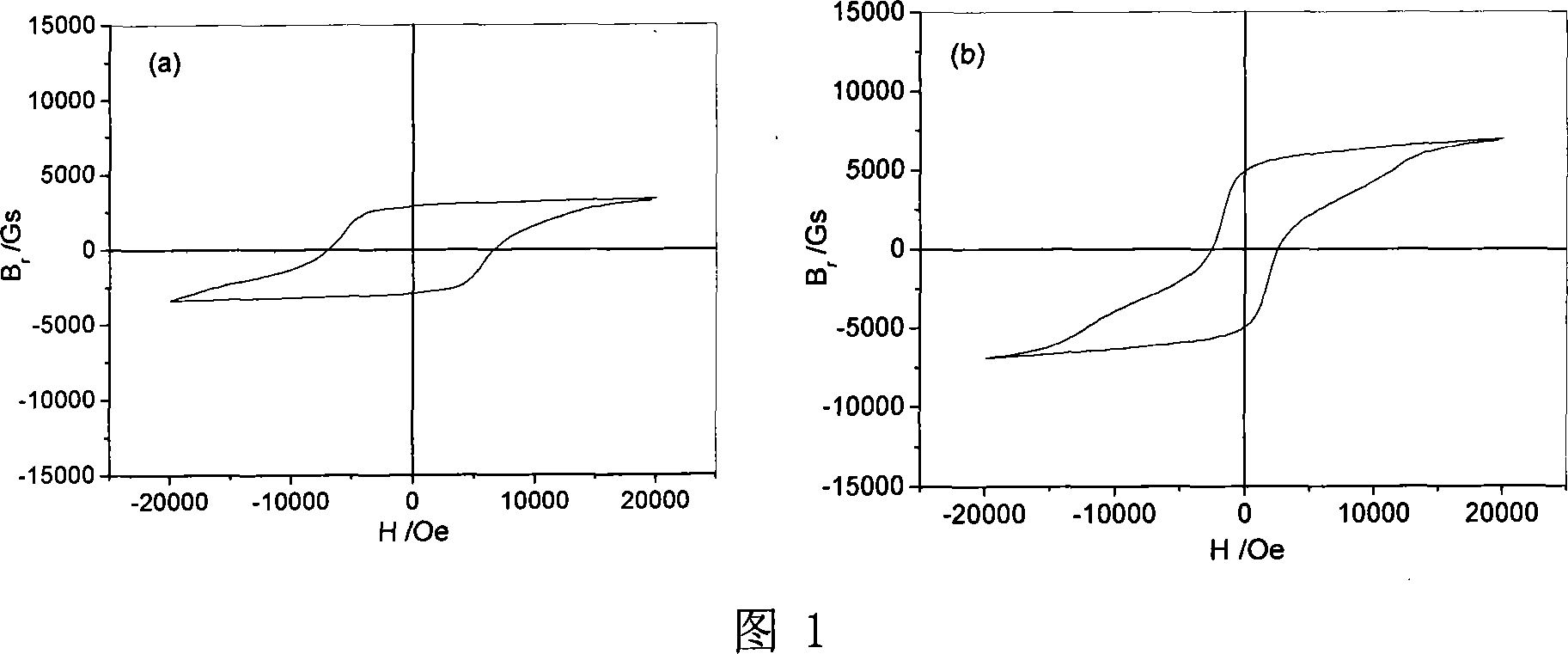

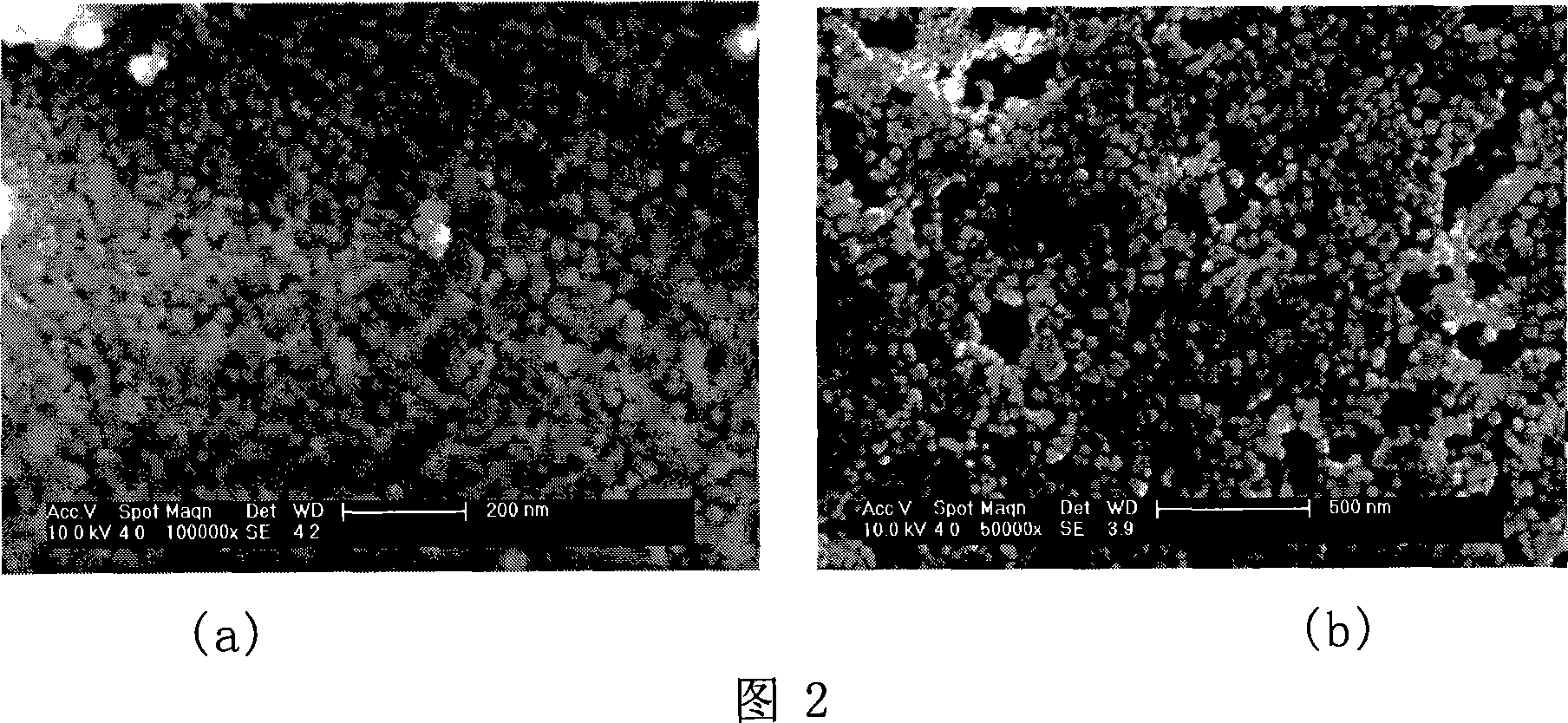

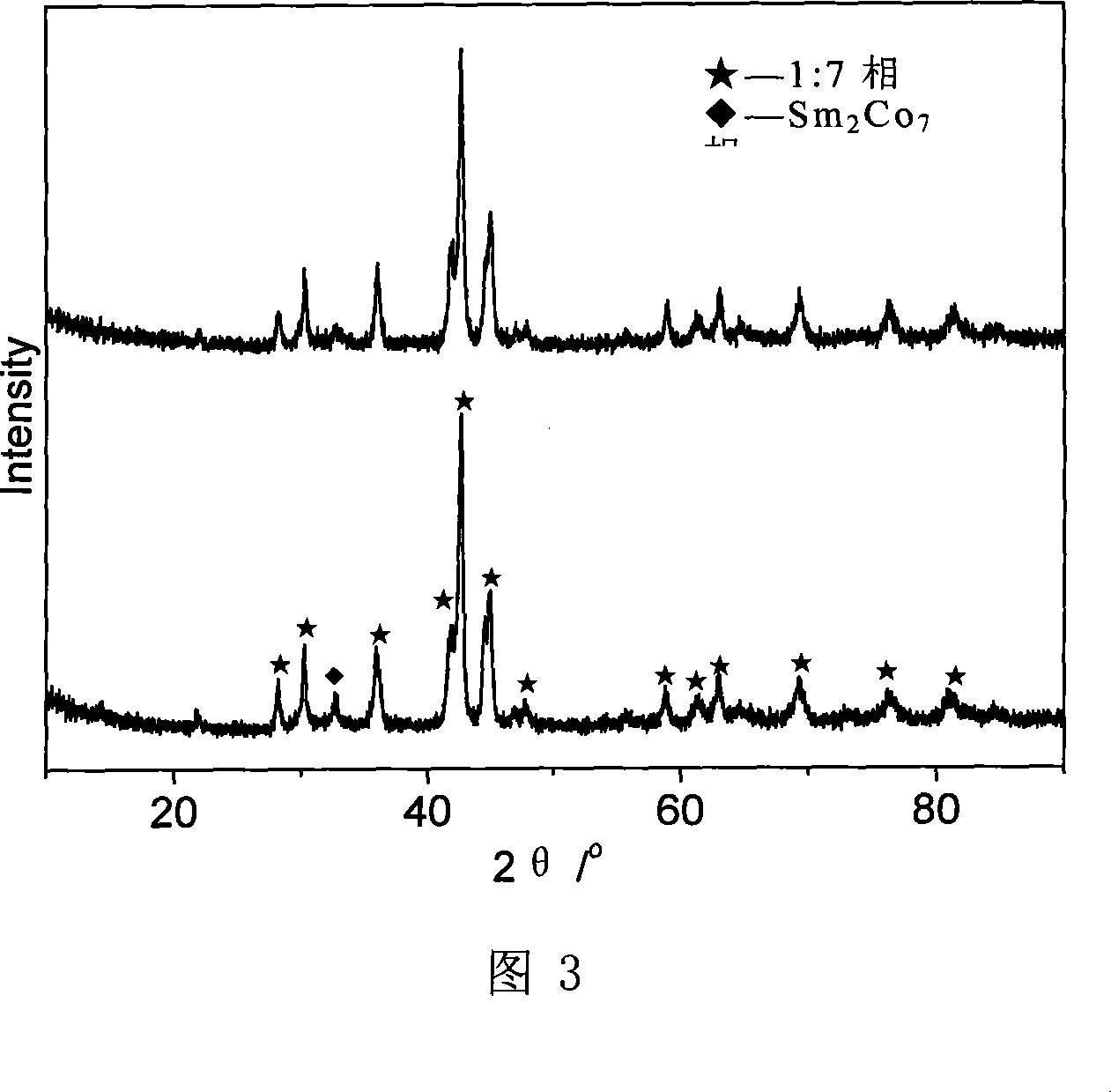

Method for preparing SmCo7 permanent-magnetic alloy with particle size smaller than 20nm

A technology of permanent magnetic alloy and particle size, which is applied in the direction of magnetism of inorganic materials, can solve the problems of using SmCo alloy, etc., and achieve the effects of excellent magnetic properties, enhanced exchange coupling, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (A), the alloy elements Sm, Co, Fe, Cu, Zr with a purity greater than 99.9% are divided into Sm (Co bal Fe 0.1 Cu 0.16 Zr 0.04 ) 6.7 After the ratio is prepared, put it in the medium frequency induction furnace and vacuumize it to 10 -3 Pa above, and then pass high-purity argon for smelting, in order to ensure the uniformity of the alloy composition, remelt twice during the alloy smelting process;

[0021] (B) Put the coarsely broken alloy ingot after smelting into a quartz tube with a nozzle at the bottom, then place the quartz tube in the center of the induction coil in the cavity of the belt throwing machine, vacuumize, and under the protection of argon, make the mother Alloy induction melting;

