Conductive slurry and transparent conductive coating

A conductive paste, transparent and conductive technology, applied in conductive coatings, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as increasing the complexity of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

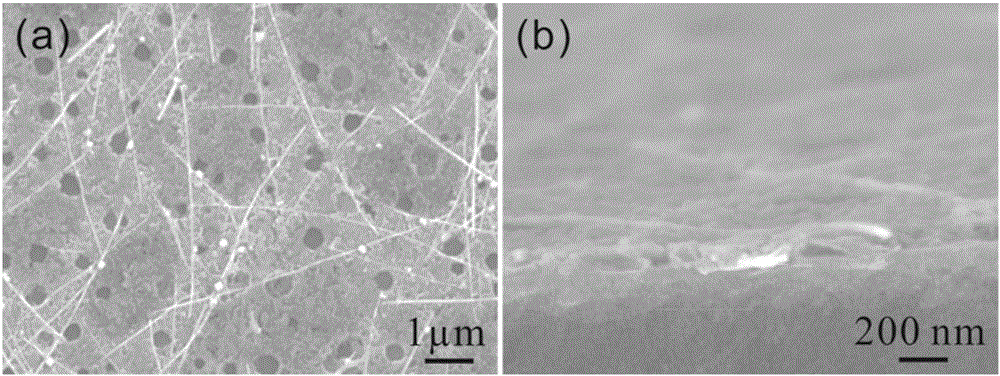

[0067] The components contained in the conductive paste are silver nanowires (AgNWs), resin matrix PVB, polyacrylic acid, tin dioxide nano filler particles, tin dioxide colloidal particles, polyether modified organosiloxane additives and ethanol solvent . The specific preparation method is:

[0068] Weigh 10 g of nano-tin dioxide with a particle size of 60 nm, and ultrasonically disperse it in 200 mL of ethanol solvent for 30 min. After the dispersion is uniform, add 8 g of mercaptopropyltriethoxysilane drop by drop. Heated in a water bath at 70 °C and refluxed for 6 h to obtain mercapto-grafted tin dioxide nano-filler particles.

[0069] The conductive filler AgNWs, the mixture of resin matrix PVB and polyacrylic acid, tin dioxide nano filler particles, tin dioxide colloidal particles, polyether modified organosiloxane additives, and ethanol solvent were mass fractioned at 0.8%, 0.6%, 1.2 %, 0.8%, 0.1%, and 96.5% are uniformly mixed to obtain a uniform and stable conductive...

Embodiment 2

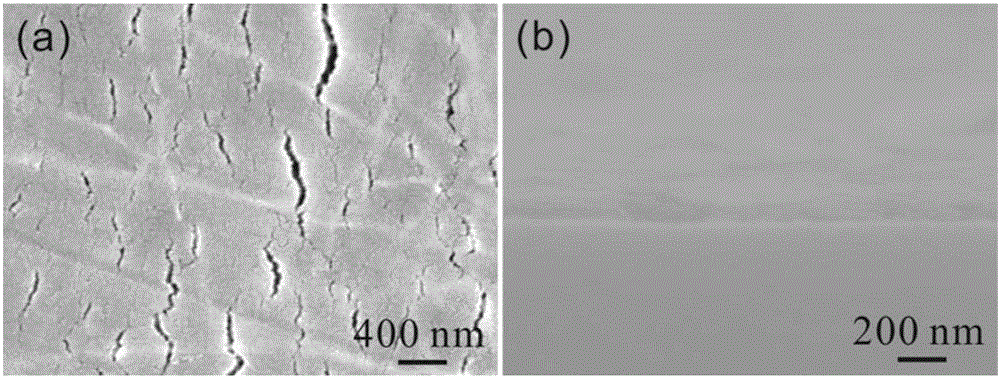

[0072] The components contained in the conductive paste are gold nanowires AuNWs, polyurethane, silicon dioxide nanometer filler particles, silicon dioxide colloidal particles, n-octanol additive and ethanol solvent. The specific preparation method is:

[0073]Immerse 5 g of polyurethane in anhydrous toluene, add 1,5-naphthalene diisocyanate and stannous octoate, and react at 50°C for 40 hours; take it out, wash it with water, and dry it under vacuum to obtain a surface-modified polyurethane with mercapto groups.

[0074] Weigh 10 g of silica nano-filler particles with an average particle size of about 30 nm, and ultrasonically disperse them in 200 mL of ethanol solvent for 30 min. After the dispersion is uniform, add 8 g of mercaptopropyltriethoxysilane drop by drop. Heated in a water bath at 70 °C and refluxed for 6 h to obtain mercapto-grafted silica nano-filler particles.

[0075] Conductive filler AuNWs, polyurethane, silica nano-filler particles, nano-silica colloidal p...

Embodiment 3

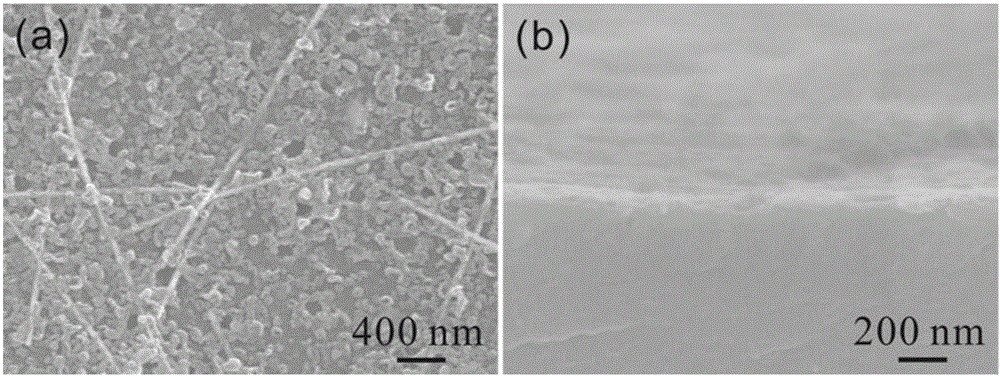

[0078] The components contained in the conductive paste are AgNWs, a mixture of polyurethane and polyester, hollow titanium dioxide nano-filler particles, polystyrene nanoparticles, and a mixed solvent of water, ethanol, and isopropanol. The water, ethanol, and isopropanol The volume ratio of propanol is 1:3:1. The specific preparation method is:

[0079] Weigh 10 g of hollow titanium dioxide nano-filler particles with a particle size of 150 nm, and ultrasonically disperse them in 200 mL of ethanol solvent for 30 min. After the dispersion is uniform, 8 g of mercaptopropyltriethoxysilane is added dropwise. Heated in a water bath at 70 °C and refluxed for 6 h to obtain mercapto-grafted hollow titania nanofiller particles.

[0080] The conductive filler AgNWs, a mixture of polyurethane and polyester (the mass ratio of the two is 5:1), hollow titanium dioxide nano-filler particles, polystyrene nanoparticles, water, ethanol, isopropyl The mixed solvent of alcohol is uniformly mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com