Wide and heavy steel plate for high-strength high-toughness and low-yield-ratio hot-bending bend and production method of wide and heavy steel plate

A high-strength toughness, steel plate technology, applied in the field of high toughness, low yield ratio hot-rolled wide and thick steel plate, X90 grade high strength, can solve the problems of high alloy cost, insufficient, low temperature toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

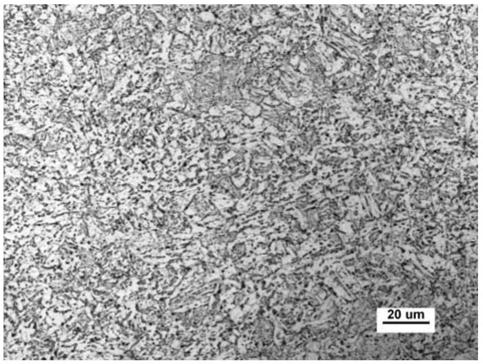

Image

Examples

Embodiment Construction

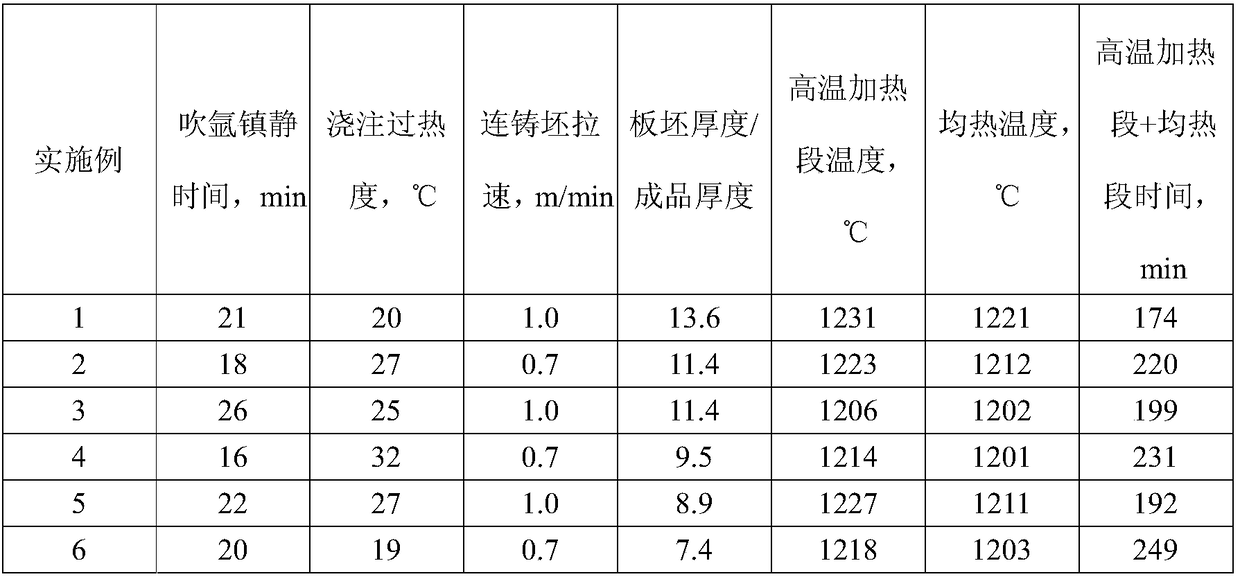

[0052] Below by embodiment the present invention will be further described.

[0053] In the embodiment of the present invention, according to the composition ratio of the technical solution, pretreatment of molten iron, converter smelting, refining outside the furnace, continuous casting, heating, rolling, cooling and heat treatment are carried out.

[0054] (1) Continuous casting: After molten steel is refined, the quenching time of argon blowing before continuous casting is not less than 10 minutes. Thickness / finished steel plate thickness is controlled at 7-14;

[0055] (2) Heating: After the continuous casting slab is cleaned, it is heated in a furnace, and a two-stage heating method is adopted. The temperature of the high-temperature heating section is 1210-1240°C, the temperature of the soaking section is 1200-1230°C, and the time of the high-temperature heating section + soaking section is not less than 150min;

[0056] (3) Rolling: The starting temperature of rough r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com