Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Improve casting fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel aluminum alloy

InactiveCN101368240AHigh tensile strengthImprove impact resistanceChemical compositionCasting defect

The invention relates to a novel aluminum alloy; the content of Si in the aluminum alloy is adjusted, based on the aluminum alloy A356.2; the chemical components thereof are as follows: larger than 7.5 to 8.2 percent of Si, 0.28 to 0.45 percent of Mg, 0.08 to 0.20 percent of Ti, not larger than 0.12 percent of Fe, not larger than 0.01 percent of Cu, not larger than 0.01 percent of Zn, not larger than 0.05 percent of Mn, not larger than 0.05 percent of Zr, not larger than 0.01 percent of Ni, not larger than 0.01 percent of Sn, not larger than 0.10 percent of microelements and the rest is Al. In the invention, as the content of Si in the aluminum alloy is properly added, the novel aluminum alloy can optimize the matching between the anti-tension intensity and the extending rate of the aluminum alloy, increase the anti-impact performance of the product and simultaneously improve the casting fluidity of the aluminum alloy and effectively reduce the casting defect; therefore, the novel aluminum alloy has the characteristics of optimizing the matching between the anti-tension intensity and the extending rate of the aluminum alloy, increasing the anti-impact performance of the product, improving the casting fluidity, avoiding casting defect, improving the product quality, and the like.

Owner:华泰铝轮毂(泰安)有限公司

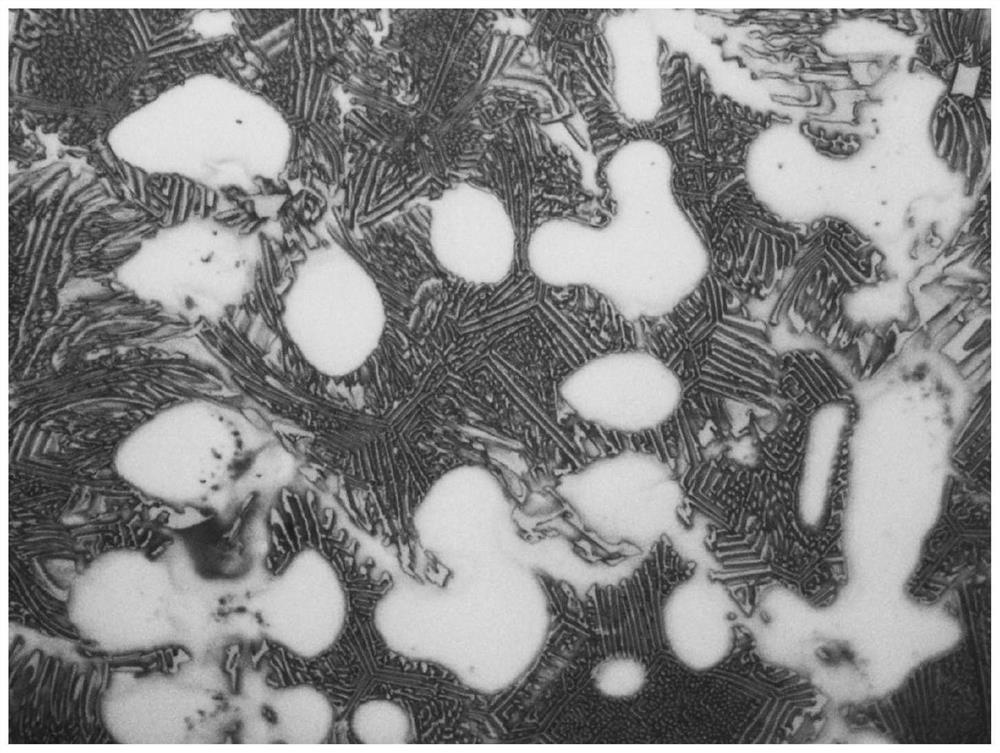

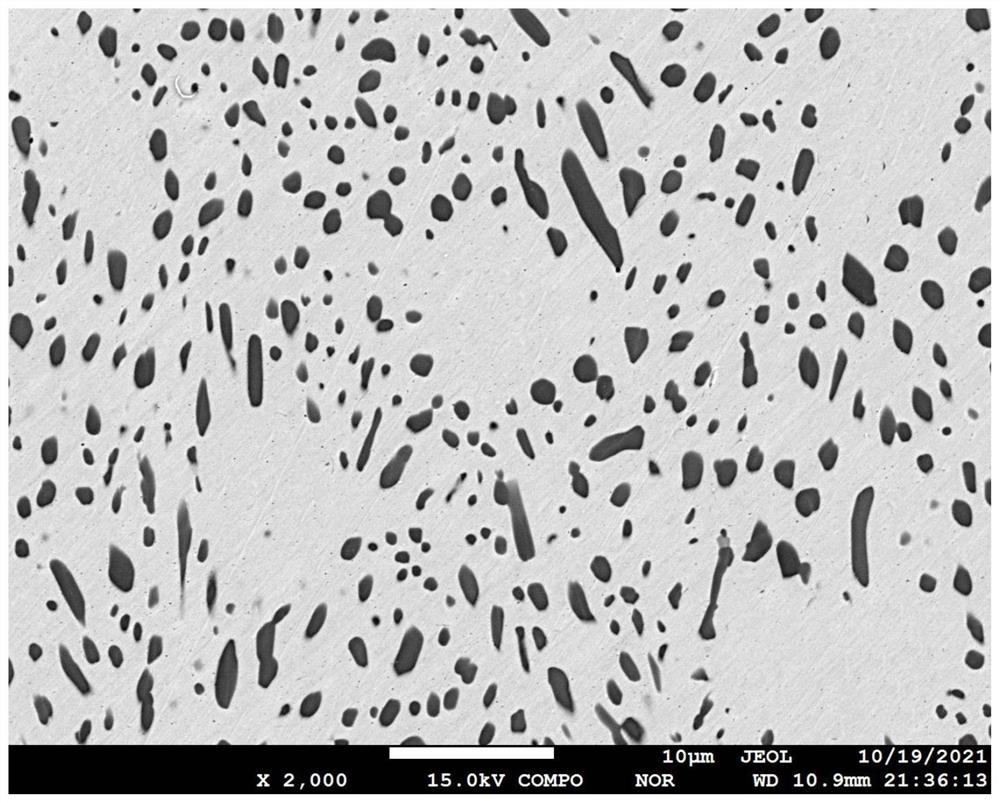

Preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy

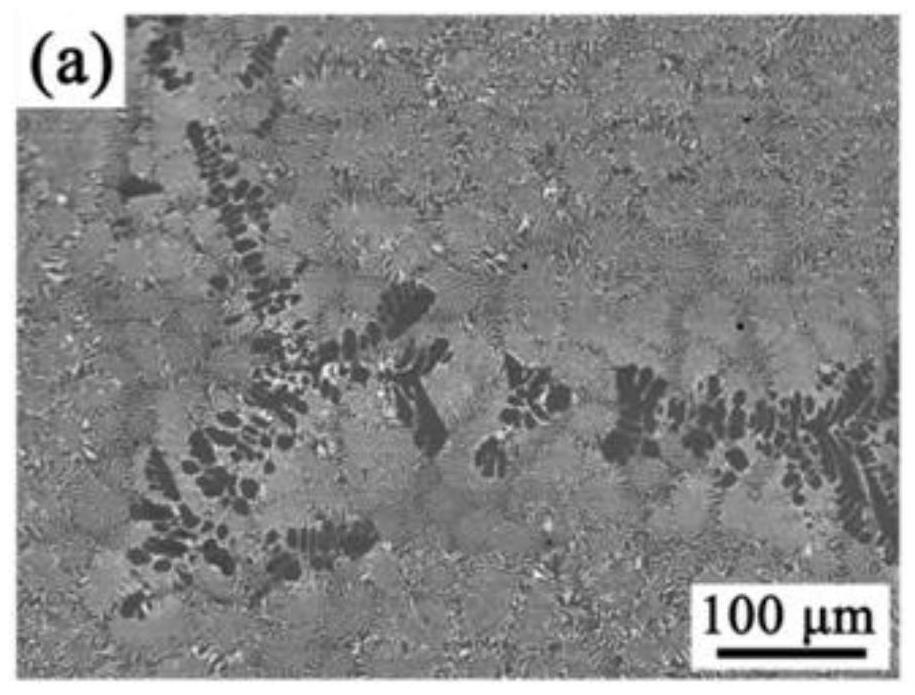

The invention relates to a preparation method of high-elasticity, corrosion-resistant and wear-resistant Cu-Ni-Sn alloy. The Cu-Ni-Sn multi-element alloy is obtained through vacuum induction melting or covering protection type non-vacuum smelting. In the casting forming process, electromagnetic stirring is applied until alloy liquid is complete solidified, and then the as-cast alloy is subjected to homogenization annealing, hot rolling and cogging, solid solution treatment, cold deformation, spinodal decomposition and other processes. The preparation method of the Cu-Ni-Sn alloy is capable ofrefining crystalline grains, reducing dendritic spacing and eliminating alloy microscopic and macroscopic structure and component segregation, provides implementation conditions for follow-up alloy plastic processing, spinodal decomposition and other processes, and has the beneficial effects that energy is saved, the production efficiency is improved, the service life of the alloy is prolonged, and the production cost is reduced.

Owner:JIANGYIN SANLING METAL PROD

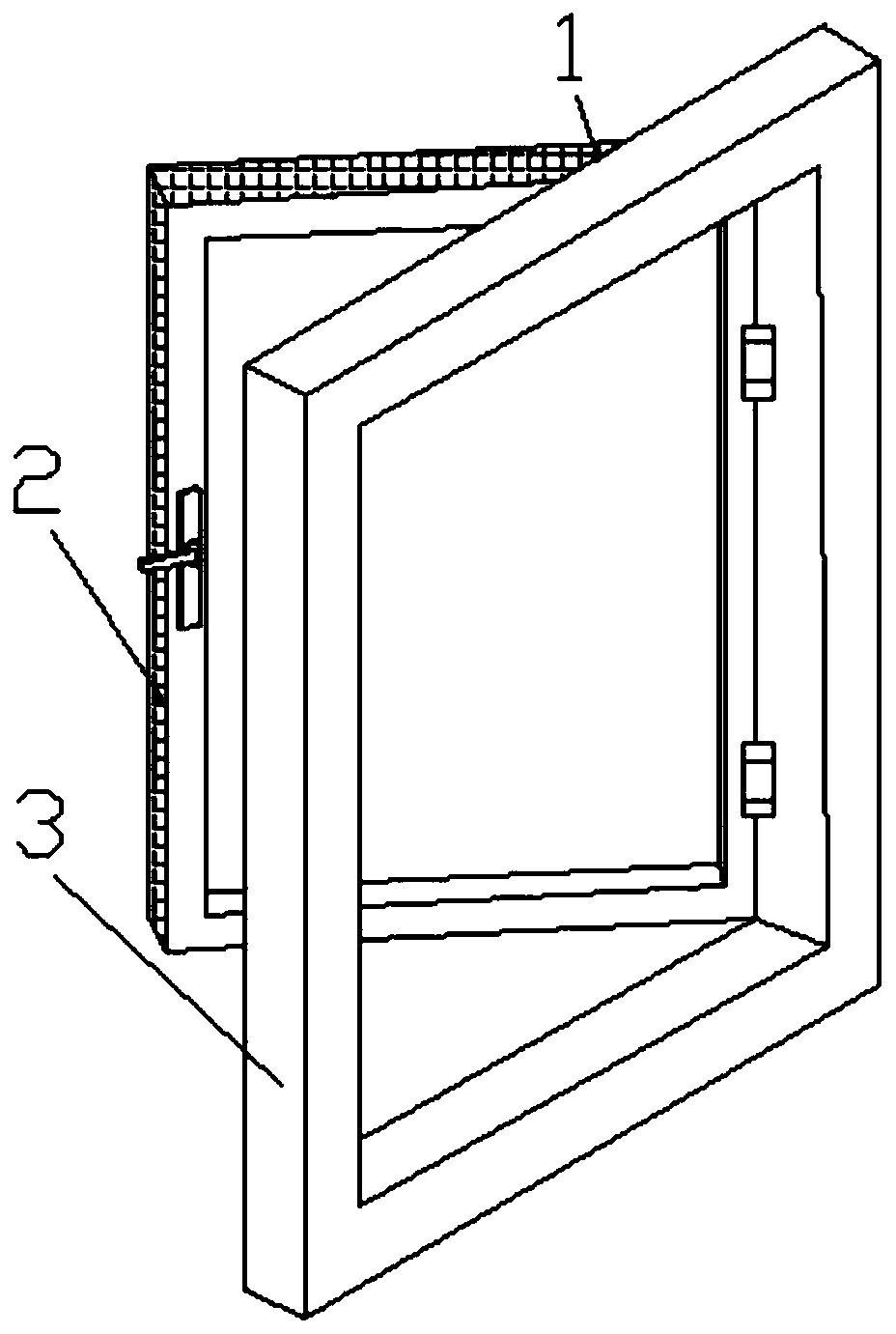

Corrosion-resistant aluminum alloy door and window and preparation method thereof

InactiveCN110792363AImprove mechanical propertiesGood casting performanceAnodisationWing arrangementsRare-earth elementManganese

The invention discloses a corrosion-resistant aluminum alloy door and window and a preparation method thereof. The corrosion-resistant aluminum alloy door and window comprises an aluminum alloy door and window body, wherein the aluminum alloy door and window body is provided with a glass frame and a window frame; the glass frame is hinged to the window frame; an oxidation film, a resin-based composite material layer and a corrosion-resistant coating are sequentially arranged on the surface of the aluminum alloy door and window body from inside to outside; and the aluminum alloy door and windowbody comprises the following raw materials in parts by weight: 95-100 parts of aluminum, 1-3 parts of silicon powder, 2-5 parts of zinc powder, 2-5 parts of copper powder, 1-3 parts of magnesium powder, 0.5-1.5 parts of tin powder, 0.5-1.5 parts of strontium powder, 0.5-1.5 parts of manganese powder, 0.5-1.5 parts of iron powder and 0.5-1.5 parts of rare earth elements. According to the corrosion-resistant aluminum alloy door and window disclosed by the invention, some tin powder, strontium powder, manganese powder, iron powder and the like are added into the components of the aluminum alloydoor and window body, so that the mechanical properties of the aluminum alloy door and window body are effectively improved, and the tensile strength, corrosion resistance and strength effects of thealuminum alloy door and window body are remarkable; and the rare earth elements are added into the aluminum alloy door and window body, so that the casting fluidity of aluminum alloy liquid is improved, and the casting properties of aluminum alloy are improved.

Owner:安徽好博智能门窗科技有限公司

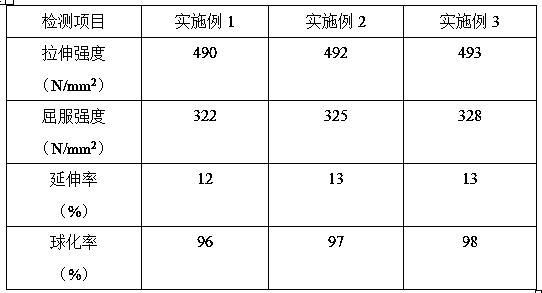

Preparation method of low-magnesium nodulizer

The invention relates to a preparation method of a low-magnesium nodulizer, and the preparation method belongs to the technical field of nodular cast iron. The preparation method takes magnesium powder, yttrium powder, cerium powder and calcium powder as raw materials, and prepares the low-magnesium nodulizer; the magnesium is a basic graphite spheroidizing element, the chemical property of magnesium is active, the desulfurization and deoxygenation capacity is high, the generated sulfide and oxide are high in melting points, low in density and prone to float out of molten iron to be removed, the spheroidizing capacity of rare earth elements such as yttrium and cerium is high, the added rare earth elements such as yttrium and cerium can play a good auxiliary spheroidizing role, the added yttrium and cerium elements can reduce the adding amount of magnesium and possible black slag defects, and a stable spheroidizing effect can be achieved even if the sulfur content of molten base iron ishigh; and by adding calcium into the molten iron, the effects of deoxidizing, desulfurizing and improving the surface tension of the molten iron can be achieved, the adding amount of main spheroidizing elements can be reduced, and the spheroidizing effect is enhanced.

