Preparation method of high-rate capacity lithium iron phosphate material

A high-rate, high-performance technology, applied in the field of preparation of high-rate lithium iron phosphate/carbon composite materials, can solve the limitations of electronic conductivity and ion diffusivity on the application range, battery cycle life and safety of lithium iron phosphate batteries , battery energy density decline and other issues, to achieve the effect of LiFePO4/C composite material coated carbon structure improvement, good application value, and high rate performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

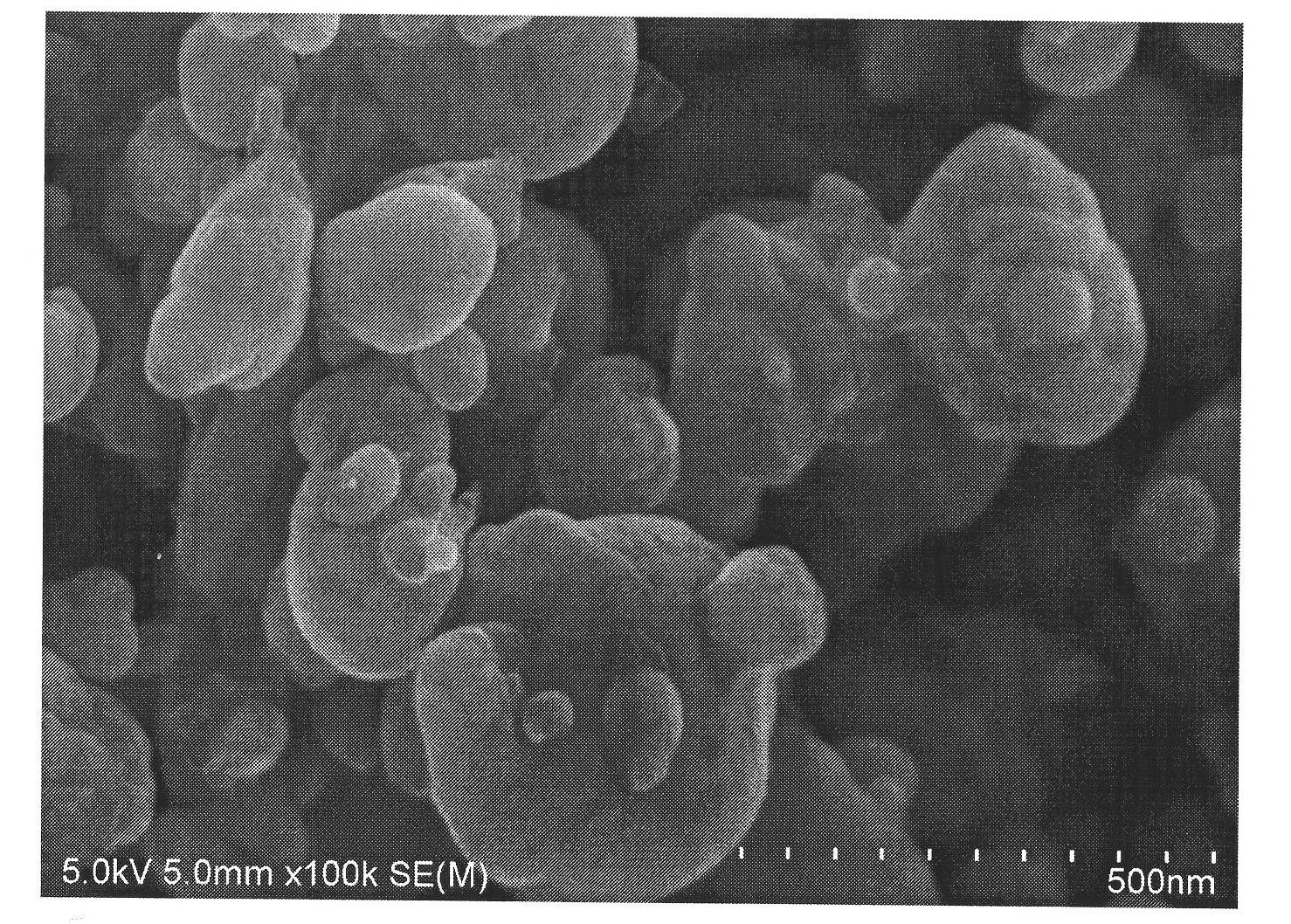

[0037] Weigh battery-grade LiOH·H 2 O, battery grade FePO 4 ·xH 2 O, catalyst cobalt acetate, its molar ratio ratio is Li: Fe: CoAc 2 =1:1:0.001, take the lithium source as 1.0 mole, battery grade LiOH·H 2 O, battery grade FePO 4 ·xH 2 O, the quality of catalyzer cobalt acetate is respectively 42g, 186.8g, 0.12g, and carbon source sucrose is taken as 25.4g according to 10% of total mass, and dehydrated alcohol 500g is ball milling medium with dehydrated alcohol, on the planetary ball mill Ball milled for 12 hours to obtain slurry.

