Aluminum alloy material for high-performance thin-wall 3D printing sand casting and preparation method thereof

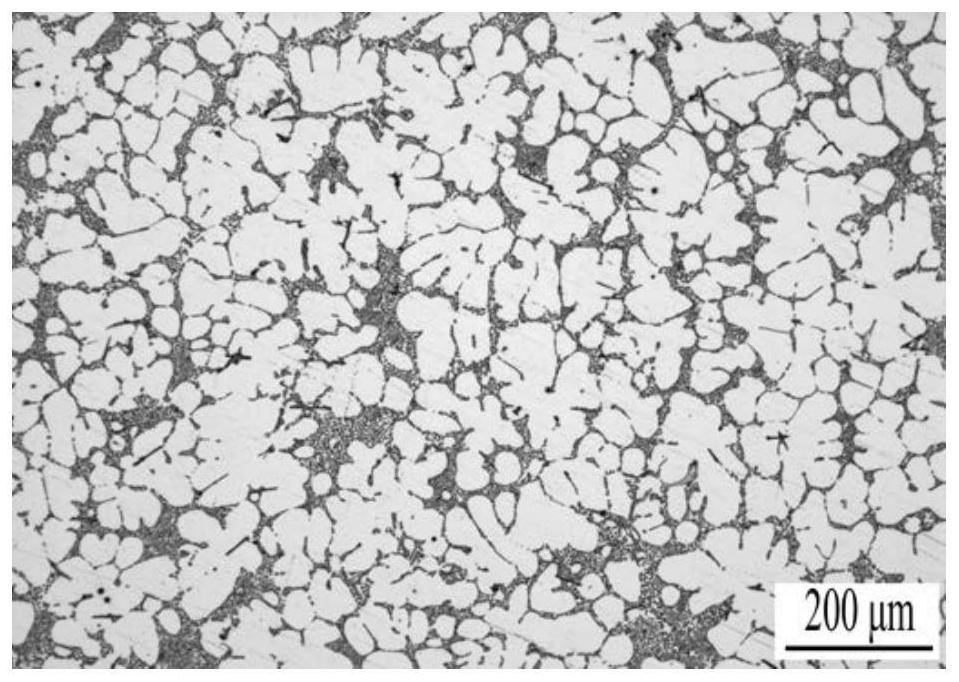

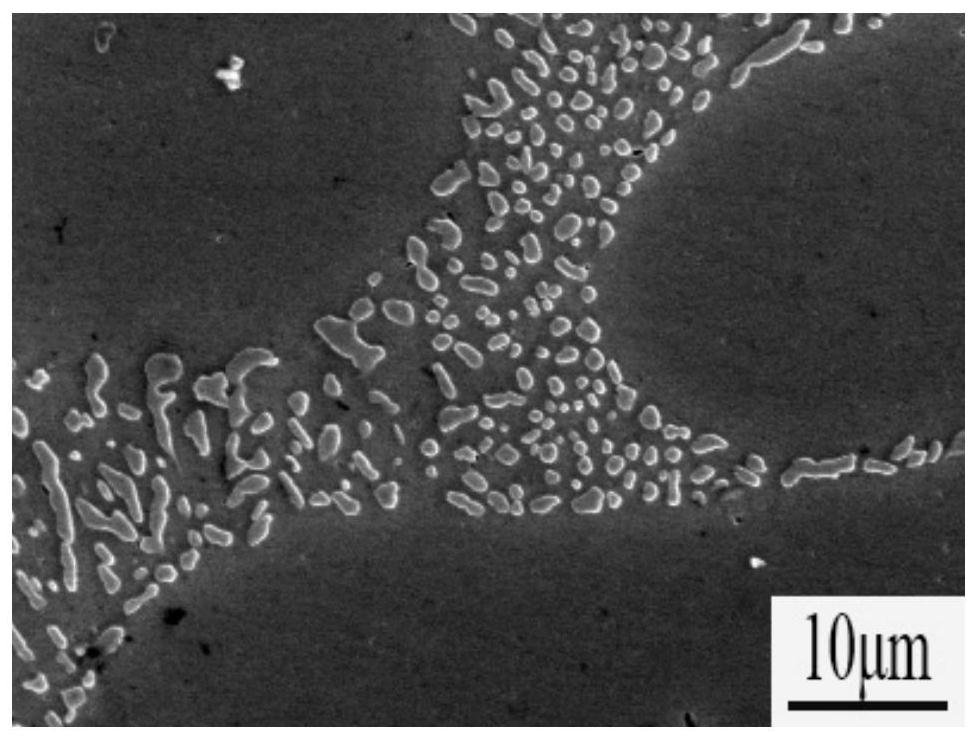

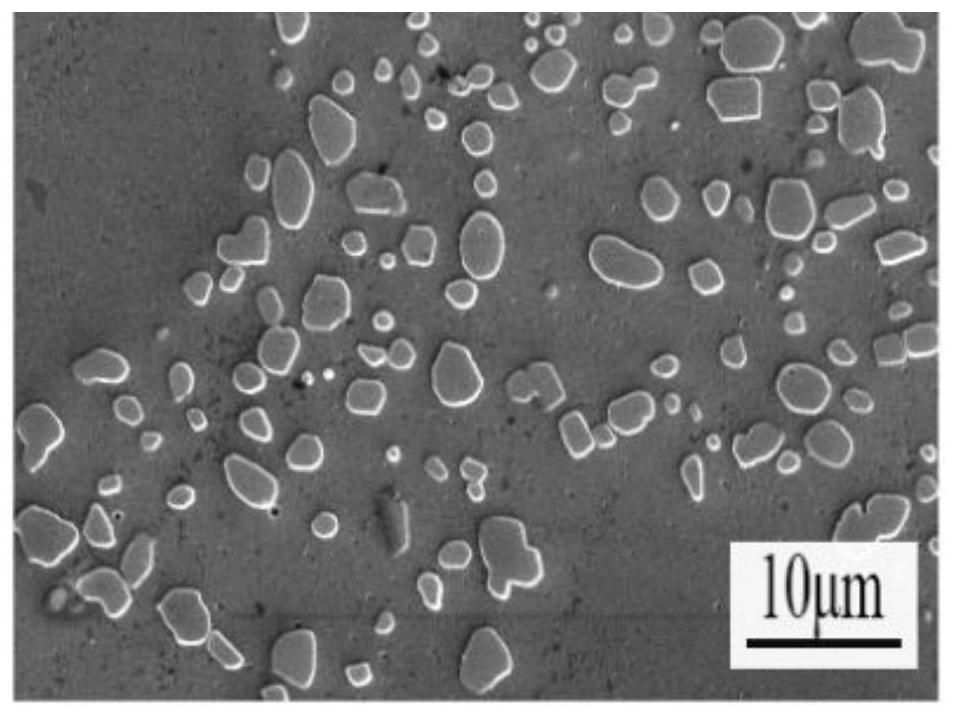

An aluminum alloy material and 3D printing technology, applied in the field of aluminum alloy materials, can solve the problems of coarse structure of sand casting aluminum alloy, slow cooling rate of sand mold, and high resin content of sand mold, and achieve less pore defects, good casting fluidity, and eutectic. Silicon fine and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides a method for preparing the aluminum alloy material for thin-walled 3D printing sand casting, comprising the following steps:

[0061] Step 1: batching, preparing A356 aluminum ingot, Al-10Zr master alloy, Al-10Sr master alloy, Al-2Sc master alloy and Al-5Ti-B master alloy.

[0062] Step 2: Add A356 aluminum ingot into the crucible, put it into the resistance furnace, and the resistance furnace is raised to 730-750°C in the order of 100°C each time. After the furnace material is completely melted, add Al-10Zr master alloy and Al-2Sc For the intermediate alloy, stir with a stirring rod for 3-5 minutes to ensure that the ingredients are even;

[0063] Step 3: When the temperature of the molten aluminum is stable at 710-730°C, add the Al-5Ti-B master alloy, stir until it is completely melted, and then let it stand for 5-15 minutes;

[0064] Step 4: When the temperature rises to 710-730°C, add Al-10Sr master alloy, stir until it is comple...

Embodiment 1

[0073] A high-performance aluminum alloy material for thin-walled 3D printing sand casting, its main components and mass percentages are as follows: Si: 6.5%; Mg: 0.35%; Ti: 0.136%; Sr: 0.031%; Fe: 0.138%; Zr : 0.16%; Sc: 0.15%; other unavoidable impurity elements ≤ 0.10%; the balance is Al.