Owner:陈红喜

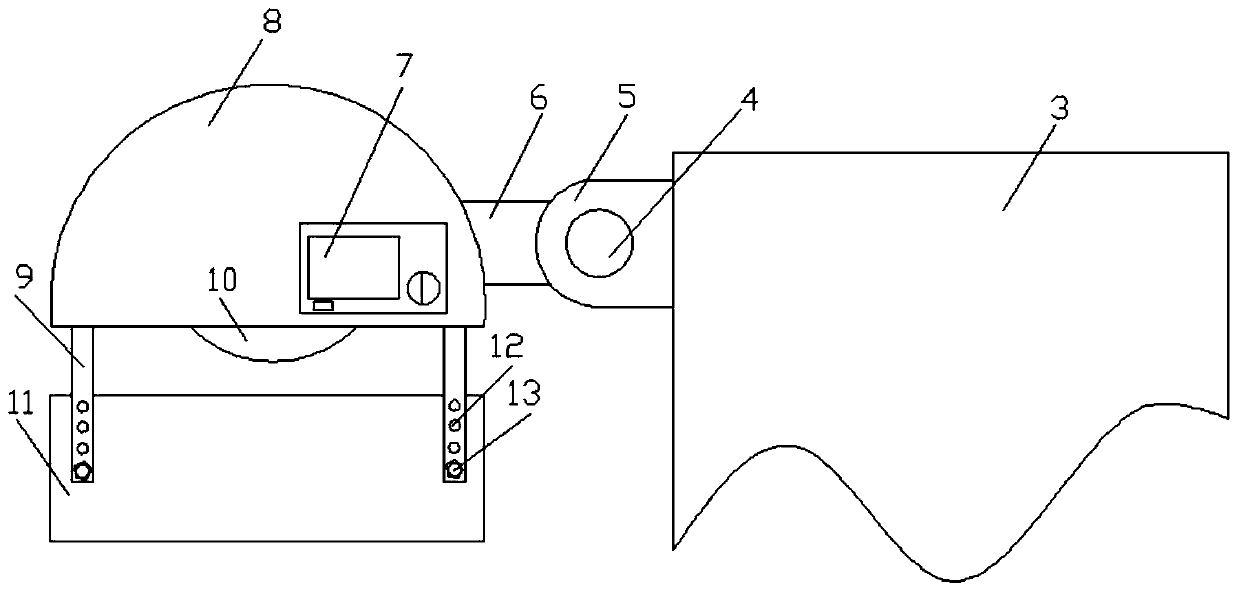

Machining method of a window and door aluminium alloy

The invention discloses a machining method of a window and door aluminium alloy. The window and door aluminium alloy comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn,0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare earth element RE and the balance of Al. The window and door aluminium alloy is prepared by using the steps of melting, slagging-off, heat preservation and standing, online refining, alloying, refining, on-line degassing, casting, homogenizing annealing, extrusion forming, heat treatment, shading, sealing treatment and the like. According to the machining method of the window and door aluminium alloy, by optimizing alloy components, a mixing ratio and a machining process, a problem that the strength and the casting performance of the aluminium alloy contradict each other can be effectively solved; and problems of large hot cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminium alloy are solved.

Owner:阜阳力佳门业有限公司

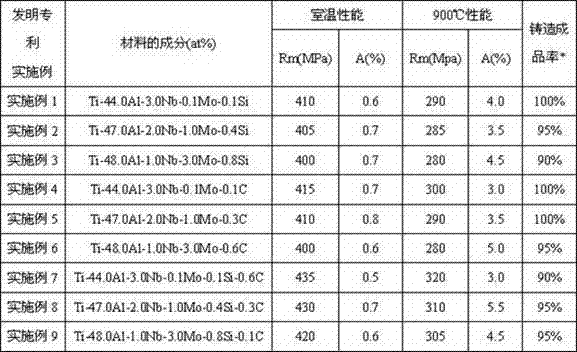

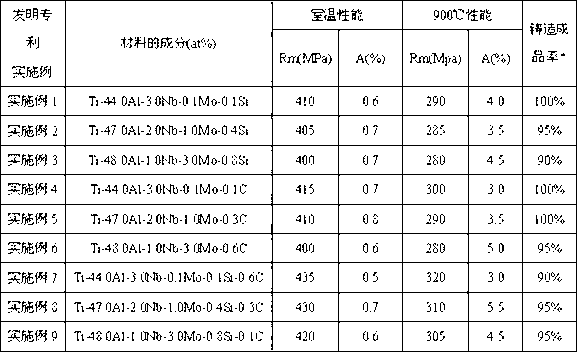

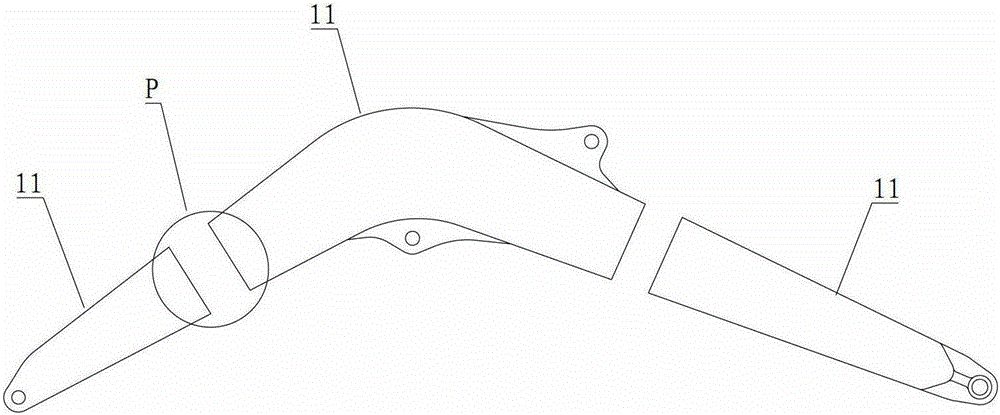

A titanium-aluminum-based alloy suitable for casting with excellent high-temperature oxidation resistance and creep performance

ActiveCN102268568ARefine layer spacingImprove high temperature creep resistanceOxidation resistantThin walled

The invention discloses a TiAl-based alloy with excellent high temperature oxidation resistance and creep resistance suitable for casting and the alloy belongs to the gamma-TiAl alloy. The TiAl-based alloy comprises the following components by atomic percent: 44.0-48.0% of Al, 1.0-3.0% of Nb, 0.1-3.0% of Mo, 0-0.8% of Si or / and 0-0.6% of C, and the balance of Ti and impurity elements, wherein thesum of the atomic percents of Si and C is 0.1-0.9%. The TiAl-based alloy disclosed by the invention has good high temperature performances and casting fluidity and is suitable for the casting of thin-walled parts; methods such as chemical treatment, thermal spraying and ion implantation which are used to increase the oxidation resistance, are not required to treat the surface of the alloy at 850-950 DEG C; and the TiAl-based alloy is particularly suitable to cast the gasoline engine supercharger turbine rotor which can work below 900-950 DEG C.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Aluminum alloy material for high-performance thin-wall 3D printing sand casting and preparation method thereof

InactiveCN111926220AImprove casting fluiditySolve the problem of difficult fillingSand castingUltimate tensile strength

The invention discloses an aluminum alloy material for high-performance thin-wall 3D printing sand casting and a preparation method thereof, and relates to the technical field of aluminum alloy production. The material comprises the following components of, in percentage by mass, 6.5%-8% of Si, 0.25%-0.45% of Mg, 0.05%-0.16% of Ti, 0.01%0-0.04% of Sr, 0.1%-0.2% of Fe, 0.16%-0.6% of Zr, 0%-0.4% ofSc, less than or equal to 0.10% of other inevitable impurity elements, and the balance Al. In addition, the invention further discloses the preparation method of the high-performance aluminum alloy. According to the alloy, the contents of Si, Mg, Sr, Ti, Zr and Sc are controlled, so that the alloy has good fluidity, a cast 3D printing sand mold casting is fine and uniform in structure, the strength and toughness of the alloy are remarkably improved, and the requirement of thin-wall 3D printing sand mold casting market development can be well met.

Owner:SOUTH CHINA UNIV OF TECH

Aluminum alloy for high-strength corrosion-resistant doors and windows and preparation method thereof

InactiveCN109161746AImprove toughnessAccelerated corrosionSurface reaction electrolytic coatingRare-earth elementUltimate tensile strength

The invention discloses an aluminum alloy for high-strength corrosion-resistant doors and windows, which comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn, 0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare-earth element Re, and the balance of Al. The aluminum alloy is prepared by the steps of melting, slag-off, heat preservation, standing, on-line refining, proportioning, refining, on-line degassing, casting, uniform annealing, extrusion molding, heat treatment, coloring and pore sealing. By optimizing the composition, proportion and processing technology of the alloy, the contradiction between the strength and the casting performance of the aluminum alloy can be effectively solved, and the problems of large thermal cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminum alloy are solved.

