Method for preparing nano lanthanum-strontium-manganese oxide

A lanthanum strontium manganese and oxide technology is applied in the field of preparation of nanometer oxides, which can solve the problems of increasing impurity content, harmful to human health, complicated production process, etc., and achieves the effects of good uniformity, little environmental pollution, and low heat treatment temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The concrete preparation method of this example is:

[0036] A. Select La at a molar ratio of 0.425:0.15:1 2 o 3 , Sr(NO 3 ) 2 and Mn(NO 3 ) 2 ; Selected La 2 o 3 Soluble in 33% dilute HNO 3 Medium, and HNO 3 with La 2 o 3 The molar ratio is 2:1; the solution is obtained, and after the solution is clarified, Sr(NO 3 ) 2 , Mn(NO 3 ) 2Add to the solution and stir, and at the same time add polyethylene glycol, polyethylene glycol and dilute HNO 3 The molar ratio is 1:2. Obtain the precursor solution;

[0037] B. NH will be used as a precipitant 4 OH solution is introduced into the titration vessel, NH 4 OH and La 3+ 、Sr 2+ , Mn 2+ The molar ratio of the sum of the moles of metal ions is 1.05:1; then the NH in the titration container 4 Add the OH solution drop by drop to the precursor solution in step A, and the drop speed is controlled at 0.05cm 3 / min, and stir at the same time, the stirring speed is 800r / min, after the drop, precipitate for 4 hours...

Embodiment 2

[0042] This example is substantially the same as Example One, and the difference is the following process parameters in the A step: La 2 o 3 , Sr(NO 3 ) 2 and Mn(NO 3 ) molar ratio of 0.33:0.33:1; dilute HNO 3 Concentration of 34% polyethylene glycol with dilute HNO 3 The molar ratio is 1:3.

[0043] The product obtained in this example is La 0.67 Sr 0.33 MnO 3 Single-phase polycrystalline powder. Figure 2a is the nanometer La obtained by the method of this example 0.67 Sr 0.33 MnO 3 X-ray diffraction pattern of the powder. As can be seen from Fig. 2a, the particle diameter of the product that this example makes is about 25nm; Fig. 2b is the nanometer La that is made by the method of this example 0.67 Sr 0.33 MnO 3 SEM photo of the powder. It can be seen from Figure 2b that the product obtained by the method of this example has uniform particle size, compact structure and high purity.

Embodiment 3

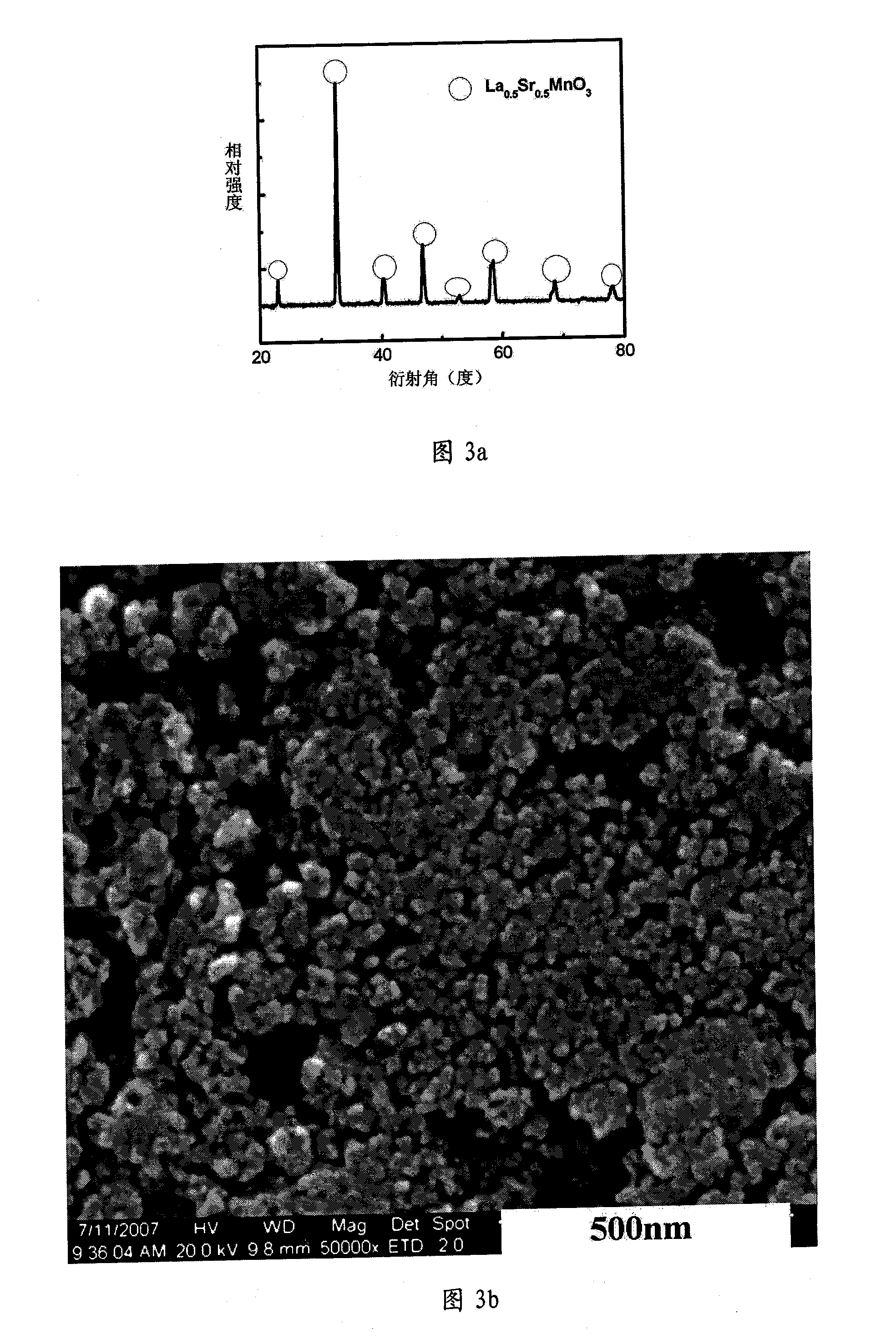

[0045] This example is substantially the same as Example One, and the difference is only the following process parameters in the A step: La 2 o 3 , Sr(NO 3 ) 2 and Mn(NO 3 ) molar ratio of 0.25:0.5:1; dilute HNO 3 The concentration is 32%.

[0046] The product obtained in this example is a single-phase La 0.5 Sr 0.5 MnO 3 Polycrystalline powder. Figure 3a is the nanometer La obtained by the method of this example 0.5 Sr 0.5 MnO 3 X-ray diffraction pattern of the powder. As can be seen from Fig. 3a, the particle diameter of the product that this example makes is about 30nm; Fig. 3b is the nanometer La that is made by the method of this example 0.5 Sr 0.5 MnO 3 SEM photo of the powder. It can be seen from Figure 3b that the product obtained by the method of this example has uniform particle size, compact structure and high purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com