High-temperature-resisting material as well as preparation method and application thereof

A high-temperature-resistant and refractory aggregate technology, which is applied in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as poor thermal shock performance, achieve good thermal shock performance, reduce upgrade costs, and increase tensile strength at room temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] To make a heat-resistant filter section:

[0071] 1. Taking material

[0072] Take materials according to the following ratio:

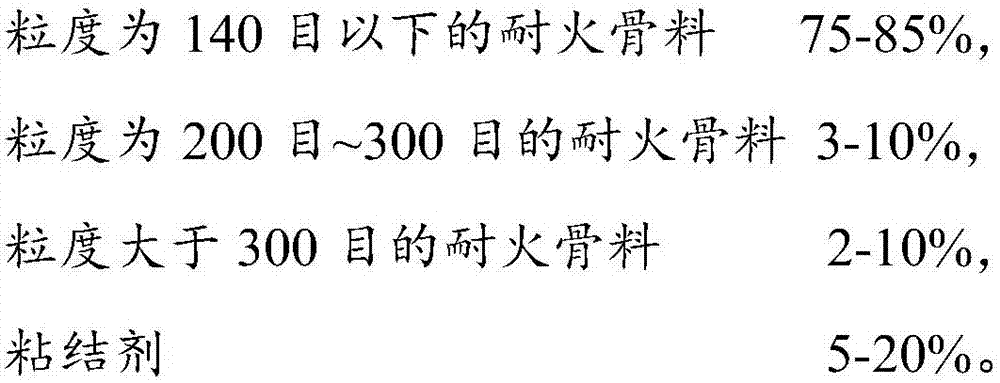

[0073]

[0074] Among them, the aggregates are all spherical or quasi-spherical.

[0075] 2. Preparation method

[0076] All raw materials are mixed in the sand mixer for 5 minutes;

[0077] The mixed wet sand is molded with a hot core box core shooter, the mold temperature is 100°C, carbon dioxide is blown in, and the mold is demoulded after 10 minutes of heat preservation; the muffle furnace is heated to 600°C at a heating rate of 4°C / min for sintering, and the heat preservation 30 minutes.

[0078] 3. Product testing

[0079] Carry out the pouring test, the pouring temperature is 1600±5°C.

Embodiment 2

[0081] The difference with Example 1 is only that the raw materials are different, as follows:

[0082] 100-140 mesh ceramsite sand 90%

[0083] 200-270 mesh clay 1%

[0084] Silica sol 9%.

Embodiment 3

[0086] The difference with Example 1 is only that the raw materials are different, as follows:

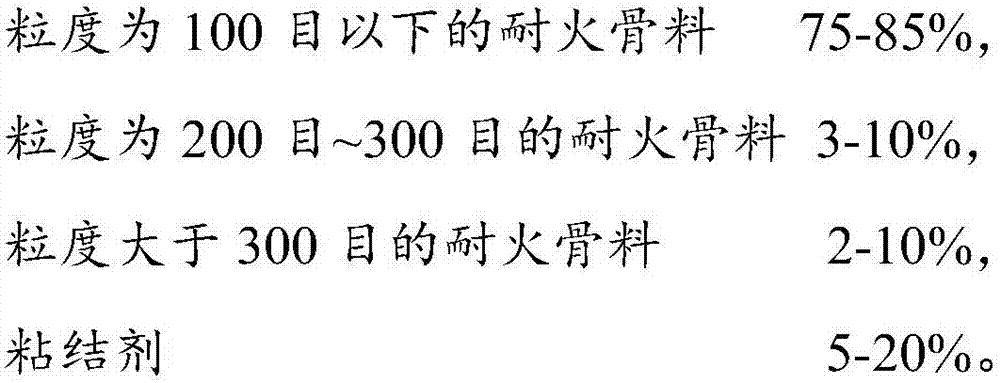

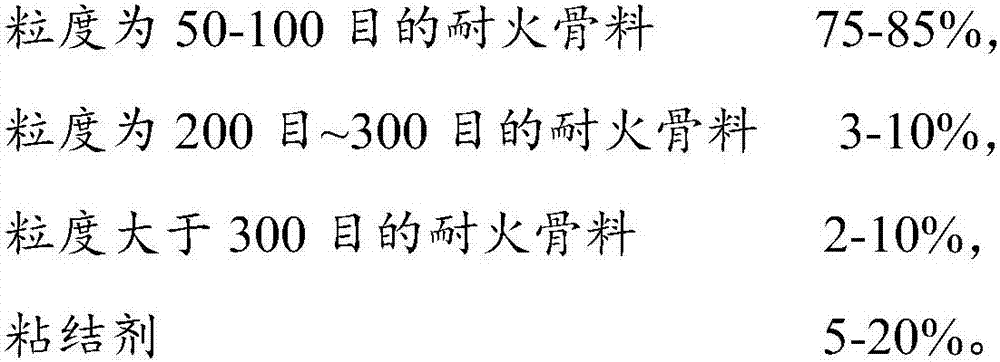

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com