Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

370results about How to "Low heat treatment temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-coercivity sintered Nd-Fe-B and product

InactiveCN104505206AIncrease profitImprove liquidityInorganic material magnetismInductances/transformers/magnets manufactureRare earthNitrogen

The invention discloses a preparation method of high-coercivity sintered Nd-Fe-B. The preparation method comprises the following steps: preparing a main phase alloy powder and a grain boundary phase alloy powder; protecting the prepared main phase alloy powder and the grain boundary phase alloy powder by using nitrogen or argon in a protective medium, and uniformly mixing, wherein the mass percent of the added grain boundary phase alloy powder accounts for 0.1-10 percent; carrying out orientation profiling and cold isostatic pressing on the mixed alloy powder; in a vacuum sintering furnace, sintering a profiled magnet block for 2-4h at the temperature of 1000-1100 DEG C, then carrying out primary tempering for 2-4h at the temperature of 800-950 DEG C, and carrying out secondary tempering for 2-4h at the temperature of 450-650 DEG C to prepare the sintered Nd-Fe-B. The invention also discloses the high-coercivity sintered Nd-Fe-B. According to the preparation method disclosed by the invention, by virtue of low melting point auxiliary alloy, the wetting temperature between a grain boundary phase and a main phase is lowered, the wetting time is prolonged, the utilization ratio of heavy rare earth is increased, the used amount of rare earth is lowered, the process is simple, the cost is low, and the high-coercivity sintered Nd-Fe-B is suitable for mass production.

Owner:ZHEJIANG UNIV

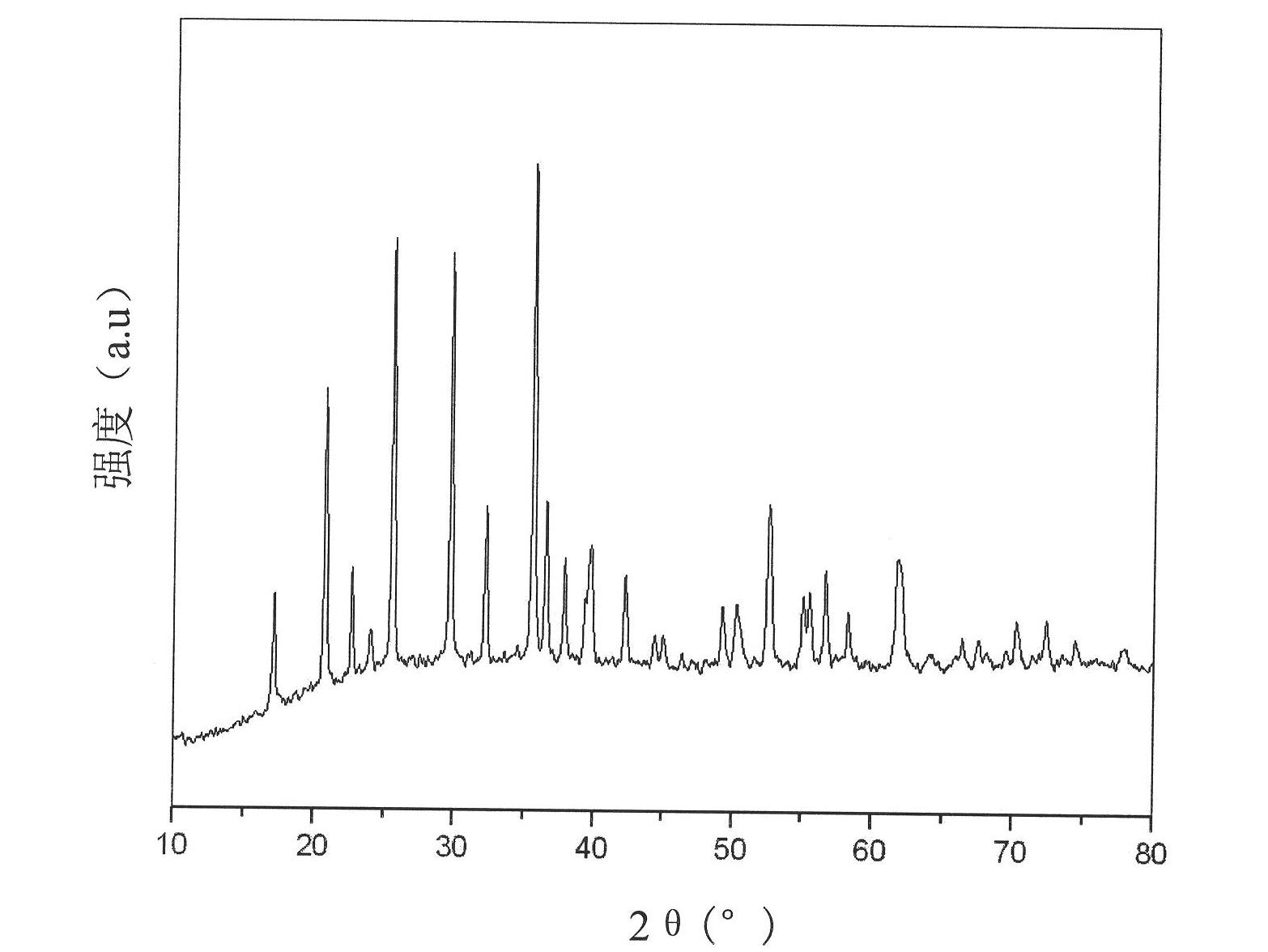

Modification method for improving high-temperature cycle performance and ionic conductance of lithium iron phosphate material

The invention discloses a modification method for improving the high-temperature cycle performance and ionic conductance of a lithium iron phosphate material. The method mainly comprises the following steps of: mixing an organic compound which contains silicon, aluminum and titanium with lithium iron phosphate; performing certain heat treatment; and coating silicon dioxide, aluminum oxide or titanium oxide onto the surface of the lithium iron phosphate material to fulfill the aim of improving the electrochemical performance of the lithium iron phosphate material. The high-temperature cycle performance and the high-magnification charging-discharging current cycle capacity of coating-modified lithium iron phosphate are enhanced, and the impedance of a prepared electrode is remarkably reduced. The lithium iron phosphate material can be applied to more fields. A coating method has the advantages of simple process, low cost, stable and controllable product performance and suitability for industrial production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

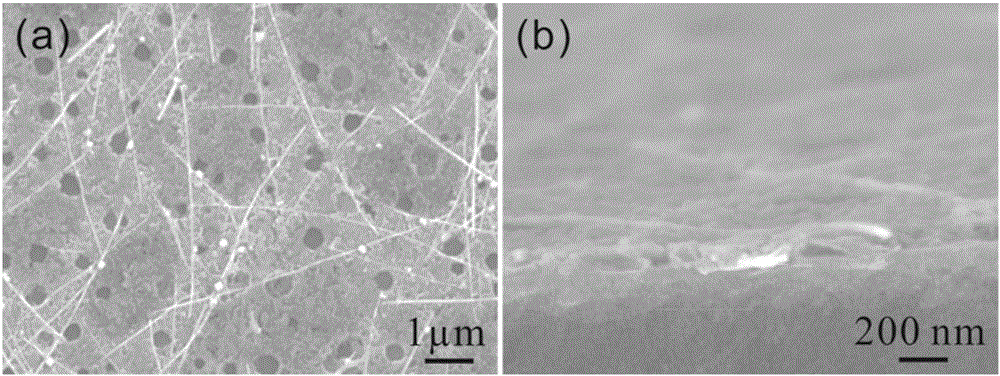

Highly conducting and oriented graphene film and production process

ActiveUS20170162291A1Reduce resistanceGood orientationProductsConductive layers on insulating-supportsElectrical conductorShear stress

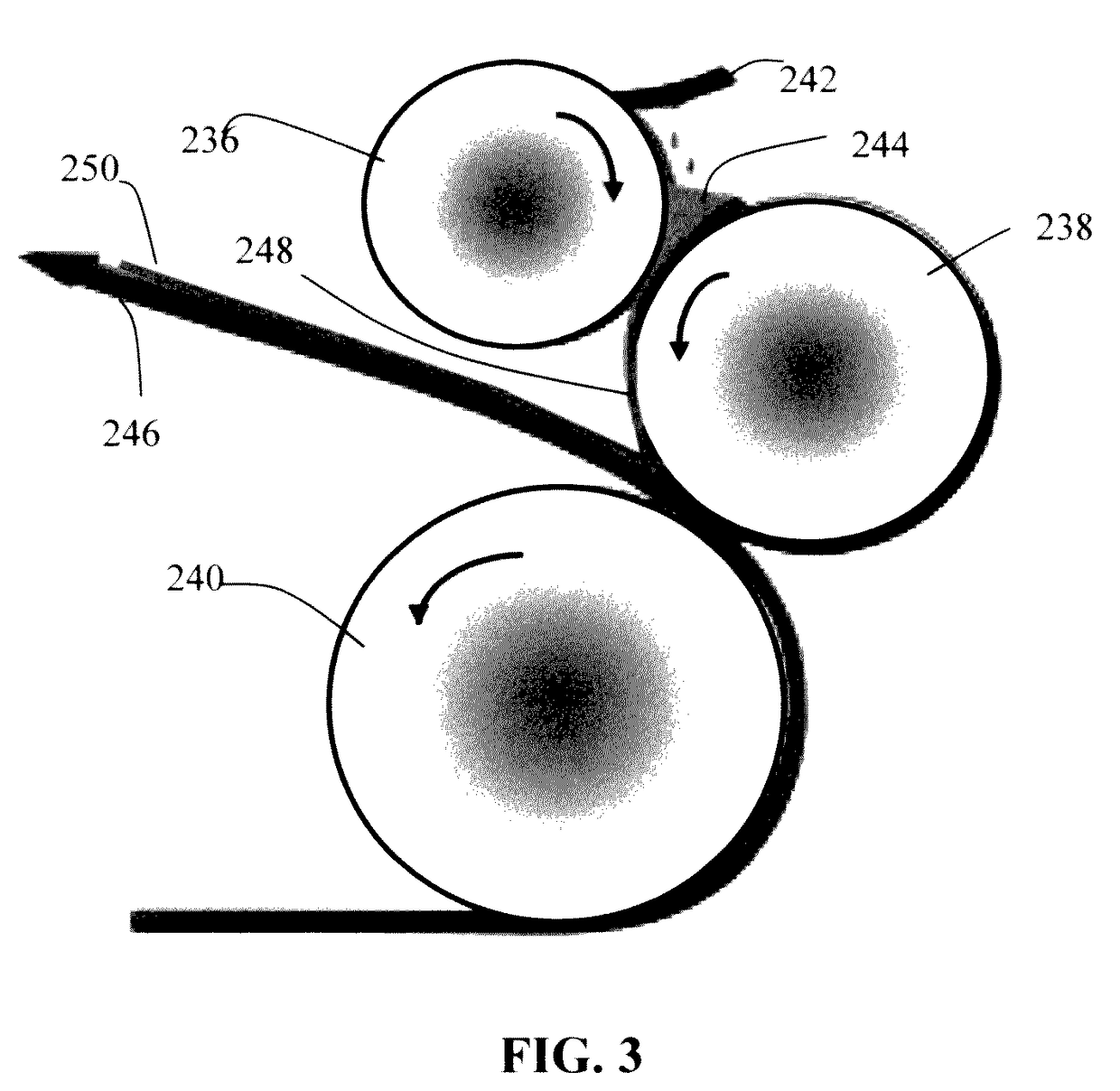

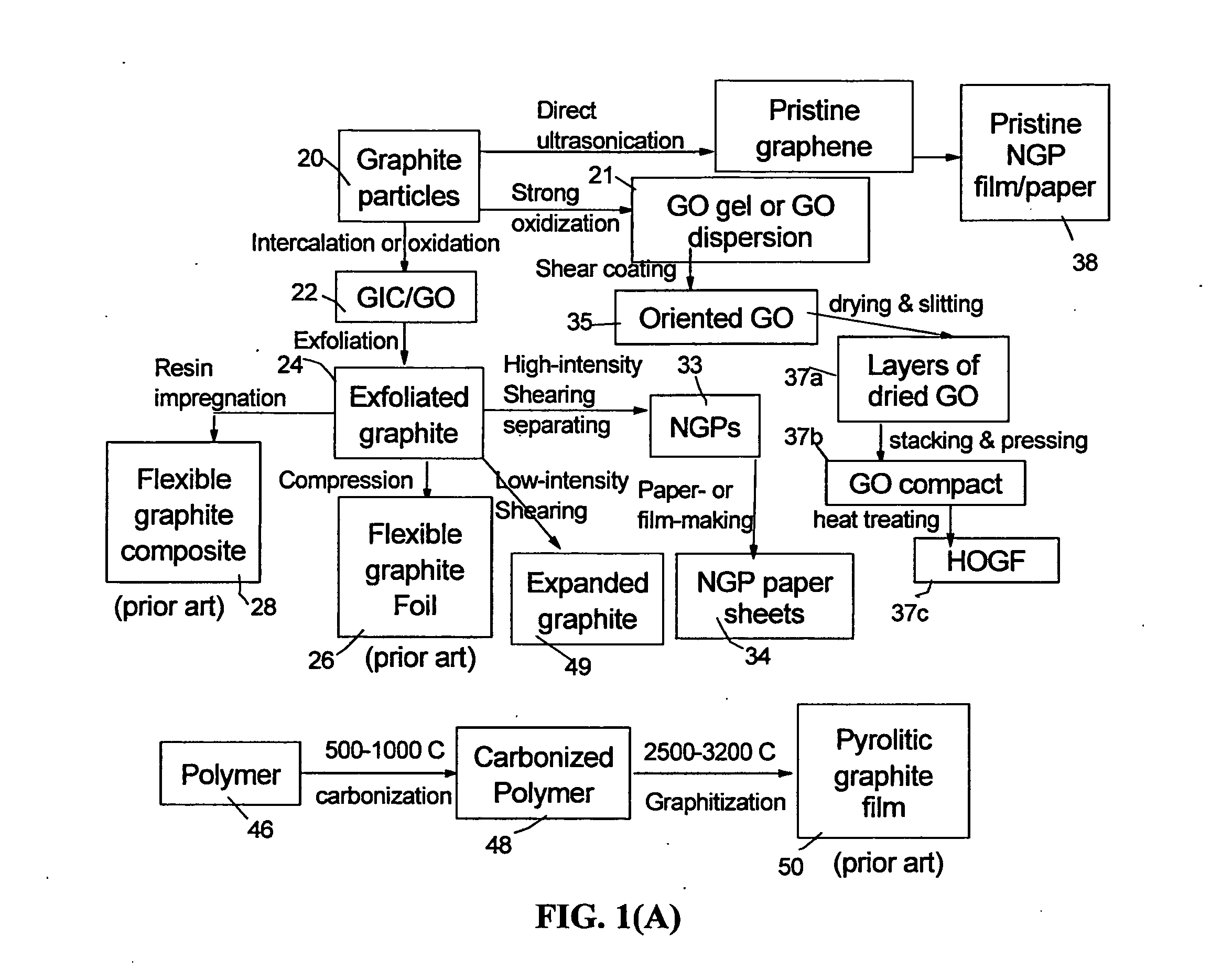

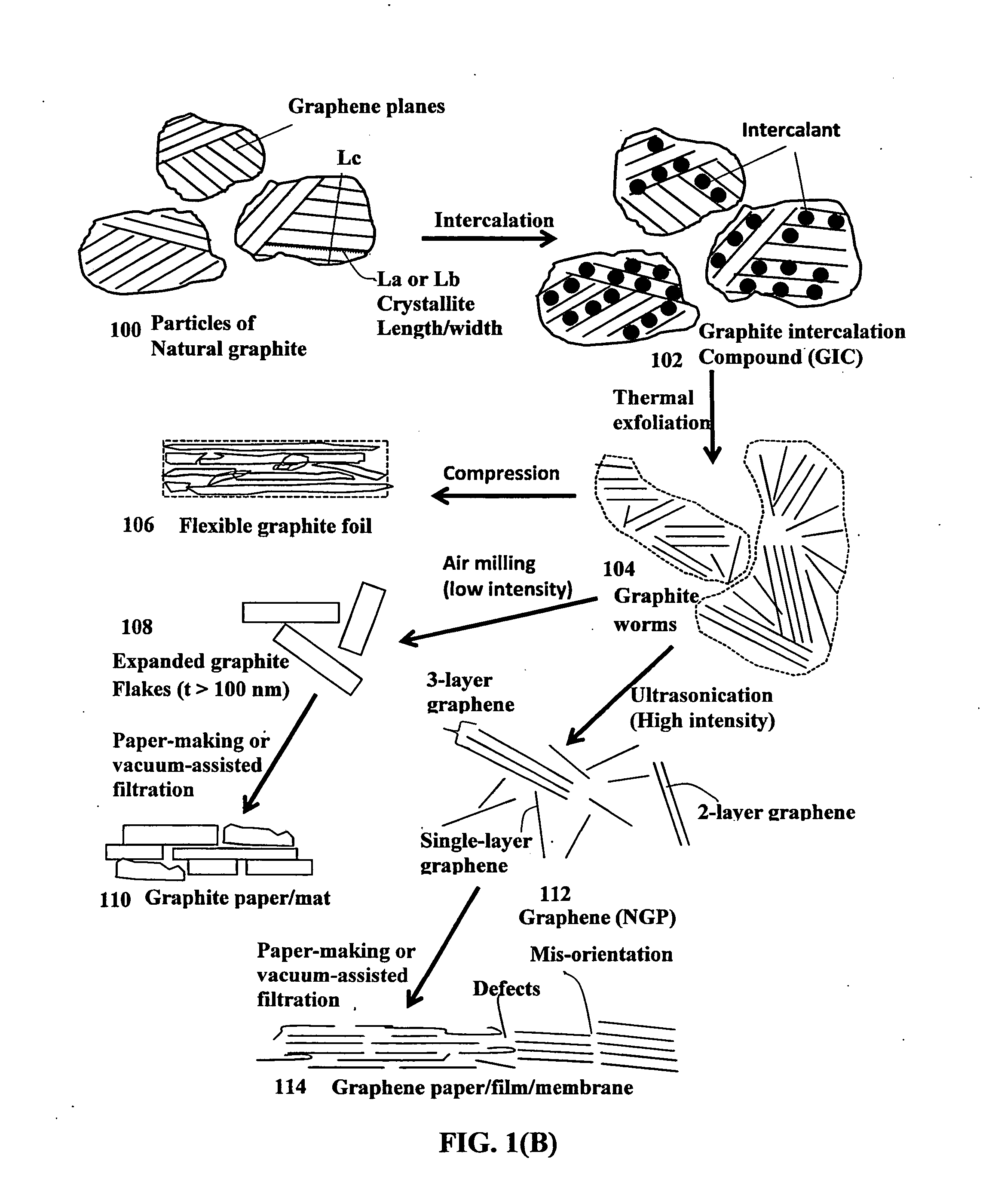

A process for producing a highly conducting film of conductor-bonded graphene sheets that are highly oriented, comprising: (a) preparing a graphene dispersion or graphene oxide (GO) gel; (b) depositing the dispersion or gel onto a supporting solid substrate under a shear stress to form a wet layer; (c) drying the wet layer to form a dried layer having oriented graphene sheets or GO molecules with an inter-planar spacing d002 of 0.4 nm to 1.2 nm; (d) heat treating the dried layer at a temperature from 55° C. to 3,200° C. for a desired length of time to produce a porous graphitic film having pores and constituent graphene sheets or a 3D network of graphene pore walls having an inter-planar spacing d002 less than 0.4 nm; and (e) impregnating the porous graphitic film with a conductor material that bonds the constituent graphene sheets or graphene pore walls to form the conducting film.