Owner:阜阳力佳门业有限公司

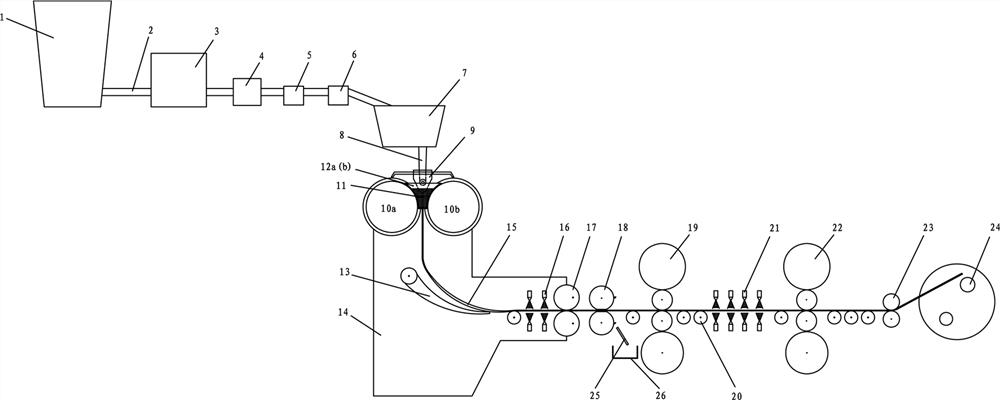

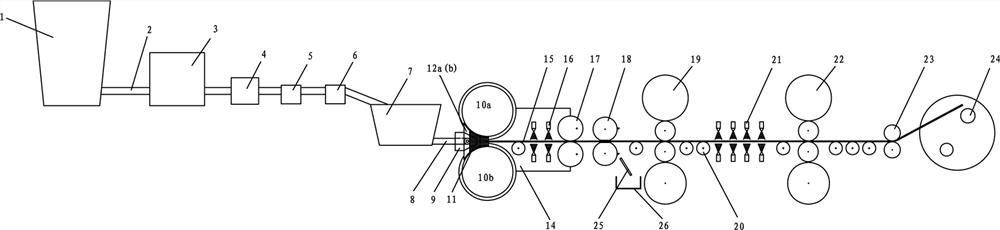

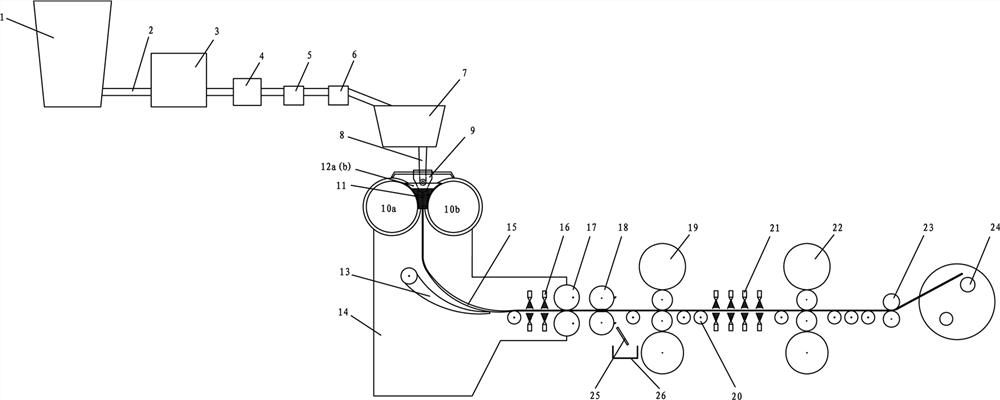

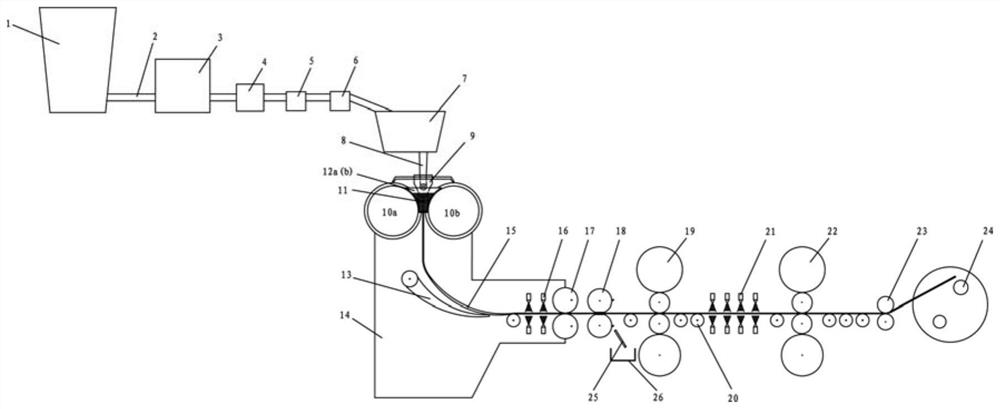

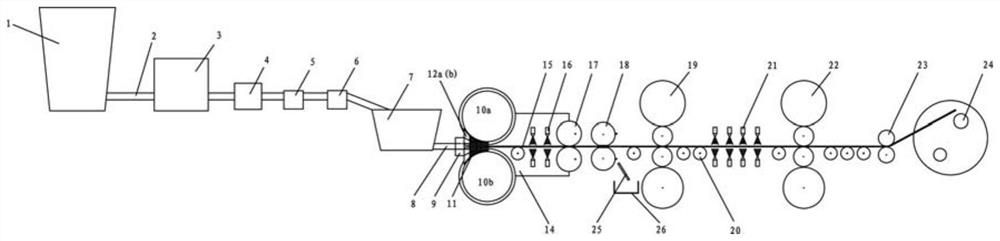

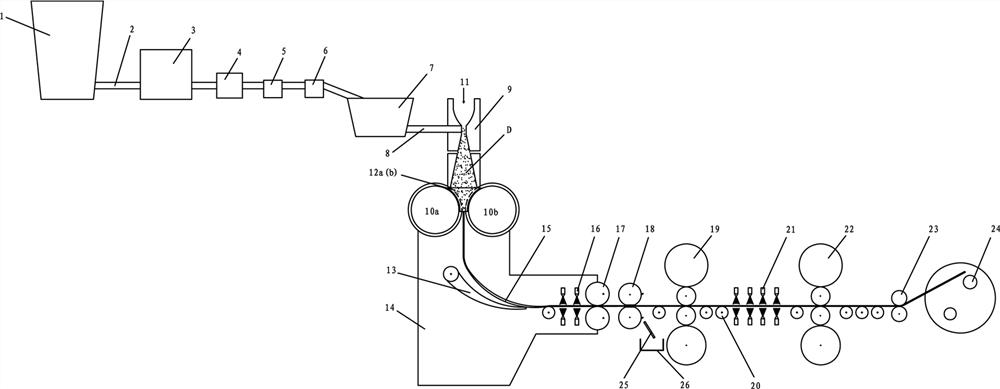

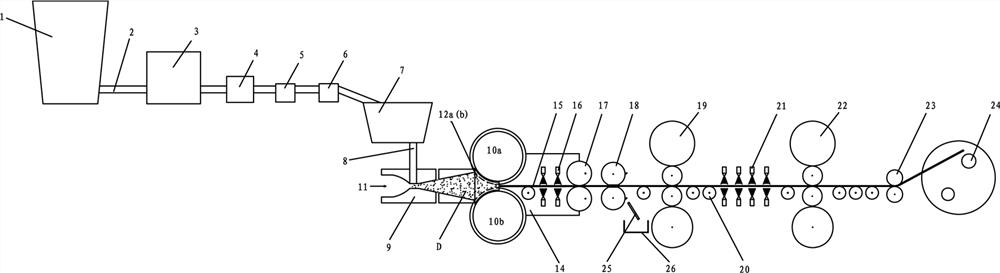

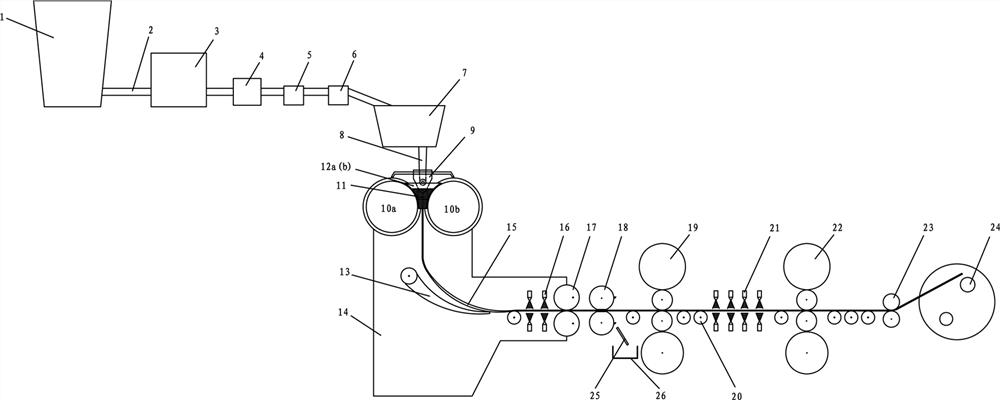

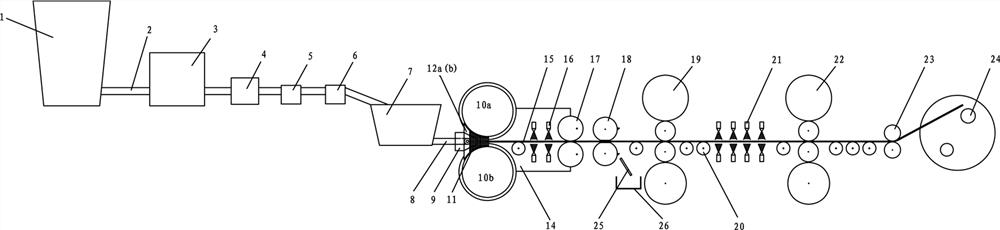

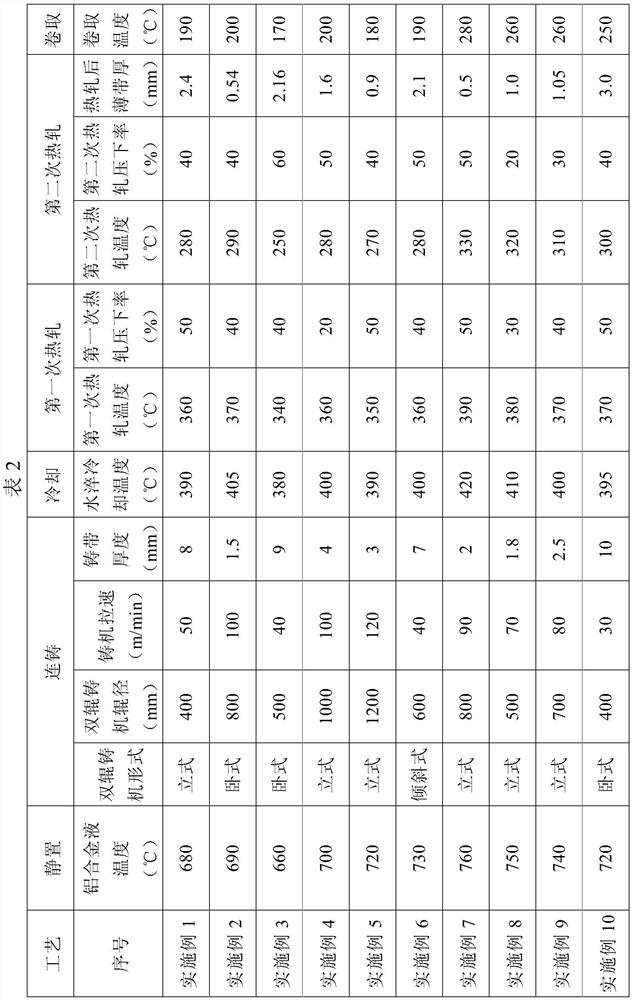

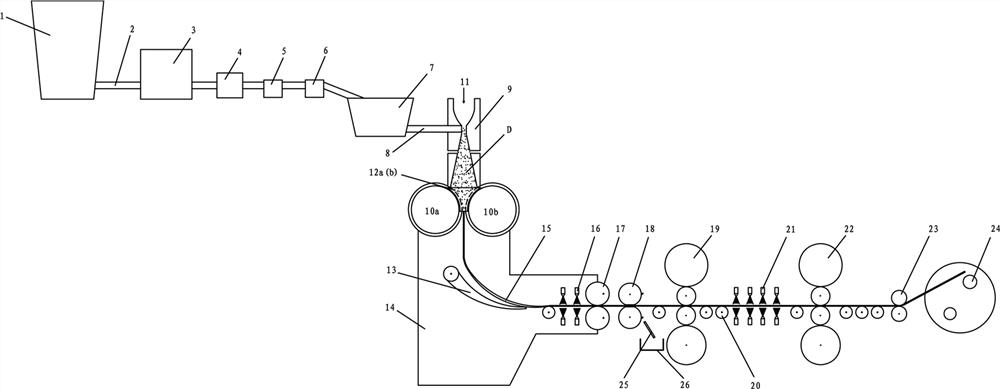

Novel 6XXX aluminum alloy plate strip for thin-strip continuous casting and preparation method of novel 6XXX aluminum alloy plate strip

ActiveCN114101608AImprove mechanical propertiesReduced hot cracking tendencyFurnace typesProcess efficiency improvementAuto industryFender

The invention relates to a thin-strip continuous casting novel 6XXX aluminum alloy plate strip and a preparation method thereof, the aluminum alloy comprises the following components in percentage by mass: 0.5-1.5% of Si, 0.1-2.0% of Mg, 0.1-1.0% of Fe, 0.05-0.5% of Mn, 0.02-0.2% of Cu, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.05%, and the content of total impurities is less than or equal to 0.15%. Compared with an existing 6XXX aluminum alloy, the novel 6XXX aluminum alloy plate strip prepared through the double-roller thin-strip continuous casting technology has the advantages that the strength is improved by 10% or above, and the formability is improved by 20% or above; and compared with a steel plate for an automobile, the light weight of 30% or above can be easily achieved. The produced second-generation ABS aluminum alloy product is widely applied to the field of automobiles, can be used for parts such as automobile engine covering parts, fenders, automobile doors, automobile roofs and trunk lids, and provides a wide space for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

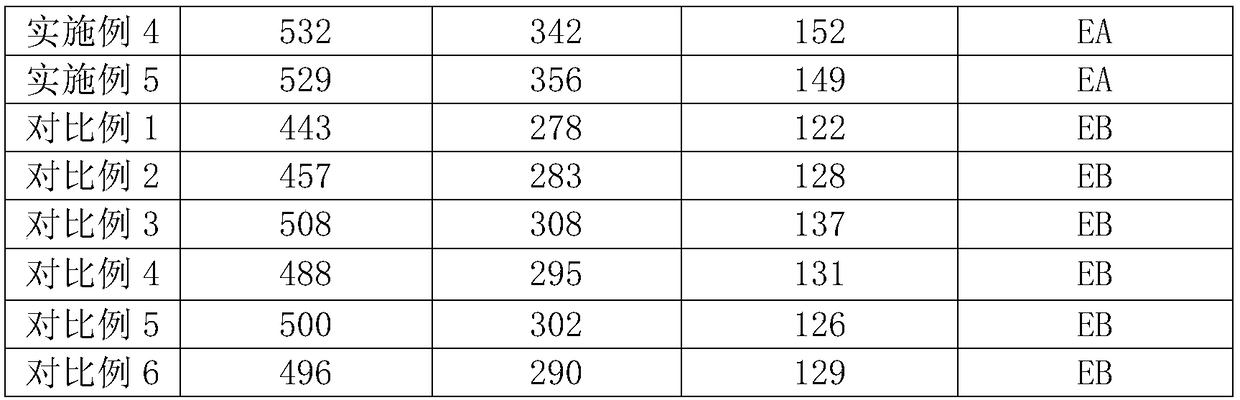

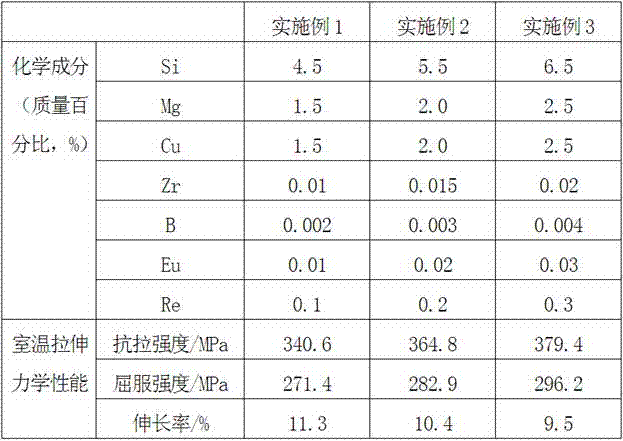

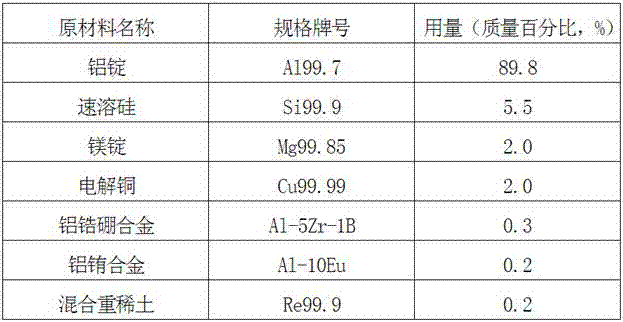

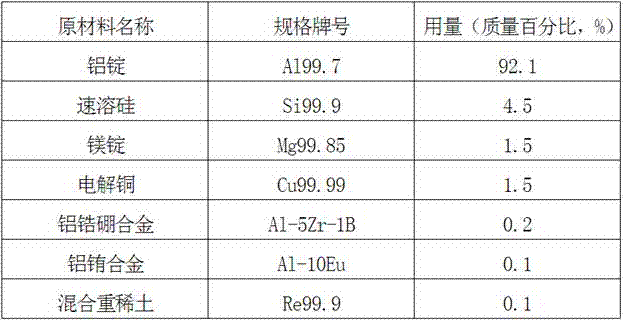

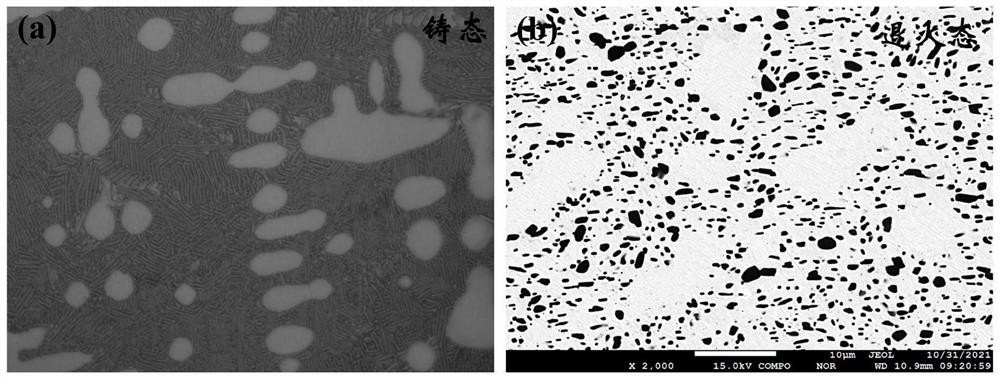

A kind of high strength and toughness casting aluminum alloy and preparation method thereof

The invention discloses cast aluminum alloy with high strength and tenacity and a preparation method thereof. The cast aluminum alloy comprises, by mass percentage, 4.5-6.5% of Si, 1.5-2.5% of Mg, 1.5-2.5% of Cu, 0.01-0.02% of Zr, 0.002-0.004% of B, 0.01-0.03% of Eu, 0.1-0.3% of RE and the balance Al and unavoidable impurities. According to the preparation method, aluminum ingots, fast dissolving silicon, magnesium ingots, electrolytic copper, Al-5Zr-1B alloy, Al-10Eu alloy and mixed heavy rare earth RE serve as raw materials; the aluminum ingots are heated and melted, the fast dissolving silicon, the magnesium ingots and the electrolytic copper are added, and molten aluminum alloy is obtained after stirring and melting; after refining and deslagging are carried out on the molten aluminum alloy, the Al-5Zr-1B alloy, the Al-10Eu alloy and the mixed heavy rare earth RE are added; the molten aluminum alloy is cast into the aluminum alloy; and the aluminum alloy is subjected to solution treatment and aging treatment. The cast aluminum alloy has high strength, good plasticity and excellent casting fluidity, can be used for being cast into car stressed structural parts in various complex shapes, and has broad market application value.

