Pretreatment method for improving dimension stability of timber

A dimensional stability and pretreatment technology, applied in impregnated wood, wood impregnation, wood processing utensils, etc., can solve problems such as deformation and cracking, achieve the effects of reducing heat treatment temperature, improving hydrophilicity, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

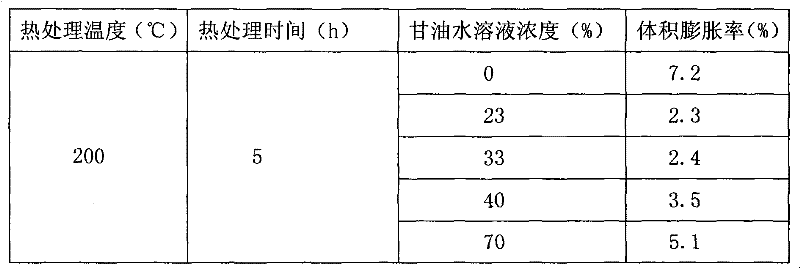

Examples

Embodiment 1

[0022] Soak poplar wood with a thickness of 20 mm, a width of 100 mm, and a length of 1000 mm in 20% aqueous glycerin solution at room temperature and pressure for 24 hours, take out the test material, and air-dry to reduce the moisture content of the wood to 10%. Put the wood into the heat treatment box, turn on the water vapor switch, rapidly raise it to 140 °C at a speed of 10 °C / h, keep it warm for 30 minutes, and dry the wood at high temperature to reduce the moisture content inside the wood to 0; raise the temperature to 160°C, keep the heat treatment for 5 hours; turn off the water vapor switch, reduce the temperature of the heat treatment box, when the temperature of the heat treatment box drops below 80°C, turn on the water vapor switch, adjust the moisture content of the wood to 7%, and remove the wood.

Embodiment 2

[0024] Soak poplar wood with a thickness of 30 mm, a width of 100 mm, and a length of 1000 mm in 30% aqueous glycerin solution for 36 hours at normal temperature and pressure, take out the test material, and air-dry to reduce the moisture content of the wood to 12%. Put the wood into the heat treatment box, turn on the water vapor switch, rapidly raise it to 140 °C at a speed of 15 °C / h, keep it warm for 45 minutes, and dry the wood at high temperature to reduce the moisture content inside the wood to 0; raise the temperature to 180°C, keep the heat treatment for 4 hours; turn off the water vapor switch, reduce the temperature of the heat treatment box, when the temperature of the heat treatment box drops below 80°C, turn on the water vapor switch, adjust the moisture content of the wood to 8%, and remove the wood.

Embodiment 3

[0026] Soak poplar wood with a thickness of 40mm, a width of 100mm, and a length of 1000mm in 40% aqueous glycerin solution at room temperature and pressure for 48 hours, take out the test material, and air-dry to reduce the moisture content of the wood to 15%. Put the wood into the heat treatment box, turn on the water vapor switch, rapidly raise it to 140 °C at a speed of 20 °C / h, keep it warm for 45 minutes, and dry the wood at high temperature to reduce the moisture content inside the wood to 0; raise the temperature to 200°C, keep heat treatment for 4 hours; turn off the water vapor switch, reduce the temperature of the heat treatment box, when the temperature of the heat treatment box drops below 80°C, turn on the water vapor switch, adjust the moisture content of the wood to 10%, and remove the wood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com