Owner:GLOBAL GRAPHENE GRP INC

Process for producing highly oriented graphene films

ActiveUS20150218003A1Low heat treatment temperatureLess-energy-intensiveMaterial nanotechnologyLamination ancillary operationsCvd grapheneGraphene foam

A process for producing a highly oriented graphene film (HOGF), comprising: (a) preparing a graphene oxide (GO) dispersion having GO sheets dispersed in a fluid medium; (b) dispensing and depositing the dispersion onto a surface of a supporting substrate to form a layer of GO, wherein the dispensing and depositing procedure includes subjecting the dispersion to an orientation-inducing stress; (c) removing the fluid medium to form a dried layer of GO having an inter-plane spacing d002 of 0.4 nm to 1.2 nm; (d) slicing the dried layer of GO into multiple pieces of dried GO and stacking at least two pieces of dried GO to form a mass of multiple pieces of GO; and (f) heat treating the mass under an optional first compressive stress to produce the HOGF at a first heat treatment temperature higher than 100° C. to an extent that an inter-plane spacing d002 is decreased to a value less than 0.4 nm.

Owner:GLOBAL GRAPHENE GRP INC

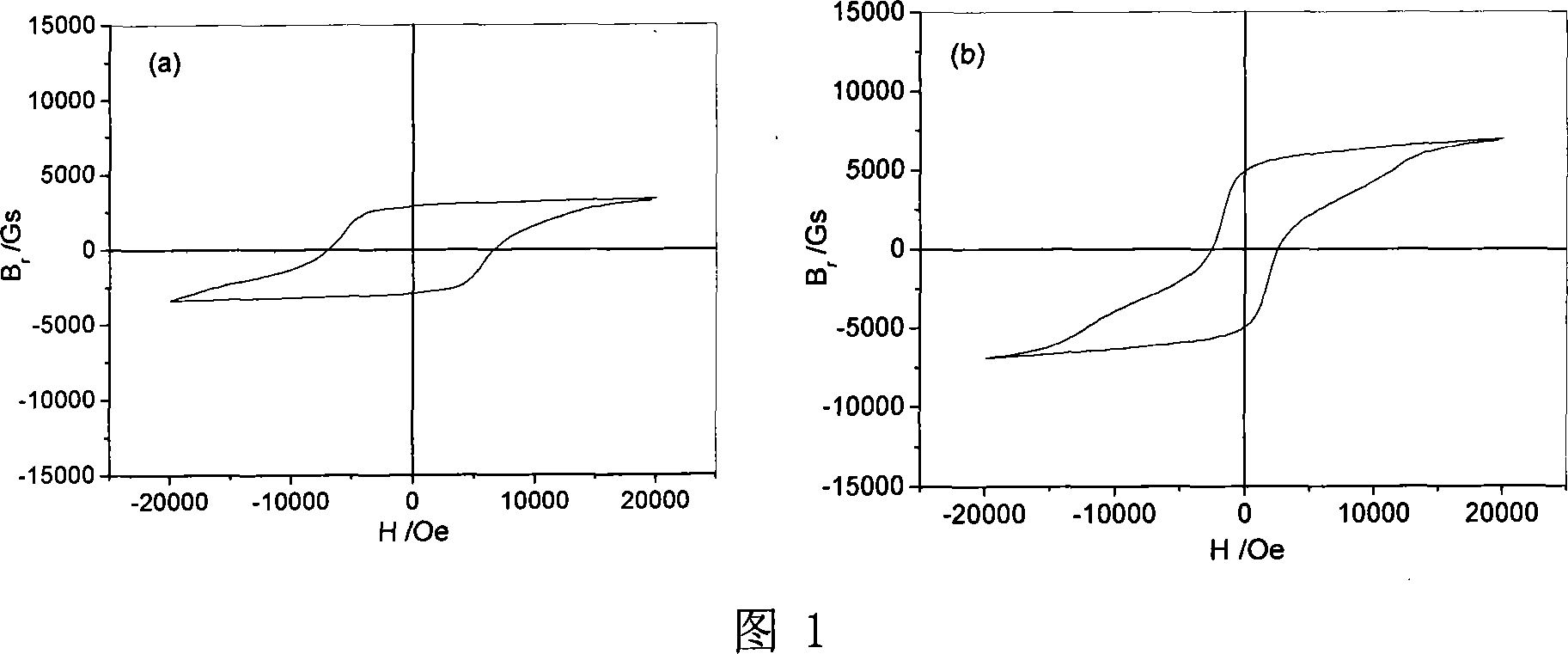

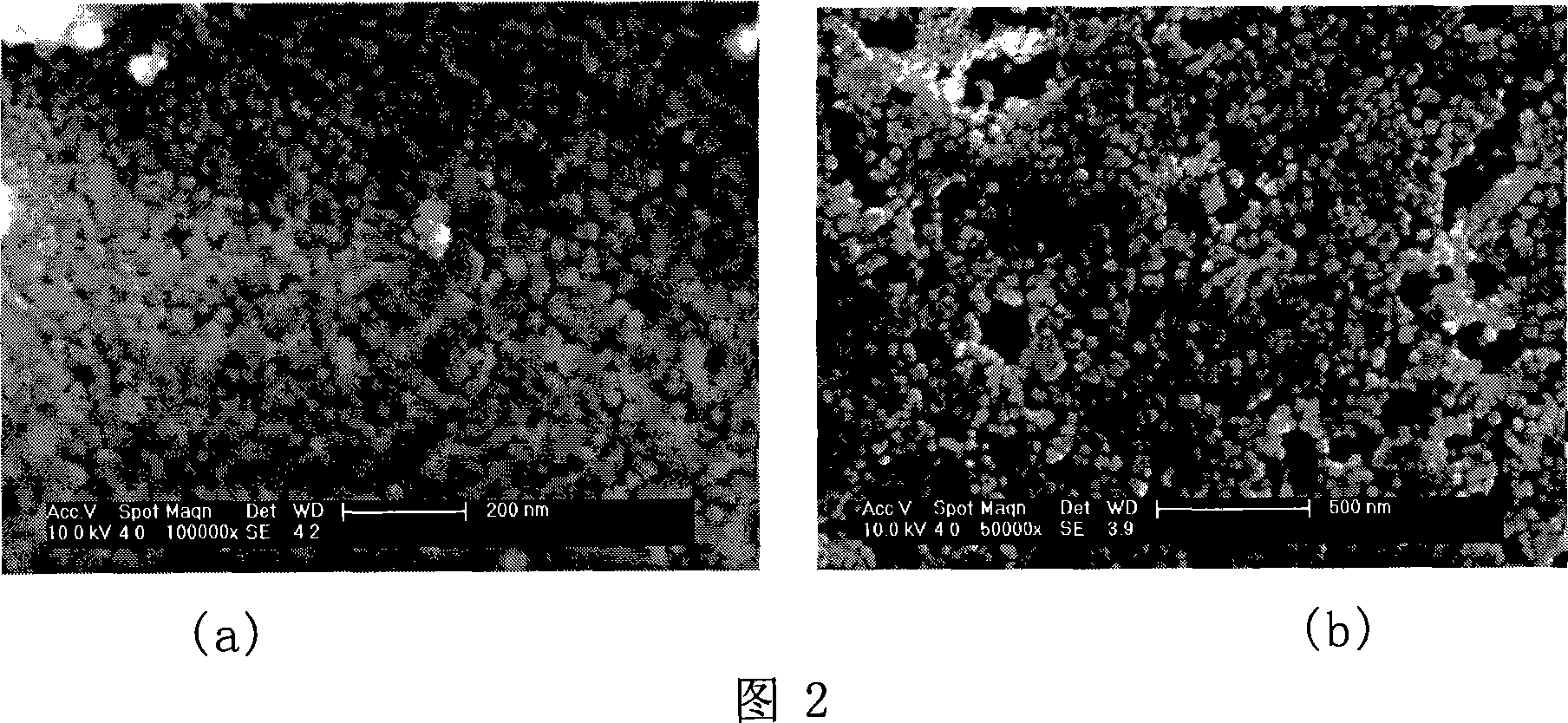

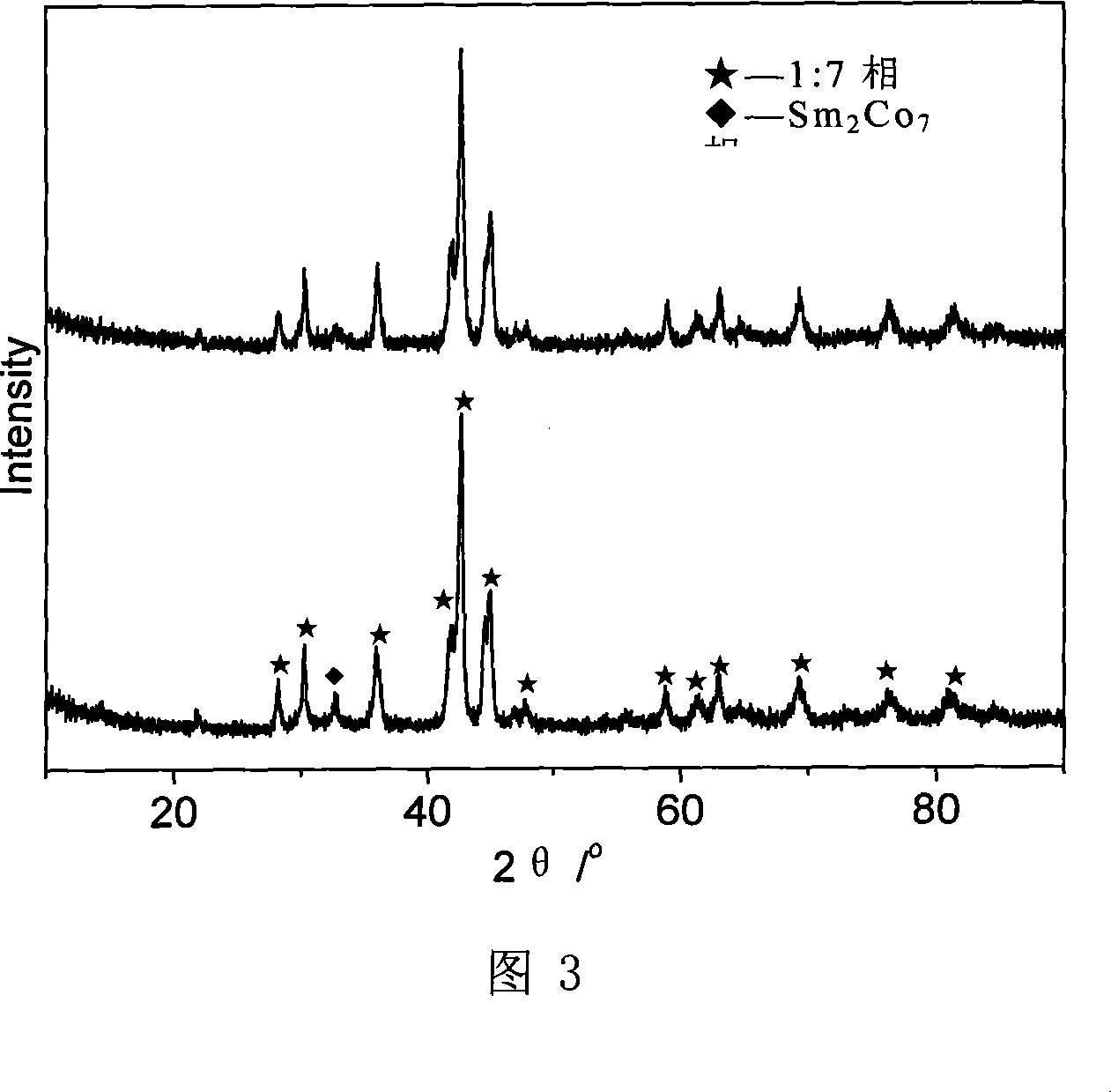

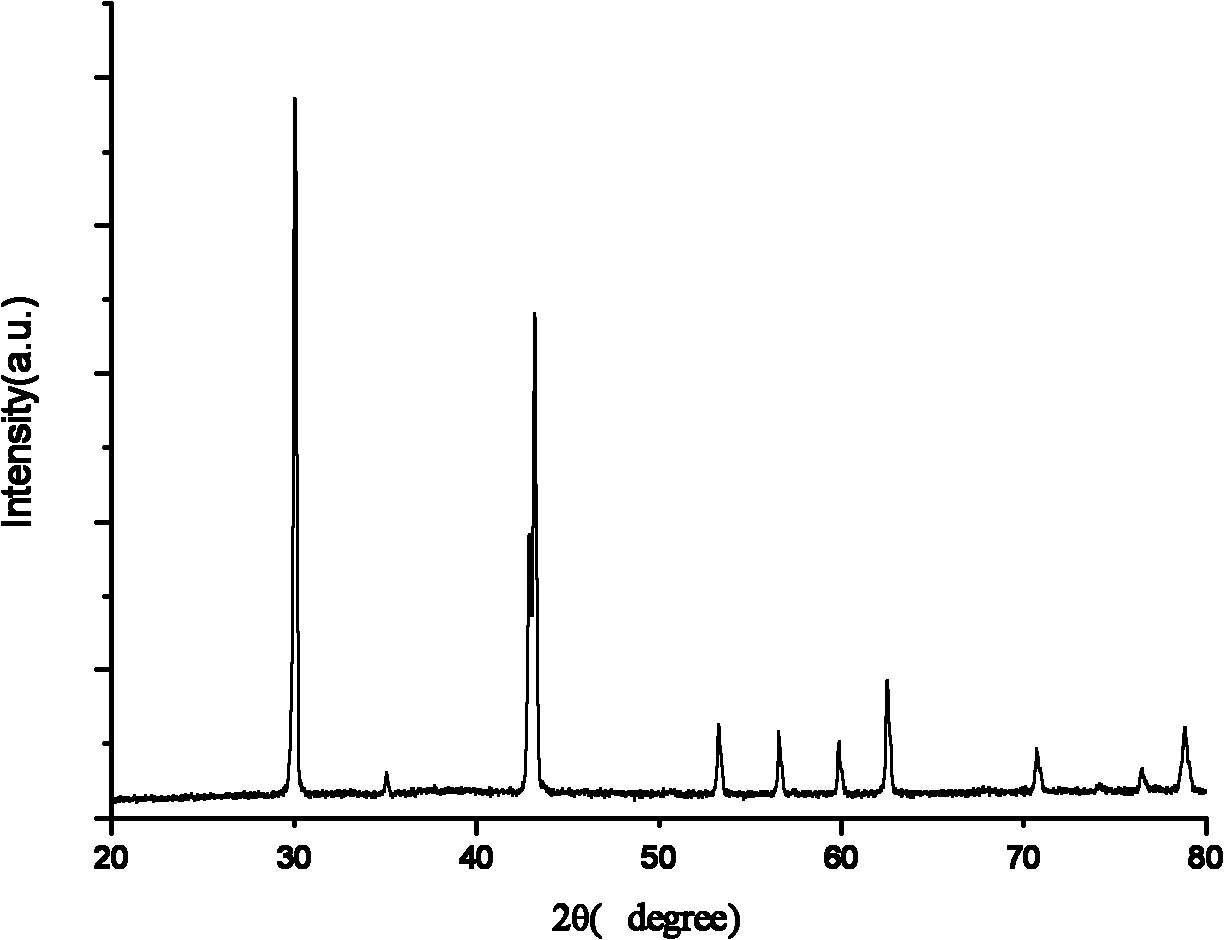

Method for preparing SmCo7 permanent-magnetic alloy with particle size smaller than 20nm

The invention discloses a preparing method of SmCo7 permanent magnet alloy whose grain size is smaller than 20nm, the RE, Co, Fe, Cu, T whose fineness is bigger than 99. 9% is mixed together just as proportion of RE(CobalFexCuyTw)z and placed in the induction furnace, the alloy ingoting which is after the fusion is cased into the quartz tube equipped with nozzle at the bottom to be melt, ejected to the surface of copper roller which is tail-wagging via the nozzle at the bottom of the quartz tube to form amorphous state alloy belt, the film belt obtained is airproofed in the quartz tube, then it is placed to the microwave welding furnace for crystal process, the temperature and time range of crystal process in the microwave welding furnace is 400-900deg.C and 10min-180min, then it is placed into water for cooling. The craftwork of the invention is simple, the cost is low, the grain size of nanometer crystal magnet which includes SmCo7 main phase is about 20nm, and it is lower than grain size obtained by general heat treatment method, the exchange coupled function between grains is increased greatly.