Owner:GUANGDONG INST OF NEW MATERIALS

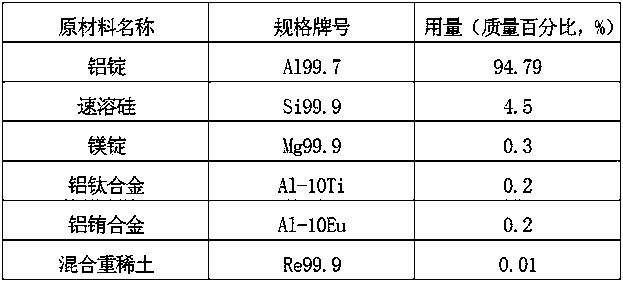

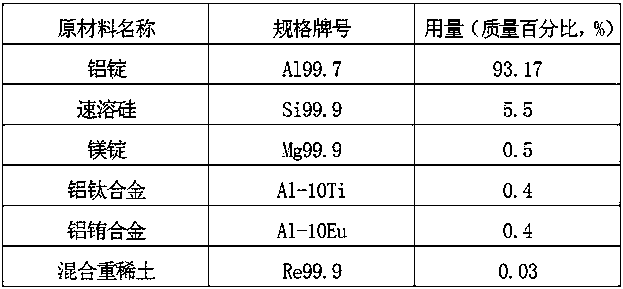

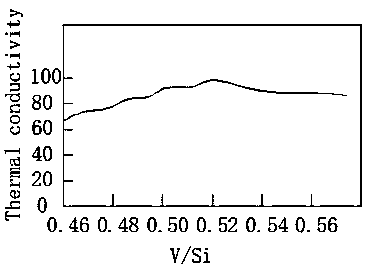

A kind of high thermal conductivity cast aluminum alloy and preparation method thereof

The invention provides high-thermal-conductivity cast aluminum alloy and a preparation method thereof. The high-thermal-conductivity cast aluminum alloy comprises, by mass, 4.5%-5.5% of Si, 0.3%-0.5% of Mg, 0.02%-0.04% of Ti, 0.02%-0.04% of Eu, 0.01%-0.03% of Re and the balance Al and inevitable impurities. The preparation method of the high-thermal-conductivity cast aluminum alloy comprises the steps that an aluminum ingot is heated and melted, added with instantly dissolved silicon and a magnesium ingot and stirred and melted, so that molten aluminum alloy is formed; after the molten aluminum alloy is subjected to refining and deslagging, aluminum-titanium alloy, aluminum-europium alloy and mixed heavy rare earth are added and stirred to enable the component of the molten aluminum alloy to be uniform; the molten aluminum alloy is cooled to 670 DEG C-690 DEG C and then subjected to still standing for 1-2 h, so that the aluminum alloy is casted; and the aluminum alloy is subjected to solid solution treatment for 6-8 h at the temperature of 495 DEG C-505 DEG C and then is subjected to aging treatment for 12-15 h at the temperature of 195 DEG C-205 DEG C after water quenching is conducted, and the aluminum alloy is cooled along with a furnace finally, so that the high-thermal-conductivity cast aluminum alloy is obtained. The high-thermal-conductivity cast aluminum alloy has the advantages of being good in casting fluidity, high in thermal conductivity coefficient and excellent in mechanical performance.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING +1

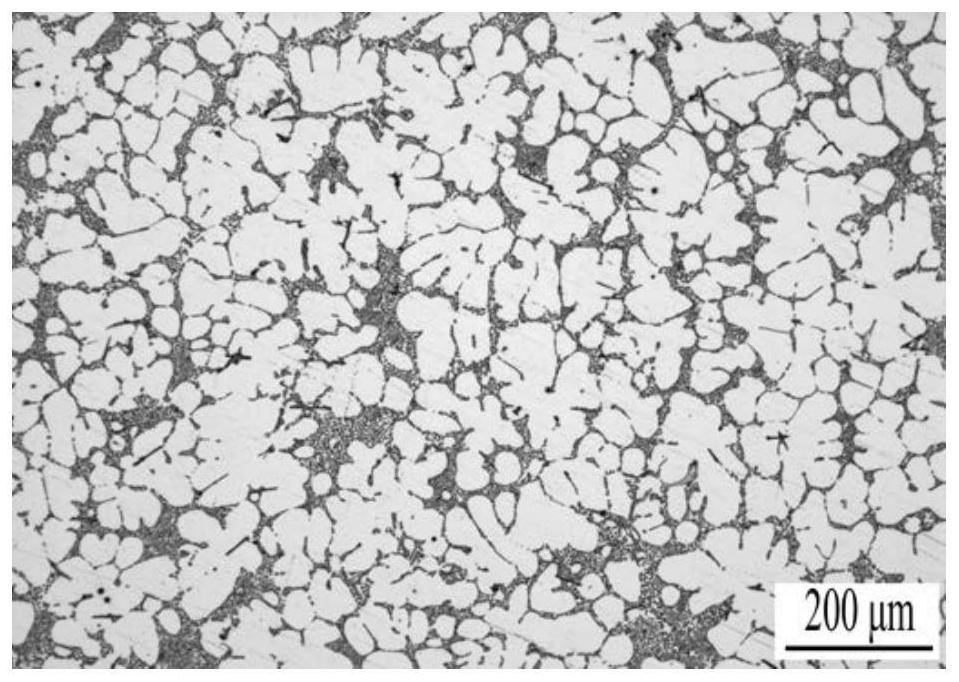

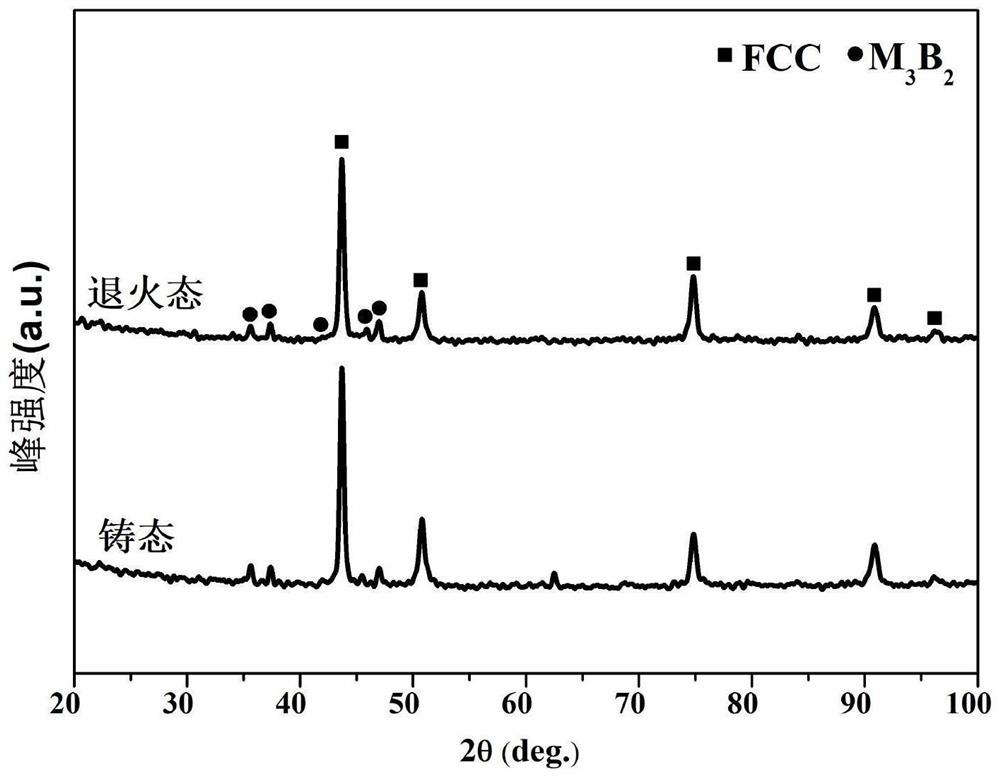

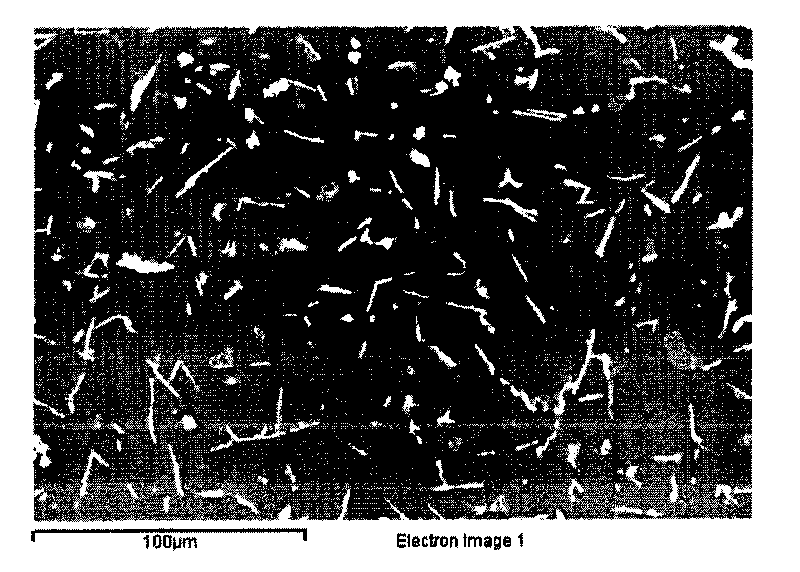

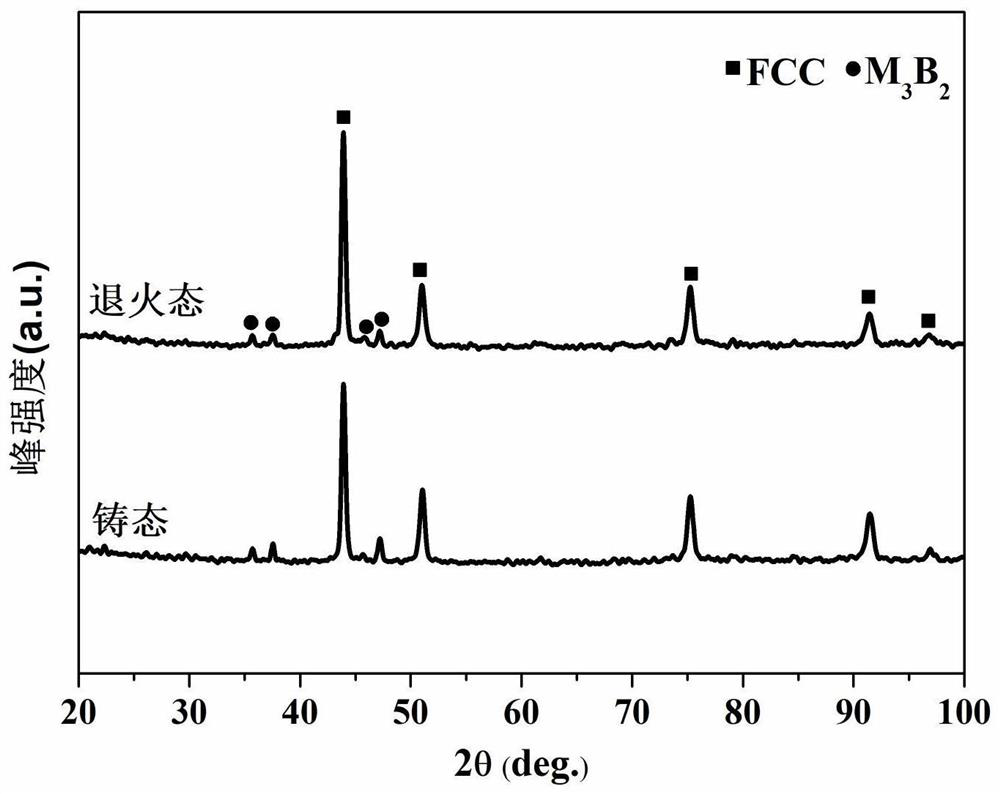

Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy with excellent thermal modification and preparation method of Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy

ActiveCN114657437ASignificant thermal modification featuresImprove fracture toughnessStress concentrationHigh entropy alloys

The invention provides a Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy with excellent thermal modification and a preparation method of the Co-Cr-Fe-Ni-V-B eutectic high-entropy alloy. A general formula of the eutectic high-entropy alloy is CoaCrbFecNidVeBf, 0.8 < = a < = 1.2, 0.8 < = b < = 1.2, 0.8 < = c < = 1.2, 1.6 < = d < = 2.4, 0.8 < = e < = 1.2, 0.3 < = f < = 0.6, and a, b, c, d, e and f are molar ratios of corresponding elements respectively. According to the eutectic high-entropy alloy, through simple high-temperature annealing heat treatment, a long-strip-shaped M3B2 phase is effectively fused and spheroidized and is in a spherical shape, stress concentration is reduced, the fracture toughness of the alloy is greatly improved, and meanwhile the tensile strength is still kept at a high level. The eutectic high-entropy alloy shows a remarkable thermal modification characteristic and has a wide application prospect in the field of engineering structures.

Owner:DALIAN UNIV OF TECH

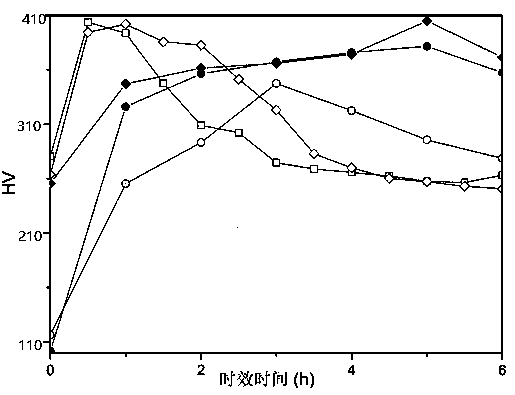

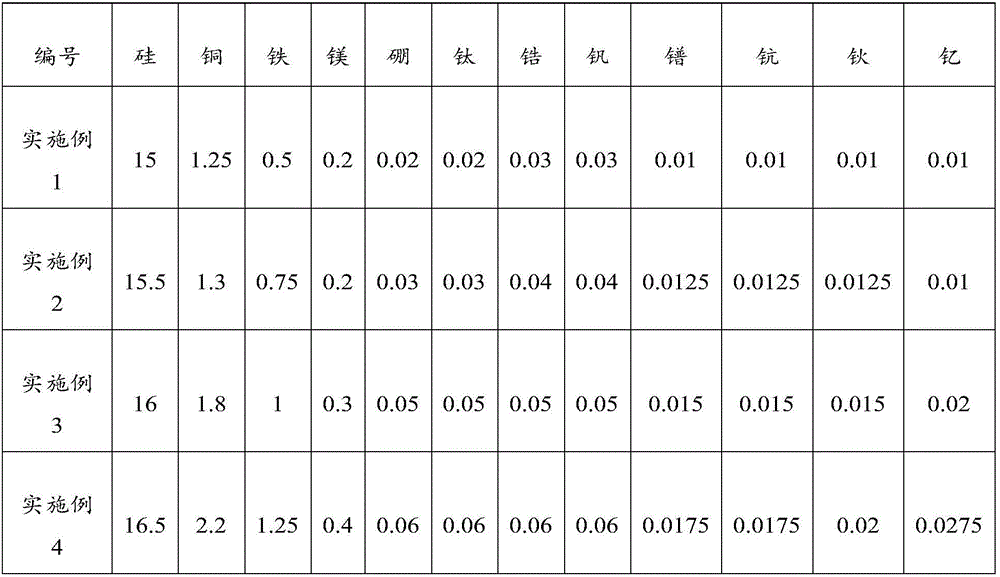

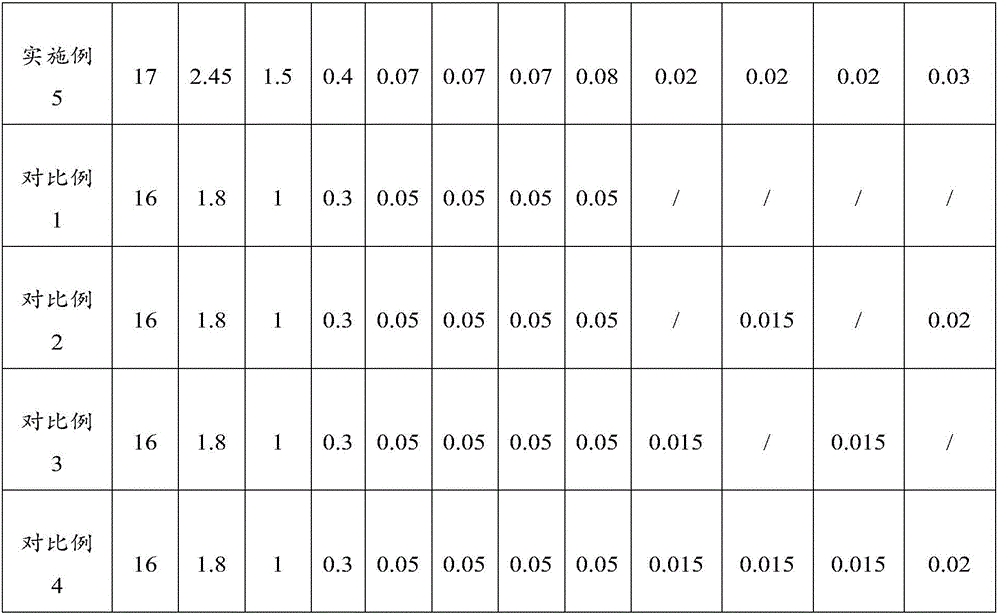

Aluminum alloy for preparing air cylinder piston for ship and preparation method thereof

