Fast microwave crystallizing process for preparing nanometer crystalline iron-base soft magnetic alloy

A technology of iron-based nanocrystals and soft magnetic alloys, applied in magnetic materials, manufacturing tools, magnetic objects, etc., can solve the problems of harmful magnetic properties, complicated processes, and few applications of metal alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

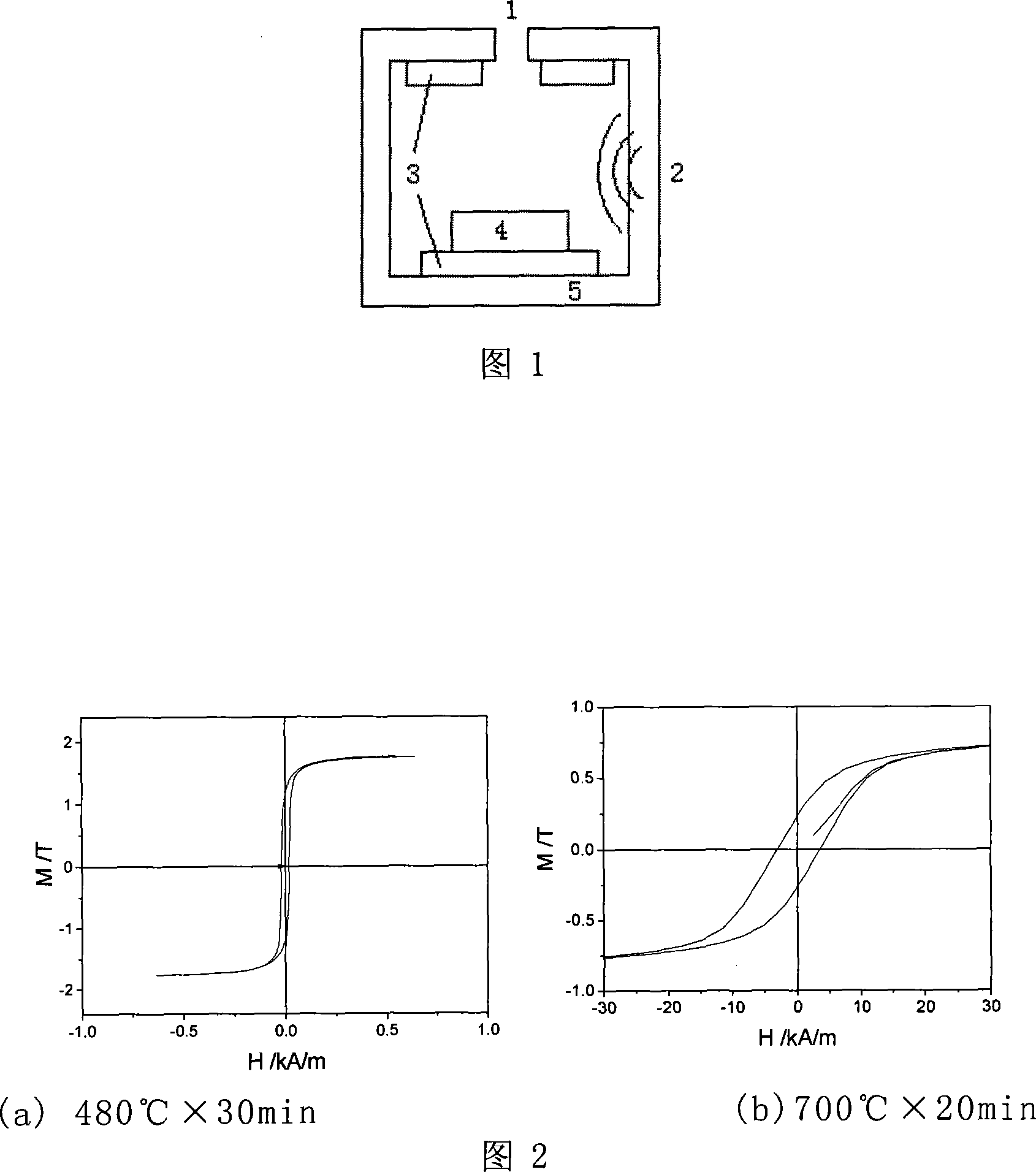

Method used

Image

Examples

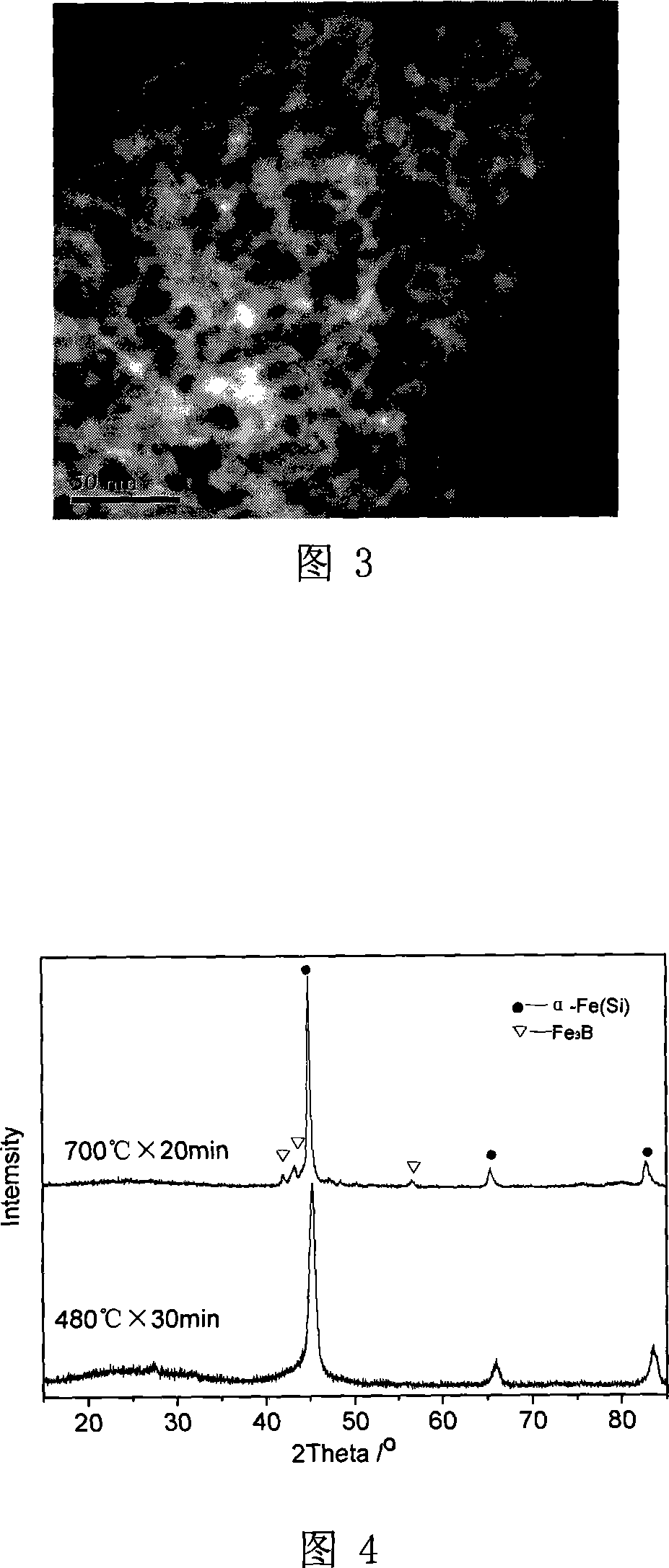

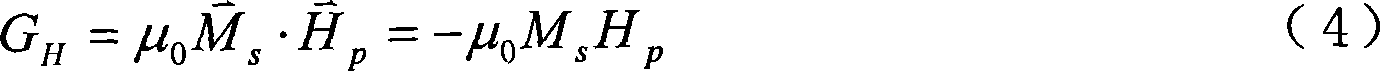

Embodiment 1

[0032] (A), Fe, Cu, Nb, Si, B with a purity greater than 99.9% are pressed as Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 After the ratio is prepared, put it into the medium frequency induction melting furnace, and vacuumize it to 10 -3 Pa above, and then pass high-purity argon for smelting, in order to ensure the uniformity of the alloy composition, remelt twice during the alloy smelting process;

[0033] (B) Put the coarsely broken alloy ingot after smelting into a quartz tube with a nozzle at the bottom, then place the quartz tube in the center of the induction coil in the cavity of the belt throwing machine, vacuumize, and under the protection of argon, make the mother Alloy induction melting,

[0034] (C), under the action of argon pressure, the alloy melt is sprayed onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube. The speed of the copper roller surface is continuously adjustable within the range of 5-45m / s. This implem...

Embodiment 2

[0037] (A), Fe, Cu, Nb, Si, B with a purity greater than 99.9% are pressed as Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 After the ratio is prepared, put it into the medium frequency induction melting furnace, and vacuumize it to 10 -3 Pa above, and then pass high-purity argon for smelting, in order to ensure the uniformity of the alloy composition, remelt twice during the alloy smelting process;

