Preparation of lithium iron phosphate positive electrode material for lithium ion power cell

A technology of lithium iron phosphate and positive electrode materials, applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of potential safety hazards, flammability, and difficulty in industrial production, and achieve improved safety, stable performance, Effect of improving electrical conductivity and tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

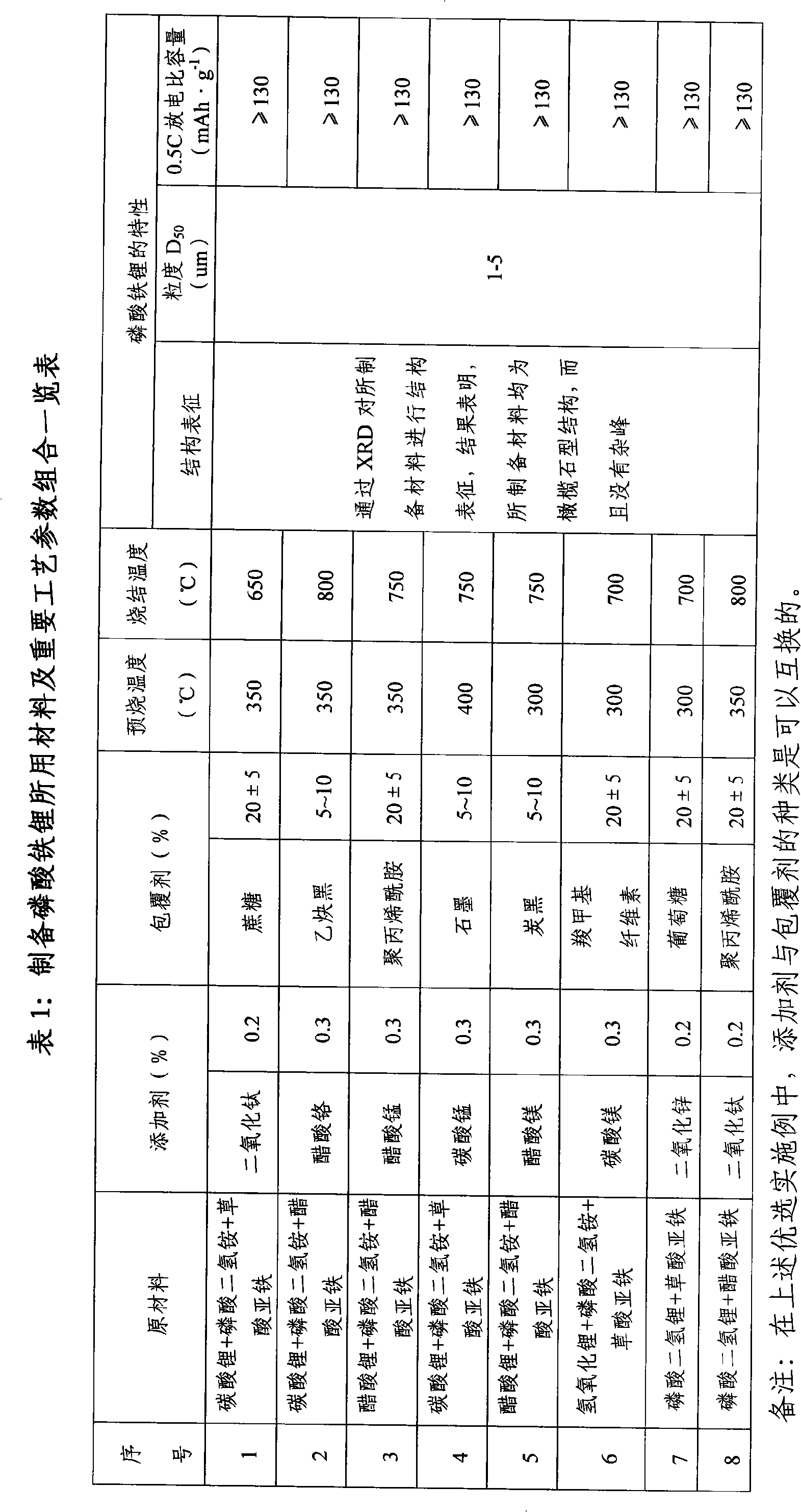

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with preferred embodiments.

[0021] The specific process steps of the first preferred embodiment of the present invention to prepare lithium iron phosphate cathode material are:

[0022] (1) Lithium carbonate with a content of 99.5%, ammonium dihydrogen phosphate with a content of 99%, and ferrous oxalate with a content of 99% are weighed according to the material ratio of Li:P:Fe=1:1:1 , and add nanoscale titanium dioxide (TiO2) with rutile structure to the ingredients 2 ), weighing 0.2% of the total mass of the ingredient, thus constituting the adulterated ingredient;

[0023] (2) Add the doping ingredients into the SX premix ball mill, and make the mass ratio of the balls in the premix ball mill to the doping ingredients be 1.5:1, and the diameter of the balls in the SX premix ball mill is 5-7mm; then Weigh the same quality of deionized water 3 to 5 times and add it to the SX premixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com