Owner:CENT SOUTH UNIV

Preparation method of phenolic resin combined honeycomb activated carbon

The invention relates to a preparation method of phenolic resin combined honeycomb activated carbon, which can be used for preparing the honeycomb activated carbon by the steps of: mixing dry powder, preparing plastic pug by mixing and kneading through a wet method, vacuum pugging, extrusion molding, drying, curing treatment and secondary heat treatment. Besides the function of bonding and improving the mechanical strength of the activated carbon, the phenolic resin also remarkably improves the heat-resisting property and water resistance of the honeycomb activated carbon; and furthermore, the honeycomb activated carbon is added with porous mineral, thus better effectively improving the mechanical strength and the specific surface area of the honeycomb activated carbon. The preparation method has lower heat treatment temperature and low production energy consumption, and effectively reduces the production cost; and the preparation technique and equipment thereof are simple, and the production investment is lower, so that the cost is further reduced.

Owner:TSINGHUA UNIV

Conductive slurry and transparent conductive coating

ActiveCN106205774AConductiveWith anti-reflectionNon-conductive material with dispersed conductive materialElectrically-conductive paintsAdditive ingredientSlurry

The invention provides conductive slurry and transparent conductive coating. The conductive slurry comprises the ingredients of metal conductive filler, a resin substrate, nanometer filler particles and / or colloid particles and a solvent. By adoption of the technical scheme of the invention, the conductive slurry system is uniform and stable, and has the characteristics of electrical conduction, antireflection, diffusion promotion, and mechanical comprehensive performance improvement; a one-step preparation method for the transparent conducive coating is realized through the slurry, and the transparent conducive coating also can be prepared by a three-step method; the prepared conducive coating has high light transmittance, high electrical conductivity, and excellent mechanical comprehensive performance; and in addition, the preparation method has a simple process, a low cost, high repeatability and a low processing temperature, so that the conductive slurry and the transparent conducive coating have high industrial application prospect.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

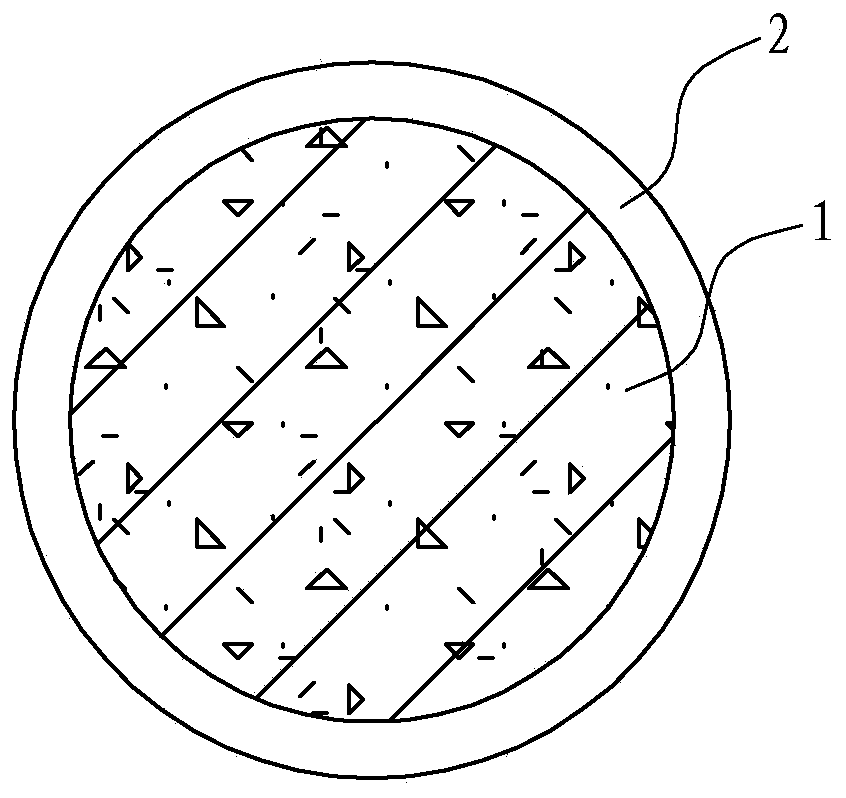

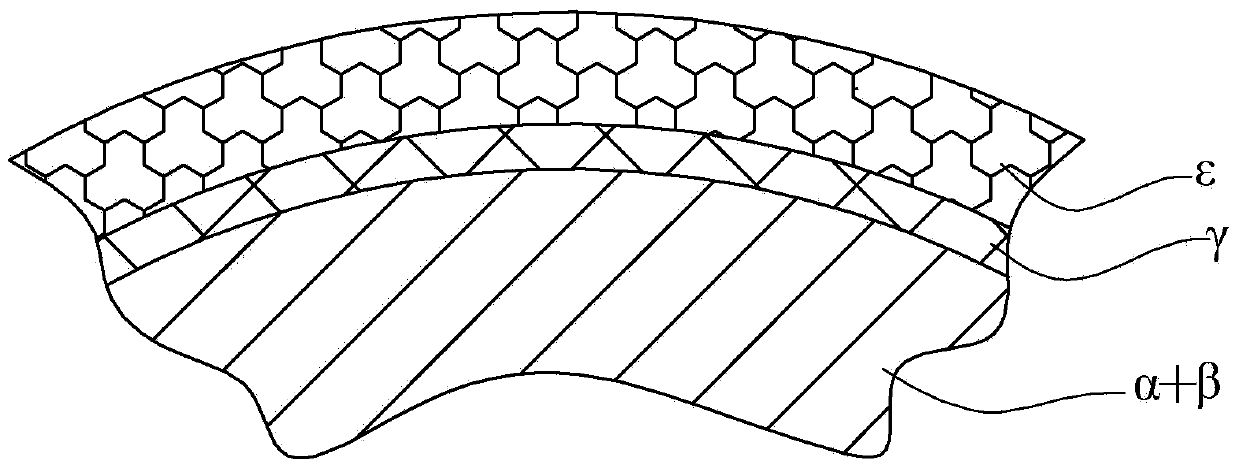

High-accuracy zinc base alloy electrode wire and preparing method thereof

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

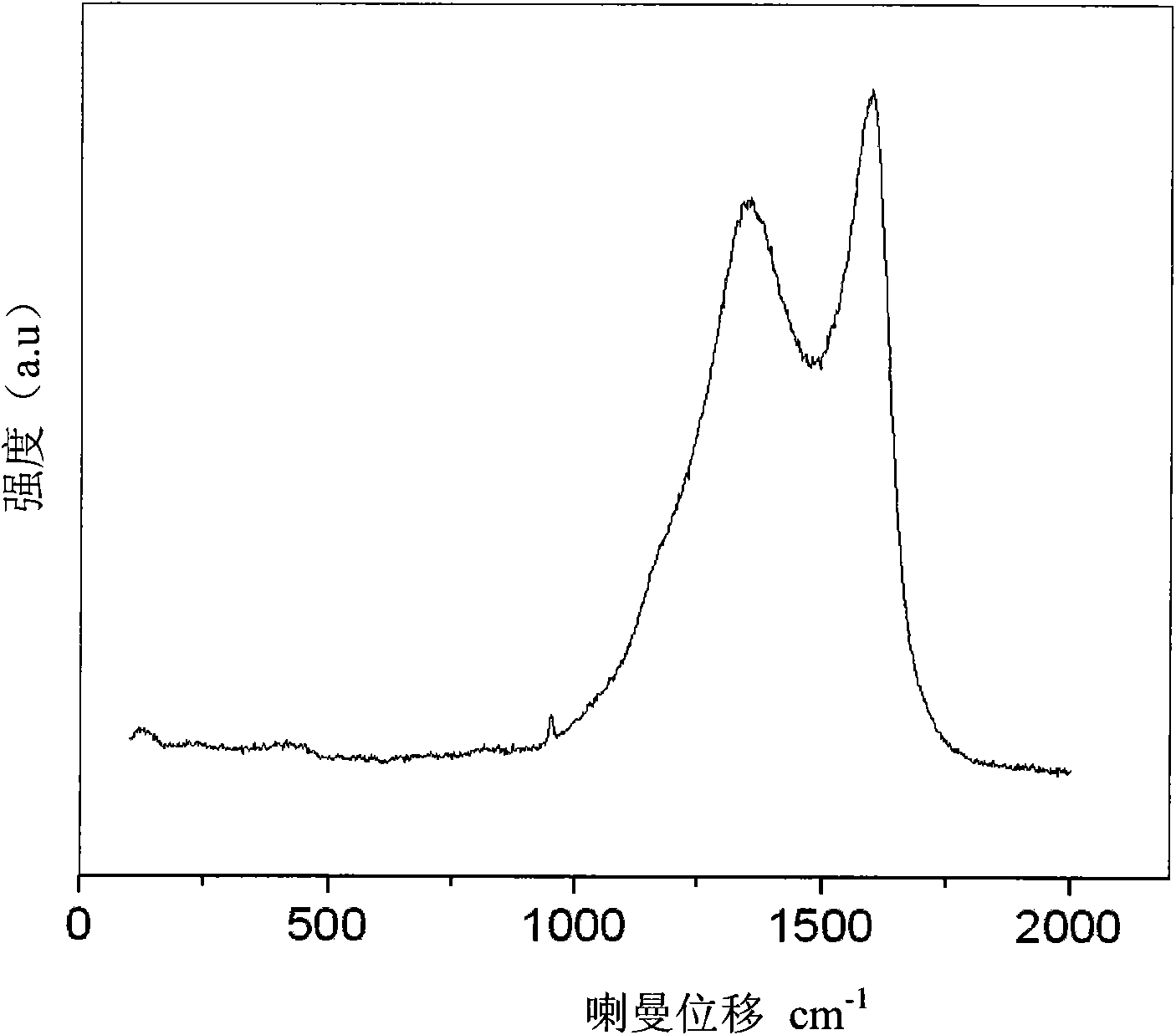

Low-temperature soft template one-step synthesis method for graphitized ordered mesoporous carbon material

The invention discloses a synthesis method of graphitized ordered mesoporous carbon at low temperature. The method comprises the following steps: by a soft template path, introducing a metal precursor salt with a catalytic graphitizing effect in the organic-organic self assembly process of a carbon source and a surfactant, then carbonizing in an inert gas atmosphere, and carrying out one-step synthesis to obtain the graphitized ordered mesoporous carbon material. The method combines two independent steps of synthesis of the mesoporous carbon material and metal load into one step, greatly simplifies the synthesis steps, has simple and convenient operation, combines the carbonization process and the graphitizing conversion process, reduces the damage of high temperature to the ordered structure of the material, and greatly reduces the heat treatment temperature of graphitizing by utilizing the catalytic effect of metal. Compared with non-graphitized ordered mesoporous carbon material, the material serving as a catalyst carrier shows better electro-catalysis performance and provides a new choice for fuel-cell catalyst carriers.

Owner:NANJING UNIV OF SCI & TECH

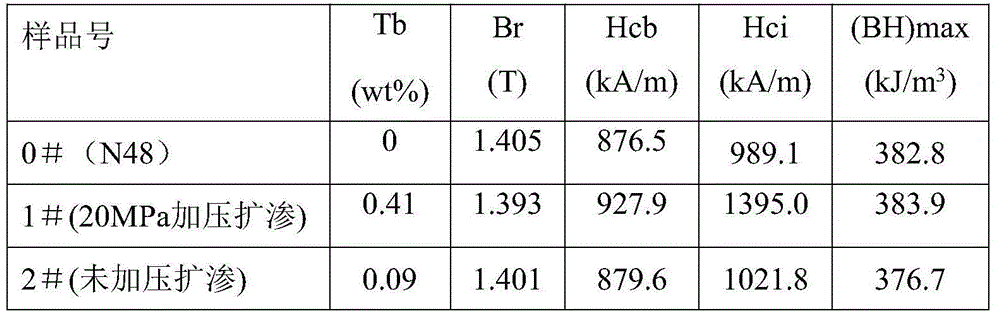

Method for accelerating permeation of Dy/Tb adhesive layer on surface of sintered neodymium-iron-boron magnet

ActiveCN104388952ARapid penetrationInhibit growthInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyRare earth

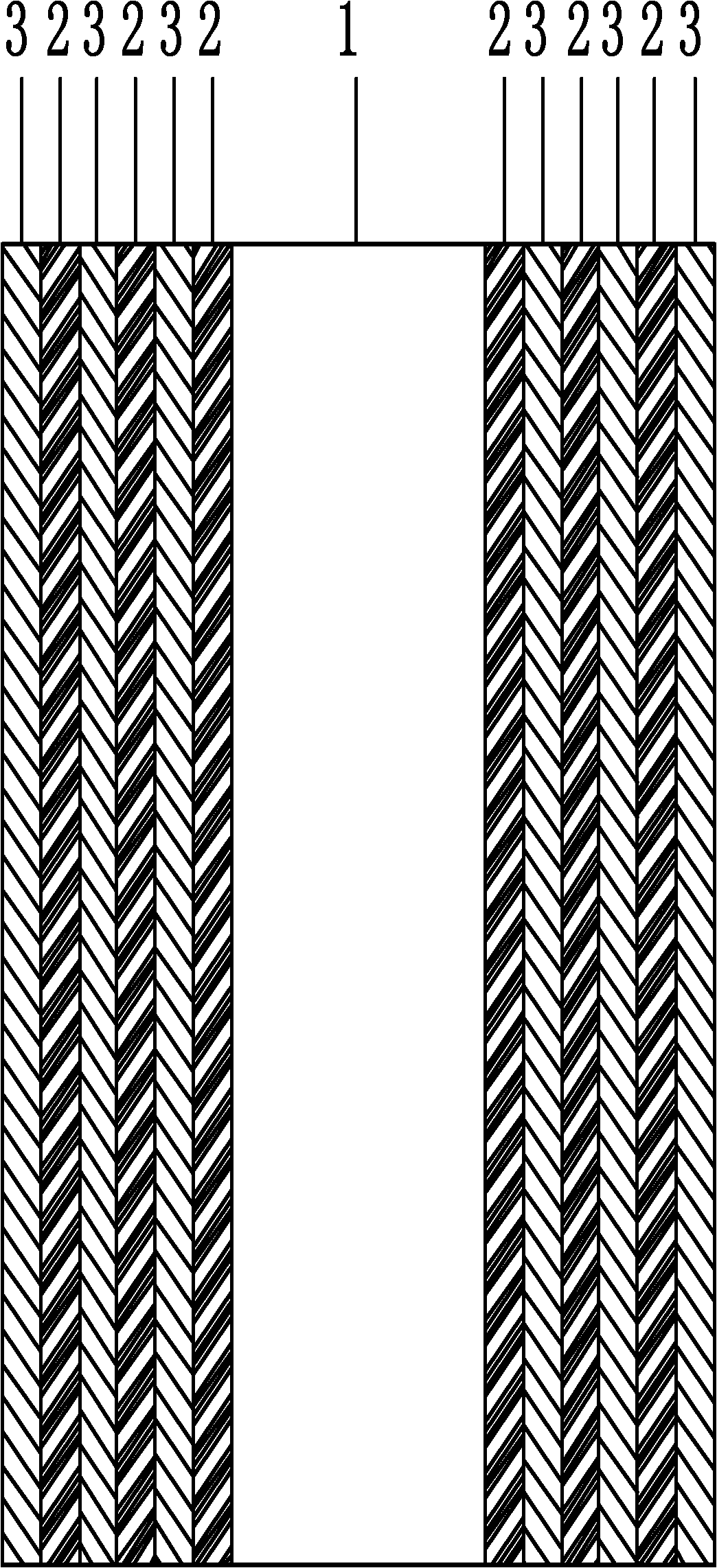

The invention belongs to the field of rare earth permanent magnetic materials, and particularly relates to a method for accelerating permeation of a Dy / Tb adhesive layer on the surface of a sintered neodymium-iron-boron magnet. The method is characterized in that a Dy / Tb element is subjected to high-pressure thermal treatment of 1-100MPa after being adhered to the surface of a sintered neodymium-iron-boron magnet, so as to accelerate permeation of the Dy / Tb element on a grain boundary of the sintered neodymium-iron-boron magnet, thus a high-coercivity magnet is obtained. The method specifically comprises the following processing steps: firstly, carrying out cleaning treatment on the surface of the neodymium-iron-boron magnet; attaching the Dy / Tb element to the clean surface of the neodymium-iron-boron magnet, and then carrying out high-pressure thermal treatment on the Dy / Tb element, so as to rapidly permeate the Dy / Tb element on the grain boundary of the magnet; further improving the magnet boundary structure through medium-temperature thermal treatment, and finally obtaining the high-coercivity neodymium-iron-boron magnet. The method has the outstanding advantages that the permeation of the Dy / Tb element on the grain boundary can be accelerated through high-pressure thermal treatment; a relatively thick sample can be processed; the thermal treatment temperature is greatly reduced; the thermal treatment time is shortened; and the efficiency is significantly improved.