[0074] Step 1: batching, preparing A356 aluminum ingot, Al-10Zr master alloy, Al-10Sr master alloy, Al-2Sc master alloy and Al-5Ti-B master alloy.

[0075] Step 2: Add A356 aluminum ingot into the crucible and put it into the resistance furnace. The resistance furnace is raised to 750°C in the order of 100°C each time. After the furnace material is completely melted, add Al-10Zr intermediate alloy and Al-2Sc intermediate Alloy, stir with a stirring rod for 3 minutes to ensure that the ingredients are even;

[0076] Step 3: When the temperature of the molten aluminum is stable at 710°C, add the Al-5Ti-B master alloy, stir until it is completely melted, and then let it stand for 5 minutes...

Embodiment 2

[0084] A high-performance aluminum alloy material for thin-walled 3D printing sand casting, its main components and mass percentages are as follows: Si: 7.12%, Mg: 0.38%; Ti: 0.05%; Sr: 0.038%; Fe: 0.2%; Zr : 0.25%; Sc: 0.3%; other unavoidable impurity elements ≤ 0.10%; the balance is Al.

[0085] Step 1: batching, preparing A356 aluminum ingot, Al-10Zr master alloy, Al-10Sr master alloy, Al-2Sc master alloy and Al-5Ti-B master alloy;

[0086] Step 2: Add A356 aluminum ingot into the crucible, put it into the resistance furnace, and the resistance furnace is raised to 740 °C in the order of 100 °C each time. After the furnace material is completely melted, add Al-10Zr master alloy and Al-2Sc master alloy , Stir for 3 minutes with a stirring rod to ensure that the ingredients are even;

[0087] Step 3: When the temperature of the molten aluminum is stable at 715°C, add the Al-5Ti-B master alloy, stir until it is completely melted, and then let it stand for 10 minutes;

[0088...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com