[0038] (B) Put the coarsely broken alloy ingot after smelting into a quartz tube with a nozzle at the bottom, then place the quartz tube in the center of the induction coil in the cavity of the belt throwing machine, vacuumize, and under the protection of argon, make the mother Alloy induction melting;

[0039] (C), under the action of argon pressure, the alloy melt is sprayed onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube. The speed of the copper roller surface is continuously adjustable within the range of 5-45m / s. This implem...

Embodiment 3

[0042] (A), Fe, Cu, Nb, Si, B with a purity greater than 99.9% are pressed as Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 After the ratio is prepared, put it into the medium frequency induction melting furnace, and vacuumize it to 10 -3 Pa above, and then pass high-purity argon for smelting, in order to ensure the uniformity of the alloy composition, remelt twice during the alloy smelting process;

[0043] (B) Put the coarsely broken alloy ingot after smelting into a quartz tube with a nozzle at the bottom, then place the quartz tube in the center of the induction coil in the cavity of the belt throwing machine, vacuumize, and under the protection of argon, make the mother Alloy induction melting,

[0044] (C), under the action of argon pressure, the alloy melt is sprayed onto the surface of the high-speed rotating copper roller through the nozzle at the bottom of the quartz tube. The speed of the copper roller surface is continuously adjustable within the range of 5-45m / s. This implem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com