Low-temperature toughness chromium-molybdenum steel plate and production method

A technology of low temperature toughness and production method, applied in furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of high alloy cost and high production cost, and achieve the effects of stable mechanical properties, low cost, and stable strength control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

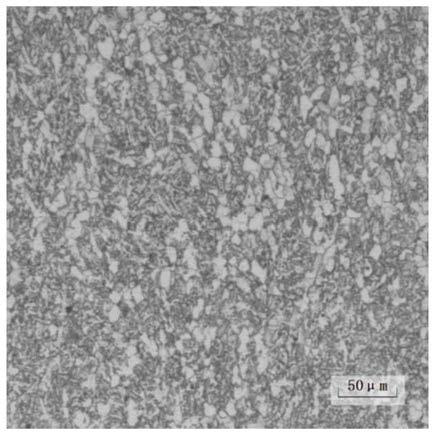

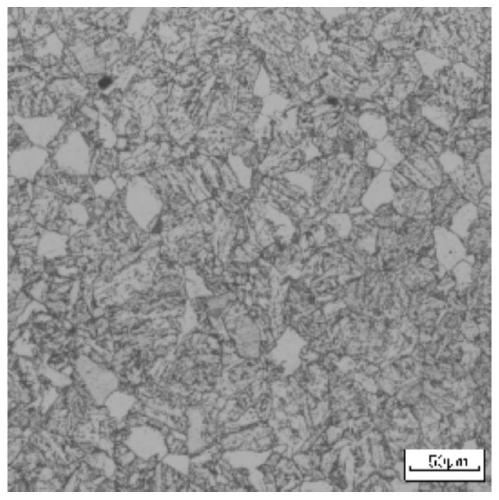

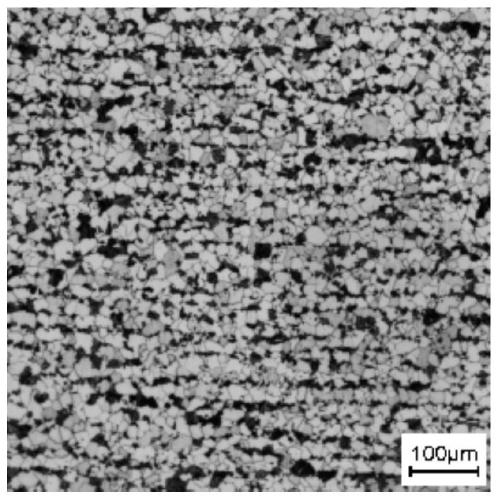

Image

Examples

Embodiment 1

[0037] A low-temperature toughness chromium-molybdenum steel sheet, including the following chemical components by mass percentage: see Table 1 below; the rest are Fe and unavoidable impurities.

[0038] The production method of the low-temperature toughness chromium-molybdenum steel plate includes the following processes:

[0039] 1) Steelmaking process: when the tapping water is 1 / 4 weight, add in the order of "ferromanganese-ferrosilicon-aluminum block", and the whole process Al is controlled at 0.020-0.040%; LF furnace adds silicon carbide, calcium carbide, Al particles and other deoxidizers Make white slag and electrify the slag for 6 minutes; RH vacuum process, vacuum degree 43Pa, vacuum time 16min, pure degassing time 10min, after RH vacuum degassing, feed calcium wire 110m, soft argon 8min after feeding wire;

[0040] 2) Billet heating process: 210mm thick billet preheating section temperature is 750-850℃, the first heating section is 1150-1200℃, the second heating section is...

Embodiment 2

[0044] A low-temperature toughness chromium-molybdenum steel sheet, including the following chemical components by mass percentage: see Table 1 below; the rest are Fe and unavoidable impurities.

[0045] The production method of the low-temperature toughness chromium-molybdenum steel plate includes the following processes:

[0046] 1) Steelmaking process: when the tapping water is 1 / 4 weight, add in the order of "ferromanganese-ferrosilicon-aluminum block", and the whole process Al is controlled at 0.020-0.040%; LF furnace adds ferrosilicon, Al particles and other deoxidizers to make white The slag is electrified for 6 minutes; RH vacuum process, vacuum degree 37Pa, vacuum time 17min, pure degassing time 11min, after RH vacuum degassing, feed calcium wire 120m, soft argon 7min after feeding wire;

[0047] 2) Billet heating process: 210mm thick billet preheating section temperature is 750-850℃, the first heating section is 1150-1200℃, the second heating section is 1230-1250℃, the soak...

Embodiment 3

[0051] A low-temperature toughness chromium-molybdenum steel sheet, including the following chemical components by mass percentage: see Table 1 below; the rest are Fe and unavoidable impurities.

[0052] The production method of the low-temperature toughness chromium-molybdenum steel plate includes the following processes:

[0053] 1) Steelmaking process: when the tapping water is 1 / 4 weight, add in the order of "ferromanganese-ferrosilicon-aluminum block", and the whole process Al is controlled at 0.020-0.040%; LF furnace adds ferrosilicon, Al particles and other deoxidizers to make white Slag, electrify the slag for 7 minutes; RH vacuum process, vacuum degree 27Pa, vacuum time 16min, pure degassing time 11min, after RH vacuum degassing, feed calcium wire 115m, soft argon after feeding 9min;

[0054] 2) Billet heating process: 250mm thick billet preheating section temperature is 750-850℃, the first heating section is 1150-1200℃, the second heating section is 1230-1250℃, the soaking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com