High-strength and high-conductivity aluminum alloy and preparation method thereof

A high-conductivity, high-strength technology, applied in the field of aluminum alloy processing, can solve the problems of low electrical conductivity, low electrical conductivity and low strength of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

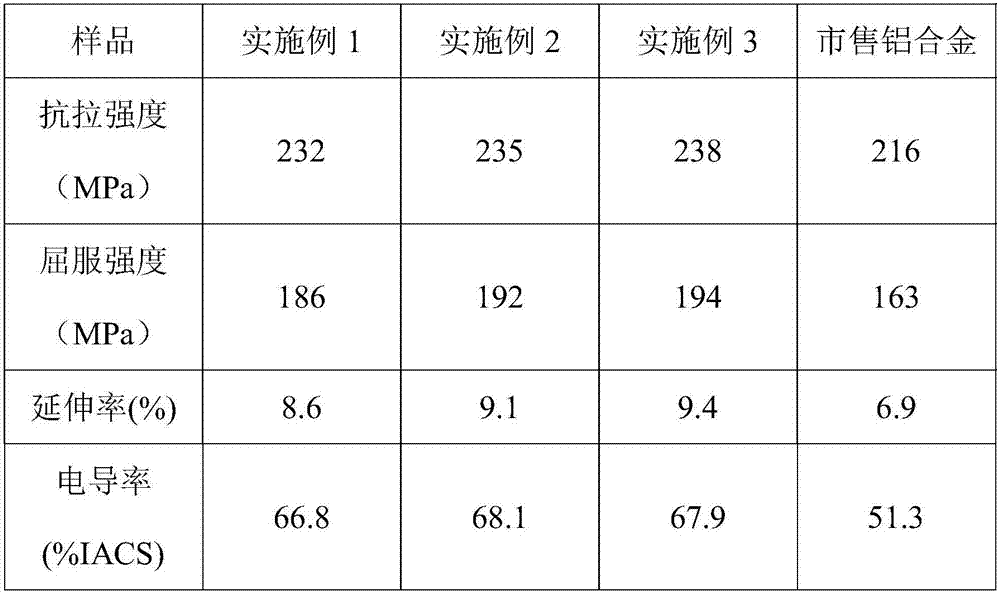

Embodiment 1

[0019] Example 1 A high-strength and high-conductivity aluminum alloy is composed of the following components by weight percentage (wt%): Mg: 0.5-0.54, Mn≤0.01, Zn≤0.01, Si: 0.41-0.45, Fe: 0.09- 0.18, Cu≤0.01, mixed rare earth Re: 0.31~0.5, the balance is Al and unavoidable impurities.

[0020] The method for preparing the above-mentioned aluminum alloy comprises the following steps:

[0021] Melting, the melting temperature is 700°C-755°C, add aluminum ingots, silicon ingots, magnesium ingots, iron additives, mixed rare earths and traces of Zn, Cu, Mn into the melting furnace, stir for 15-20 minutes before using argon Refining for 15-20 minutes, after online degassing and then scraping off the surface ash, the aluminum liquid stands still for 15-20 minutes;

[0022] Casting, the casting temperature is 690℃~730℃, the casting speed is 60~95mm / min, the casting water pressure is 0.05~0.15MPa, and then the ingot is homogenized, the treatment temperature is 560±5℃, and the time is...

Embodiment 2

[0024] Example 2 A high-strength and high-conductivity aluminum alloy is composed of the following components by weight percentage (wt%): Mg: 0.52-0.53, Mn≤0.009, Zn≤0.009, Si: 0.43-0.44, Fe: 0.11- 0.13, Cu≤0.009, mixed rare earth Re: 0.34~0.45, the balance is Al and unavoidable impurities.

[0025] The method for preparing the above-mentioned aluminum alloy comprises the following steps:

[0026] Melting, the melting temperature is 700°C-755°C, add aluminum ingots, silicon ingots, magnesium ingots, iron additives, mixed rare earths and traces of Zn, Cu, Mn into the melting furnace, stir for 15-20 minutes before using argon Refining for 15-20 minutes, after online degassing and then scraping off the surface ash, the aluminum liquid stands still for 15-20 minutes;

[0027] Casting, the casting temperature is 695℃~715℃, the casting speed is 60~95mm / min, the casting water pressure is 0.05~0.15MPa, and then the ingot is homogenized, the treatment temperature is 560±5℃, and the ti...

Embodiment 3

[0029] Example 3 A high-strength and high-conductivity aluminum alloy is composed of the following components by weight percentage (wt%): Mg: 0.523, Mn: 0.0018, Zn: 0.0048, Si: 0.436, Fe: 0.116, Cu: 0.0027, Mixed rare earth Re: 0.4, the balance is Al and unavoidable impurities.

[0030] The method for preparing the above-mentioned aluminum alloy comprises the following steps:

[0031] Melting, the melting temperature is 740°C, adding aluminum ingots, silicon ingots, magnesium ingots, iron additives, mixed rare earths and traces of Zn, Cu, Mn into the melting furnace, stirring for 15-20 minutes and then refining with argon for 15-20 minutes After 20 minutes, remove the ash on the surface after online degassing, and let the molten aluminum stand for 15 to 20 minutes;

[0032] Casting, the casting temperature is 705°C, the casting speed is 60-95mm / min, the casting water pressure is 0.05-0.15MPa, and then the ingot is homogenized, the processing temperature is 560±5°C, the time i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com