InactiveCN106756295AImprove casting fluidityImprove hardness and friction resistanceMachines/enginesPistonsYttriumMagnesium

The invention provides an aluminum alloy for preparing an air cylinder piston for a ship and a preparation method thereof and belongs to the field of aluminum alloys. The aluminum alloy comprises, by weight, 15-17% of silicon, 1.25-2.45% of copper, 0.5-1.5% of iron, 0.2-0.4% of magnesium, 0.02-0.05% of boron, 0.02-0.07% of titanium, 0.03-0.07% of zirconium, 0.03-0.08% of vanadium, 0.01-0.02% of praseodymium, 0.01-0.02% of scandium, 0.01-0.02% of holmium, 0.01-0.03% of yttrium and the balance aluminum. The aluminum alloy is high in friction-resistant property, yield strength and creep-resistant property. The aluminum alloy preparation method sequentially comprises the following steps of ingot casting, hot extrusion, quenching and aging treatment according to a formula, the preparation technique is simple, alloy internal stress can be effectively removed, and the mechanical property of the alloy is reinforced.

Owner:重庆顺博铝合金股份有限公司

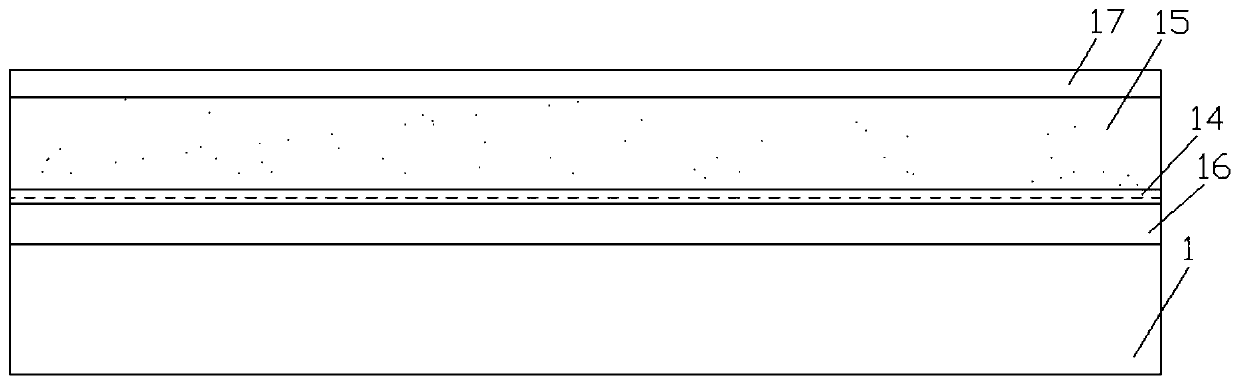

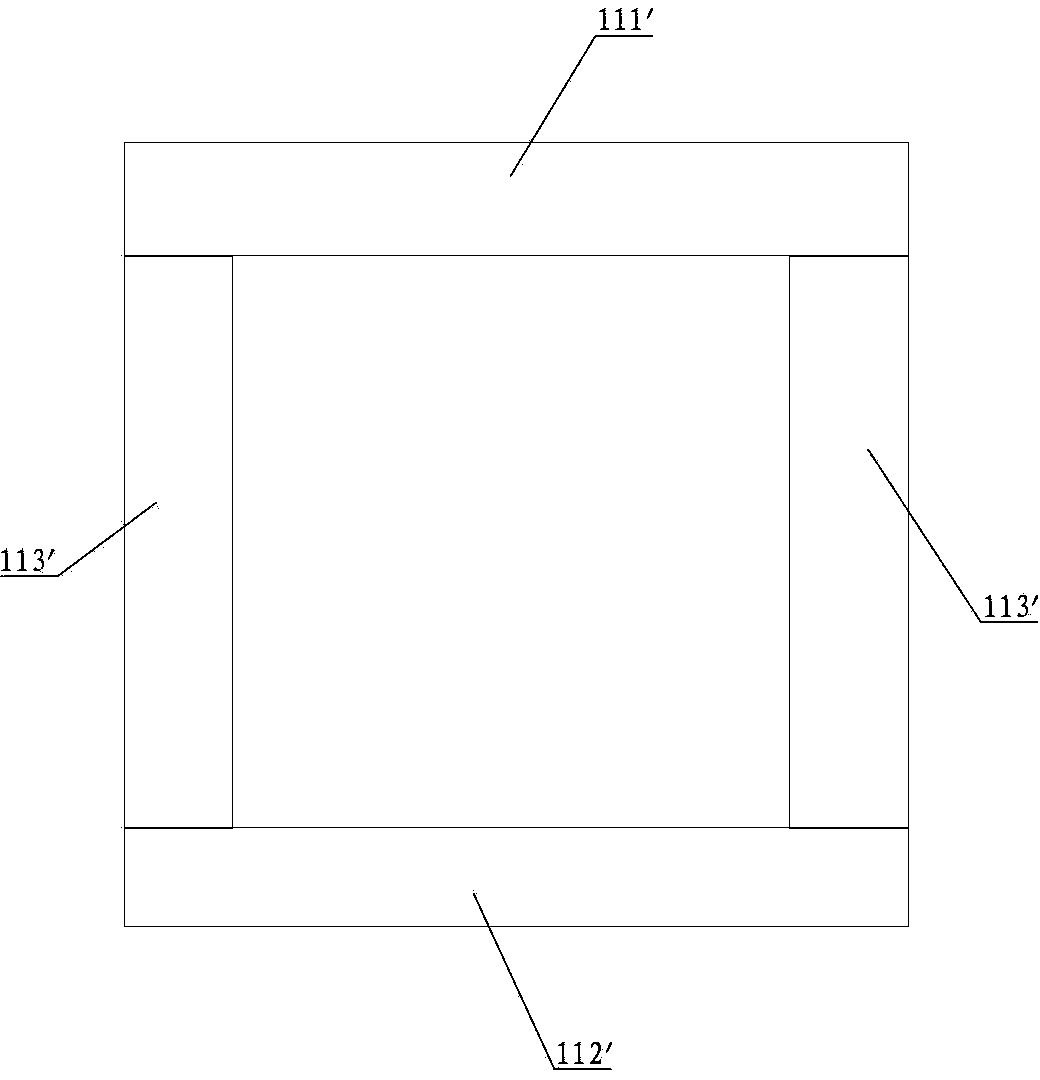

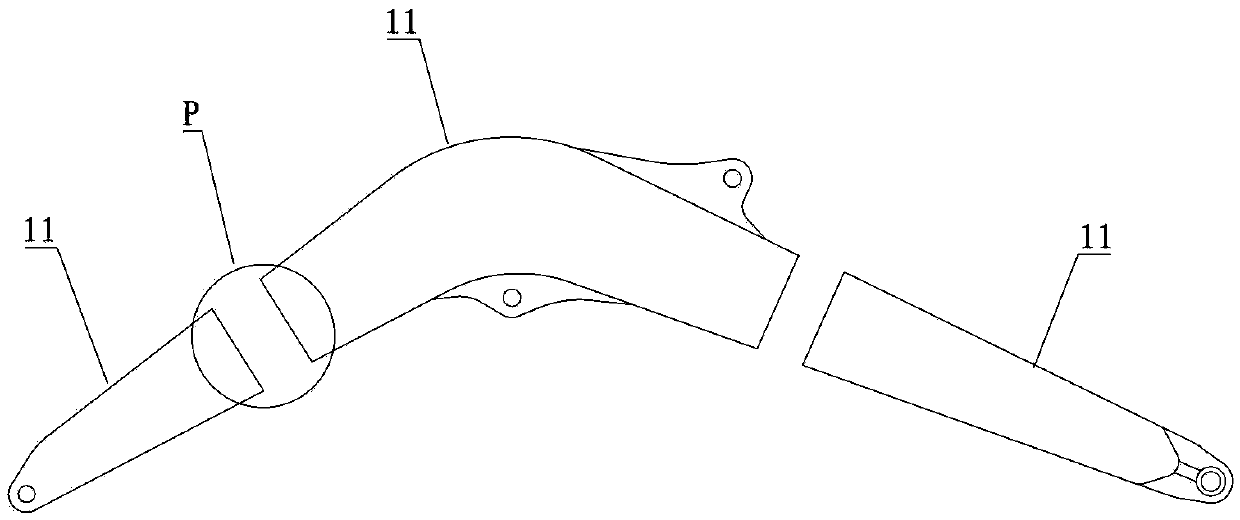

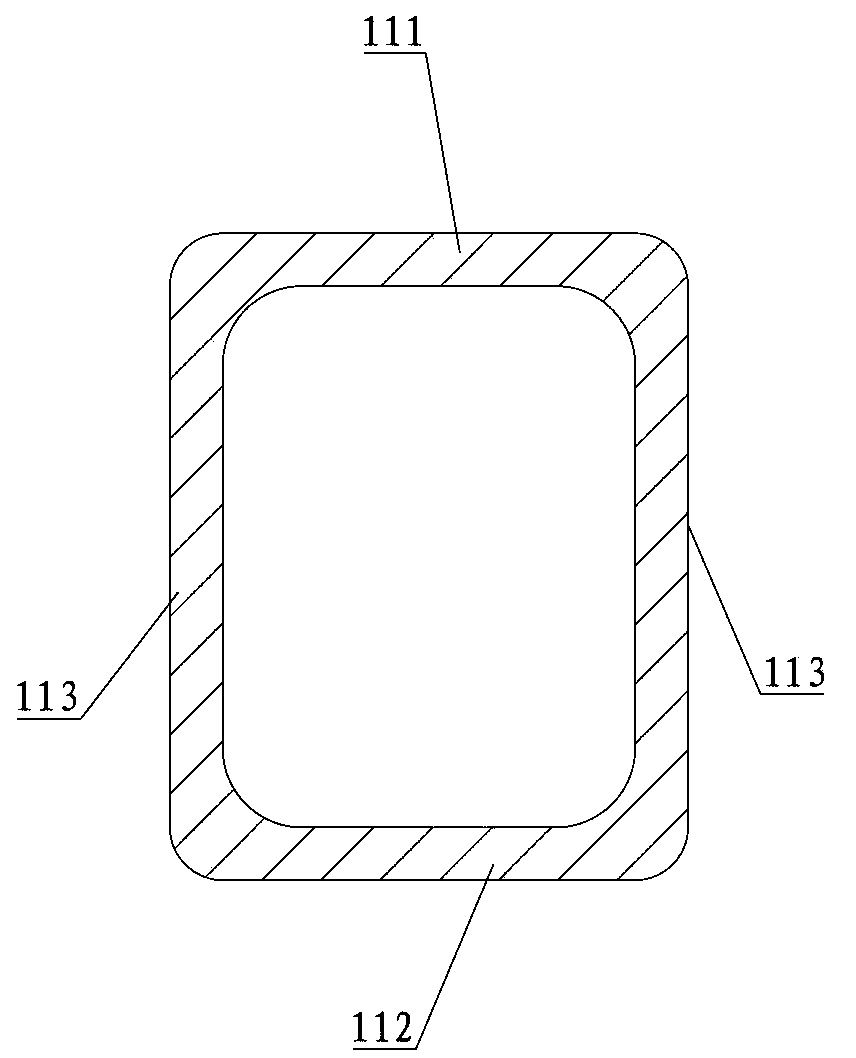

Engineering machine and box-type working device thereof

InactiveCN103422520AReduce weightImprove mechanical propertiesMechanical machines/dredgersFailure rateMechanical property

The invention discloses an engineering machine and a box-type working device of the engineering machine. The box-type working device is made of cast aluminum alloy. The aluminum alloy is Al-Cu-Mn series alloy or Al-Zn series alloy or Al-Si series alloy. The aluminum alloy has the smaller density and is beneficial to reducing the weight of the working device. Meanwhile, a dense and firm Al2O3 protection membrane is further easily formed on the surface of the aluminum alloy, and the corrosion resistance of the working device is improved. Due to the fact that the mechanical properties of the aluminum alloy are close to those of steel materials, the requirements for bearing acting force and resisting impact during operation can be met. In addition, the aluminum alloy has the excellent cast flowing property, cast flaws are not easily formed, and the premise is provided for the guarantee of the mechanical properties of the working device. The working procedure for mutually welding a top plate, a bottom plate and side plates into a box-type structure can also be eliminated, the number of welding joints can be reduced, the mechanical uniformity of the working device is improved, and the failure rate is reduced.

Owner:SANY HEAVY MACHINERY

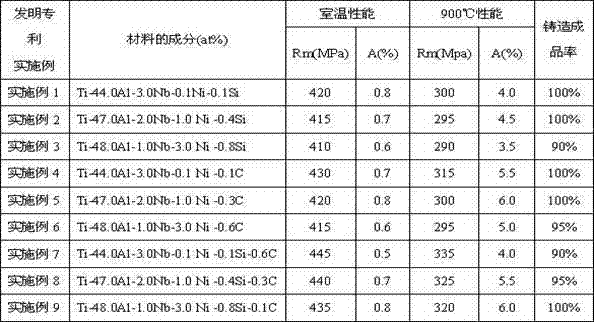

A titanium-aluminum-based alloy with excellent high-temperature creep performance and casting performance

The invention introduces a titanium-aluminum-based alloy with excellent high-temperature creep property and casting performance and belongs to gamma-TiAl alloy. The alloy is composed of the following components: 44.0-48.0at% of Al, 1.0-3.0at% of Nb, 0.1-3.0at% of Ni, one or two of Si and C and the balance of Ti and impurity elements, wherein the amount of Si is 0-0.8at%, the amount of C is 0-0.6at%, and the total amount of Si and C is 0.1-0.9at%. The titanium-aluminum-based alloy introduced by the invention has good high-temperature creep property and good casting fluidity, and is suitable for casting thin-walled parts; at the temperature of 850-950 DEG C, the surface of the titanium-aluminum-based alloy is not subjected to chemical treatment, thermal spraying, ion implantation and the like to improve the oxidation resistance of a material; and the titanium-aluminum-based alloy is especially suitable for casting gasoline engine turbocharger turbine rotor which works at the temperaturebelow 900-950 DEG C.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Environment-friendly composite spheroidizing agent applied to thick and big ductile iron

The invention relates to an environment-friendly composite spheroidizing agent applied to thick and big ductile iron. The composite spheroidizing agent comprises, by weight, 78-90 parts of spheroidizing agents, 5-20 parts of melt-resisting agents, 1-5 parts of dreg removing agents, 2-8 parts of purifying agents, 1-6 parts of desulfurizing agents and 2-5 parts of nucleating agents. The spheroidizing agent has the advantages shown by rear earth and magnesium during spheroidizing, and overcomes the defects of the rear earth and the magnesium. The magnesium is a primary spheroidizing element according to its ratio in the composite spheroidizing agent, while the rare earth has a secondary assisted spheroidizing function. The composite spheroidizing agent has good effects in desulfurizing, deoxidizing, iron liquid purifying, interference element eliminating, eutectic point reducing and supercooling degree increasing, and has the following effects on the performance of the ductile iron: improving casting mobility, reducing temperature of iron liquid oxidation films, changing shrinkage characters of ductile iron, reducing shrinking and loosening, improving mechanical performance, refining graphite and improving abrasive resistance.

