Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

204results about How to "Improve thermal shock performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379AImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

Infrared energy-saving coating with anti-corrosion and anti-coking functions and preparation method thereof

InactiveCN102585571AStress reliefLow shrinkageAnti-corrosive paintsInorganic adhesivesBoron nitrideManganese(III) oxide

The invention relates to an infrared energy-saving coating with anti-corrosion and anti-coking functions, which is prepared from a component A and a component B according to the weight ratio of 1: 1-2. The particle size of powder materials in the component A is not less than 280 meshes and the component A is prepared from the following powder materials according to the weight ratio: 40-60 parts of spinel structure infrared composite darkening agent, 10-30 parts of corundum powder and 3-10 parts of high-temperature binding agent. The component A further comprises an anti-coking agent, and the anti-coking agent is prepared from the following powder materials according to the weight ratio: 3-10 parts of graphite, 0-10 parts of boron nitride and 1-5 parts of manganese sesquioxide. The component B is of a film-forming substance and prepared from the following raw materials according to the weight ratio: 60-80 parts of water glass, 10-30 parts of silica sol and 0-20 parts of water-borne resin solution. The invention further discloses a preparation method of the coating. The coating provided by the invention has the advantages: corrosion prevention, capability of reducing coking, high temperature resistance and excellent infrared radiation performance.

Owner:KING STRONG MATERIAL ENG LTD

Water gap lining layer material for continuous casting

The invention discloses a water gap lining layer material for continuous casting. The material is prepared from the following components in percent by weight: 20-60 percent of corundum, 0-30 percent of electrofusion zirconium mullite, 0-40 percent of fused silica, 3-40 percent of ceramic hollow sphere, 1-10 percent of light burning alumina, 2-6 percent of sintering assistant, 2-6 percent of phosphate bonding agent and 4-8 percent of solid phenolic resin bonding agent. A water gap for continuous casting produced by adopting the material is suitable for cold casting, and a lining basically has no nodule blocking phenomenon; the lining has high strength and does not have phenomena of chambering and abnormal erosion; a water gap has long service life; and the continuous casting production efficiency is improved.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

Enhanced metal ceramic abrasion-resistant composite material and preparation method thereof

The invention discloses an enhanced metal ceramic abrasion-resistant composite material and a preparation method thereof. The composite material is composed of, by mass, 25-35 parts of nano molybdenum carbide, 15-25 parts of nano ceramic powder, 10-15 parts of glass fiber, 5-10 parts of cobalt, 10-15 parts of chrome, 10-15 parts of titanium carbonitride, 1-3 parts of zirconium oxide, 3-5 parts of silicon oxide, 8-10 parts of cerium oxide, 1-3 parts of aluminium oxide, 5-10 parts of niobium carbide, 5-15 parts of silicon carbide, 1-3 parts of vanadium carbide, 4-9 parts of copper, 1-5 parts of titanium powder, 1-5 parts of coupling agents, 1-3 parts of antistatic agents and 1-3 parts of curing agents. The preparation method of the enhanced metal ceramic abrasion-resistant composite material just comprises mixing, drying, sintering and cooling. The metal ceramic composite material has good properties that the bending resistant strength is up to 2500 MPa and the Rockwell hardness is up to 93; in addition, the metal ceramic composite material also has good properties of abrasion resistance and high temperature resistance; the preparation method is simple and feasible and suitable for application and popularization on a large scale.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

Stemming and purpose thereof

Owner:XINJIANG BAYI IRON & STEEL

A coal ash-iron tailing based porous heat insulation material and a preparation method thereof

InactiveCN102167618AReduce pollutionImprove resource utilizationCeramic materials productionCeramicwareFoaming agentResource utilization

The invention belongs to the field of novel heat insulation material technology and specifically relates to a coal ash-iron tailing based porous heat insulation material and a preparation method thereof. The preparation method of the coal ash-iron tailing porous heat insulation material is characterized by mixing solid mixed powder and water, granulating and burning, wherein the water, by mass, accounts for 8% to 15% of the solid mixed powder, the solid mixed powder is prepared by mixing a powdery solid waste, a binder, a fluxing flexibilizer and a composite foaming agent, and the solid mixed powder comprises, by mass, 30% to 60% of the powdery solid waste, 30% to 50% of the binder, 5% to 20% of the fluxing flexibilizer and 5% to 10% of the composite foaming agent. The porous heat insulation material is characterized by high compressive strength, heat insulation and lightness and the method not only improves the use ratio of resources, but also reduces the environmental pollution caused by the waste.

Owner:WUHAN UNIV OF TECH

Taphole stemming used for oversize blast furnaces

Belonging to the technical field of refractory materials, the invention relates to taphole stemming used for oversize blast furnaces over 4500m<3>. The taphole stemming used for oversize blast furnaces comprises by weight: 25-50% of brown corundum, 5-20% of silicon carbide, 7-25% of ferro-silicon nitride, 15-30% of a composite carbon material, 5-15% of kaolin, 3-7% of composite refractory material micropowder, and 1-5% of composite metal powder. The stemming is prepared by the steps of: conducting weighing and burdening according to the above ratio of various raw materials, mixing them well and adding a coal tar binder accounting for 15-25% of the total weight of the additionally added dry materials, then conducting rolling and mulling so as to obtain a mud material. The stemming of the invention has good comprehensive performance, stable taphole depth, long tapping time, good erosion and scouring resistance, as well as good construction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

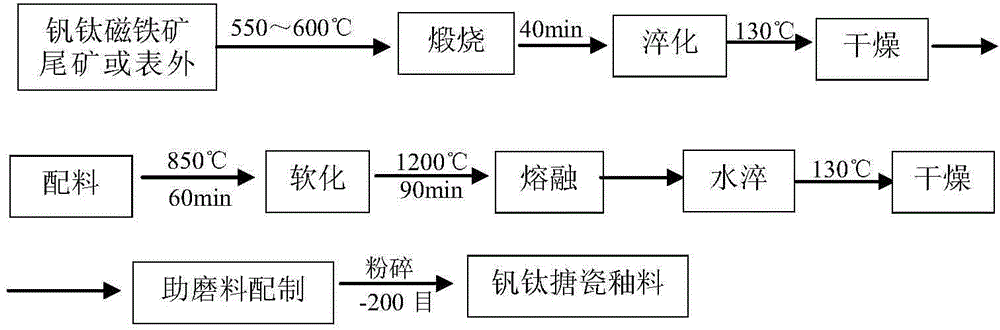

Vanadium-titanium enamel glaze material, and preparation method thereof

The invention belongs to the technical field of enamel material, and specifically relates to a vanadium-titanium enamel glaze material, and a preparation method thereof. The preparation method is used for solving technical problems that cost of a conventional vanadium-titanium enamel glaze material is high, glossiness of enamel glaze obtained via sintering is not high enough, fishscaling is observed, and acid and alkali resistance is not high enough. The vanadium-titanium enamel glaze material is prepared from, by mass, 22 to 28 parts of pretreated vanadium-titanium magnetite titanium separation tailing or vanadium-titanium boundary ore, 20 to 22 parts of feldspar powder, 5 to 8 parts of quartz sand, 24 to 26 parts of borax, 1.5 to 2 parts of sodium nitrate, 3.5 to 5.5 parts of lithium carbonate, 5 to 7 parts of fluorite powder, 0.1 to 0.3 part of sodium fluosilicate, 3 to 5 parts of cryolite, 2 to 4 parts of limestone, 3 to 4 parts of cobalt nitrate, 1 to 2 parts of nickel nitrate, 2 to 3 parts of sodium vanadate, and 1 to 2 parts of antimony oxide. Firm combination of the vanadium-titanium enamel glaze material with carbon steel billet can be realized; acid and alkali resistance is higher than that stipulated by national standard; and the vanadium-titanium enamel glaze material can be used for a plurality of matrixes such as hot-rolled carbon steel and cast iron.