Owner:UNIV OF SCI & TECH BEIJING

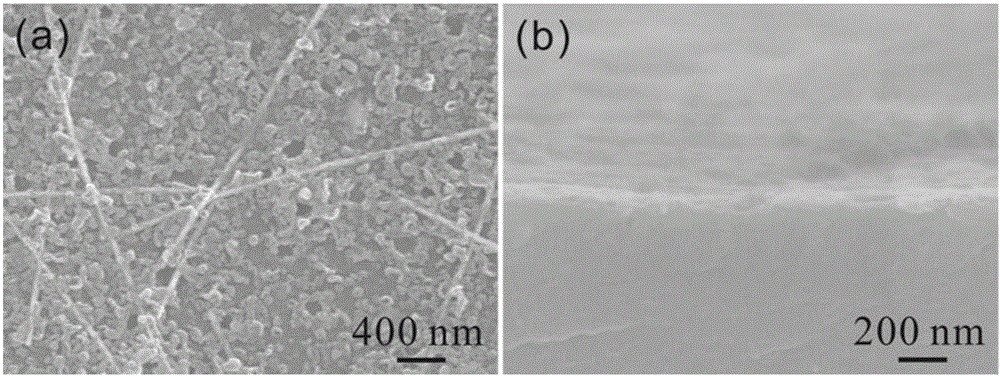

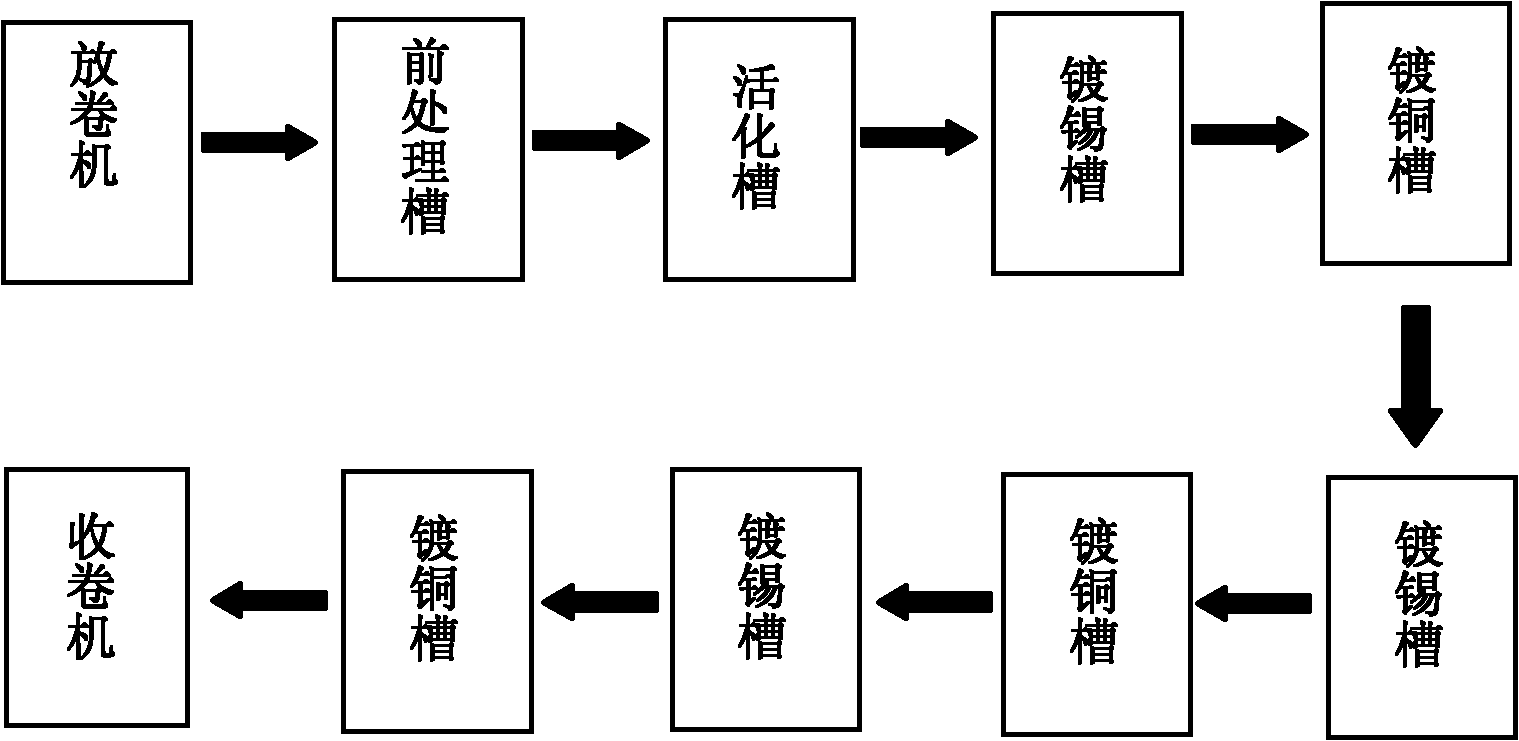

Tin/copper foam alloy cathode material for lithium ion cells and preparation method thereof

ActiveCN102013488AImprove conductivityImprove cycle performanceCell electrodesCopper coatingMicrometer

The invention discloses a tin / copper foam alloy cathode material for lithium ion cells and a preparation method thereof. In the invention, foam copper serving as a substrate is coated and plated with tin / copper alternate multilayer lamination structure; and then the tin / copper alloy cathode material is obtained by heat treatment. A tin coating is formed directly on the foam copper strip substrate, and a copper coating is formed on the outmost layer; in the multilayer lamination structure, each coating is 0.1 to 1.0 micrometer thick, and the thicknesses of all coatings are the same; the thickness ratio of each tin coating to each copper coating is 1:1.7-1:2.1; and the heat treatment temperature is 150 to 400 DEG C and the heat treatment time is 0.5 to 6 hours. The tin / copper foam alloy cathode material prepared by the method has a high charge-discharge specific capacity and high cycle performance; and the maximum primary discharge specific capacity is up to 610mAh / g, and after 50 circles, the specific capacity reduces only by 1 to 3 percent. In the invention, the preparation process is simple, and large-scale industrial production can be performed.

Owner:HUNAN YONGSHENG NEW MATERIALS

Fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy

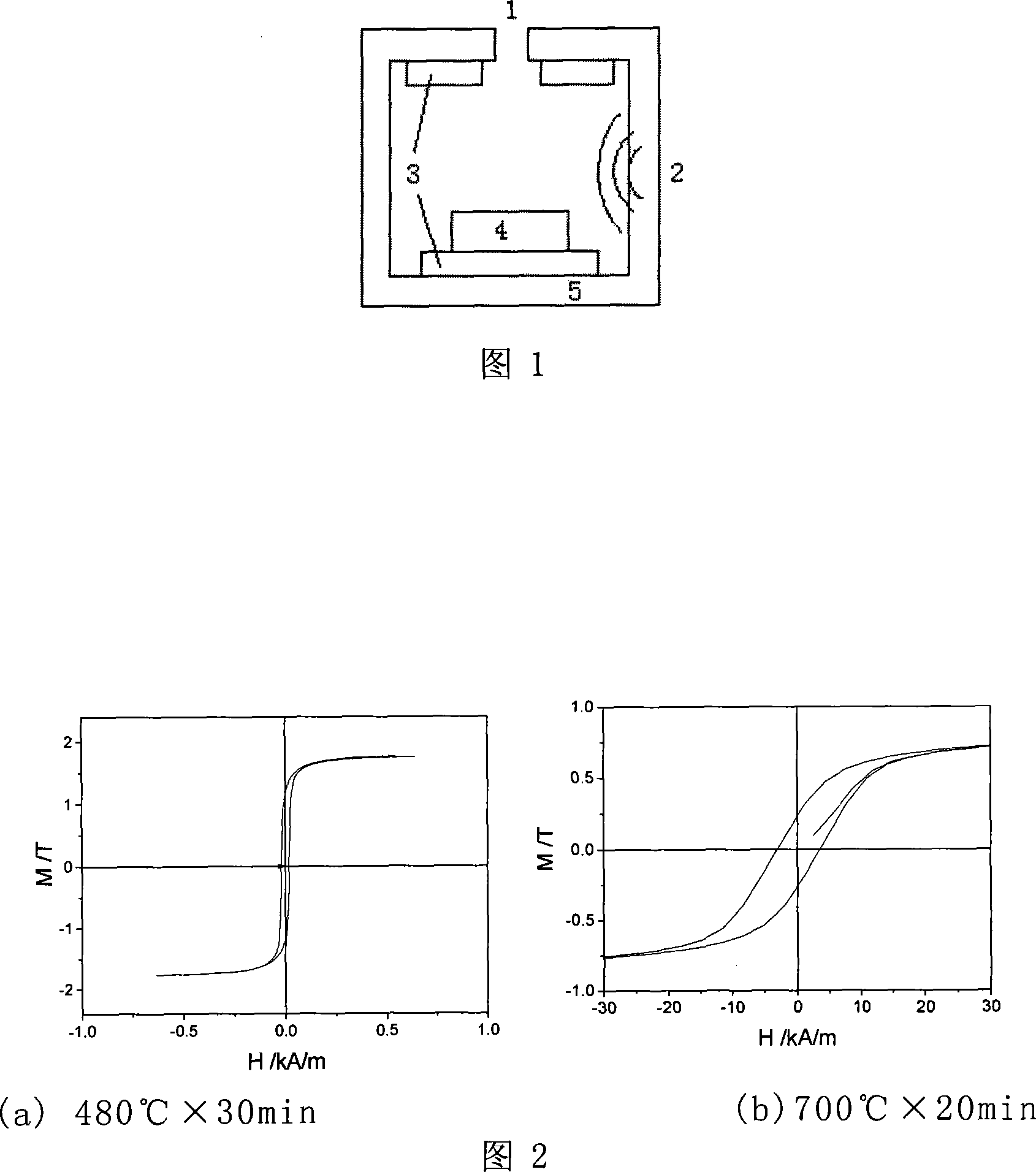

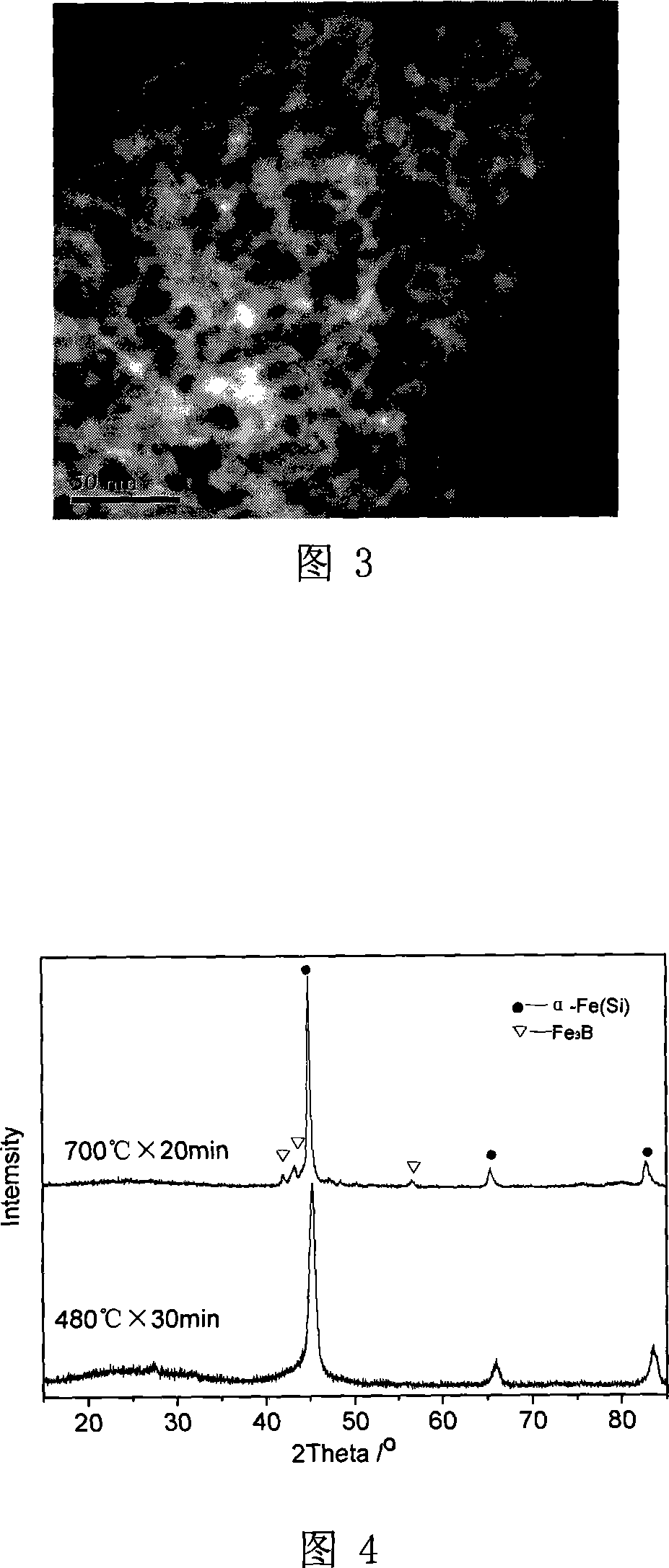

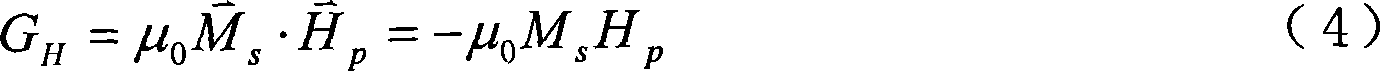

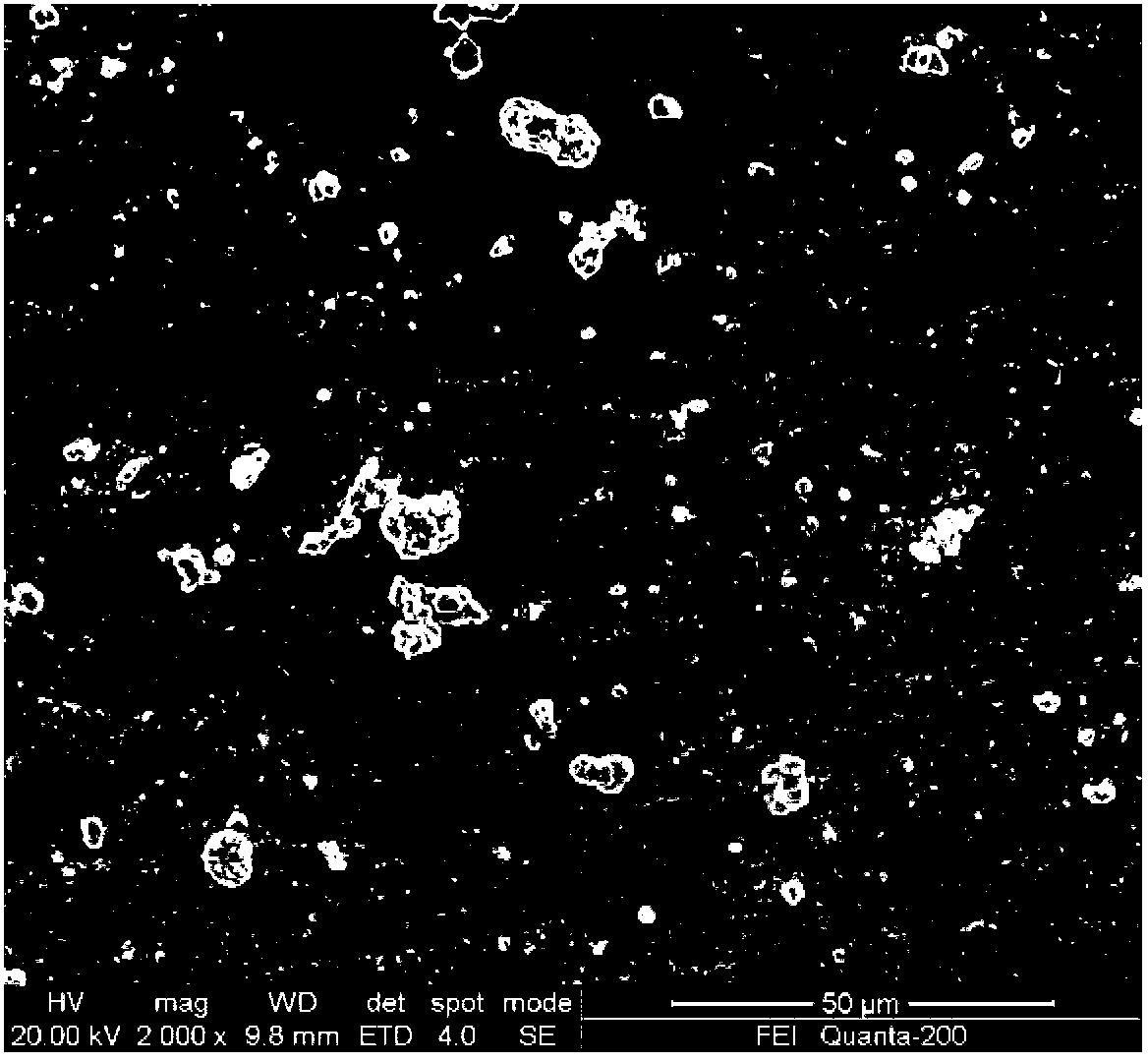

The present invention discloses fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy. The technological process includes the following steps: 1. smelting alloy with Fe, Cu, Nb, Si and B in the ratio of Fe73.5Cu1Nb3Si13.5B9 in an induction furnace at vacuum 3-10 Pa in high purity Ar; 2. setting coarsely crushed alloy inside quartz pipe with nozzle in the bottom, setting the quartz pipe inside induction coil in a belt spinning machine, and melting the mother alloy in protecting Ar atmosphere; 3. spraying the alloy liquid under the pressure of Ar to the surface of rotating copper roller to form non-crystalline alloy belt; and 4. sealing the thin belt in quartz tube and crystallizing treatment in a microwave sintering furnace at 400-900 deg.c for 10-180 min to obtain ideal nanometer crystal structure.