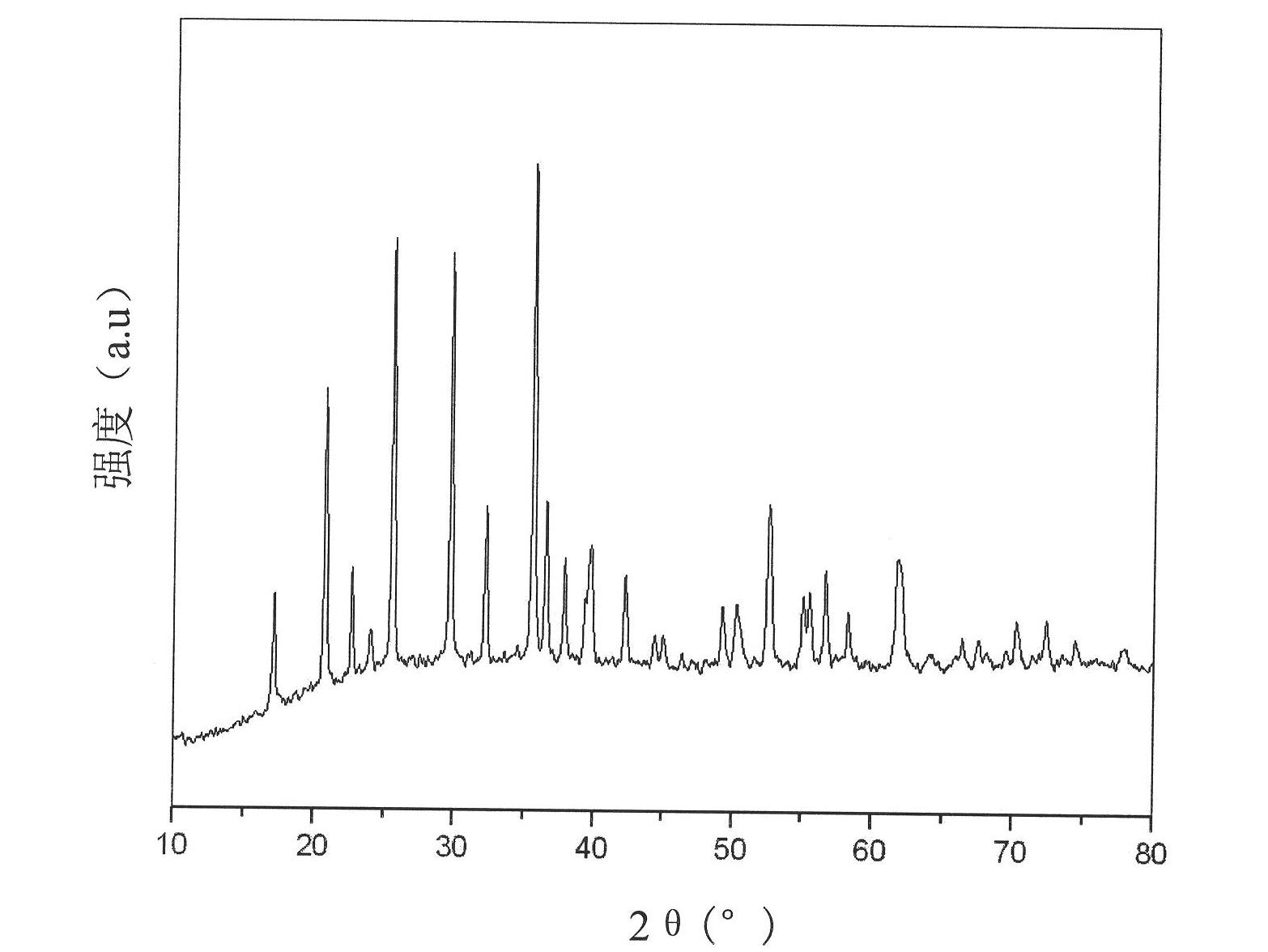

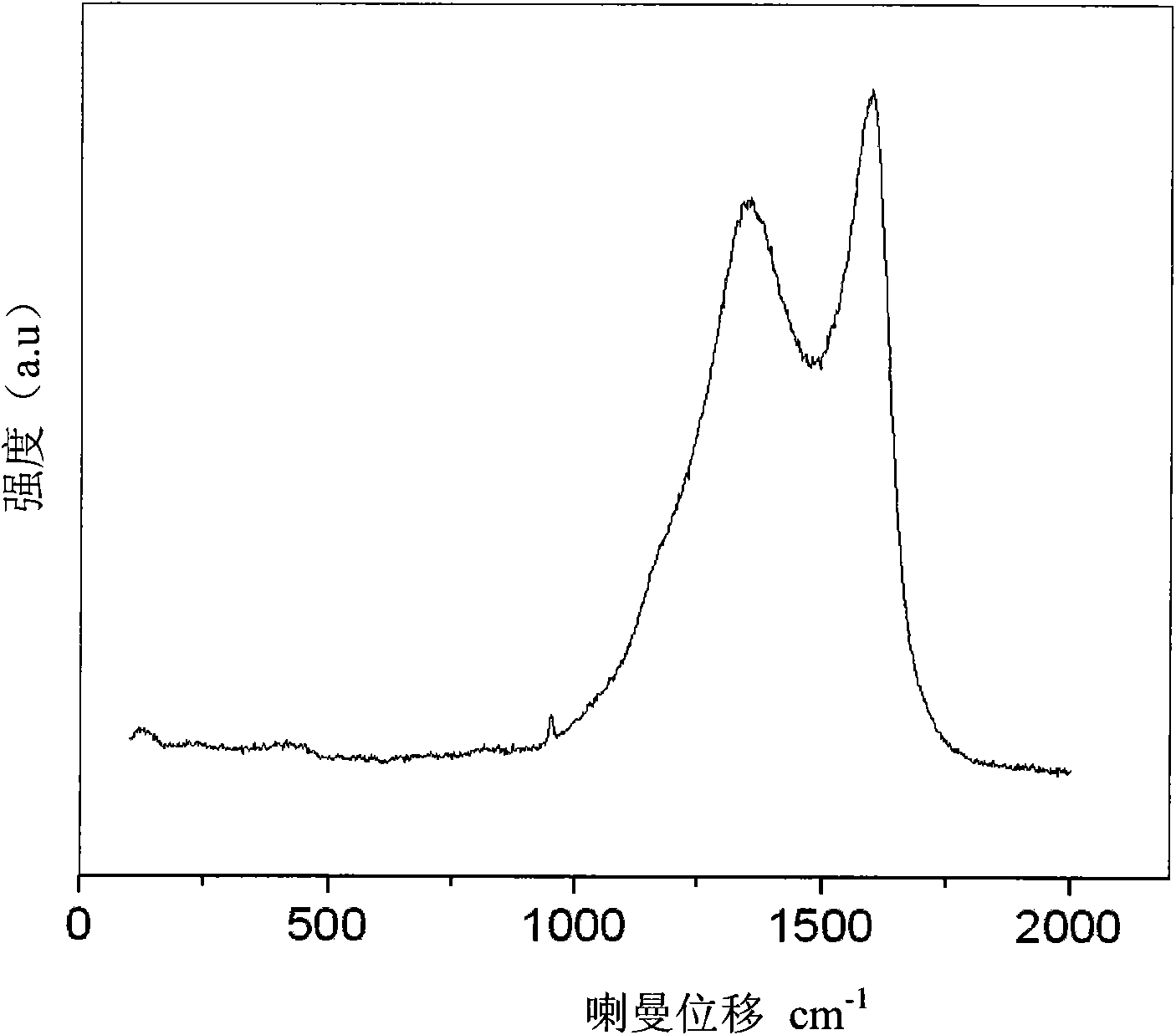

[0038] The above slurry was spray-dried to obtain a precursor, which was roasted in an argon-protected vacuum well-type furnace at a heating rate of 5 °C / min, kept at 750 °C for 10 h, and cooled to room temperature with the furnace to obtain LiFePO 4 / C cathode material. The weight percentage of carbon in the positive electrode material was measured to be 1.25%.

[0039] Assembling a simulated battery on the above-prepared LiFePO 4 / C cath...

Embodiment 2

[0042] Weigh out battery-grade LiCO 3 , battery grade FePO 4 ·xH 2 O, Catalyst FeCl 3 , the molar ratio of which is Li:Fe:FeCl 3 =1:1:0.01, take lithium source as 1 mole, battery grade LiCO 3 , battery grade FePO 4 ·xH 2 O, Catalyst FeCl 3 The quality of each is 37g, 186.8g, 1.63g, the carbon source glucose is