Owner:PANZHIHUA UNIV

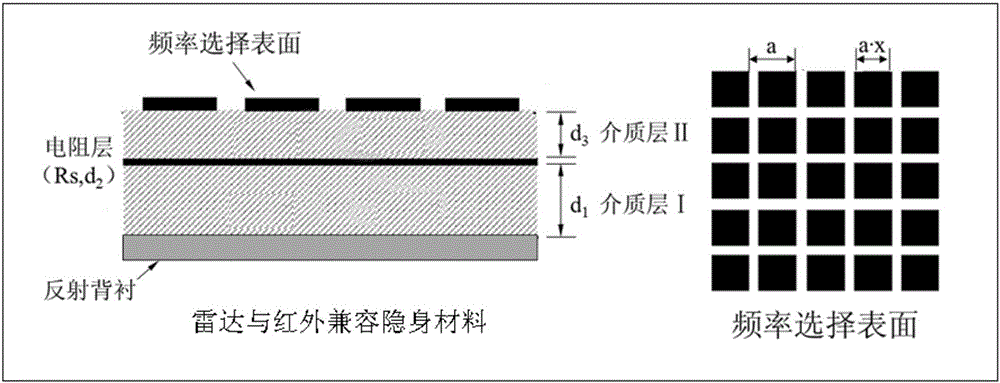

High-temperature-resistant radar and infrared compatible stealth material based on frequency selective surface and preparation method of high-temperature-resistant radar and infrared compatible stealth material

ActiveCN106003864AGood high temperature resistanceStrong antioxidantLamination ancillary operationsVacuum evaporation coatingOxideMetal coating

The invention discloses a high-temperature-resistant radar and infrared compatible stealth material based on a frequency selective surface. The high-temperature-resistant radar and infrared compatible stealth material comprises a dielectric layer I, a resistance layer, a dielectric layer II and the frequency selective surface from inside to outside sequentially, wherein the dielectric layer I and the dielectric layer II are made of oxide fiber reinforced oxide based composite materials; the resistance layer mainly comprises a high-temperature-resistant resistance coating; the frequency selective surface mainly comprises an anti-oxidative metal coating with periodical patterns, high temperature resistance and low infrared emittance. The preparation method comprises steps as follows: the dielectric layer I is prepared firstly, and the resistance layer is prepared on the dielectric layer I with a silk-screen printing technology; then the dielectric layer II is prepared on the resistance layer; finally, the frequency selective surface is prepared on the dielectric layer II with a physical deposition technology and a laser etching technology, and the stealth material is prepared. The radar and infrared compatible stealth material can be resistant to high temperature of 1,000 DEG C or higher, and has better high temperature resistance and excellent oxidation resistance.

Owner:NAT UNIV OF DEFENSE TECH

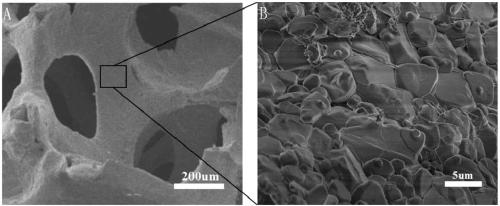

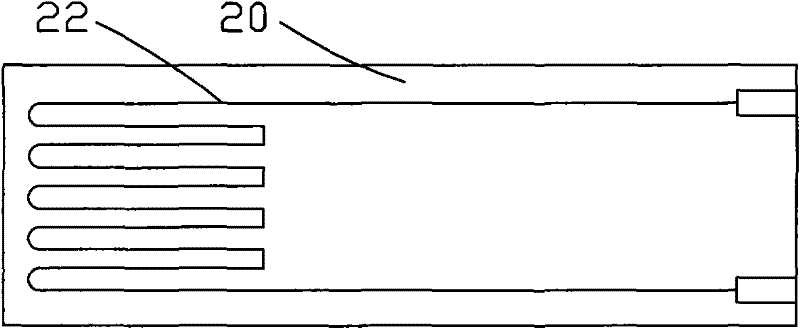

Silicon nitride composite ceramics heater

InactiveCN101318822AGood thermal conductivityHigh thermal conductivityTemperature resistanceThermal conductivity

The invention discloses a silicon nitride composite ceramic heating element which is prepared by heat pressing and sintering a heating source and a silicon nitride composite ceramic heating matrix, wherein, the heating source is a tungsten alloy wire or a tungsten alloy printing conductive film, and the silicon nitride composite ceramic heating matrix comprises the following compositions by weight percentage: 71 to 87.05 percent of Si3N4, 0.75 to 6 percent of MgAl2O4, 3 to 10 percent of Y2O3, 0.1 to 2 percent of Ta2O5, 0.1 to 4 percent of La2o3, 1.5 to 6 percent of AlN, 5 to 12 percent of BN, and 0.1 to 5 percent of BaO. The product has better thermal conductivity, the coefficient of the thermal conductivity improved by 11 to 17 percent, better high temperature resistance and thermal shock resistance, good corrosion resistance, high intensity, long service life and safe and reliable use.

Owner:冷水江市明玉陶瓷工具有限责任公司

High temperature resistant environment-friendly nano modified inorganic coating, its preparation method and application

The invention, relating to an alloy high temperature protection technology, discloses a high temperature resistant environment-friendly nano modified inorganic coating, its preparation method and application. The coating comprises liquid potassium metasilicate, aluminium trippolyhosphate, aluminium oxide, nano metal powder and Zn powder. The preparation method comprises the following steps: uniformly mixing aluminium trippolyhosphate, aluminium oxide, nano metal powder and Zn powder to obtain a mixture; then, adding the mixture in potassium metasilicate with stirring and fully mixing; adding distilled water in the mixture obtained by the last step, stirring in a mixer with the rotating speed of 2000-2600 rpm for 5-30 min, and then filtering with 200-mesh sieve to obtain the coating, wherein, the weight ratio of distilled water to the mixture obtained by the last step is 1: (3-10). According to the invention, the problems that inorganic coating is easy to peel of base material and the like existing in the prior art are solved. The coating has the advantages of high temperature resistance, corrosion resistance, water resistance, good thermal shock resistance, no toxicity, no pollution, and favorable environmental protection, and is suitable for alloy products operating in high temperature environment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation methods of high temperature resistant anticorrosion potassium silicate coating and corresponding coat

ActiveCN102558924AImprove antioxidant capacityAccelerated corrosionAlkali metal silicate coatingsAnti-corrosive paintsPotassium silicateSilicic acid

