bar is 380℃, heat preservation for 1h; obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com