Novel mine vulcanizing machine profile and preparation method thereof

A technology for mines and models, applied in the field of new mining vulcanized machine materials and their preparation, can solve the problems of limited development, cracking sensitivity, etc., and achieve the effects of improving alloy structure, refining grains, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The invention provides a method for preparing a new type of vulcanized machine material for mining, comprising the following steps:

[0044] S1: Before smelting production, do furnace cleaning first; remove metal or non-metallic residues accumulated in various places in the smelting furnace to prevent the melt from being polluted by metal impurities and affect material properties;

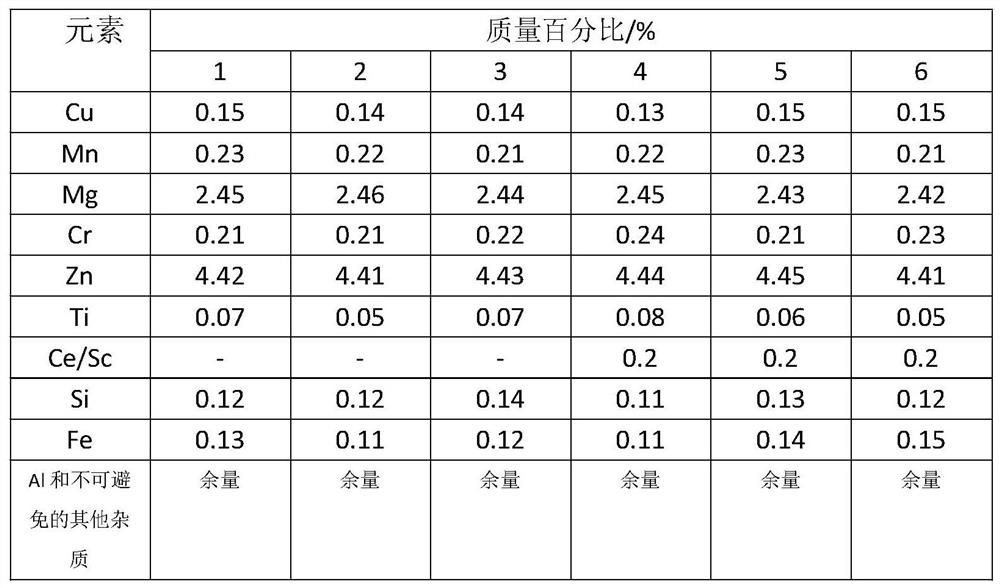

[0045] S2: configure the smelting raw materials according to the composition and mass percentage of the aluminum alloy extruded bar; specifically, the smelting raw materials in the S2 include pure metals, master alloys, rare earth elements and modifiers; the pure metal composition includes pure aluminum Ingots, pure magnesium ingots, pure zinc ingots; master alloys include Al-Cu, Al-Mn, Al-Ti, Al-Cr, Cu elements and trace elements such as Al-Cu, Al-Mn, Al-Ti, Al-Cr The rare earth element is added in the form of a master alloy; the rare earth element is Ce / Sc, and the rare earth element is ad...

Embodiment 2

[0063] This embodiment provides a new type of vulcanized machine material for mining, including pure metal, intermediate alloy, rare earth element and modifier; the pure metal composition includes pure aluminum ingot, pure magnesium ingot, and pure zinc ingot; the intermediate alloy includes Al-Cu, Al-Mn, Al-Ti, Al-Cr, Cu elements and trace elements are added in the form of Al-Cu, Al-Mn, Al-Ti, Al-Cr master alloys; rare earth elements are Ce / Sc, Rare earth elements are added in the form of Al-Ce / Al-Sc master alloys; modifiers are added in the form of Al-Ti-B wires.