The invention relates to preparation methods of a high temperature resistant anticorrosion potassium silicate coating and a corresponding coat. The high temperature resistant anticorrosion potassium silicate coating is formed by a solute and a solvent, wherein the solute comprises a component A liquid potassium silicate having a module of 3.0-4.0 and a weight accounting for 30-80% of the total weight of the coating, and a component B which comprises nanometer Cr powder having a weight accounting for 1-15% of the total weight of the coating, aluminum triphosphate having a weight accounting for 3-20% of the total weight of the coating, Zn powder having a weight accounting for 5-20% of the total weight of the coating and Al2O3 having a weight accounting for 10-50% of the total weight of the coating; and the solvent is water, and the weight ratio of the solvent to the solute is 1:3-10. The method for preparing the coat through utilizing the coating comprises the following steps: spraying or brushing the coating on the surface of a sandblasted steel iron part, drying the surface for 5-10min, carrying out temperature maintenance for 0.5-4h according to a furnace temperature of 200-260DEG C, taking out the part, and air-cooling the part to obtain the coat. The coat of the invention has the characteristics of high temperature resistance, anticorrosion and water resistance, and has the advantages of good thermal shock resistance, nontoxicity, no pollution, and environmental protection benefiting.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-calcium low-iron magnesian dry method ramming mass and its production method

The present invention provides one kind of high calcium low iron magnesia material as refractory ramming material and its preparation process. The present invention has materials including light burnt magnesia powder, light burnt dolomite powder, fused magnesia, superfine fused magnesia powder, iron oxide scale as rolling waste, iron oxide powder as steel making side product, and diesel oil. The present invention has high heat resistance, high load softening performance, high breaking strength, high heat shock performance, high slag corrosion resistance and thin furnace bottom sintered layer. It is especially new steel making process, and can maintain excellent performance at high temperature.

