Low carbon magnesia-alumina-carbon brick combining ceramics at high temperature and preparation method thereof

A carbon-magnesium-aluminum-carbon brick and ceramic combination technology, applied in the field of refractory materials, can solve the problems of high cost of graphene, difficulty in dispersion, carbonization of molten steel, etc., and achieve excellent medium and high temperature strength and thermal shock resistance, and the production process is simple. , Improve the effect of high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0048] The preparation method of low-carbon magnesia-aluminum carbon bricks in each embodiment is as follows:

[0049] First dry-mix the fused magnesia particles, high alumina bauxite particles, and zircon particles for 3 minutes, add the binder for wet mixing for 4 minutes, then add flake graphite and mix for 8 minutes, and finally add fused magnesia powder and corundum The fine powder, zircon fine powder, metal Al fiber and elemental Si fiber are mixed and milled for 12 minutes, and the material is trapped and pressed into a green embryo, which is then processed in a drying kiln at 200°C for 10 hours.

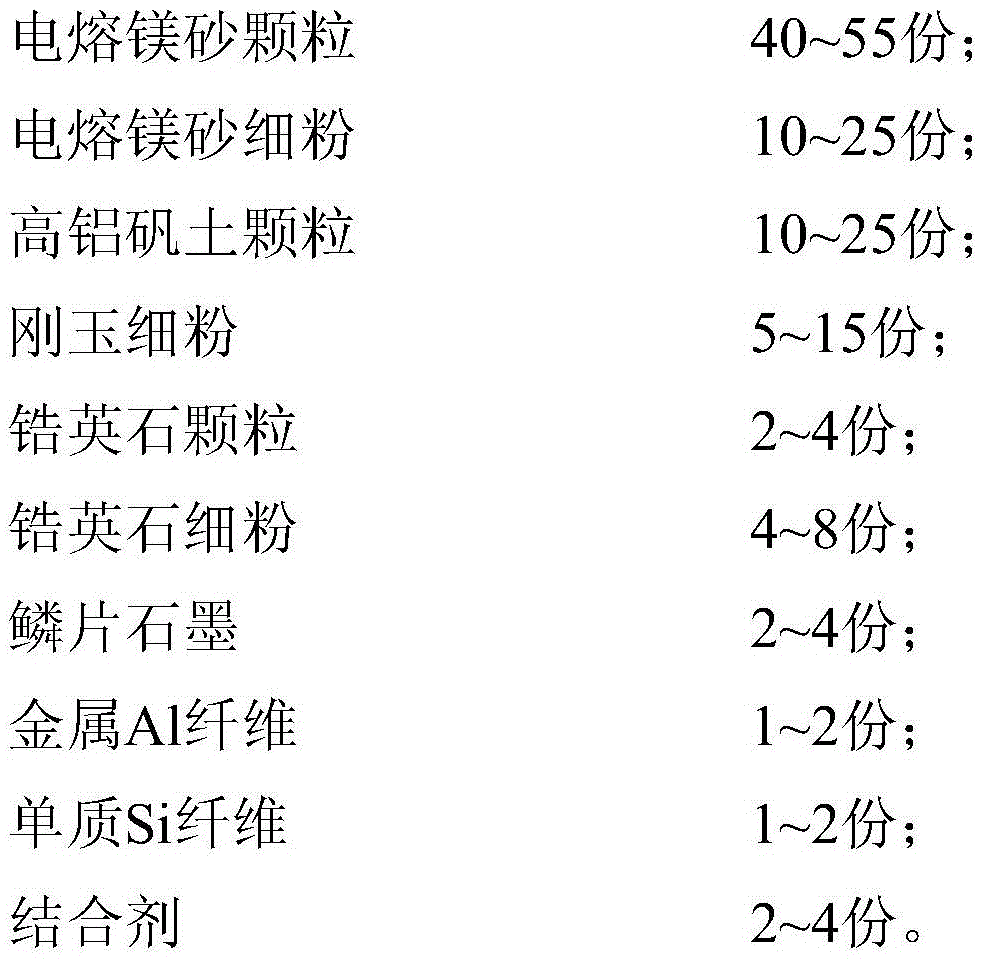

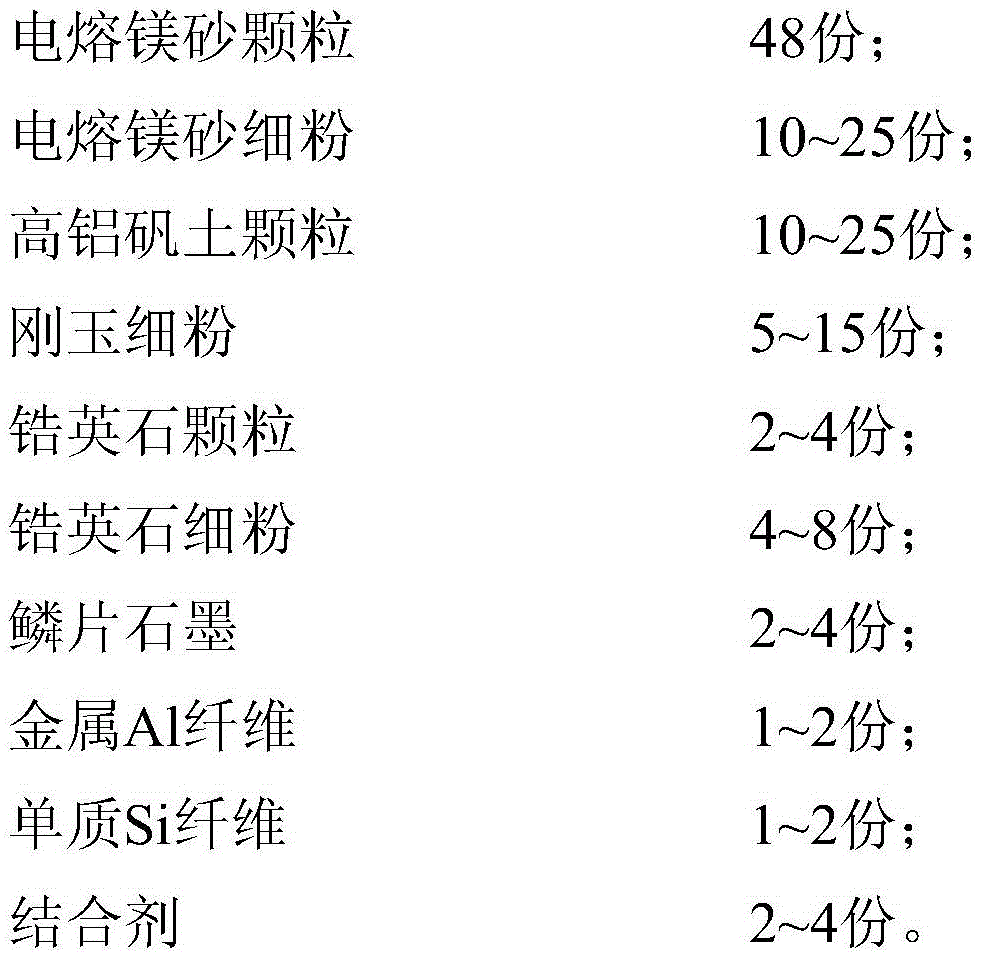

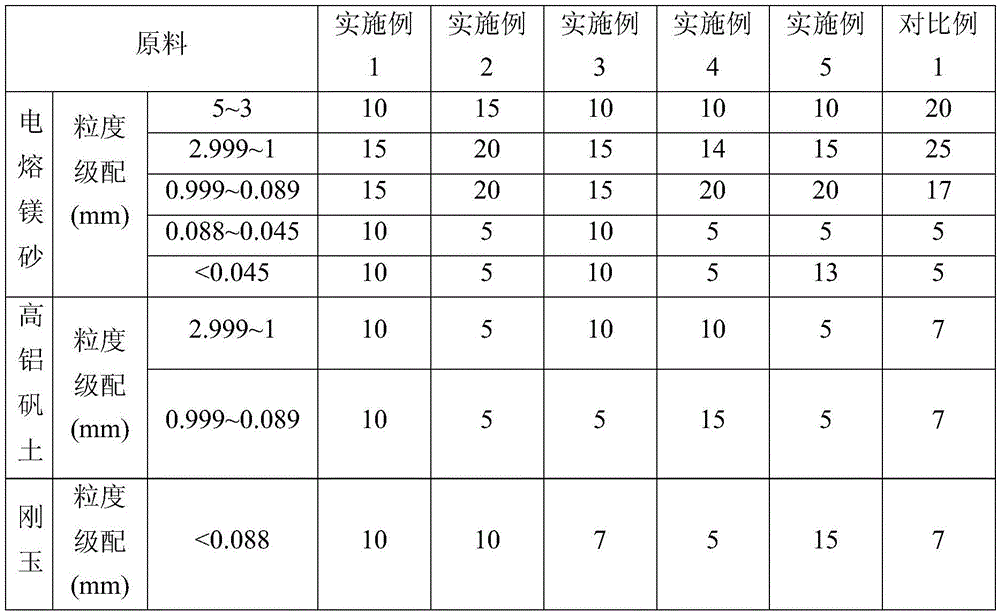

[0050] The raw material weight composition of Examples 1 to 5 is shown in Table 1, and the performance test results of the low-carbon magnesia-aluminum carbon bricks prepared in Examples 1 to 5 are shown in Table 2.

[0051] Table 1

[0052]

[0053]

[0054] The chemical composition and mass percentage of the fused magnesia particles and fused magnesia fine powder used in Table 1 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com