[0022] (C), under the action of argon pressure, the alloy melt is sprayed onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube to form an amorphous alloy strip, and the speed of the copper roller surface can be co...

Embodiment 2

[0026] (A), the alloy elements Sm, Co, Fe, Cu, Zr with a purity greater than 99.9% are divided into Sm (Co bal Fe 0.1 Cu 0.16 Zr 0.04 ) 6.7 After the ratio is prepared, put it in the medium frequency induction furnace and vacuumize it to 10 -3 Pa above, and then pass high-purity argon for smelting, in order to ensure the uniformity of the alloy composition, remelt twice during the alloy smelting process;

[0027] (B) Put the coarsely broken alloy ingot after smelting into a quartz tube with a nozzle at the bottom, then place the quartz tube in the center of the induction coil in the cavity of the belt throwing machine, vacuumize, and under the protection of argon, make the mother Alloy induction melting;

[0028] (C), under the action of argon pressure, the alloy melt is sprayed onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube to form an amorphous alloy strip, and the speed of the copper roller surface can be co...

Embodiment 3

[0032] (A), the alloy elements Sm, Co, Fe, Cu, Zr with a purity greater than 99.9% are divided into Sm (Co bal Fe 0.197 Cu 0.049 Zr 0.024 ) 7.5 After the ratio is prepared, put it in the medium frequency induction furnace and vacuumize it to 10 -3 Pa above, and then pass high-purity argon for smelting, in order to ensure the uniformity of the alloy composition, remelt twice during the alloy smelting process;

[0033] (B) Put the coarsely broken alloy ingot after smelting into a quartz tube with a nozzle at the bottom, then place the quartz tube in the center of the induction coil in the cavity of the belt throwing machine, vacuumize, and under the protection of argon, make the mother Alloy induction melting;

[0034] (C), under the action of argon pressure, the alloy melt is sprayed onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube to form an amorphous alloy strip, and the speed of the copper roller surface can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com