Owner:CENT SOUTH UNIV

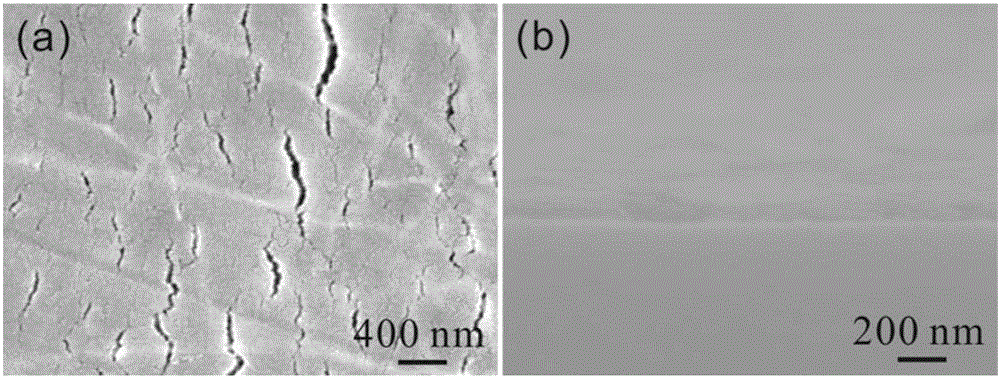

Carbon nano tube enhanced tin-copper-nickel alloy cathode and preparation method thereof

InactiveCN103022418AHigh charge-discharge specific capacityStrong cycle performanceCell electrodesCopper nickel alloyCopper foil

The invention discloses a carbon nano tube enhanced tin-copper-nickel alloy cathode used for a lithium ion battery, and a preparation method of the cathode. According to the invention, the electroplating method is adopted to composite carbon nano tubes into an electrode, and chemical nickel plating processing to the carbon nano tubes is performed before electroplating; and furthermore, a Cu-(CNTs-Ni) connection layer is added between active material and a current collector, thereby improving the circulation property of the alloy cathode greatly. According to the invention, copper foil is used as a current collector (electroplating substrate) to composite and electroplate a Cu-(CNTs-Ni) composite coating and a Sn-(CNTs-Ni) composite coating in sequence, and finally the carbon nano tube enhanced tin-copper-nickel alloy cathode is obtained by heat treating. The lithium ion battery tin-copper-nickel alloy cathode prepared by adopting the method has a specific discharge capacity of 500-700 mAh / g for the first time, and the specific capacity is only decayed by 4-6 percent after 200 times of circulation. According to the invention, the process is simple, the performance of the prepared alloy cathode is good, and the alloy cathode is suitable for performing large-scale industrialized production.

Owner:XIANGTAN UNIV

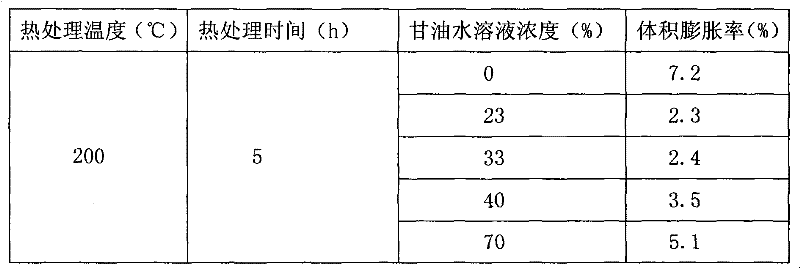

Pretreatment method for improving dimension stability of timber

InactiveCN102241032AImprove hydrophilicityGood dimensional stabilityPressure impregnationWood impregnation detailsPretreatment methodWater vapor

The invention discloses a pretreatment method for improving dimension stability of timber. The method comprises the following steps: pretreating timber with glycerin and then carrying out air seasoning on the timber so as to enable the water content of the timber to decline to less than 15%; putting the timber into a heat treatment box, turning on a vapor switch, allowing the temperature of the heat treatment box to rapidly rise to 140 DEG C at a rate of 10 to 20 DEG C / h, keeping the temperature for 30 to 60 min, and drying the timber at a high temperature so as to enable the water content of the timber to decline to 0; allowing the temperature to rise to 160 DEG C to 200 DEG C and maintaining heat treatment for 2 to 5 h; turning off the vapor switch, allowing the temperature of the heat treatment box to decline, turning on the vapor switch when the temperature of the heat treatment box declines to 80 DEG C, adjusting the water content of the timber to be 7% to 10%, and moving the timber out. According to the invention, pretreatment of the timber with an aqueous solution of glycerin enables pyrolysis of chemical components in the timber to be accelerated, molecular chains of the timber to break and to form new crosslinked bond, and dimension stability and corrosion resistance of the timber to be effectively improved.

Owner:NORTHWEST A & F UNIV

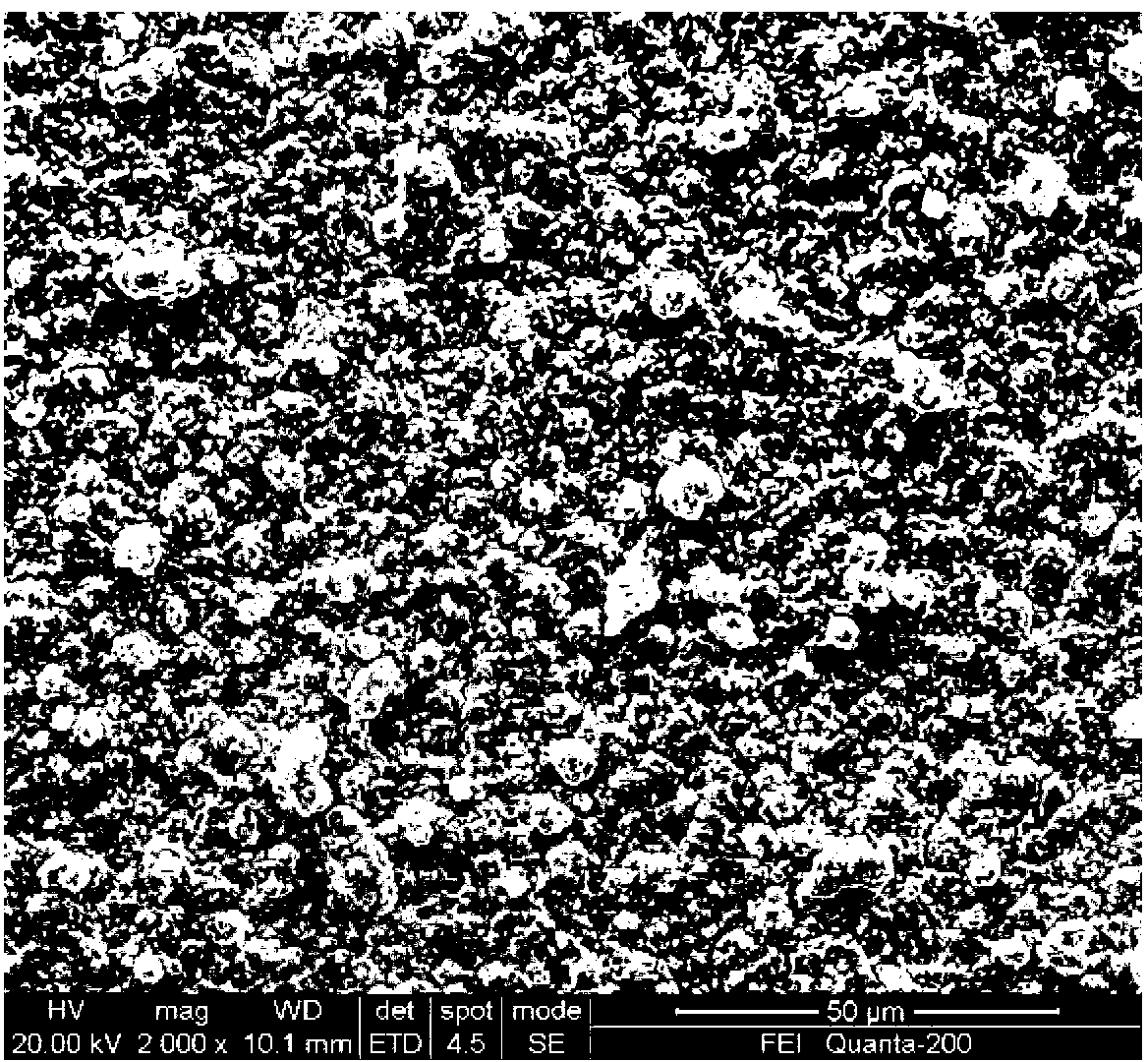

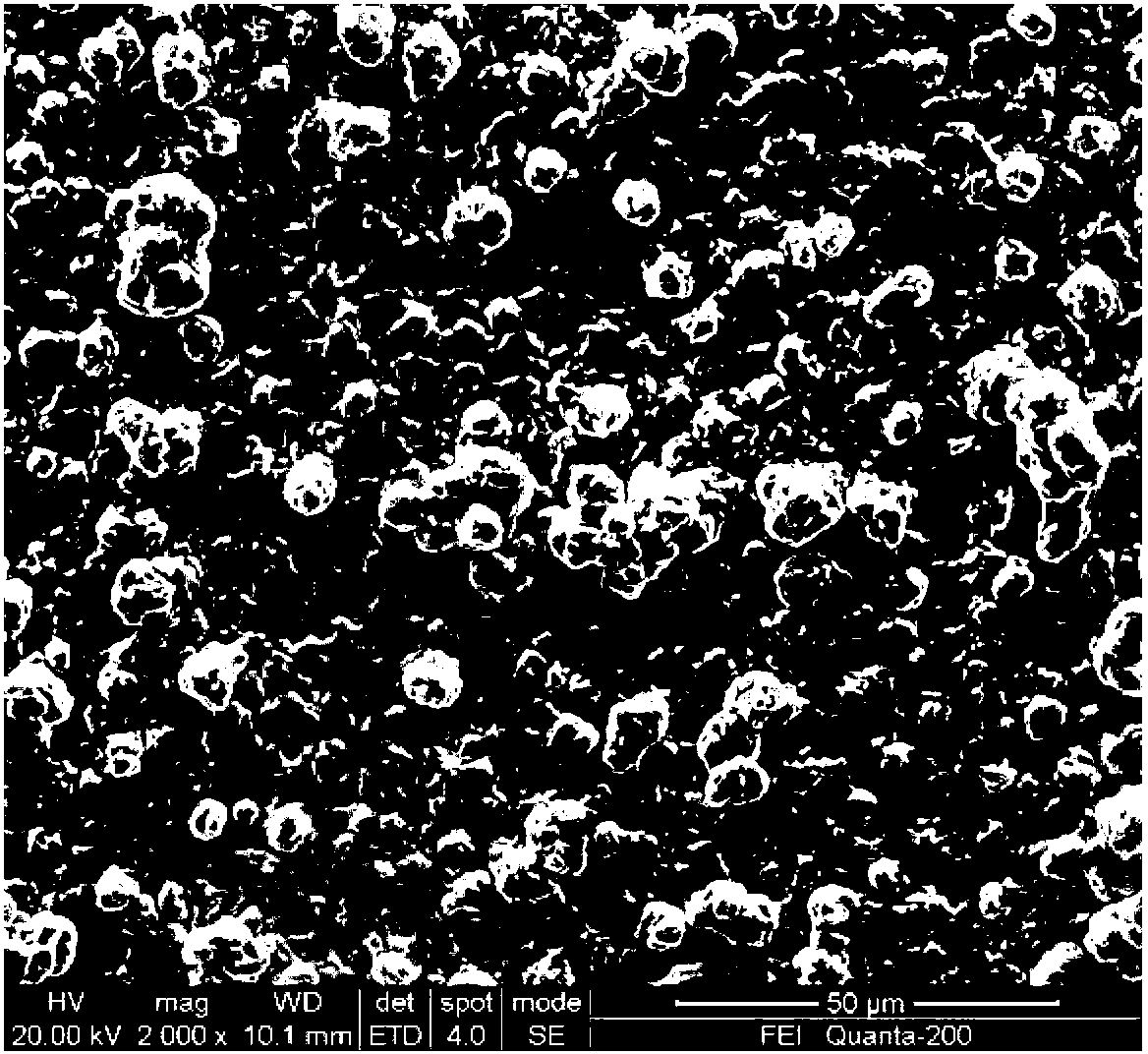

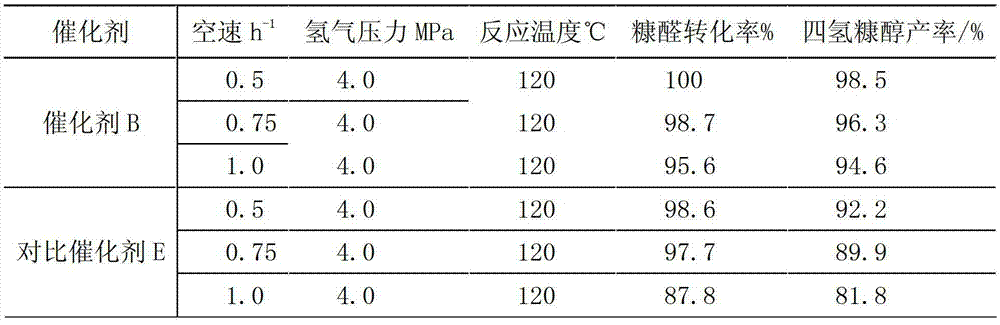

Preparation method and application of fixed bed framework metal catalyst

InactiveCN103203240ALow heat treatment temperatureImprove flame retardant performanceOrganic compound preparationHydrocarbon by hydrogenationKetoneOrganic compound

The invention discloses a preparation method and the application of a fixed bed framework metal catalyst. The method includes: adopting a halogen substituted organic polymer as a coupling agent of active metal aluminum alloy powder, preparing aluminum alloy powder containing transition metal in VIII class, IB class or VB class into particles in certain shapes, adopting forming methods like direct kneading method for band extrusion or tabletting or coating method for attaching the alloy powder on the surface of a carrier with certain strength, subjecting the formed particles to heat treatment under certain atmosphere for improving strength, and activating with an inorganic alkaline solution to obtain the fixed bed framework metal catalyst. The catalyst prepared by the method can be used for fixed bed hydrogenation reaction of unsaturated organic compounds like aldehyde, ketone, ester, nitrile, olefine, aromatic and nitro compounds. The aluminum alloy particles are low in heat treatment temperature, the strength of the carrier can be fully utilized by the coating method, and the aluminum alloy particles after being activated have excellent hydrogenation activity and stability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