Owner:海城华宇耐火材料有限公司

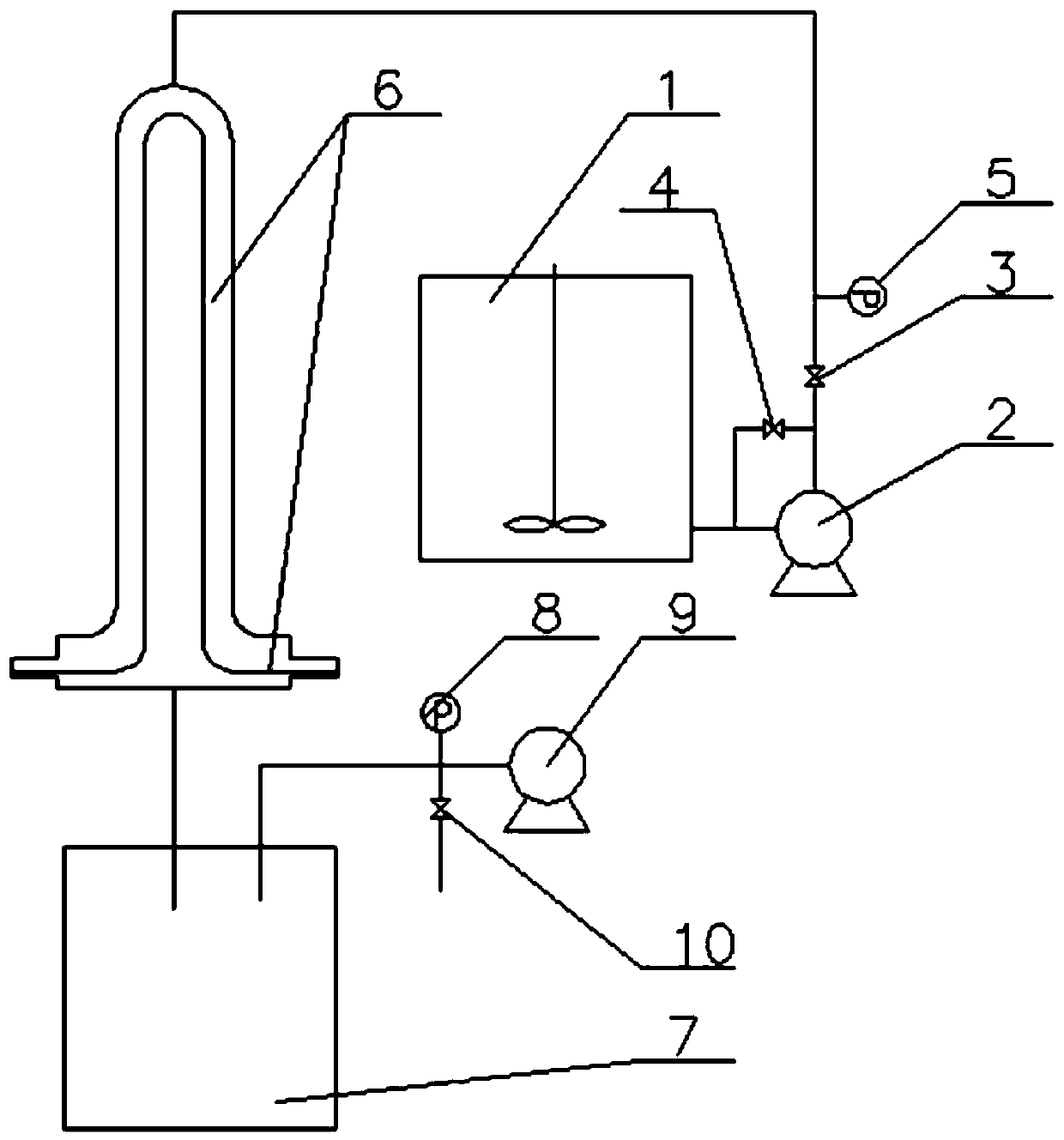

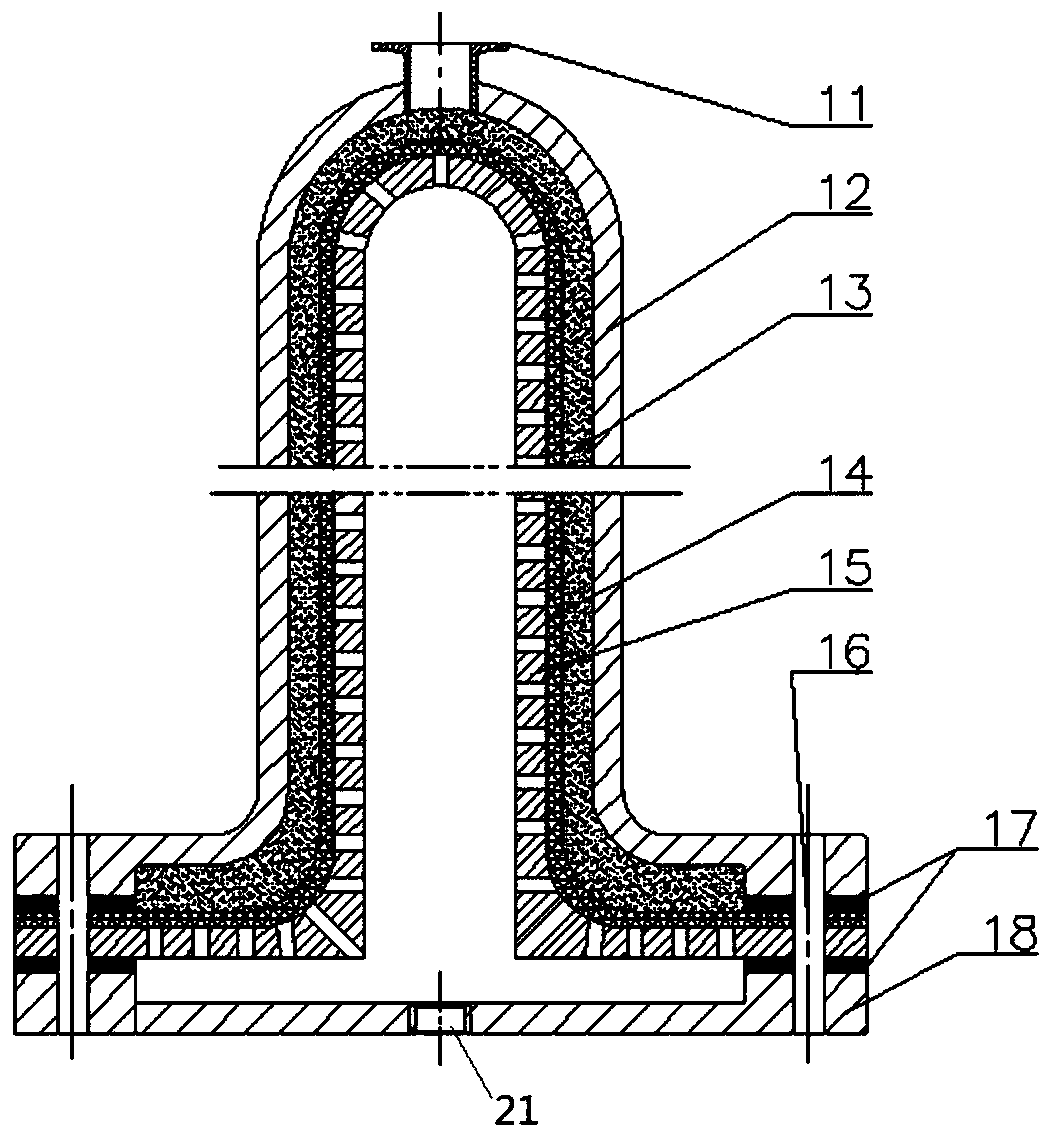

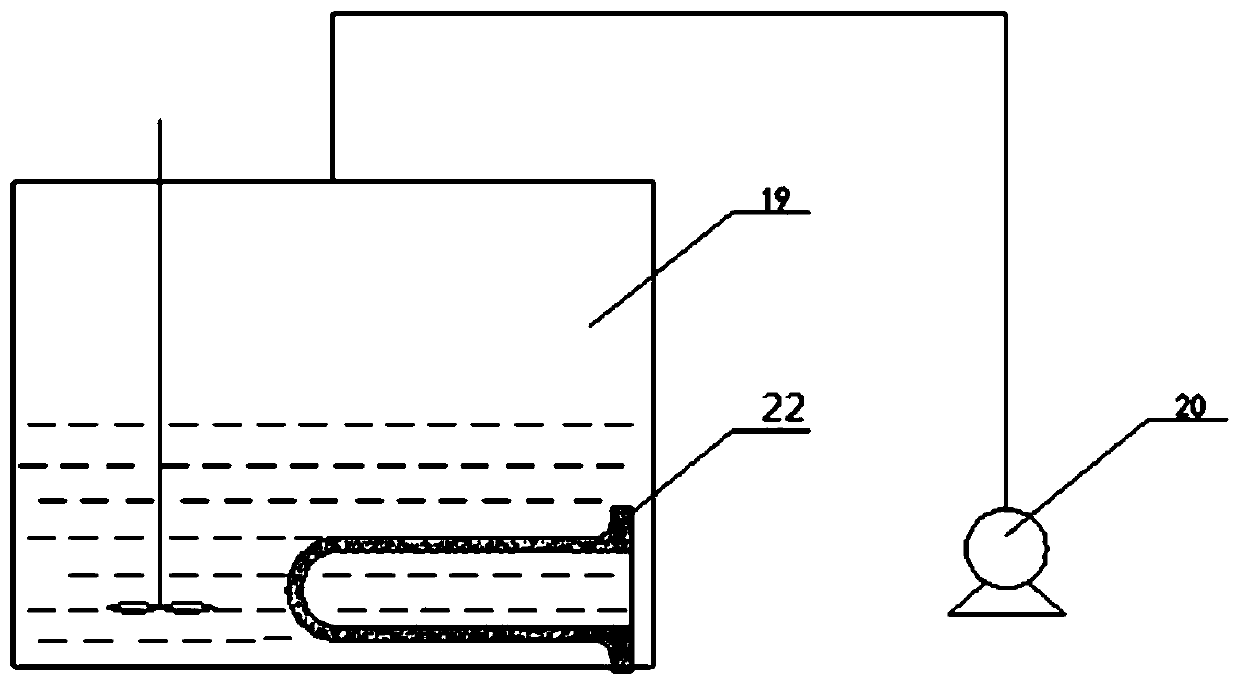

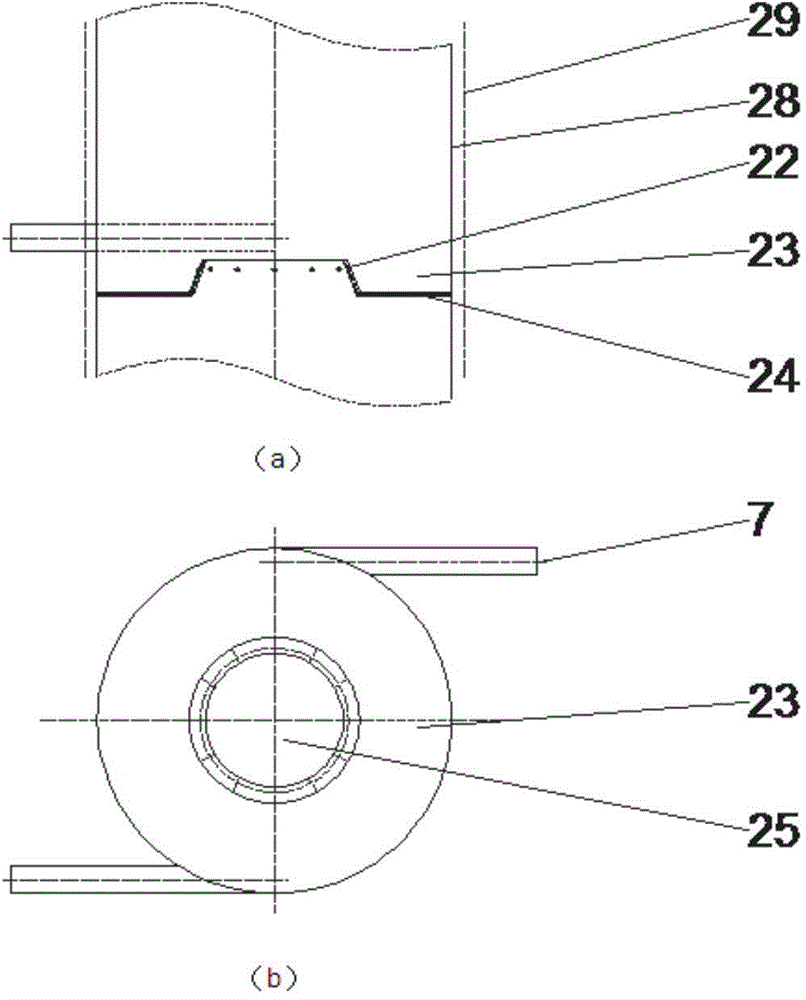

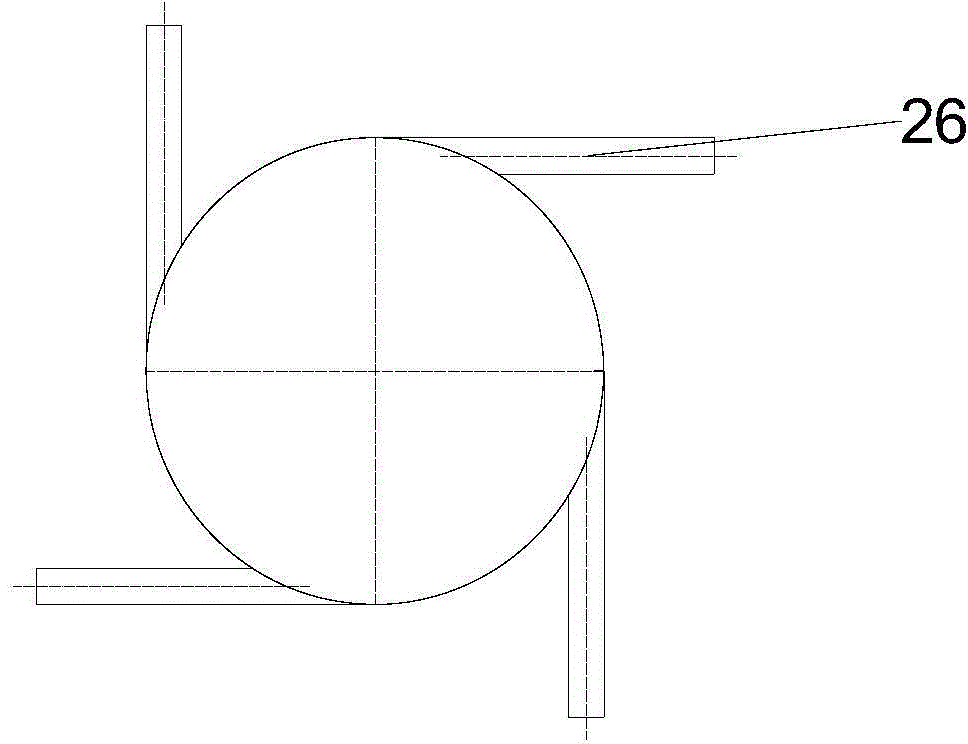

Ceramic fiber filtering tube, preparation method and pressurization and suction forming device

ActiveCN110038368AHigh strengthUniform densityDispersed particle filtrationMembrane filtersFiberVacuum pressure

The invention discloses a ceramic fiber filtering tube, a preparation method and a pressurization and suction forming device. The pressurization and suction forming device comprises a forming mold, apressurization pump, a dosage bunker, a vacuum pump and a vacuum filtrate tank, wherein the forming mold comprises an inner template, an upper template, a lower template, filter cloth and a blank tubecavity; the filter cloth and the blank tube cavity are arranged between the inner template and the upper template respectively; the filter cloth is arranged on the inner template; the lower templateis connected with the upper template; the upper and lower flange faces of the inner template are provided with sealing gaskets respectively; the top of the upper template is provided with a quick coupler for charging water or slurry; the quick coupler is connected with the pressurization pump; the pressurization pump is connected with the dosage bunker; the middle part of the lower template is provided with a water outlet for discharging water or slurry; the water outlet is connected with the vacuum filtrate tank; the vacuum filtrate tank is connected with the vacuum pump; a vacuum pressure gauge and a blow-off valve are arranged between the vacuum filtrate tank and the vacuum pump. The pressurization and suction forming device adopts a pressurization forming and suction sizing demolding form, is simple in structure, is convenient for forming, and is convenient to operate.