Owner:TIANJIN YUTIAN ALLOY MFG

Low-lead brass alloy

The invention relates to a low-lead brass alloy, comprising: by the total weight of the brass alloy, 62.5-63 wt % copper, 0.16-0.24 wt % lead, 0-0.02 wt % antimony, 0-0.01 wt % magnesium, 0-0.2 wt % tin, 0.0005-0.0009 wt % boron, 0.55-0.7 wt % aluminum, 0.05-0.15 wt % iron, 0-0.15 wt % nickel, 0.09-0.12 wt % arsenic, 0-0.005 wt % zirconium, 0-0.01 wt % impurities, and a balance of zinc.

Owner:JIANGXI AUDY BRASSWORK

Magnesium alloy suitable for compression casting ultrathin wall member and preparation method

The invention relates to a magnesium alloy suitable for die casting of ultra-thin-wall castings and a preparation method thereof, and belongs to the field of magnesium aluminum alloy. The compositionsin weight percent of the alloy are 11.0 to 14.0 percent of aluminum, 0.5 to 2.0 percent of neodymium, 0.1 to 1.0 percent of praseodymium, 0.2 to 1.0 percent of zinc, 0.2 to 0.4 percent of manganese,and the balance being magnesium element and inevitable impurity elements. The preparation method for the magnesium alloy is to adopt protective atmosphere of CO2 and SF6 for smelting, wherein the smelting temperature is between 710 and 750 DEG C. The alloy prepared consists of alpha phase, Mg17Al12 phase containing the neodymium or the praseodymium, and magnesium, aluminum, neodymium and praseodymium complex intermetallic compound phase. The mechanical property of the magnesium alloy is superior to that of an AZ91D magnesium alloy, and the casting fluidity of the magnesium alloy is obviously superior to that of the AZ91D and improved by 25.6 percent compared with the AZ91D, so that the magnesium alloy is suitable for die casting or semi-solid casting and can also be used for sand mold or iron mold gravity casting or low-pressure casting.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

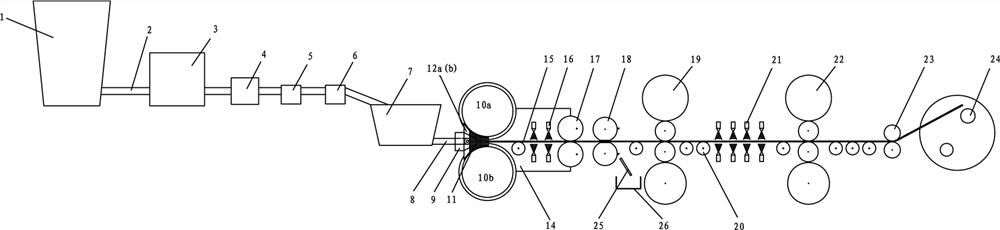

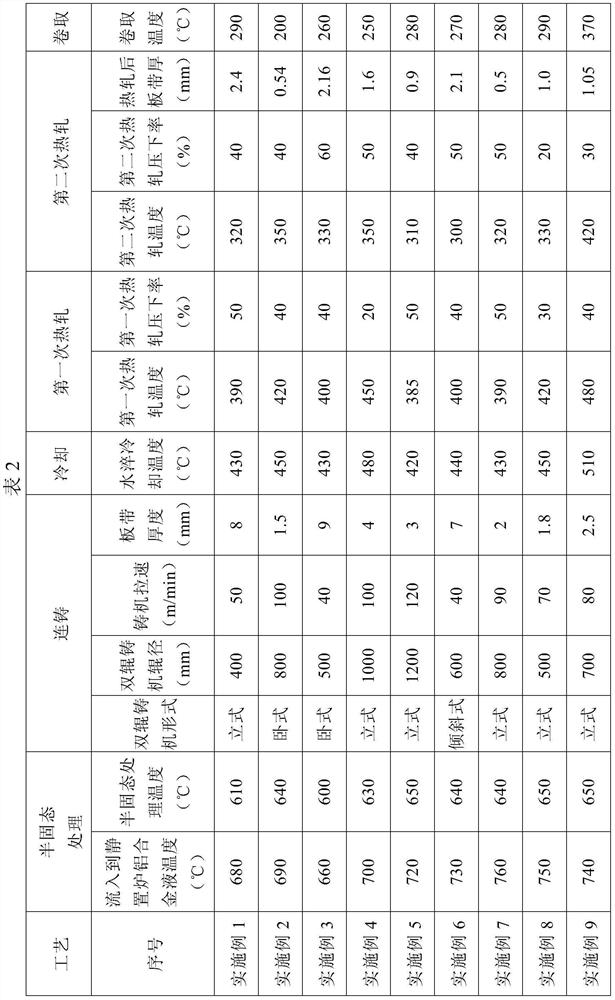

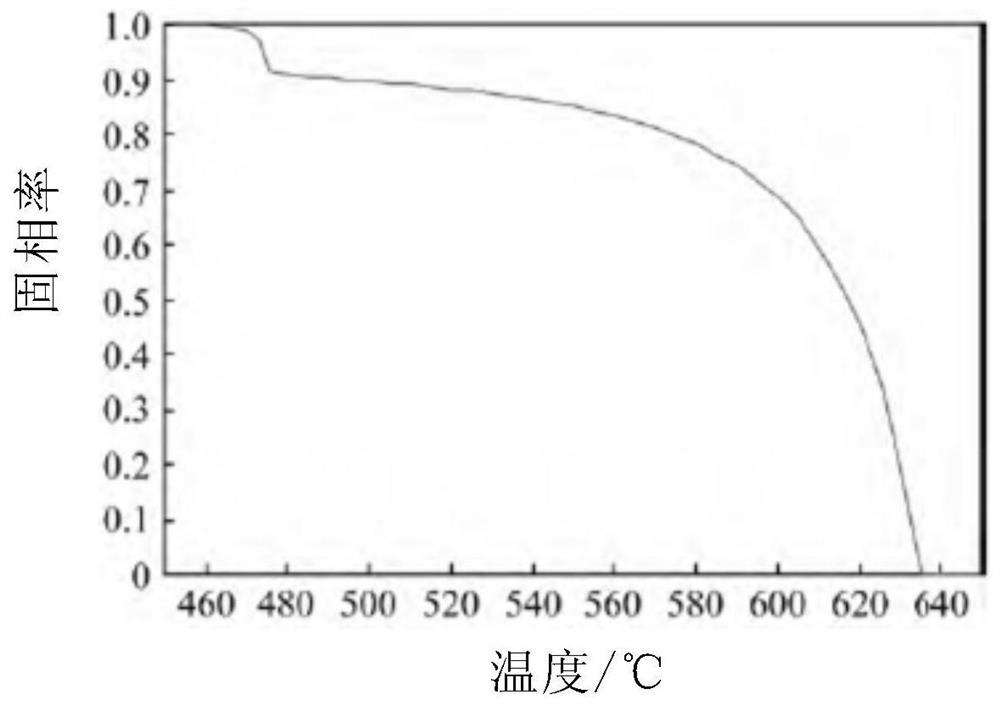

Thin-strip continuous casting high-performance 6XXX aluminum alloy plate strip and preparation method thereof

ActiveCN114107744AImprove mechanical propertiesReduced hot cracking tendencyMetal rolling arrangementsAuto industryFender

The invention discloses a thin-strip continuous casting high-performance 6XXX aluminum alloy plate strip and a preparation method thereof, the aluminum alloy plate strip comprises the following components in percentage by mass: 0.5-1.5% of Si, 0.1-2.0% of Mg, 0.1-1.0% of Fe, 0.05-0.5% of Mn, 0.02-0.2% of Cu, 0.01-0.08% of Ti, 0.001-0.008% of B and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.05%, and the content of total impurities is less than or equal to 0.15%. According to the preparation method, semisolid treatment is combined with a twin-roll thin-strip continuous casting process, and compared with an existing 6XXX aluminum alloy, the strength of the prepared 6XXX aluminum alloy plate strip is improved by 20% or above, and the formability is improved by 30% or above; and compared with a steel plate for an automobile, the weight is reduced by more than 40% easily. The produced aluminum alloy plate strip is a second-generation ABS aluminum alloy product, is widely applied to the field of automobiles, particularly can be used for automobile engine covering parts and can also be used for parts such as fenders, automobile doors, automobile roofs and trunk lids, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

TiAl-based alloy with excellent high temperature oxidation resistance and creep resistance suitable for casting

ActiveCN102268568BImprove antioxidant capacityImprove high temperature performanceChemical treatmentThermal spraying

The invention discloses a TiAl-based alloy with excellent high temperature oxidation resistance and creep resistance suitable for casting and the alloy belongs to the gamma-TiAl alloy. The TiAl-based alloy comprises the following components by atomic percent: 44.0-48.0% of Al, 1.0-3.0% of Nb, 0.1-3.0% of Mo, 0-0.8% of Si or / and 0-0.6% of C, and the balance of Ti and impurity elements, wherein thesum of the atomic percents of Si and C is 0.1-0.9%. The TiAl-based alloy disclosed by the invention has good high temperature performances and casting fluidity and is suitable for the casting of thin-walled parts; methods such as chemical treatment, thermal spraying and ion implantation which are used to increase the oxidation resistance, are not required to treat the surface of the alloy at 850-950 DEG C; and the TiAl-based alloy is particularly suitable to cast the gasoline engine supercharger turbine rotor which can work below 900-950 DEG C.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

