Preparation method for porous NiTi alloy based on selective dissolution and product

A selective and alloying technology, applied in the field of preparation of porous NiTi alloys, which can solve the problems of limited pore size uniformity, inability to prepare porous NiTi alloys, and large pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

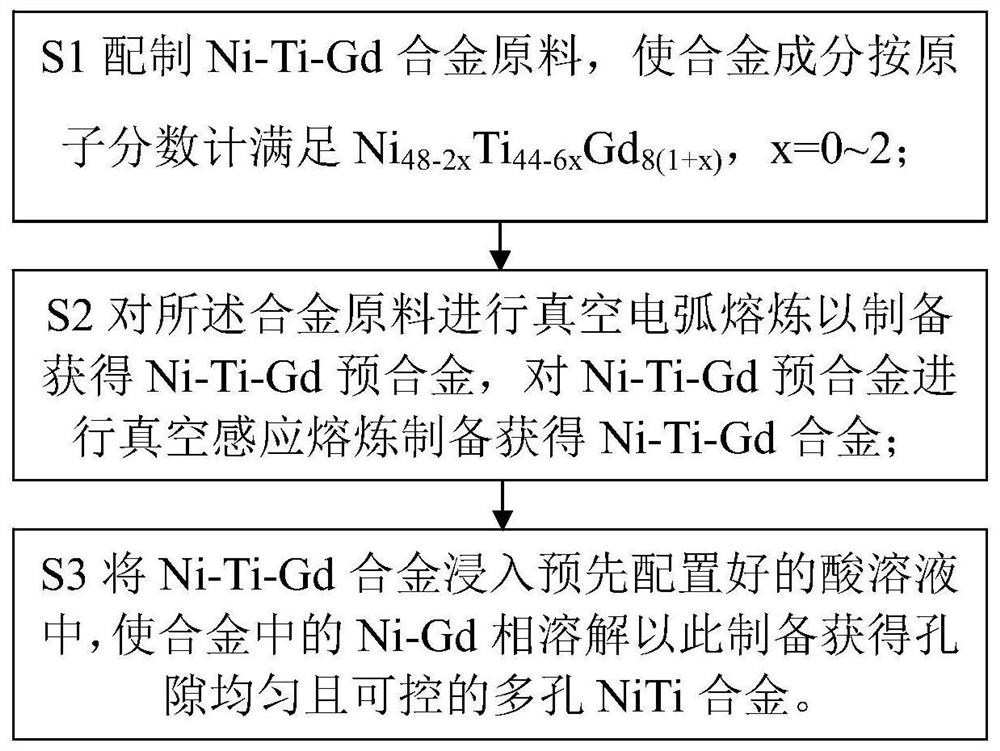

[0037] Specifically, as figure 1 As shown, the method for preparing a porous NiTi alloy based on selective dissolution provided by the embodiment of the present invention, that is, a method for preparing and regulating the pore structure of a porous NiTi alloy by a selective dissolution process, includes the following steps:

[0038] S1 ingredients:

[0039] According to a certain proportion, the raw material nickel block, titanium block and gadolinium block are batched, and the target alloy composition is calculated as Ni by atomic fraction 48-2x Ti 44-6x Gd 8(1+x) , where, x=0~2, under this ratio, pre-alloying can form a structure containing only NiTi and NiGd, and the atomic ratio of Ni and Ti is appropriate, which is conducive to its shape memory effect, where the larger X is, the pre-alloying The smaller the proportion of NiTi in the medium, the higher the porosity of porous NiTi; the purity of nickel blocks, titanium blocks, and gadolinium blocks are all above 99.9%; ...