Owner:HEFEI HEYI ENVIRONMENTAL PROTECTION TECH ENG

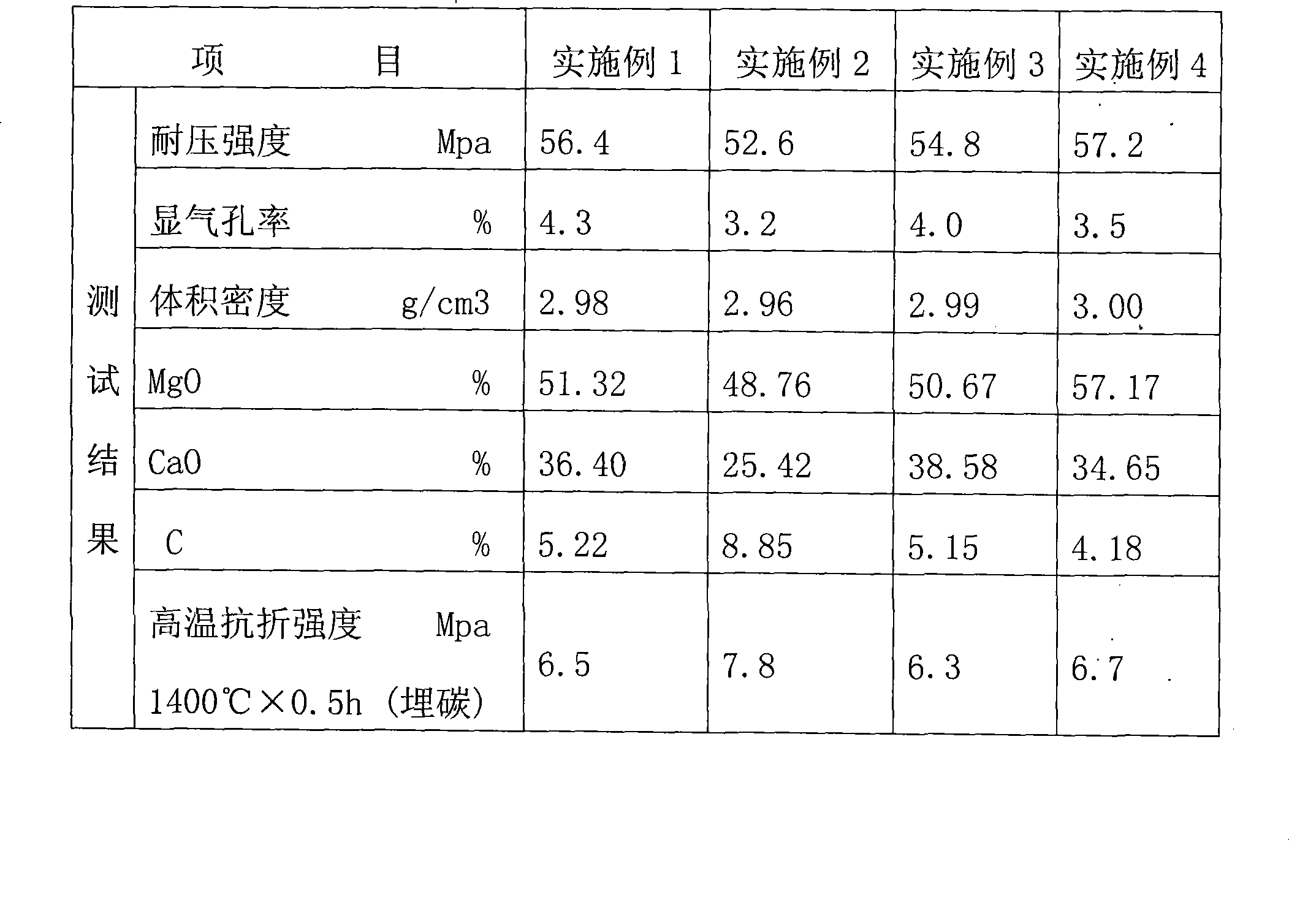

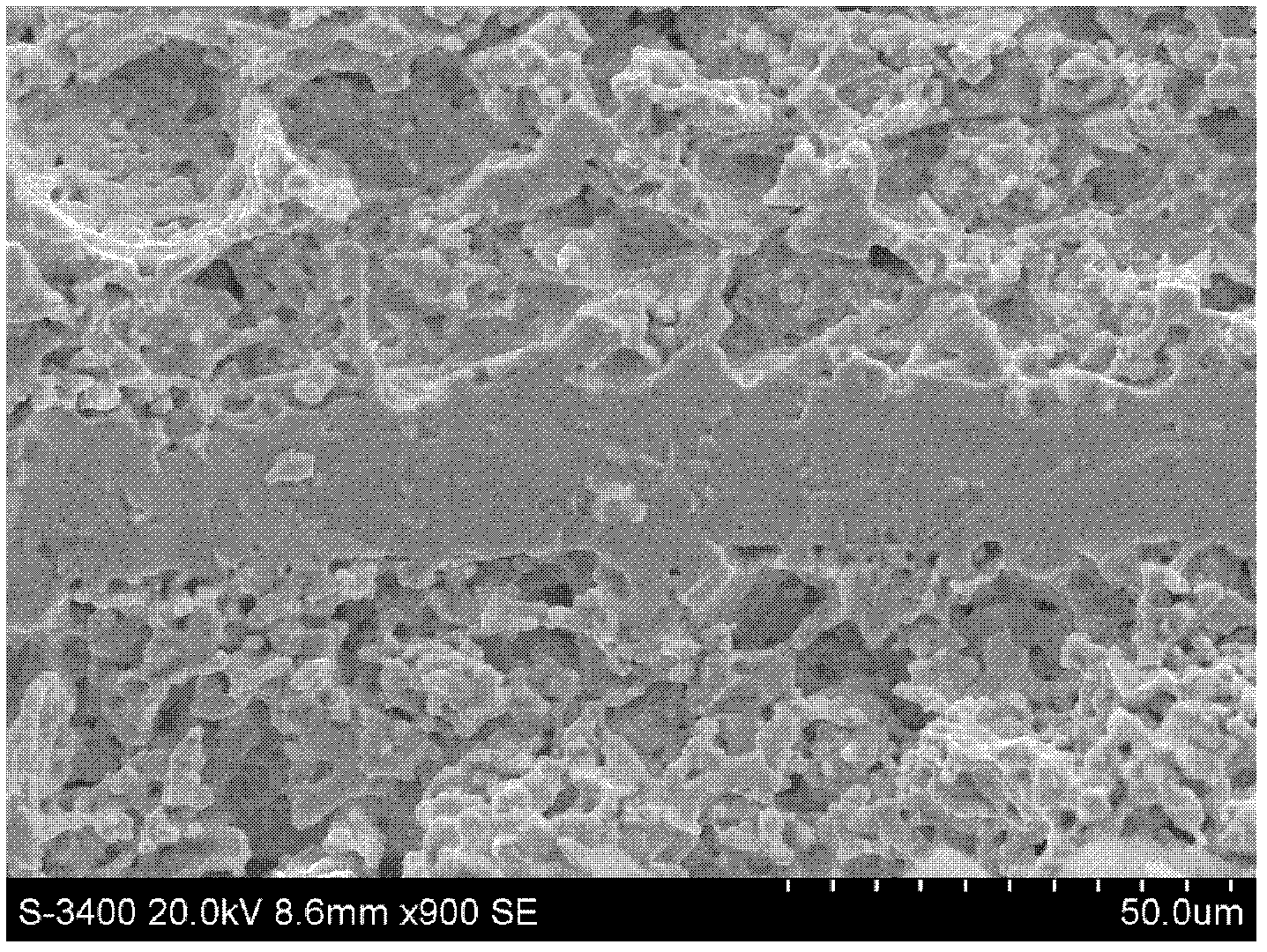

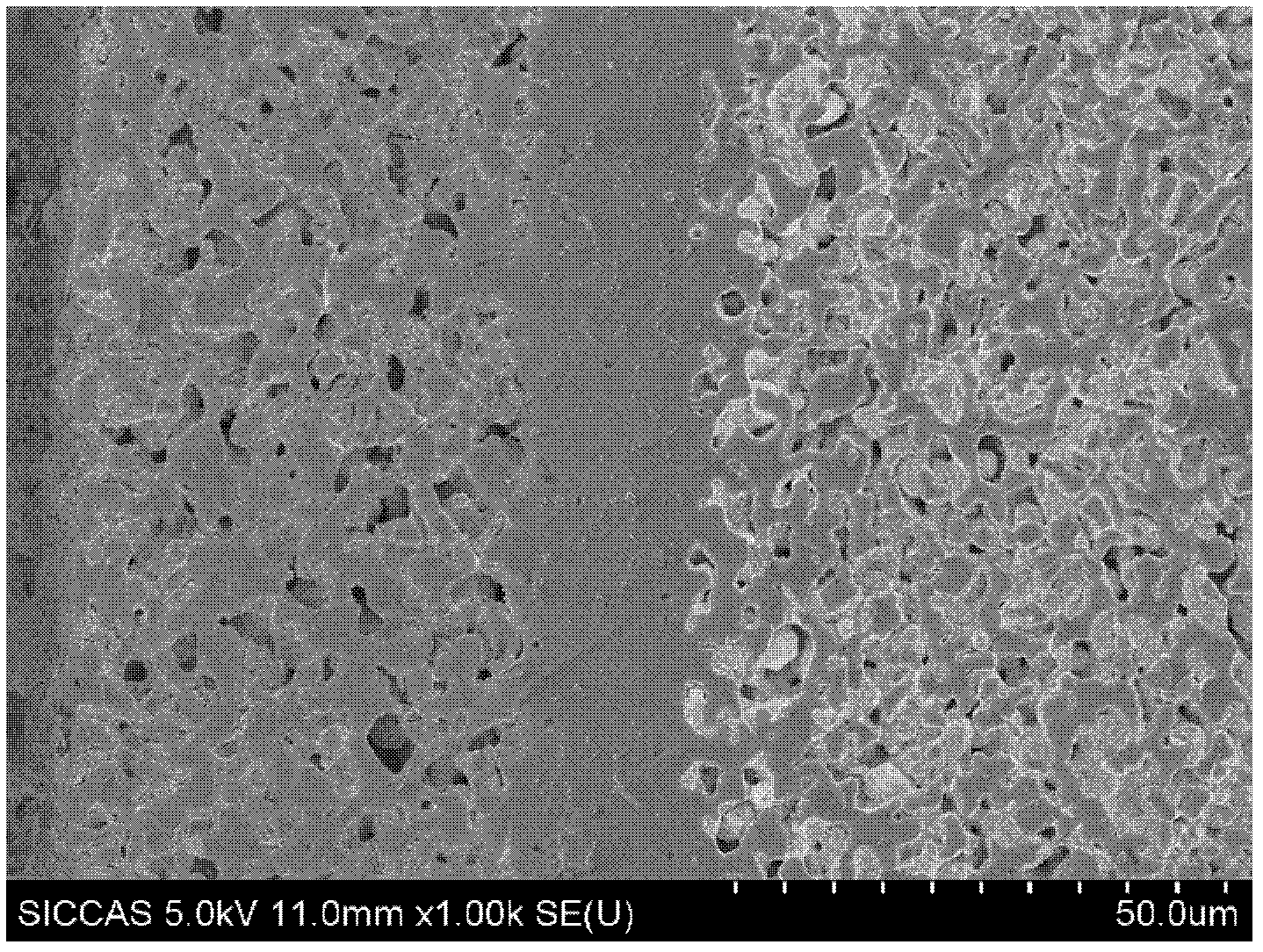

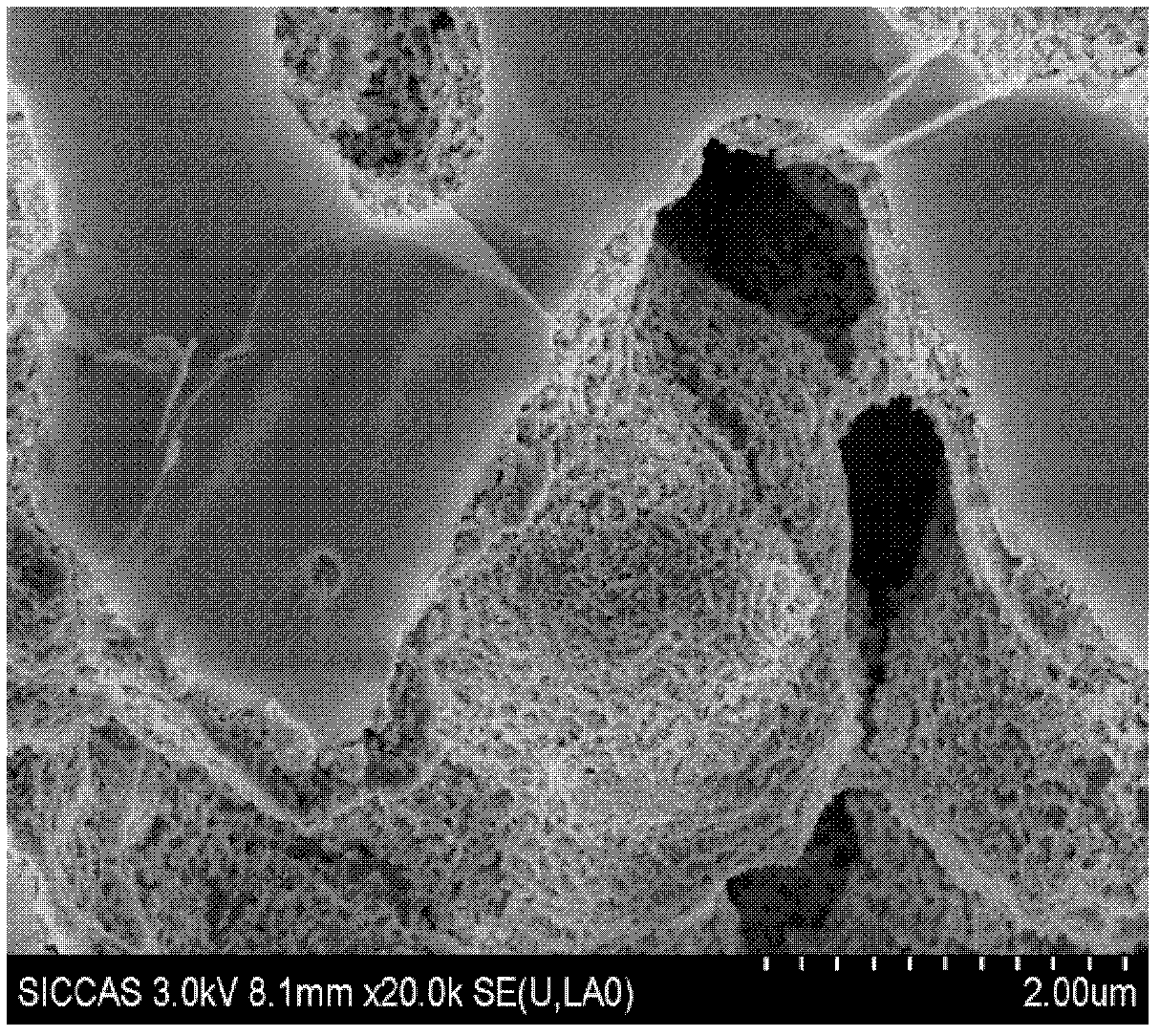

High-calcium magnesia-calcium-carbon brick and manufacturing method thereof

The invention relates to a high-calcium magnesite-dolomite carbon brick and a method for making the same. The invention adopts a technical proposal that the high-calcium magnesite-dolomite carbon brick is made from the following raw materials by weight percentage: 40 to 60 percent of 1 to 5mm calcium magnesite clinker, 5 to 15 percent of less than or equal to 1mm calcium magnesite clinker, 1 to 15 percent of less than or equal to 1mm magnesite clinker, 20 to 30 percent of less than or equal to 0.088mm magnesite powder, 2 to 8 percent of graphite, 0.5 to 3 percent of less than or equal to 0.088mm aluminum powder, 0.5 to 3 percent of less than or equal to 0.088mm silicon powder, 0.5 to 3 percent of less than or equal to 0.088mm silicon carbide powder and 3 to 6 percent of phenolic resin. The method comprises: mixing the raw materials uniformly according to a mixture ratio and pressing the well mixed raw materials into green bricks; keeping the green bricks at 220 DEG C for 4 to 7 hours and drying the green bricks for more than 20 hours totally; and performing hydration-proof treatment to the green bricks after the green bricks are moved out of a drying kiln. The brick is alkaline and can overcome the defects of molten steel pollution and unstable service life.