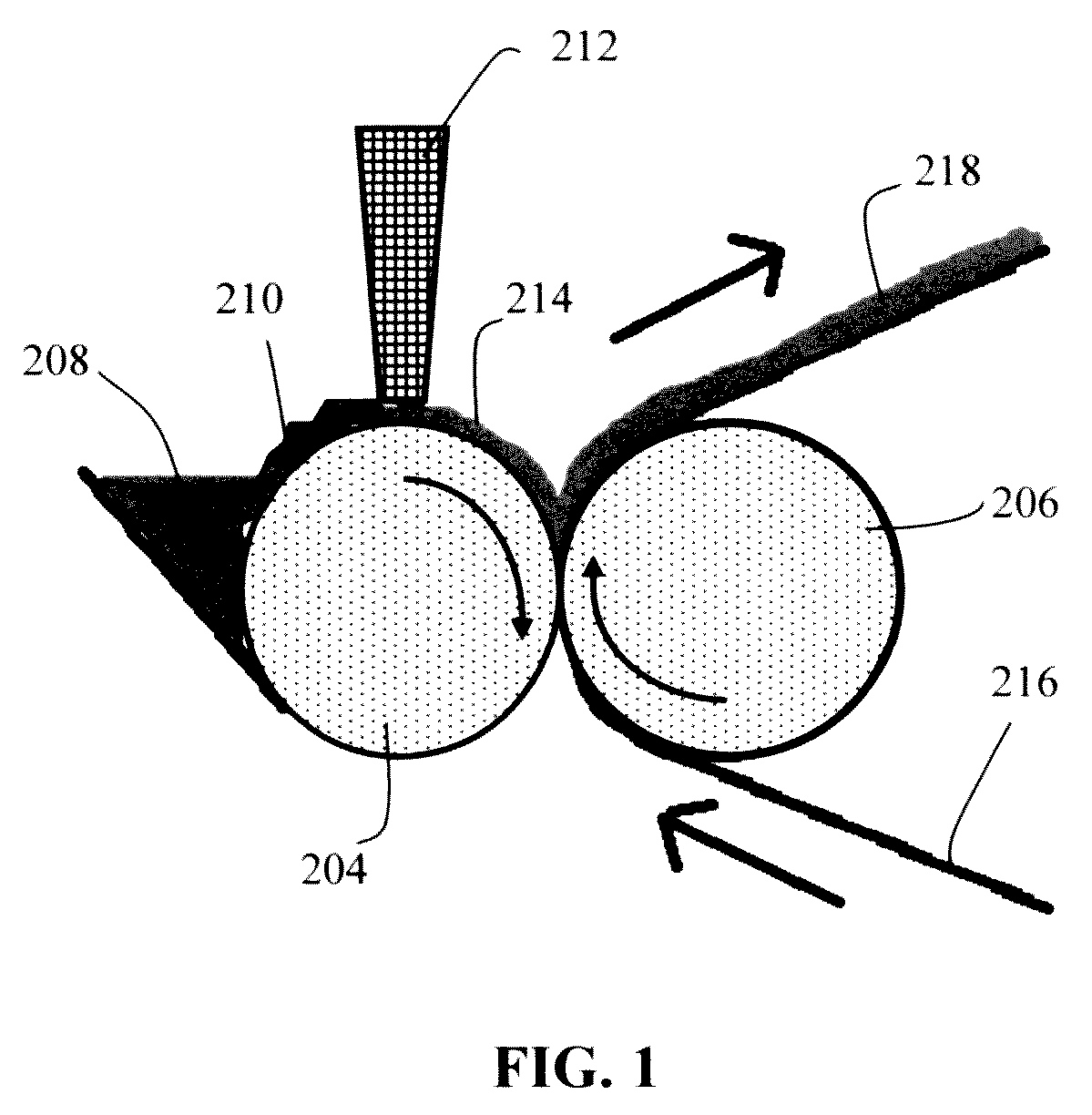

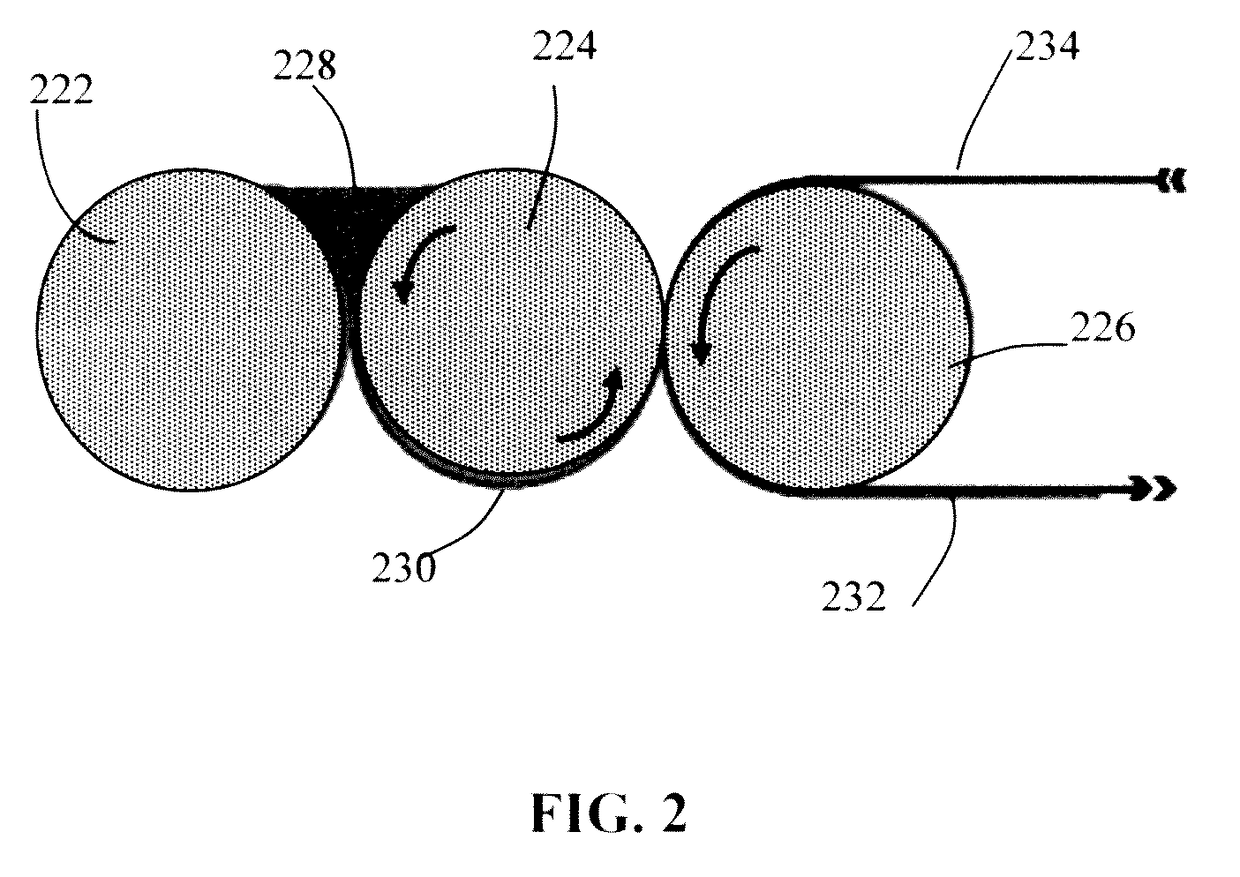

Preparation method for high-performance conducting copper slurry

The invention discloses a preparation method for high-performance conducting copper slurry. The preparation method includes the steps of firstly, dissolving copper precursor and surface protective agent in organic solvent to obtain reaction liquid A; dissolving reducing agent in organic solvent to obtain reaction liquid B; secondly, feeding reaction liquid A and B into a micro-reactor respectively through a delivering pump, and mixing for reaction; thirdly, adding precipitator to reaction liquid obtained in the second step, separating by filtering or centrifuging, and cleaning obtained precipitate; and fourthly, dispersing cleaned precipitate with non-polar or weak-polar solvent to obtain the high-performance conducting copper slurry. The conducting copper slurry obtained by the preparation method requires low thermal treatment temperature after printing, and is high in metal content which can exceed 60%.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

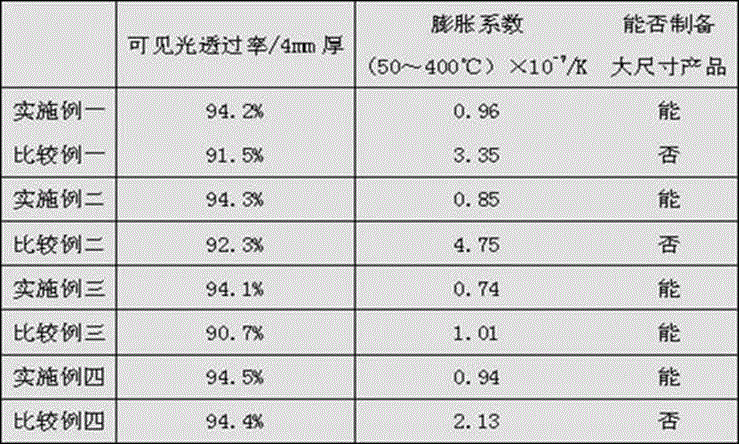

Ultralow-expansion-coefficient high-transparency microcrystalline glass and preparation method thereof

The invention discloses an ultralow-expansion-coefficient high-transparency microcrystalline glass which comprises the following components in percentage by weight: 65-69% of SiO2, 19-20% of Al2O3, 3.1-4.2% of Li2O, 3-4.5% of B2O3, 0.1-0.4% of Na2O, 0.1-0.4% of K2O, 0.3-0.5% of MgO, 0.6-1.4% of BaO, 0.6-1.4% of ZnO, 1.0-1.7% of TiO2, 1.0-1.3% of ZrO2, 0.4-0.8% of P2O5, 0.3-0.8% of F and 0.02-0.3% of CeO2. The preparation method comprises the following steps: melting glass raw materials, cooling, molding, annealing, crystallizing, and carrying out after treatment to obtain the microcrystalline glass finished product. The microcrystalline glass has the advantages of high transparency and ultralow expansion coefficient, and can be used for manufacturing large-size or complex-structure products.

Owner:虎石新材料(宜兴)有限公司

Alloy grinding ball and production method thereof

The invention discloses an alloy grinding ball and a production method thereof. Through reasonably adjusting composition proportion, waste steel and high carbon ferro-chrome are taken as main raw materials, tungsten is added, noble metals, such as molybdenum, nickel, copper and the like are not added, carbides taking Cr7C3 and WC as main principle is mainly formed so as to improve hardness and toughness of the material, in addition, yttrium-based heavy rare earth is used for discharge molten steel so as to carry out modification for refining grain, crushing the carbides, reducing split of the carbides on a substrate and decreasing segregation of chemical compositions; a thermal treatment process is optimized, heat treatment granulation of eutectic carbides is promoted, oil quenching is used for carrying out forced circulating heat treatment, toughness, hardness and wear resistance of the product are improved, the heat treatment temperature is reduced, the electric energy is saved, and the production cost is reduced.

Owner:GUIZHOU NORMAL UNIVERSITY

Method for coating antireflection film on inner wall and outer wall of outer tube of all-glass vacuum solar energy heat-collecting tube

The invention discloses a method for coating an antireflection film on the inner wall and outer wall of the outer tube of an all-glass vacuum solar energy heat-collecting tube, comprising the following steps: 1) preparing SiO2 sol; 2) preparing TiO2 sol; 3) coating a layer of SiO2 film on the outer tube of the solar energy heat-collecting tube by a pulling method; and 4) adopting the same coatingfilm condition and method as in step 3), and continuously coating a layer of TiO2 film on the outer tube processed in step 3). In the invention, a sol-gel method is used to coat the antireflection film on the inner wall and outer wall of the outer tube of the all-glass vacuum solar energy heat-collecting tube, the transmissivity of the outer tube after being coated with the film is improved to 96-98% to ensure that solar energy heat absorbed by the surface of an inner tube can be increased by 6-8%, thus improving the heat gain of the whole all-glass vacuum solar energy heat-collecting tube, so as to achieve the purpose of improving the heat efficiency of the all-glass vacuum solar energy heat-collecting tube.

Owner:上海圣元新能源科技有限公司

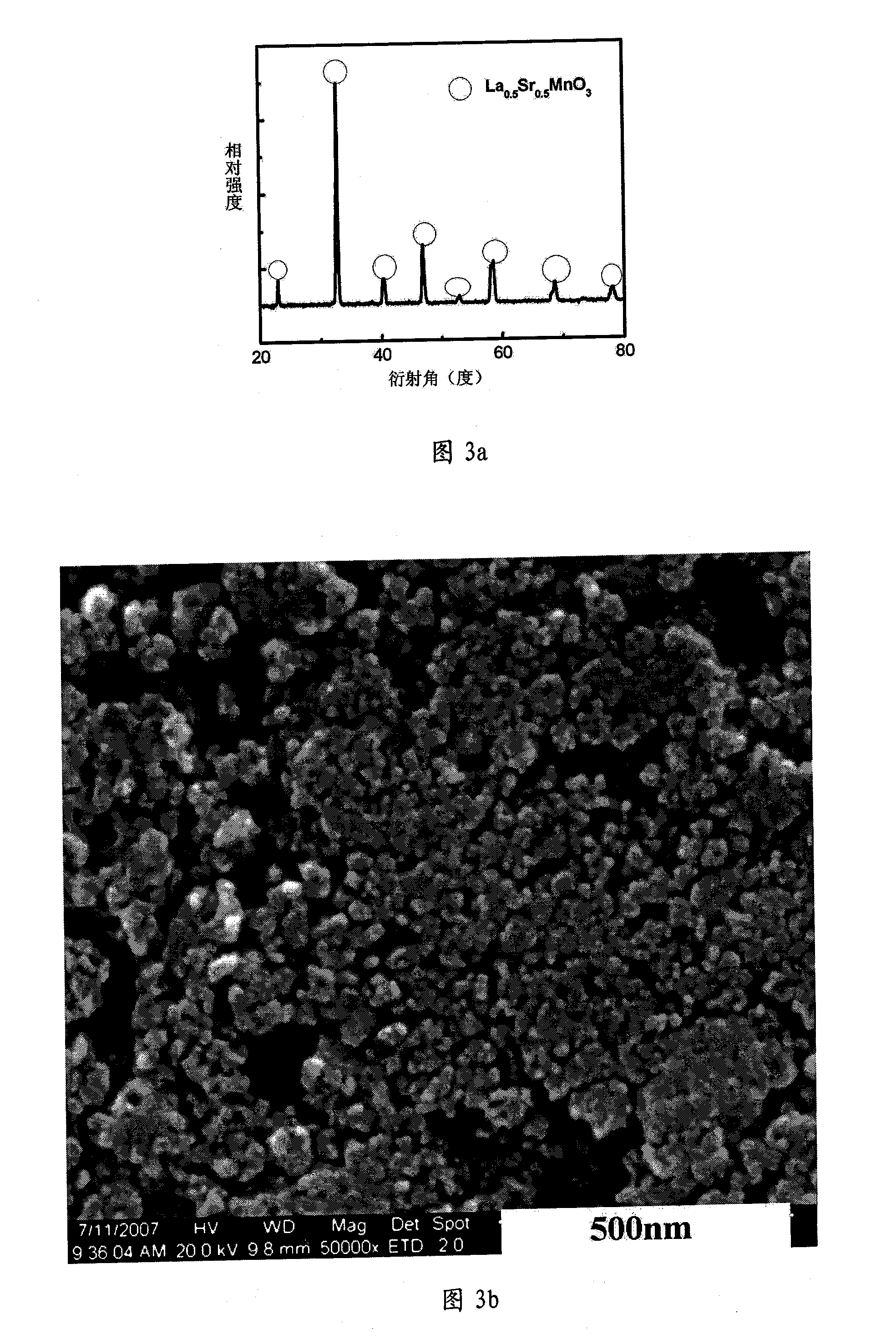

Method for preparing nano lanthanum-strontium-manganese oxide

The invention provides a method for preparing nanometer lanthanum strontium manganese oxide (La1-xSrxMnO3) powder, which dissolves lanthana, strontium nitrate and manganous nitrate which are taken as raw materials into a nitric acid solution, then adopts ammonia water as a precipitant to carry out precipitation reaction at room temperature: the precipitate is heat-treated at the temperature of 600-700 DEG C to obtain nanometer perovskite structure lanthanum strontium manganese oxide (La1-xSrxMnO3) polycrystalline powder. The lanthanum strontium manganese oxide oxide powder with different grain sizes (20-35nm) can be obtained by changing the temperature and time of the heat treatment. The method has the advantages that the reaction is moderate, the grain diameter of the oxide powder is uniform, the structure is compact and the performance is stable; the preparation technique is simple, the production cost is low and the invention is suitable for industrial production and so on.

Owner:SOUTHWEST JIAOTONG UNIV

Anode active material and preparation method and application thereof

ActiveCN111180693AIncrease capacityImprove Coulombic efficiencyCell electrodesSecondary cellsPhysical chemistrySilicon oxide

The invention relates to an anode active material and a preparation method and application thereof. The anode active material includes: silicon oxide particles; and elemental silicon nanoparticles dispersed in the silicon oxide particles, wherein the median particle size of the monatomic silicon nanoparticles is 0.2-20 nm; the silicon oxide particles comprise lithium, the lithium in the silicon oxide particles comprises a lithium silicate compound, and the lithium silicate compound comprises one or more of Li2Si2O5, Li6Si2O7, Li2SiO3, Li8SiO6 and Li4SiO4. The anode active material disclosed bythe invention has the advantages of high capacity and coulombic efficiency, good multiplying power and cycle performance, the low expansion rate and the like when being used in a secondary battery. The preparation method is good in repeatability and high in safety. The secondary battery provided by the invention has the characteristics of high volume energy density, good rate capability, good cycling stability, low expansion rate and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

Method for producing anode active material containing lithium, magnesium compound oxide