Embodiment 1

[0056] 1) Polish the nickel block, titanium block, and gadolinium block with a purity of 99.9%, remove the surface oxide skin, and then perform ultrasonic cleaning treatment in absolute ethanol. After drying, follow the Ni 48 Ti 44 Gd 8 Atomic formulation of nickel block, titanium block and gadolinium block;

[0057] 2) Put the prepared raw materials into the vacuum arc melting furnace and vacuumize to 3×10 -3 After Pa, argon gas is introduced into the vacuum chamber until the chamber pressure is -0.05MPa; the raw material is arc-melted at a melting temperature of 1800°C, and the alloy ingot at each station is kept for 3 minutes after it is completely melted, and then the sample is turned over with a turning rod Turn the alloy ingot over and remelt it. Each alloy ingot is smelted 4 times. After the smelting is completed, it is cooled with the water-cooled copper mold, and the pre-alloyed Ni is taken out. 48 Ti 44 Gd 8 ;

[0058] 3) Cut the pre-alloy into suitable small p...

Embodiment 2

[0064] 1) Polish the nickel block, titanium block, and gadolinium block with a purity of 99.9%, remove the surface oxide skin, and then perform ultrasonic cleaning treatment in absolute ethanol. After drying, follow the Ni 48 Ti 44 Gd 8 Atomic formulation of nickel blocks, titanium blocks and gadolinium blocks.

[0065] 2) Put the prepared raw materials into the vacuum arc melting furnace and vacuumize to 3×10 -3 After Pa, argon gas is passed into the vacuum chamber until the chamber pressure is -0.05MPa; the raw material is arc-melted at a melting temperature of 1650°C, and the raw material is kept for 3 minutes after it is completely melted to cool it completely, and then it is cooled with a turning rod. Re-melt after turning over, smelting 4 times in total, after the smelting is completed, the bottom mold in the arc melting furnace, that is, the water-cooled copper mold, is cooled, and the pre-alloyed Ni is taken out. 48 Ti 44 Gd 8 ;

[0066] 3) Cut the pre-alloy into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

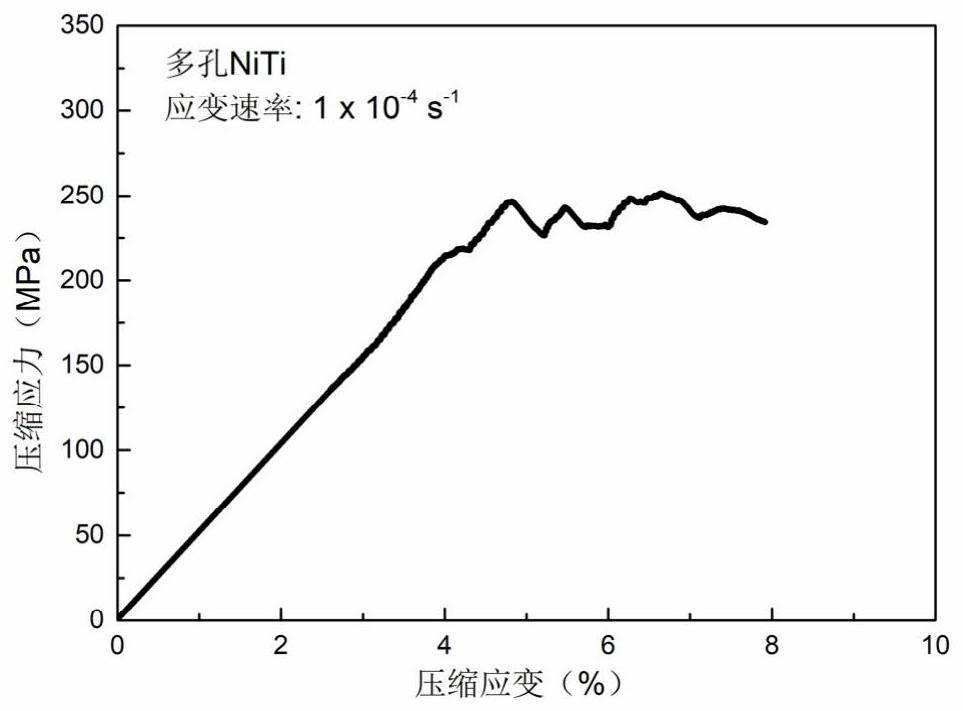

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com