Owner:DASHIQIAO JINLONG REFRACTORY MATERIAL

Non-sintering sialon bonded corundum-spinel castable and method for preparing RH (Ruhstahl Hausen) insert tube prefabricated member inner core with same

ActiveCN103880442AImproved thermal shock stabilityImprove high temperature mechanical propertiesMetal powderUltimate tensile strength

The invention discloses a non-sintering sialon bonded corundum-spinel castable and a method for preparing an RH (Ruhstahl Hausen) insert tube prefabricated member inner core with the same. The castable comprises the following raw materials: 50-72% of fused white corundum, 8-21% of spinel, 2-9% of silicon metal powder, 3-11% of 200-mesh fused white corundum, 2-6% of alpha-alumina and 3-7% of rho-alumina; besides, an additive FS60 with weight accounting for 0.04-0.13% of total weight of various raw materials is added. The castable and the method have the beneficial effects that as the castable adopts sialon bonding, impacts of existence of CaO in existing traditional castable cement on the high temperature property and corrosion resistance of the prefabricated member are overcome, thus greatly improving the high temperature strength and thermal shock resistance of the castable; in combination with the 1700 DEG C service conditions of the product, generation of sialon in the service process is achieved, the production cost is effectively reduced, and the service life of the product is prolonged by 30-50%.

