Preparation method of graphene oxide composite nano filter membrane

A graphene composite, nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve good large-scale industrial application prospects, high hydrophilicity, and the effect of improving salt rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

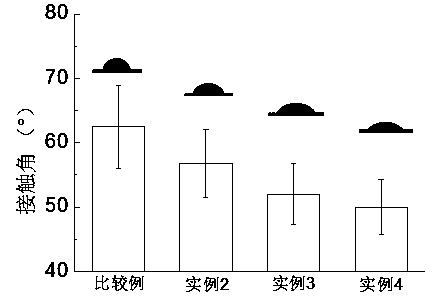

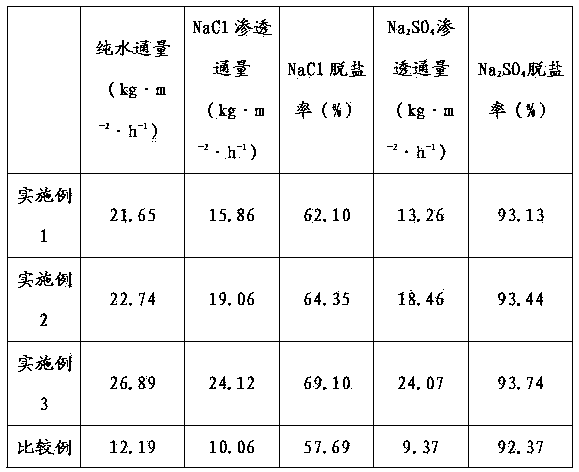

Examples

Embodiment 1

[0037] (1). The graphene oxide aqueous solution was prepared by the modified Hummmers method.

[0038] Put expandable graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98% to the expandable graphite, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, when the temperature is lower than 20 Stir evenly under the condition of ℃, add 50ml of concentrated sulfuric acid for every 1g of expandable graphite, and the quality of potassium permanganate is twice that of expandable graphite.

[0039] Add ultrapure water to the above solution for dilution, heat it in a constant temperature water bath to 90-100°C, keep it for 30-40min, then add hydrogen peroxide solution with a mass fraction of 30%, and cool it to room temperature, the solution changes from brown to soil Yellow, the volume ratio of concentrated sulfuric acid: ultrapure water: hydrogen peroxide is 50:100:10.

[0040] Filter the above ...

Embodiment 2

[0046] (1). The graphene oxide aqueous solution was prepared by the modified Hummmers method.

[0047]Put expandable graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98% to the expandable graphite, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, when the temperature is lower than 20 Stir evenly under the condition of ℃, add 60ml of concentrated sulfuric acid for every 1g of expandable graphite, and the quality of potassium permanganate is 3 times that of expandable graphite.

[0048] Add ultrapure water to the above solution for dilution, heat it in a constant temperature water bath to 90-100°C, keep it for 30-40min, then add hydrogen peroxide solution with a mass fraction of 30%, and cool it to room temperature, the solution changes from brown to soil Yellow pasty colloid, the volume ratio of concentrated sulfuric acid: ultrapure water: hydrogen peroxide is 50:200:20.

[0049] Fi...

Embodiment 3

[0055] (1). The graphene oxide aqueous solution was prepared by the modified Hummmers method.

[0056] Put expandable graphite as raw material in a container, add concentrated sulfuric acid with a mass fraction of 98% to the expandable graphite, keep the temperature of the mixture at 0°C in an ice-water bath, then add potassium permanganate, when the temperature is lower than 20 Stir evenly under the condition of ℃, add 75ml of concentrated sulfuric acid for every 1g of expandable graphite, and the quality of potassium permanganate is 4 times that of expandable graphite.

[0057] Add ultrapure water to the above solution for dilution, heat it in a constant temperature water bath to 90-100°C, keep it for 30-40min, then add hydrogen peroxide solution with a mass fraction of 30%, and cool it to room temperature, the solution changes from brown to soil Yellow pasty colloid, the volume ratio of concentrated sulfuric acid: ultrapure water: hydrogen peroxide is 50: 300: 40.

[0058]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com