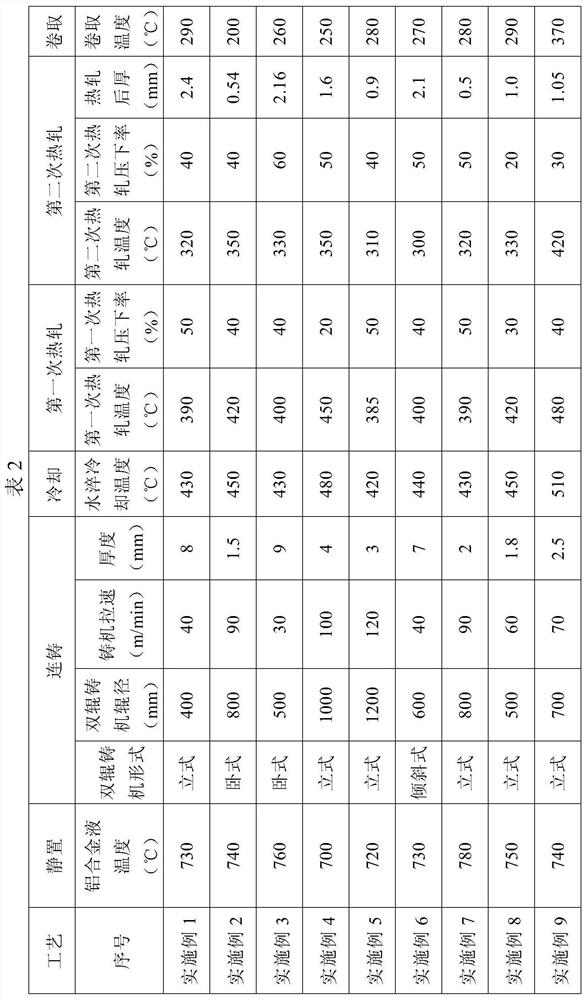

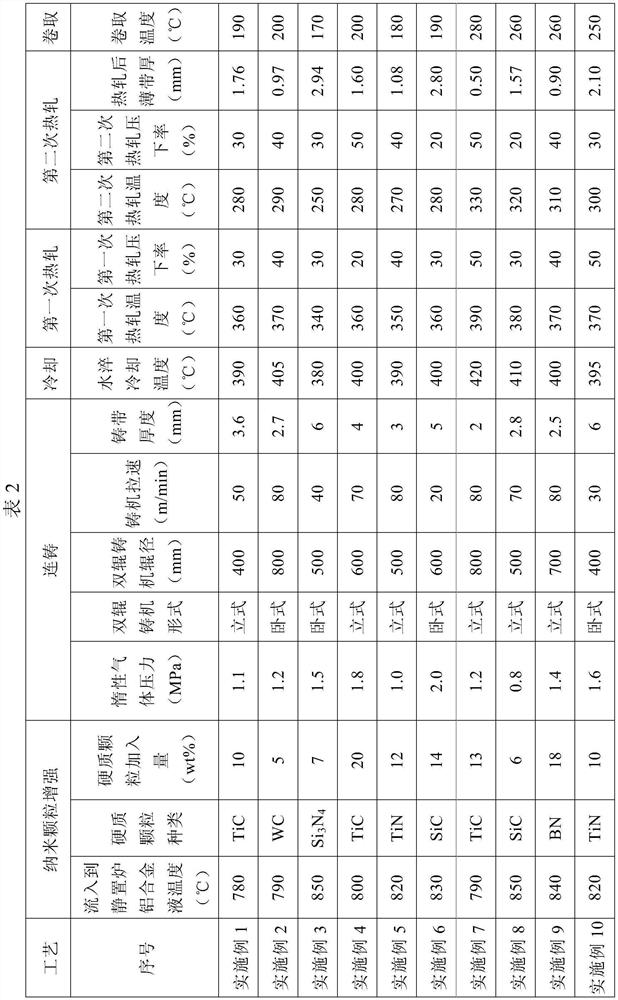

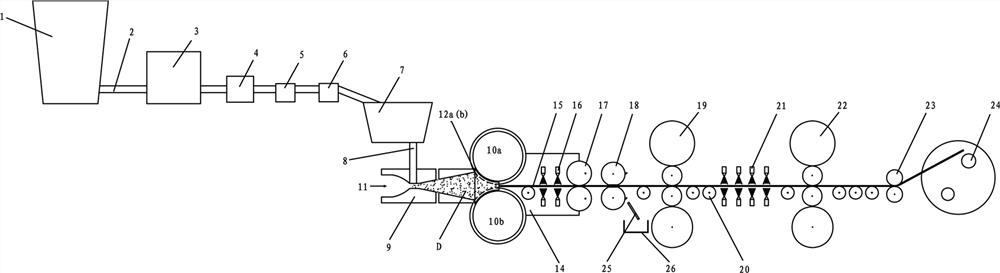

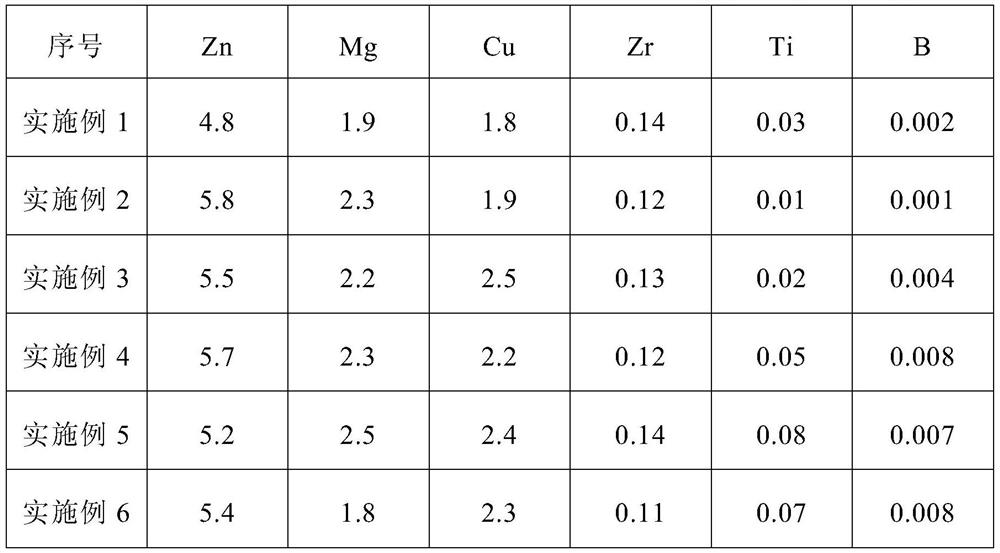

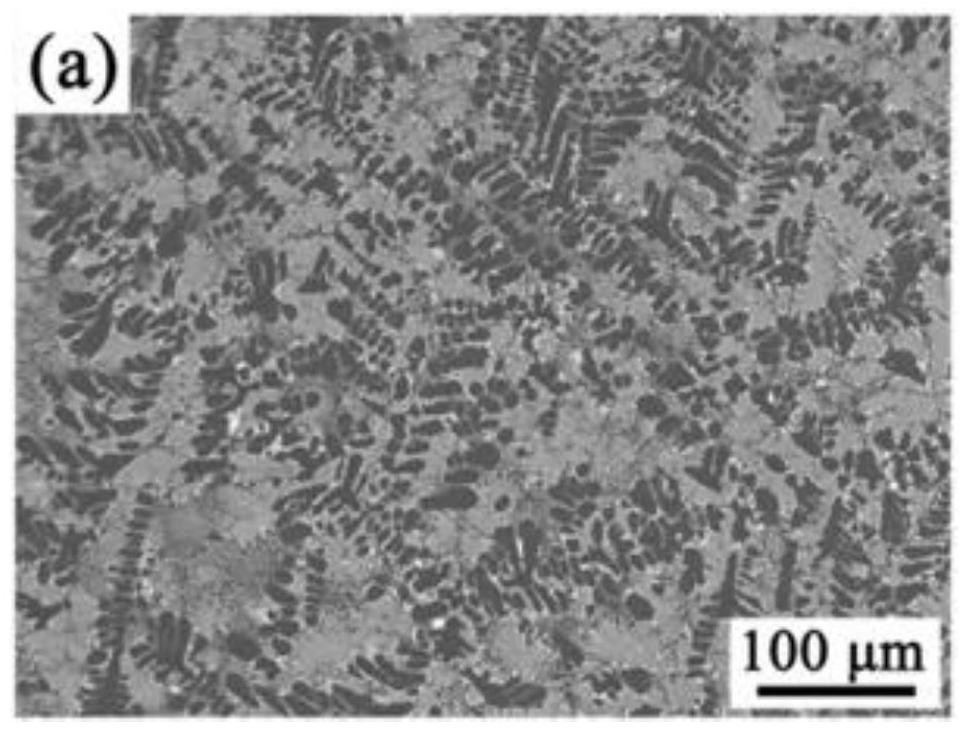

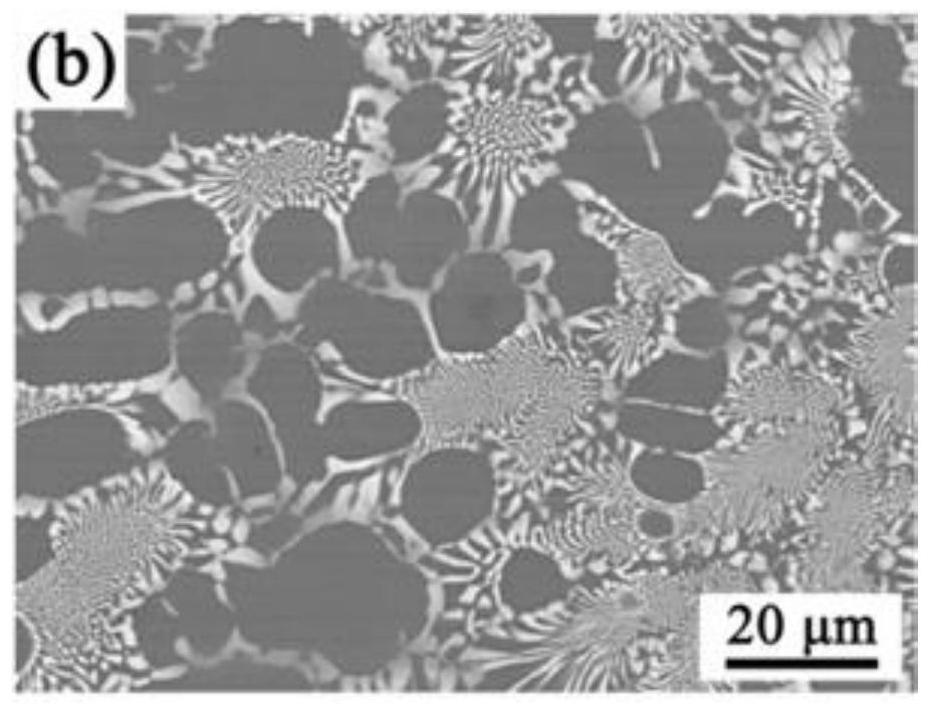

Preparation method of thin-strip continuous casting high-performance 7XXX aluminum alloy thin strip

ActiveCN114107762AHigh strengthHigh hardnessMetal rolling arrangementsSemi solidUltimate tensile strength

The invention relates to a preparation method of a thin-strip continuous casting high-performance 7XXX aluminum alloy thin strip, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 2) performing semi-solid state treatment; 3) continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. The microstructure of the 7XXX aluminum alloy thin strip obtained through the method is a fine isometric crystal matrix structure, and compared with an existing 7XXX aluminum alloy, the strength is improved by 15% or above, and the ductility is improved by 25% or above; compared with a steel plate, the weight is reduced by more than 40%.

Owner:BAOSHAN IRON & STEEL CO LTD

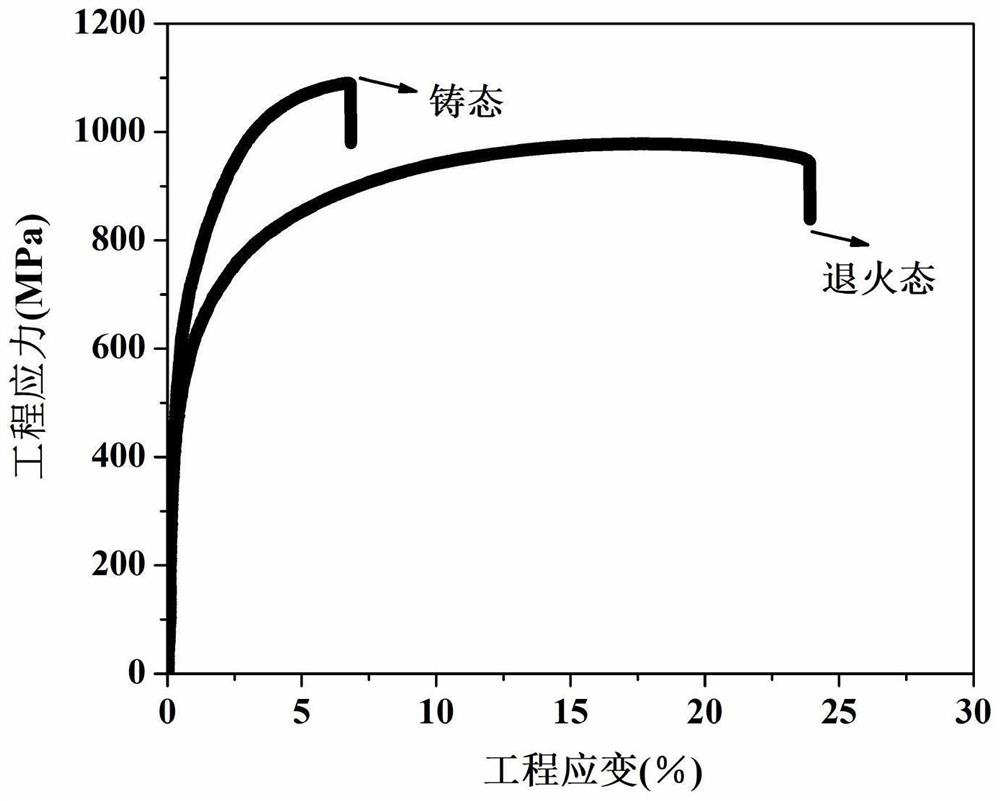

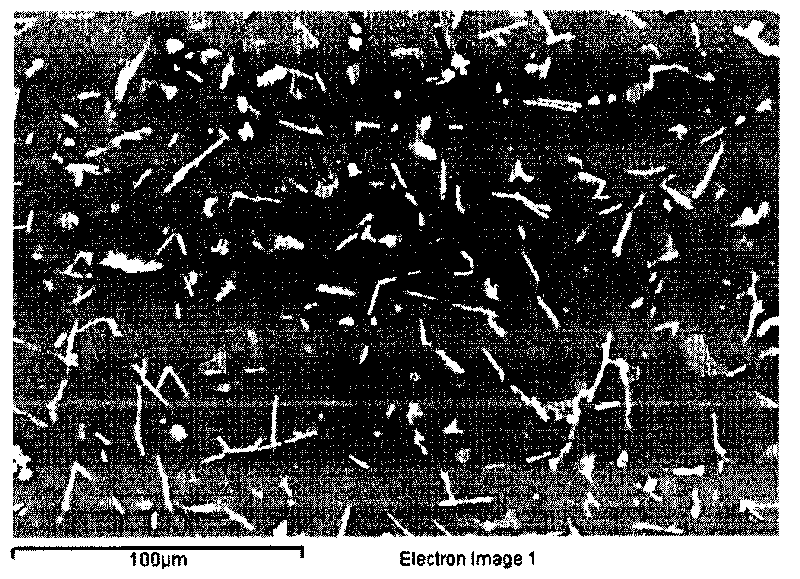

High-strength and high-plasticity six-element eutectic high-entropy alloy and preparation method thereof

ActiveCN114686744AHigh tensile strengthHigh elongation at breakHigh entropy alloysMechanical properties of carbon nanotubes

The invention provides a high-strength and high-plasticity six-element eutectic high-entropy alloy and a preparation method thereof. The general formula of the eutectic high-entropy alloy is CoCrNi2VxBySiz, x is more than or equal to 0.3 and less than or equal to 0.9, y is more than or equal to 0.2 and less than or equal to 0.6, z is more than or equal to 0.1 and less than or equal to 0.3, and x, y and z are respectively molar ratios of corresponding elements. The invention further discloses a preparation method of the eutectic high-entropy alloy. The eutectic high-entropy alloy is of an irregular eutectic microstructure in an as-cast state, and the phase structure is composed of FCC and M3B2 type borides. After specific two-stage annealing treatment, the comprehensive mechanical property of the eutectic high-entropy alloy is greatly improved, the tensile strength of the eutectic high-entropy alloy reaches up to 1016-1153 MPa, the elongation at break is 10.9-20.1%, and therefore the eutectic high-entropy alloy has wide application prospects in the engineering field.

Owner:DALIAN UNIV OF TECH

Preparation method for niobium-containing cast iron-based motor shell

InactiveCN110952029AImprove thermal conductivityImprove plasticityProcess efficiency improvementNiobiumFerrosilicon

The invention discloses a preparation method for a niobium-containing cast iron-based motor shell, and relates to the technical field of motor shells. The preparation method comprises the following steps of (1) smelting to obtain molten iron; (2) sequentially adding ferrosilicon, carbon scrap steel, ferromanganese and copper into a smelting furnace, adjusting the temperature of the molten iron, keeping the temperature, then reducing the temperature, then sequentially adding ferromolybdenum and ferrocolumbium, and keeping the temperature to obtain composite molten iron; (3) carrying out spheroidizing treatment by adopting dam type ductile iron ladle, and adding an inoculant into the spheroidized ladle; (4) pouring the composite molten iron into the spheroidized ladle, and carrying out inoculation treatment; and (5) pouring the molten iron subjected to the inoculation treatment in the step (4) into a motor shell mold, carrying out solidifying and molding, and carrying out demolding to obtain the motor shell. The motor shell prepared by the preparation method for the niobium-containing cast iron-based motor shell has excellent heat-conducting property.

Owner:ANHUI XUANLIDA MOTOR CO LTD

Preparation method of novel 7XXX aluminum alloy thin strip with high performance through jet casting and rolling

The invention relates to a preparation method of a novel 7XXX aluminum alloy thin strip with high performance by jet casting, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 (2) nano-particle enhancement; 3) spray deposition and continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip cast and rolled through the spray deposition combined double-roller thin strip cast rolling technology has the advantages that the strength is improved by 25% or above, and the ductility is improved by 35% or above; compared with a steel plate, the weight is reduced by 50% or more.

Owner:BAOSHAN IRON & STEEL CO LTD

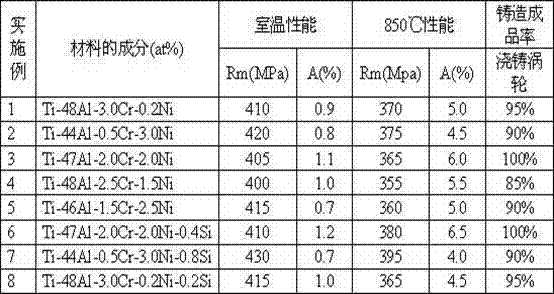

Titanium-aluminum base alloy with excellent room temperature ductility and casting fluidity and preparation method of titanium-aluminum base alloy

InactiveCN102181748BImprove antioxidant capacityGood plasticity at room temperatureImpurityInduction furnace

The invention discloses a titanium-aluminum base alloy with excellent room temperature ductility and casting fluidity and a preparation method of the titanium-aluminum base alloy. The alloy belongs to gamma-TiAL alloys, and comprises the following components: 44.0 to 48.0 atom percent of Al, 0.5 to 3.0 atom percent of Cr, 0.2 to 3.0 atom percent of Ni, 0 to 0.8 atom percent of Si, and the balanceof Ti and inevitable impurity elements. The preparation method comprises the following steps of: smelting qualified raw materials in a vacuum consumable electrode arc skull furnace or vacuum induction furnace, and performing casting forming; and during the casting forming, performing vacuum melting on a titanium-aluminum alloy cast ingot, and then performing casting or performing the casting after argon filling melting. The titanium-aluminum base alloy has high room temperature ductility and casting fluidity and is suitable for casting thin-wall parts, and when the titanium-aluminum base alloy is in use at 800 to 850 DEG C for a long time, the surface needs no antioxidation treatment.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Construction machinery and its box-type working device

InactiveCN103422520BReduce weightImprove mechanical propertiesMechanical machines/dredgersFailure rateVolumetric Mass Density

The invention discloses an engineering machine and a box-type working device of the engineering machine. The box-type working device is made of cast aluminum alloy. The aluminum alloy is Al-Cu-Mn series alloy or Al-Zn series alloy or Al-Si series alloy. The aluminum alloy has the smaller density and is beneficial to reducing the weight of the working device. Meanwhile, a dense and firm Al2O3 protection membrane is further easily formed on the surface of the aluminum alloy, and the corrosion resistance of the working device is improved. Due to the fact that the mechanical properties of the aluminum alloy are close to those of steel materials, the requirements for bearing acting force and resisting impact during operation can be met. In addition, the aluminum alloy has the excellent cast flowing property, cast flaws are not easily formed, and the premise is provided for the guarantee of the mechanical properties of the working device. The working procedure for mutually welding a top plate, a bottom plate and side plates into a box-type structure can also be eliminated, the number of welding joints can be reduced, the mechanical uniformity of the working device is improved, and the failure rate is reduced.