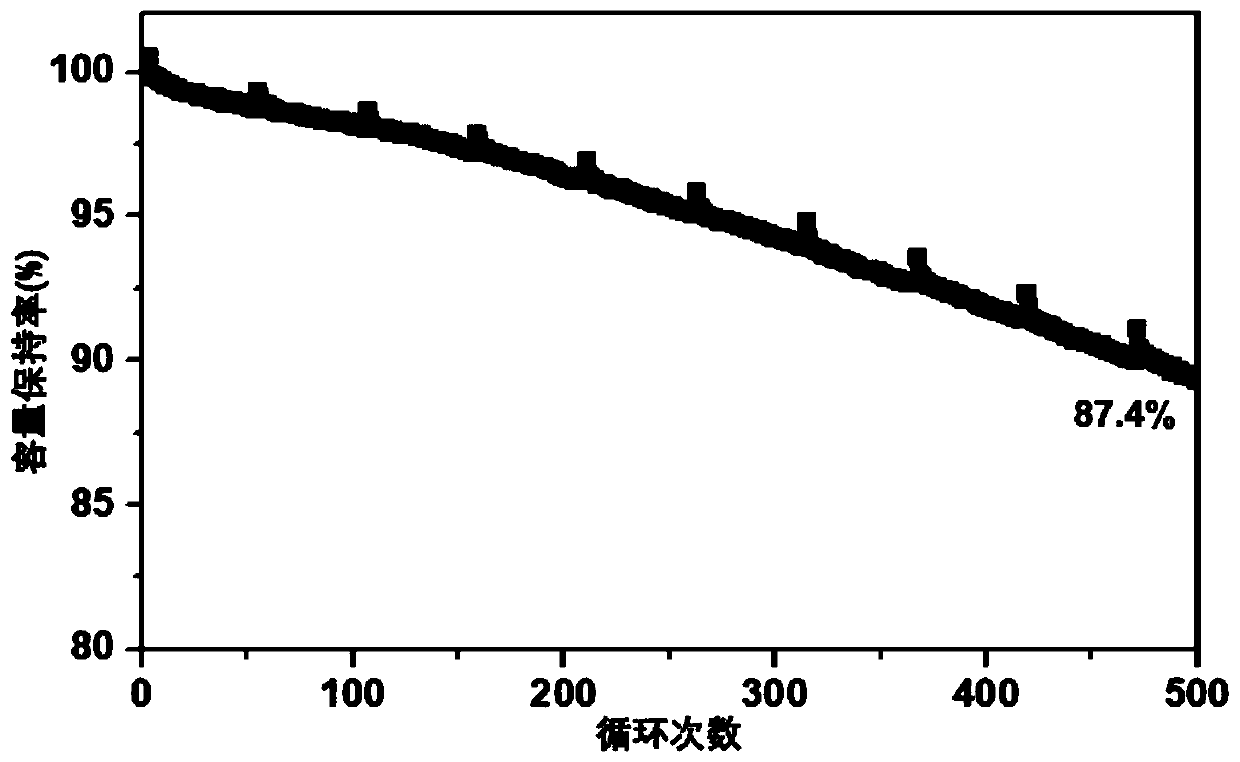

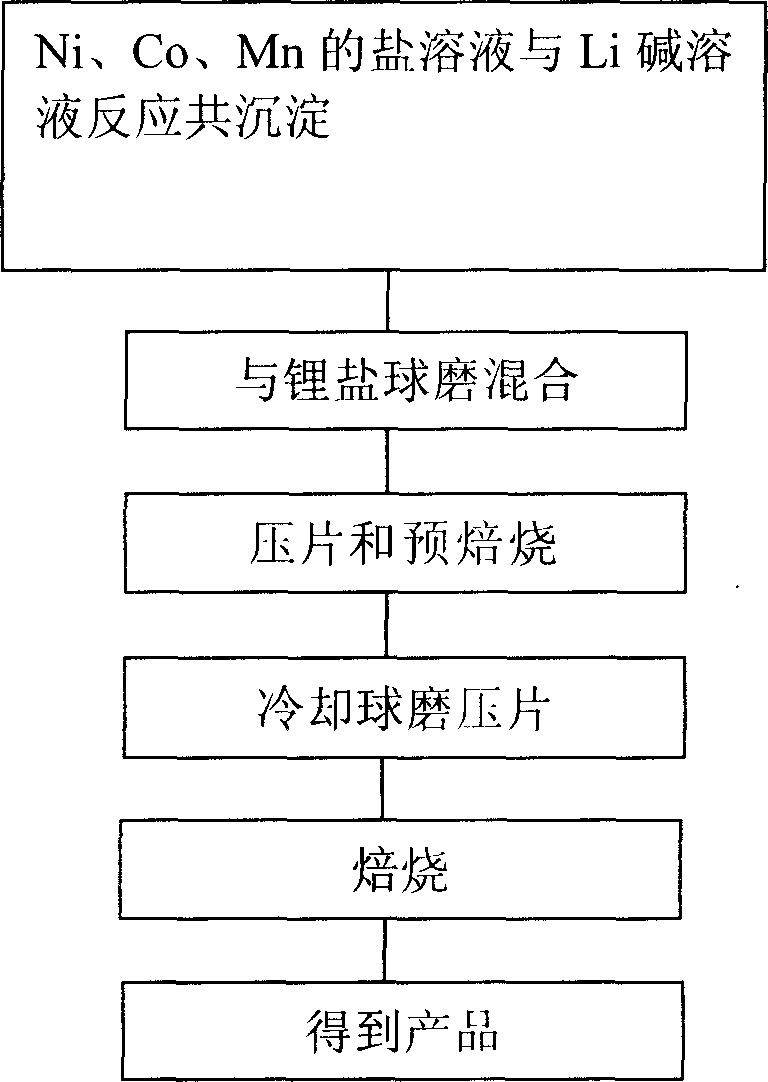

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

Method for preparing peroxo-titanic acid photocatalytic coating agent

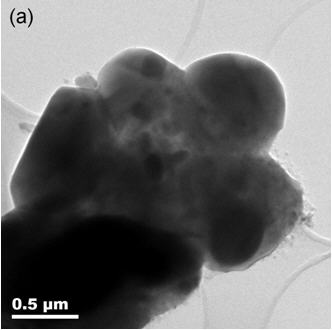

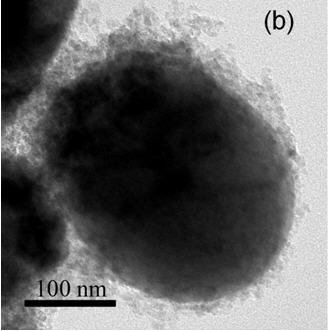

InactiveCN1733846ALow heat treatment temperatureLow costSpecial surfacesCoatingsLight ActivityMetallic materials

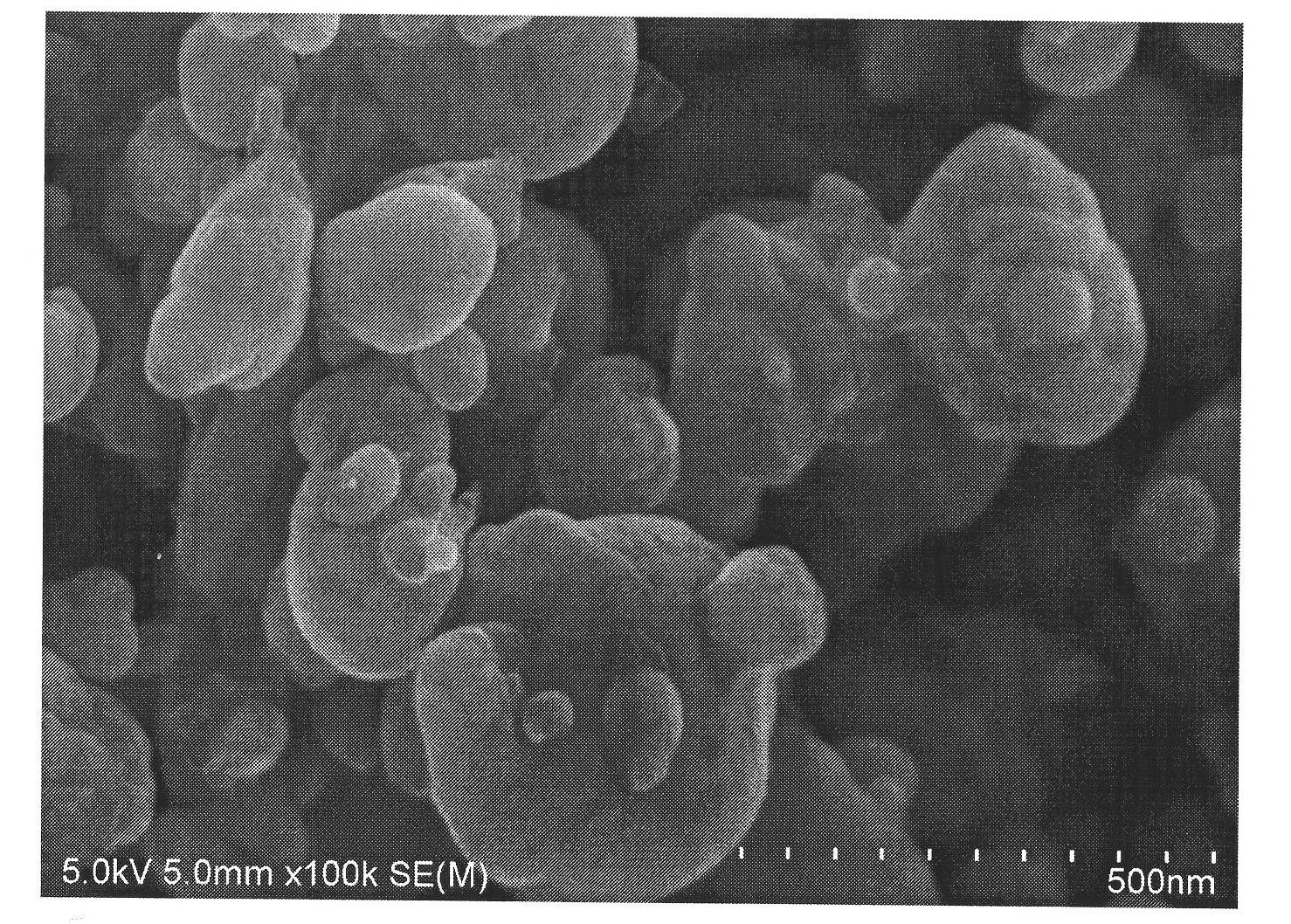

The invention discloses a method for peroxy titanic acid with visible-light activity for supported photocatalyst. Wherein, preparing clear solution with given concentration by TiSO4 to drip with diluted ammonia into deionized water with given pH value as basic solution; mixing and holding given pH value to form precursor deposition of titanium oxide; continuing to mix for some time; taking solid-liquid separation to the suspending liquid to clean for 3-5 times, dripping some H2O2 peptizer to deposite and obtain the product. The film coating can crystallize and form anatase phase at 150Deg. The membrane layer particle is 10-20 nano sphere or ~20X~100 nano column.

Owner:TIANJIN UNIV

Method for preparing hard carbon negative electrode materials of lithium ion battery

The invention discloses a method for hard carbon negative electrode materials of a lithium ion battery and belongs to the technical field of hard carbon negative electrode materials of the lithium ion battery. By means of the method, one or several kinds with any proportion of sulfuric acid, sulfate, boric acid, borate, phosphoric acid, phosphate, muriatic acid, muriate and ammonia or ammonium salt is / are chosen as a catalyst / catalysts for preparing the hard carbon negative electrode materials of the lithium ion battery in a catalysis method, and compared with the catalysts used in the prior art, the catalysts used in the preparing process of the materials are reduced in low-temperature section stabilized heat treatment temperature, the time is shortened by nearly 10 times, a large number of resources are saved, production cost is reduced, and capacity is improved.

Owner:DONGFANG ELECTRIC CORP LTD

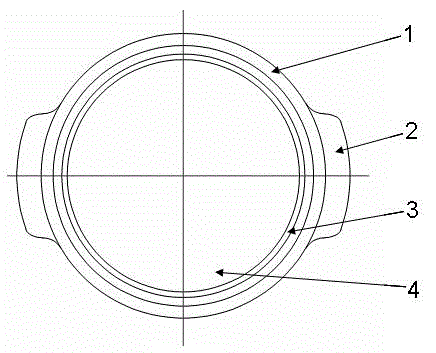

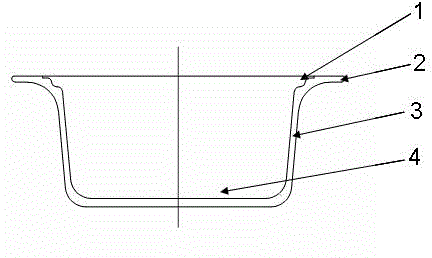

Fe-Ai-Al powder core annular magnet and preparation method thereof

ActiveCN106158340AImprove permeabilityGood soft magneticTransportation and packagingMetal-working apparatusAl powderNano al2o3

The invention discloses a Fe-Ai-Al powder core annular magnet and a preparation method thereof. The preparation method comprises the following steps: (1) pouring original Fe-Ai-Al alloy powder into an acetone solution containing a coupling agent and uniformly stirring; putting the uniformly-stirred alloy powder into a vacuum drying box and drying; (2) adding an insulating additive into the dried powder; after uniformly stirring, drying again, wherein the insulating additive is a mixture of organic silicon resin, nano aluminum oxide and kaolin; (3) pressing the prepared mixed powder into a magnet ring; and (4) keeping the heat of the magnet ring at 350 DEG C-450 DEG C for 20min-40min, carrying out heat treatment and cooling along a furnace to obtain Fe-Ai-Al magnetic powder core. The magnetic powder core disclosed by the invention has good properties, a simple preparation process and low cost and is applicable to industrial production.