[0064] Preferably, the element content of the vulcanized machine material for mining is: Si≤0.20%, Fe≤0.25%, Cu0.10~0.20%, Mn0.20~0.30%, Mg2.0~2.8%, Cr0.15~ 0.25%, Zn4.4~4.8%, Ti0.15~0.18%, Ce0.2% / Sc0.3% The balance is Al and other unavoidable impurities, and the individual content of other unavoidable impurities is ≤0.05%, the total amount ≤0.15%.

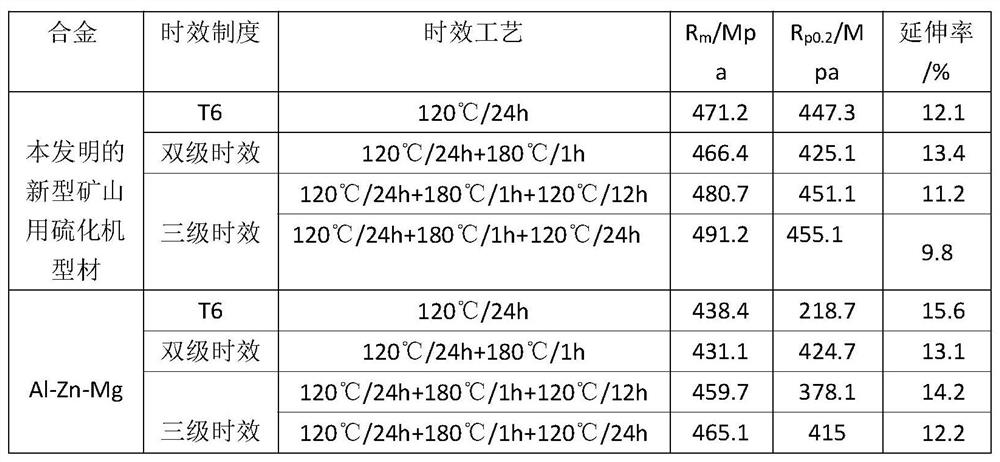

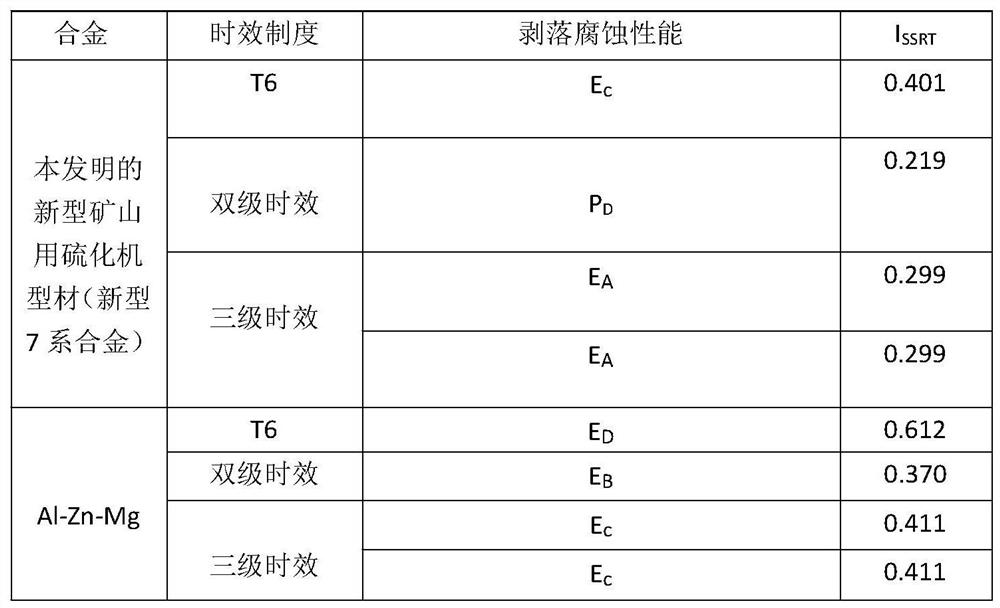

[0065] The technical effect of the present invention is descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com