Owner:SANY HEAVY MACHINERY

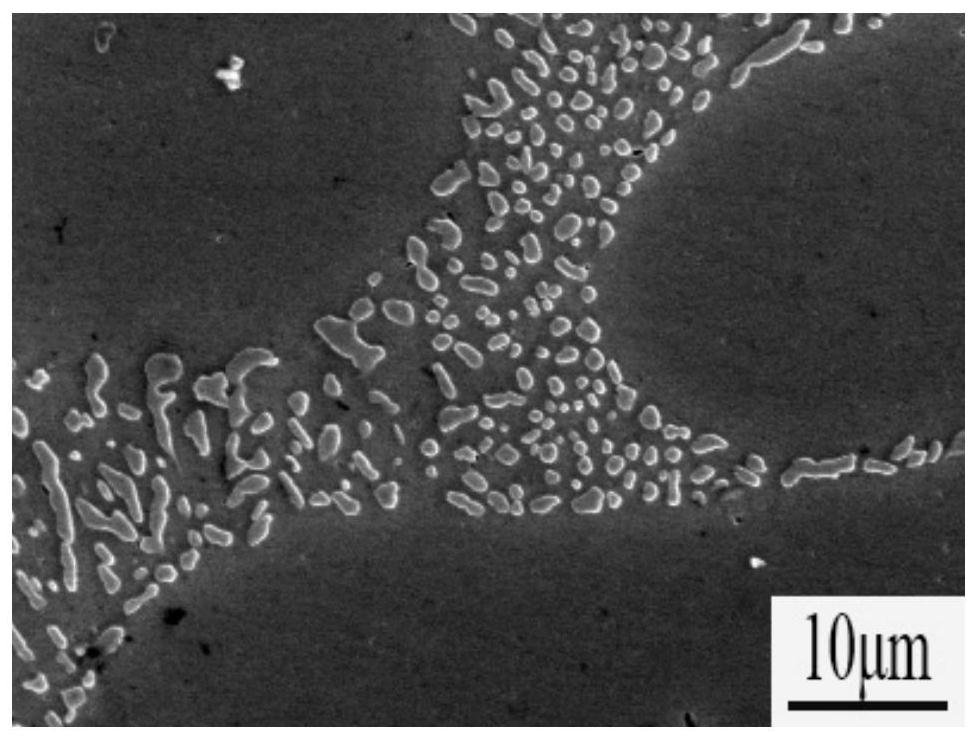

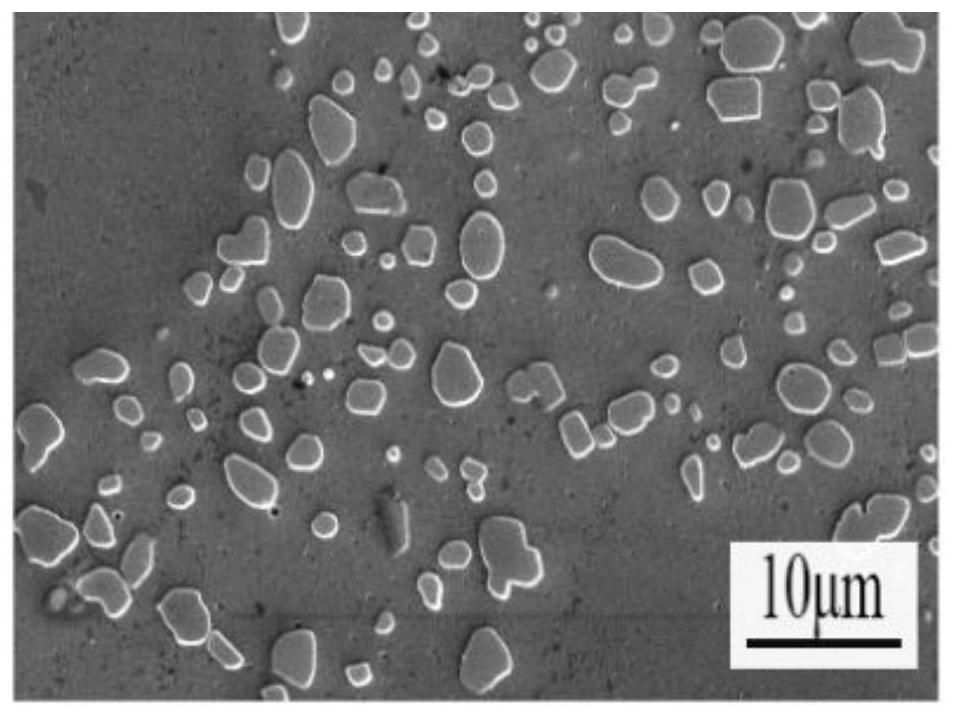

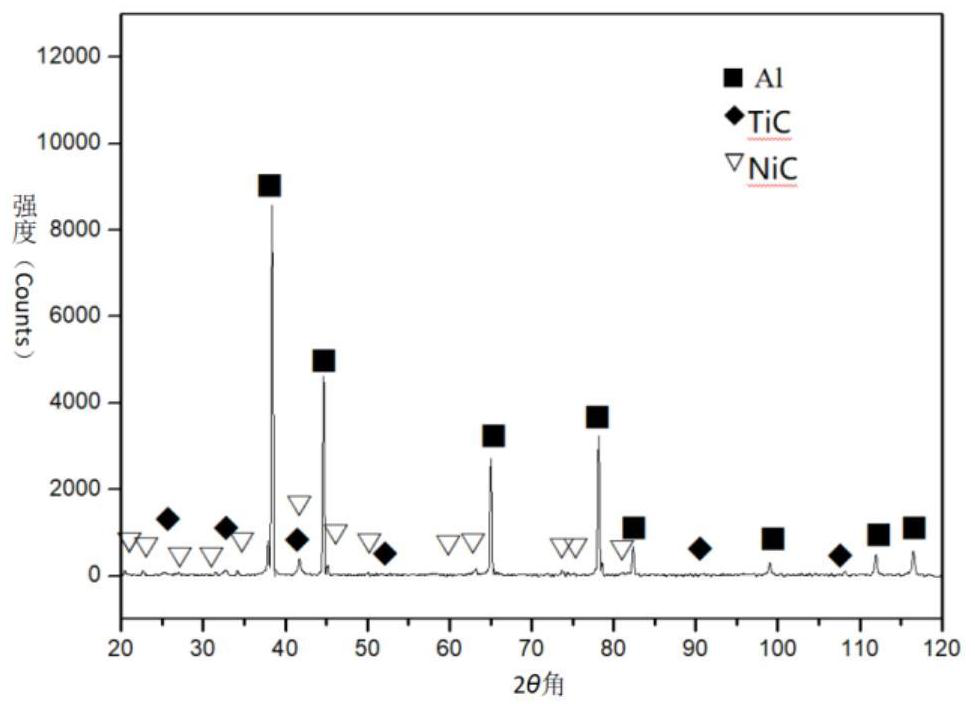

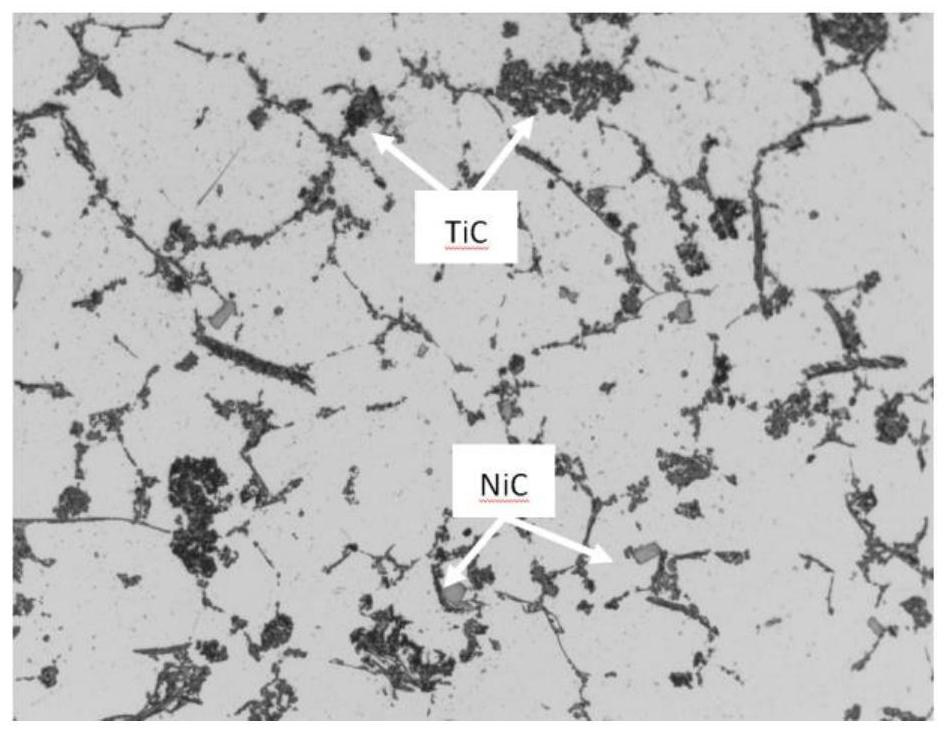

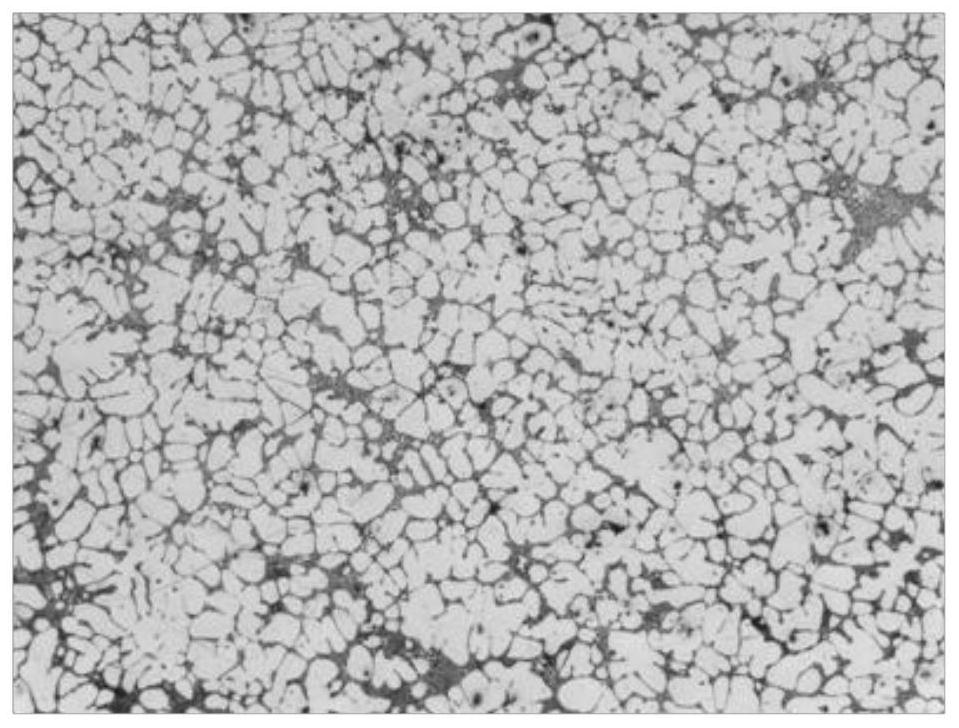

A kind of grain refiner of secondary aluminum alloy and its preparation method and application

The invention discloses a grain refiner for recycled aluminum alloys, a preparation method and application thereof, and belongs to the technical field of aluminum alloy grain refiners. The grain refiner is composed of the following components by mass percentage: Ti 3.8-4.2%, Ni0.9-1.1%, C 0.7-0.9%, Fe≤0.15%, the balance is Al and other unavoidable impurity elements , the individual content of other impurity elements is ≤0.05%, and the total content is ≤0.15%. The refiner of the present invention contains TiC particles and NiC particles at the same time, and through the compound refinement effect of TiC particles and NiC particles on α-Al grains, the α-Al grains of the recycled aluminum alloy can be transformed from coarse dendritic to fine The uniform equiaxed or near-spherical shape solves the problem of difficult grain refinement of secondary aluminum alloys, and is conducive to improving the casting performance and mechanical properties of secondary aluminum alloys.

Owner:GUANGDONG ENG POLYTECHNIC COLLEGE +1

Novel 7XXX aluminum alloy thin strip for thin strip continuous casting and preparation method of novel 7XXX aluminum alloy thin strip

The invention relates to a strip continuous casting novel 7XXX aluminum alloy strip and a preparation method thereof, the aluminum alloy comprises the following components by mass percent: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2%. The aluminum alloy thin strip is prepared through the double-roller thin strip continuous casting technology, the microscopic structure of the aluminum alloy thin strip is a fine equiaxed crystal matrix structure, and compared with an existing 7XXX aluminum alloy, the strength of the aluminum alloy thin strip is improved by 10% or above, and the ductility of the aluminum alloy thin strip is improved by 20% or above; compared with a steel plate, the weight is reduced by 30% or more. The material can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and can provide a wide space for aerospace high reinforcement, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Jet cast rolling high-performance 7XXX aluminum alloy thin strip and preparation method thereof

ActiveCN114107764AImprove mechanical propertiesReduced hot cracking tendencyMetal rolling arrangementsNacelleFlight vehicle

The invention relates to a jet cast rolling high-performance 7XXX aluminum alloy thin strip and a preparation method thereof, the aluminum alloy thin strip comprises the following components in percentage by mass: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.1%, and the content of total impurities is less than or equal to 0.2%. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip prepared through the spray deposition and double-roller thin strip cast rolling combined technology has the advantages that the strength is higher by 20% or above, and the ductility is higher by 30% or above; compared with a steel plate, the weight is reduced by more than 40%. The produced aluminum alloy thin strip can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and a wide space can be provided for aerospace high strengthening, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of high-entropy alloy containing eutectic structure and preparation method thereof

ActiveCN113444955BImprove mechanical propertiesSimple ingredientsHigh entropy alloysUltimate tensile strength

The invention discloses a high-entropy alloy containing eutectic structure (NiAl)100-3xMoxCrxVx according to the atomic percentage, 7.5≤x≤10, wherein Ni and Al are in an equiatomic ratio; the invention also discloses the eutectic The preparation method of the high-entropy alloy with the microstructure specifically comprises: first weighing the raw material according to the atomic ratio, then pickling the raw material, and finally smelting in a melting furnace to obtain the high-entropy alloy with the eutectic structure. The high-entropy alloy prepared by the method of the invention has excellent strength and toughness.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com