Owner:SOUTH CHINA UNIV OF TECH

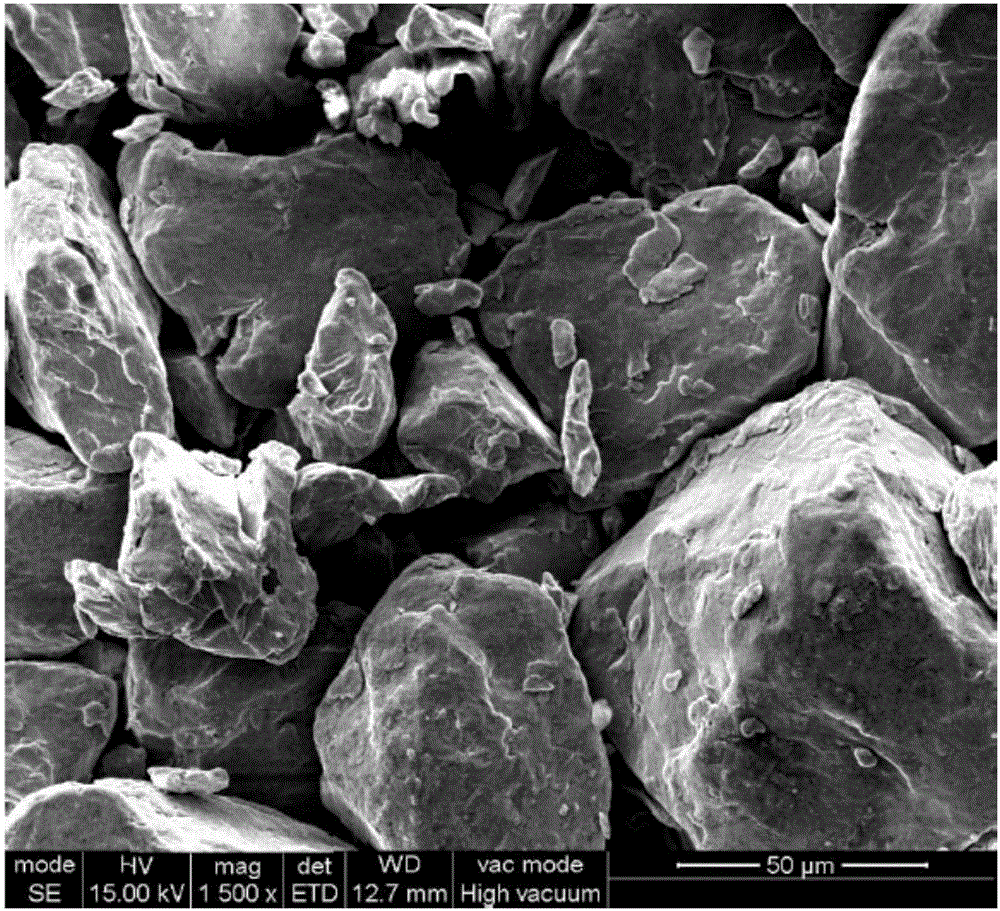

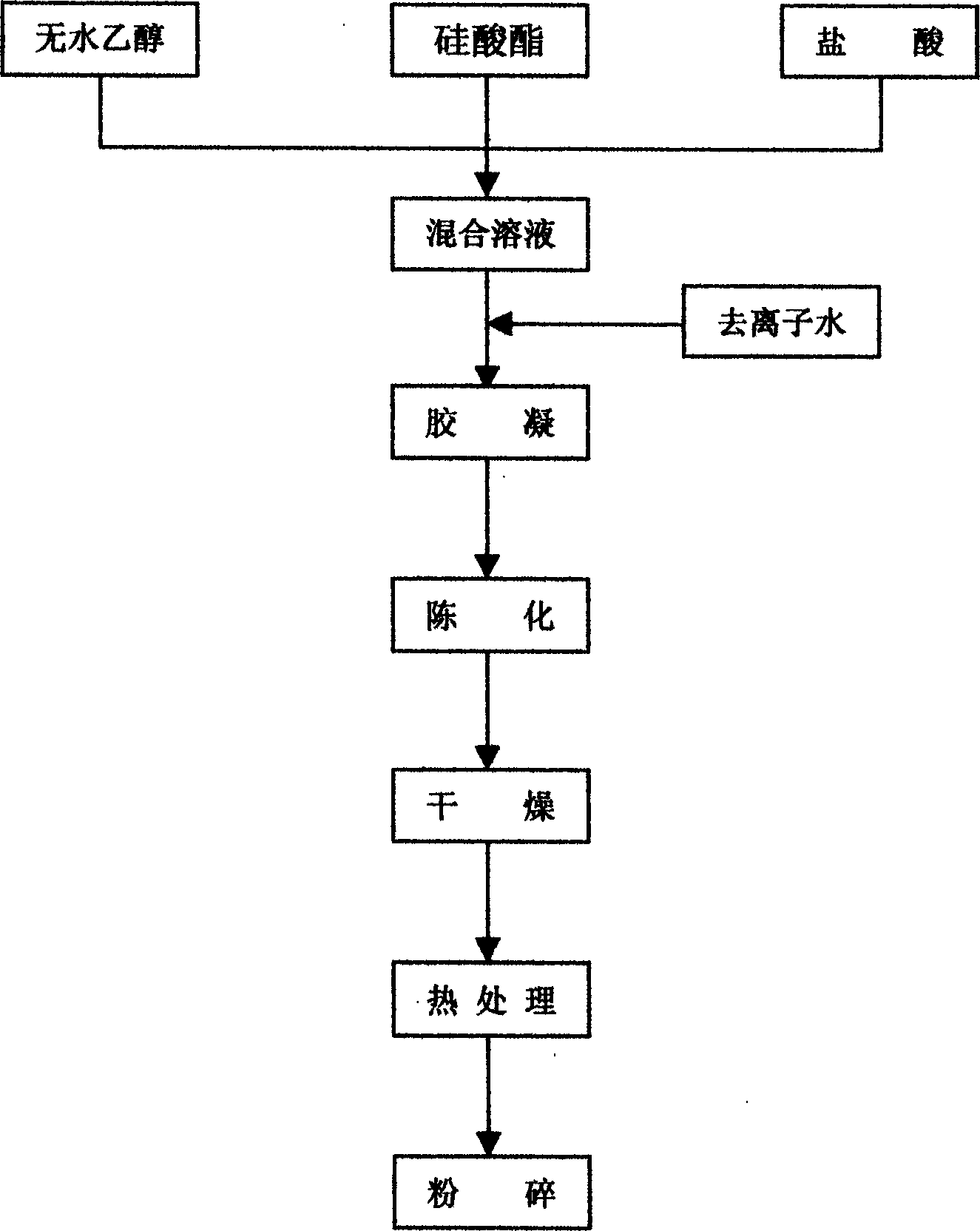

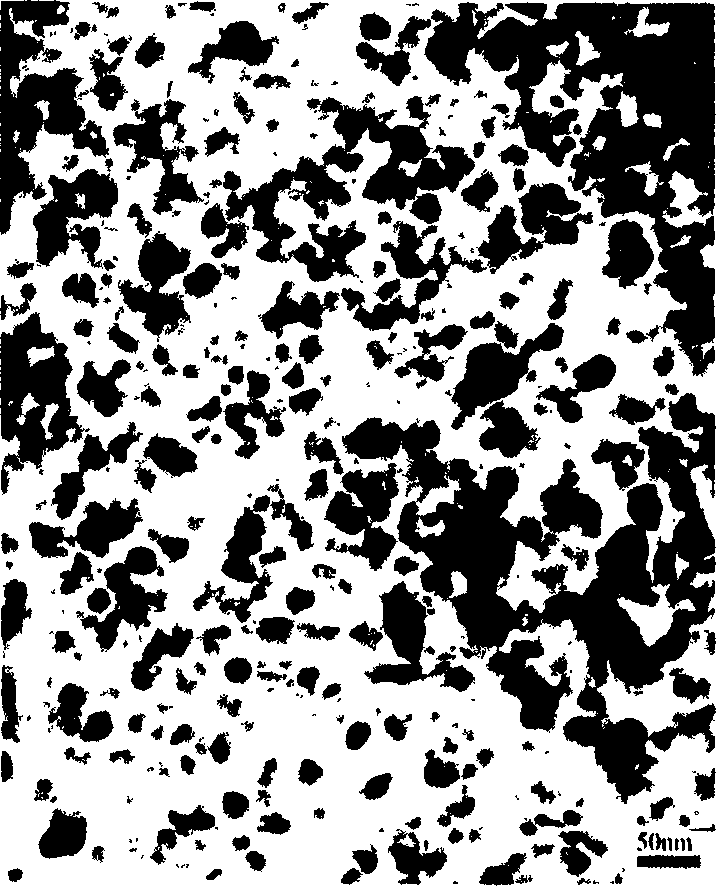

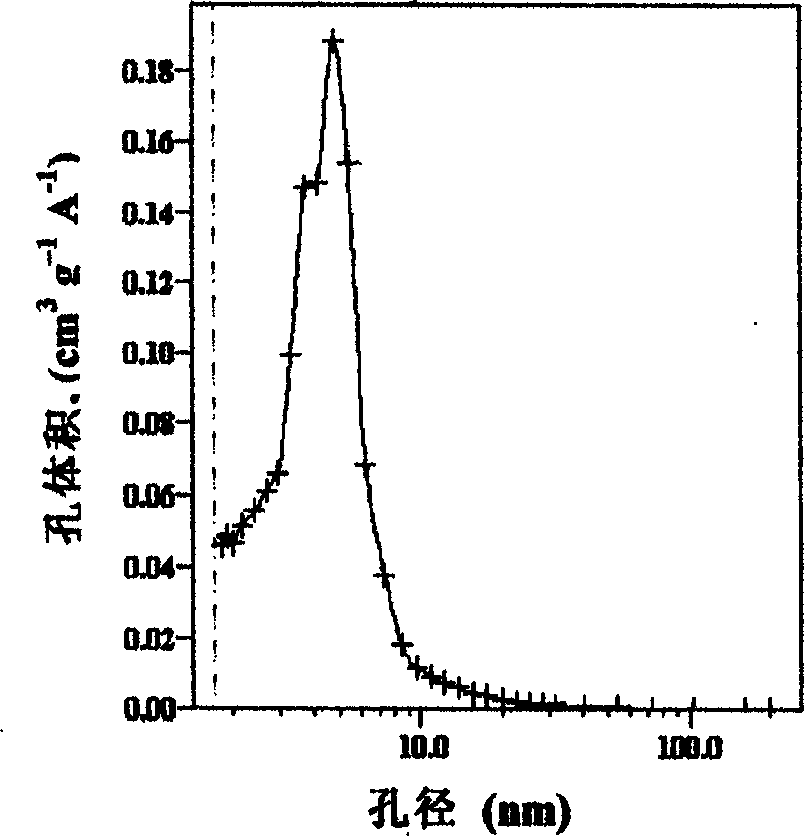

Process for preparing medium porous nano silicon dioxide powder with high activity

The preparation process of medium porous nano silica powder includes hydrolysis and condensation reaction of silicate ester to prepare SiO2 sol, preparing SiO2 gel, ageing and drying SiO2 gel. It features the heat The of aged and dried white amorphous SiO2 at 150-200 deg.c for 5-8 hr; and ball milling of the powder after heat treatment for 8-48 hr. The said process can produce medium porous nano SiO2 powder with grain size distribution of 5-50 nm, average pore diameter 5.1-5.9 nm, porosity 85-93 %, surface hydroxy content 51-55 %. The product may be used as selective absorbent, loaded catalyst and various sensors as well as in the production of ink absorbent, sunproof record paper and cosmetics. The produced powder has purity as high as 99.9 %, extremely high activity and low cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

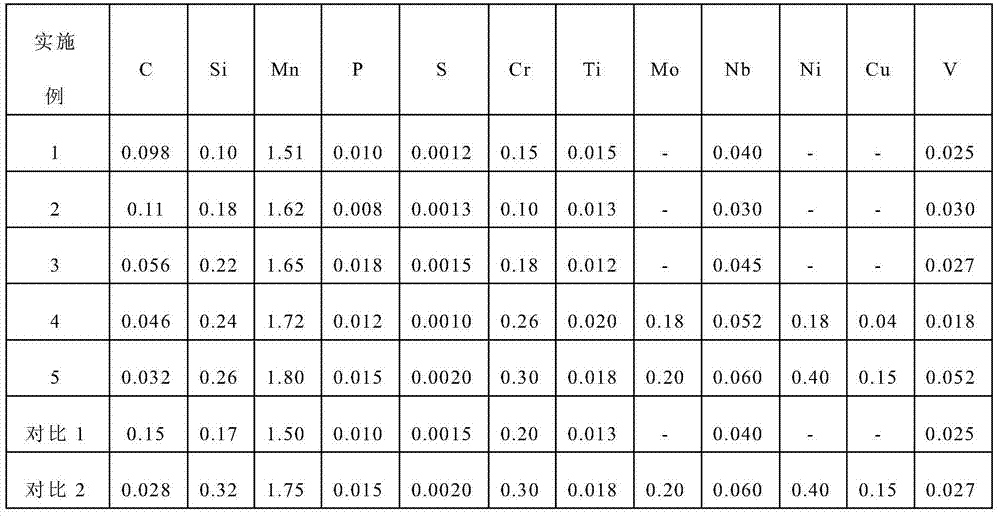

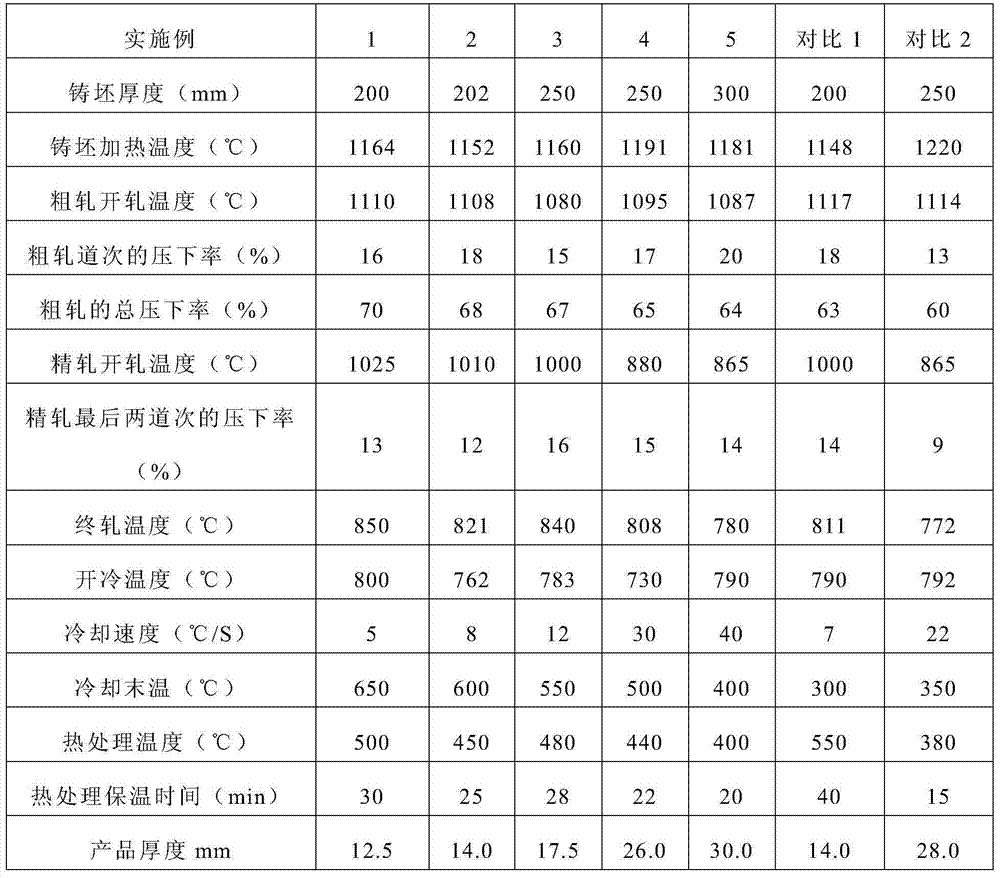

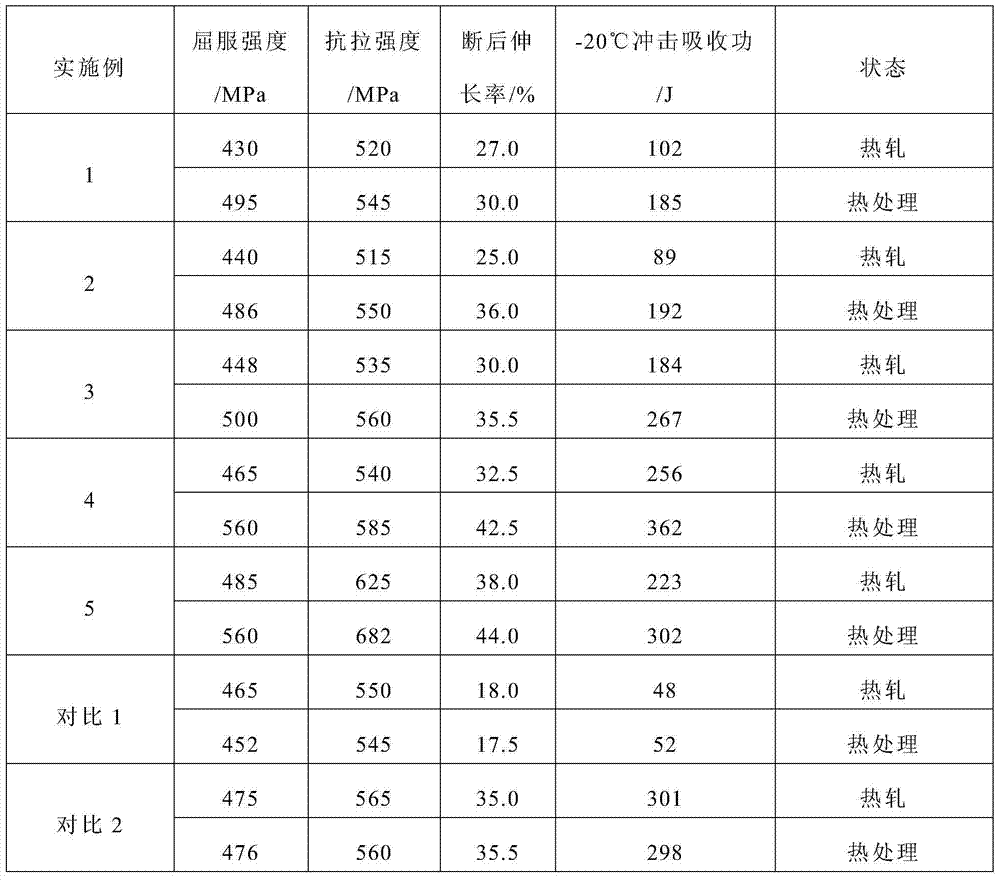

High-strength high-toughness steel plate and preparation method thereof

The invention discloses a high-strength high-toughness steel plate. The steel comprises the following chemical components in percentage by weight: 0.032-0.11% of C, 0.10-0.26% of Si, 1.51-1.80% of Mn, 0.03-0.06% of Nb, 0.012-0.020% of Ti, at most 0.052% of V, at most 0.20% of Mo, at most 0.40% of Ni, at most 0.30% of Cr, at most 0.15% of Cu, at most 0.018% of P, at most 0.0020% of S, and the balance of Fe and inevitable impurities. The invention also discloses a preparation method of the high-strength high-toughness steel plate, which comprises the following steps: 1) blank casting; 2) heating; 3) rolling; 4) cooling; 5) heat treatment; and 6) air cooling. The method has the advantages of simple hot rolling technique, low heat treatment temperature, short holding time, low energy consumption and lower production cost, obtains the product with higher quality, and enhances the yield.

Owner:武钢集团有限公司

Preparation method of high-rate capacity lithium iron phosphate material

The invention discloses a preparation method of a high-rate capacity lithium iron phosphate material, which comprises the steps of: weighing FePO4.xH2O and a lithium source compound as raw materials according to the mol ratio of Li to Fe of (1-1.05) :1, adding a carbon source compound and a catalyst (nitrate or acetate of Fe, Co, Ni and the like), ball-grinding for 0.5-24h by using deionized water, absolute ethyl alcohol or acetone as a ball grinding medium to obtain slurry, spraying and drying the slurry and then thermally treating under the protection of an inert gas, and in the process, with the thermal cracking of the carbon source compound, promoting the carbon source compound to form a carbon cladding cover with higher graphitization crystallinity under a lower temperature through mutual action of the catalyst and the carbon source compound. The lithium iron phosphate cathode material prepared by adopting the preparation method has higher electronic conductivity and higher specific capacity under the condition of lower carbon content, greatly improved high-rate performance especially, and better application value in the field of power batteries.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

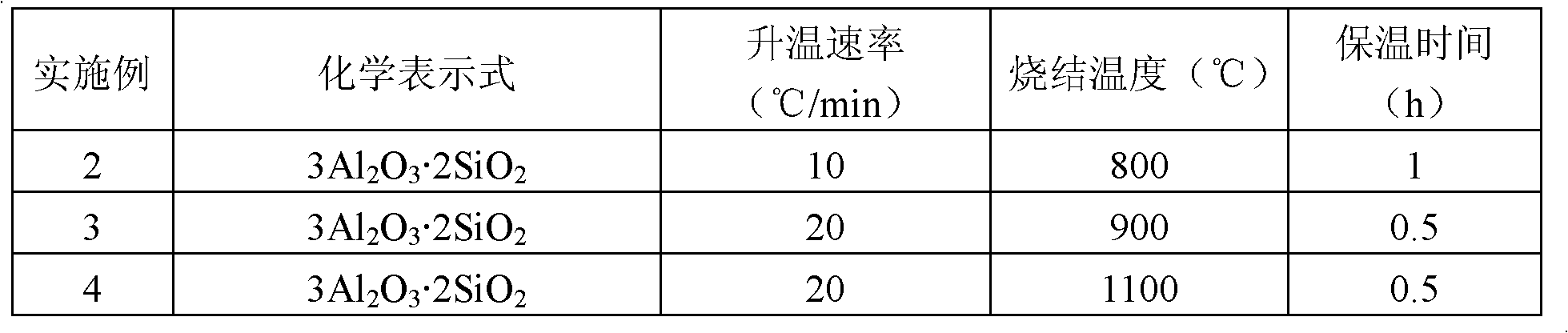

Mullite fiber preparation method

The invention discloses a mullite fiber preparation method which is efficient, rapid, environment-friendly and low in cost. The method includes: taking raw materials according to stoichiometric ratio of elements in the mullite fiber chemical formula, preparing colloid, performing fiber forming and drying for colloid discharging to obtain mullite non-crystal fiber, adding the fiber into a sagger made of wave permeable materials, placing the sagger in a special microwave oven, controlling heating rate by adjusting the microwave power under the air or oxygen atmosphere, heating to a heat treatment temperature, and cooling to the room temperature to obtain the mullite fiber. The mullite fiber prepared by the method is high in impurity and low in porosity, the grain size is about 30nm, and the fiber diameter ranges from 6 micrometers to 10 micrometers. Further, the mullite fiber is excellent in uniformity, brittle fracture and chalking of the fiber are greatly reduced, yield is increased, heat treatment temperature is lowered, heat insulation time is shortened, and production efficiency is greatly improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing strontium sodium bismuth titanate piezoelectric ceramic by sol-gel auto-igniting process

The invention discloses a method for preparing strontium sodium bismuth titanate piezoelectric ceramic by a sol-gel auto-igniting process. The method comprises the steps of: by using a complexing agent, nitric acid, acetic acid or carbonate and butyl titanate as raw materials, adjusting pH value by adopting ammonium hydroxide, carrying out complexing hydrolysis reaction in water and alcohol solution, performing microwave heating for dehydration condensation to obtain xerogel, and heating the xerogel at 500 DEG C to perform auto-igniting reaction to obtain strontium sodium bismuth titanate ceramic powder with narrow particle size (10-40nm). The ceramic can be densely sintered at 980-1020 DEG C due to nanometer small-size effect and can keep good piezoelectric property, the equipment required by the method is simple and has no special environment requirement, the process is stable at normal temperature, the repeatability is strong, the synthesized powder has high purity and the heat treatment temperature is low, therefore, the ceramic can be widely applied to the fields such as piezoelectric vibrators, micro positioners, ultrasonic transducers and the like.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com