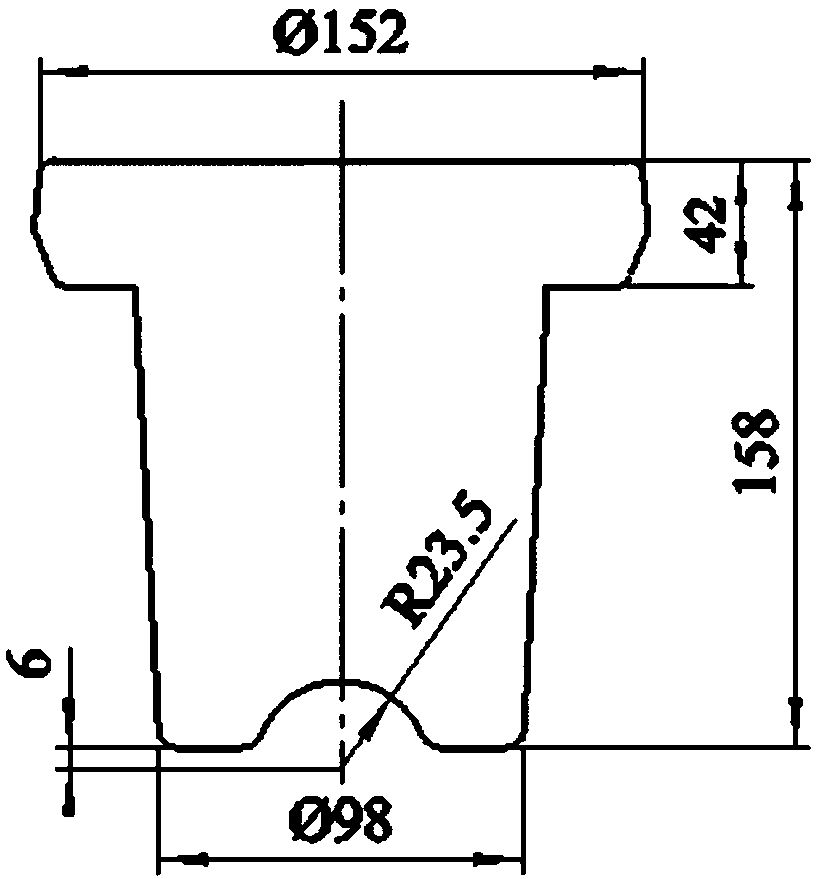

Die forging forming method of TC4 titanium alloy round-T-shaped forge piece

A technology for titanium alloys and forgings, applied in the field of die forging of TC4 titanium alloy round-T-shaped forgings, can solve the problems of coarse local structure, unqualified ultrasonic flaw detection, etc., to optimize the bottom shape, facilitate metal forming, and ensure flow line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The first step is forging drawing design;

[0040] The second step, blank inspection

[0041] The blank is inspected, and it is required that the primary α phase content of the blank is 60% in addition to meeting the relevant standards. The α+β / β phase transition point is 995°C.

[0042] The third step, billet calculation: Calculate the size and weight of the billet according to the shape, size and weight of the die forging, the forging deformation ratio, and calculate the diameter and length of the required billet according to the forging deformation ratio. The calculation method is as follows:

[0043] 3.1. Calculation of blank weight:

[0044] G of the weight of the blank 1 , the weight of die forging G 2 , Weight of die forging burrs g 2 .

[0045] G 1 =(G 2 +g 2 )×1.01

[0046] G 1 =(8.14+0.9)×1.01=9.13Kg

[0047] 3.2. The size of the blank:

[0048] Forging large end diameter D 2 , billet diameter D 1 ,

[0049] D. 1 =0.9×D 2

[0050] D. 1 =0....

Embodiment 2

[0067] The first step is forging drawing design;

[0068] The second step, blank inspection

[0069] The billet is inspected, and the billet is required to meet the relevant standards, the content of the primary α phase is 85%, and the α+β / β phase transition point is 992°C.

[0070] The third step, billet calculation: Calculate the size and weight of the billet according to the shape, size and weight of the die forging, the forging deformation ratio, and calculate the diameter and length of the required billet according to the forging deformation ratio. The calculation method is as follows:

[0071] 3.1. Calculation of blank weight:

[0072] G of the weight of the blank 1 , the weight of die forging G 2 , Weight of die forging burrs g 2 .

[0073] G 1 =(G 2 +g 2 )×1.01

[0074] G 1 =(19.99+1.9)×1.01=22.10Kg

[0075] 3.2. The size of the blank:

[0076] Forging large end diameter D 2 , billet diameter D 1 ,

[0077] D. 1 =0.9×D 2

[0078] D. 1 =0.9×197=177.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com