weighed as 40g according to 15% of the total mass, and 400g of absolute ethanol is used as the ball milling medium on a planetary ball mill for 16 hours to obtain a slurry .

[0043] The above slurry was spray-dried to obtain a precursor, which was roasted in an argon-protected vacuum well-type furnace at a heating rate of 5 °C / min, kept at 700 °C for 10 h, and cooled to room temperature with the furnace to obtain LiFePO 4 / C cathode material.

[0044] The weight percentage of carbon in the positive electrode material was measured to be 2.1%.

[0045] Assembling a simulated battery on the above-prepared LiFePO 4 / C cathode material for electrochemical performa...

Embodiment 3

[0049] Weigh out battery-grade LiCO 3 , battery grade FePO 4 ·xH 2 O, catalyst zinc acetate, its molar ratio ratio is Li: Fe: ZnAc 2 =1:1:0.01, take lithium source as 1 mole, battery grade LiCO 3 , battery grade FePO 4 ·xH 2 O, the quality of catalyzer zinc acetate is respectively 37g, 186.8g, 1.24g, takes by weighing carbon source polyvinyl alcohol to be 25g, dehydrated alcohol 500g, is ball milling medium with dehydrated alcohol, ball mills 15h on planetary ball mill, obtains slurry material.

[0050] The above slurry was spray-dried to obtain a precursor, which was roasted in an argon-protected vacuum well-type furnace at a heating rate of 5 °C / min, kept at 700 °C for 10 h, and cooled to room temperature with the furnace to obtain LiFePO 4 / C cathode material. The weight percentage of carbon in the positive electrode material was measured to be 2.5%.

[0051] Assembling a simulated battery on the above-prepared LiFePO4 / C cathode material for electrochemical perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com