Owner:郑州市裕丰耐火材料有限公司

Low-temperature solid oxide fuel cell and making method thereof

ActiveCN103219525ASimple processEasy industrial scale-upFinal product manufactureCell electrodesOxide ceramicFuel cells

The invention relates to a low-temperature solid oxide fuel cell and a making method thereof. The structure of the low-temperature solid oxide fuel cell comprises an anode film deposited on the inner wall of a porous perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta composite film, a cathode film deposited on the inner wall of the porous perovskite structure oxide ceramic La1-xSrxGa1-yMgXO3-delta composite film, and a compact perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta electrolyte film positioned between the anode film and the cathode film, wherein each of x, y and delta is equal to or more than 0 and equal to or lower than 0.2, and the perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta composite film is formed through a porous perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta substrate, the perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta and a porous perovskite structure oxide ceramic La1-xSrxGa1-yMgyO3-delta film. The invention also provides the making method of the low-temperature solid oxide fuel cell.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Diamond glaze for ceramic tiles

The invention provides a diamond glaze for ceramic tiles.One), a formula comprises: spodumene powder, frit powder, potassium feldspar powder, calcined talc powder, barium carbonate powder, wollastonite powder, kaolin powder, white alundum powder, and zinc oxide; two), a preparation method comprises the steps: 1, preparing the frit powder, potassium feldspar, wollastonite, raw talc, barium carbonate, calcite, quartz, crude aluminum oxide, 95 zinc oxide, potassium carbonate and strontium carbonate, 1), placing all materials in a melting furnace, and heating to 1500 DEG C to obtain frit; 2), taking out for cooling to normal temperature, crushing, screening with a 100-mesh screen for use, and if disqualification occurs, crushing and screening until qualification; 2, placing all materials of formula one) into a stirrer, and stirring well to obtain the diamond glaze.The method has a simple process, the diamond glaze has high glaze, can prevent cracking, cut facture and the like, has excellent wear resistance and is useful in the production of polished tiles closer to nature and richer in color.

Owner:XIANGYANG GAOMING MINING IND CO LTD

High-temperature-resisting material as well as preparation method and application thereof

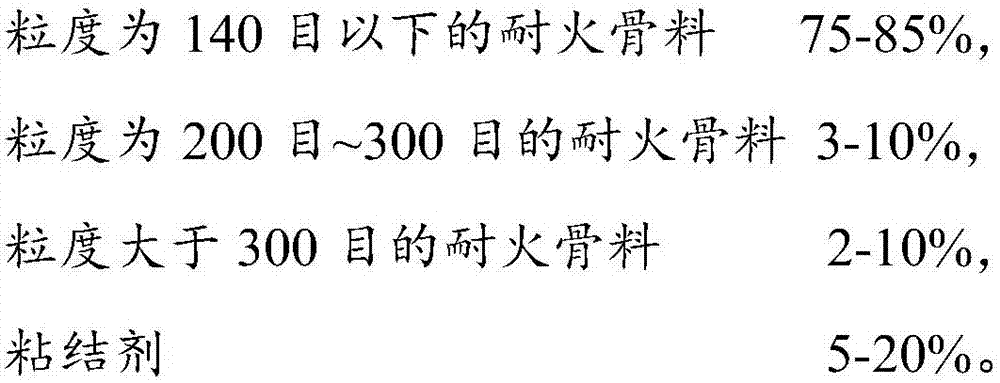

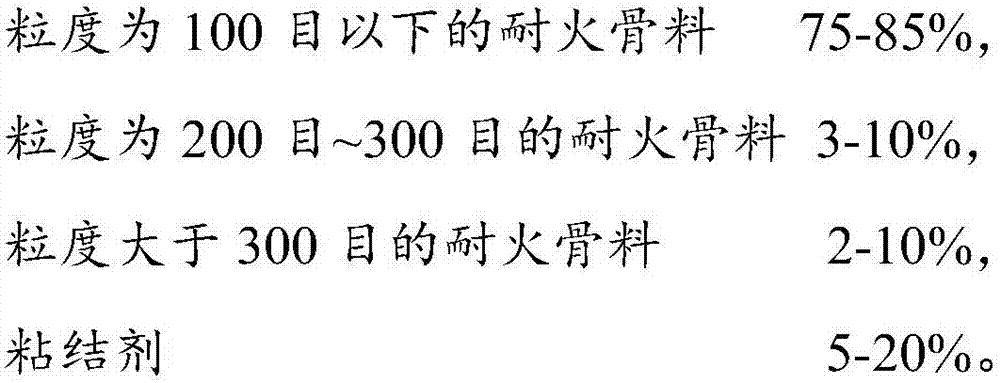

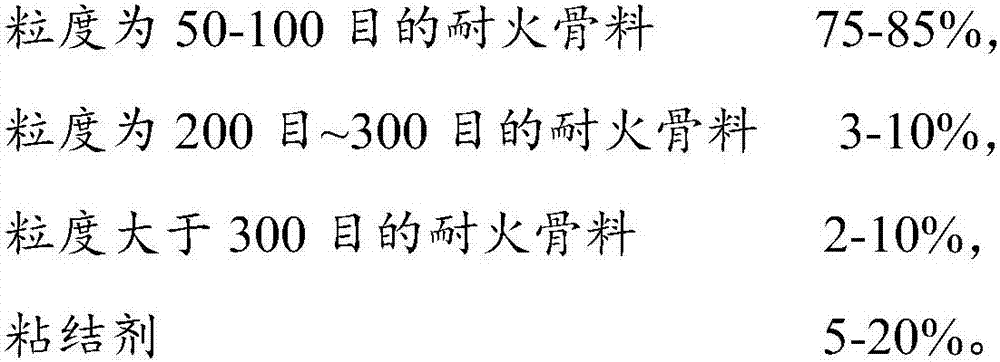

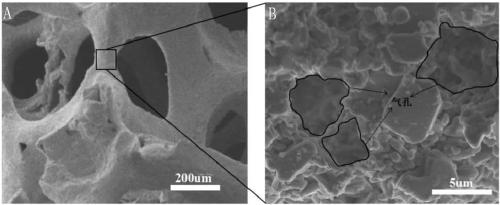

ActiveCN107382342AImprove thermal shock performanceIncreased tensile strength at room temperatureFoundry mouldsFoundry coresPorosityGranularity

The invention provides a high-temperature-resisting material as well as a preparation method and application thereof. The high-temperature-resisting material is mainly prepared from the following components by mixing and sintering: based on the weight percentage content, 60 percent to 90 percent of refractory aggregate with the granularity of 140 meshes or less, 1 percent to 25 percent of refractory aggregate with the granularity of 200 meshes or more and 2 percent to 25 percent of a binding agent. According to the high-temperature-resisting material provided by the invention, the refractory aggregate with different granularities is combined according to a scientific proportion and then is sintered, so that bridging connection, realized by point contact, between the refractory aggregate (namely aggregate) and the other aggregate can be promoted, and tight connection of bridging is also promoted; a microscopic structure is adopted so that the porosity of the material reaches 30 percent or more and the volume density is less than or equal to 1.5g / cm<3>; cracks are not easily expanded so that the thermal shock performance is good, the pouring temperature is greater than or equal to 1650 DEG C and the room-temperature tensile strength is greater than or equal to 1.0MPa.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

Foamed ceramic for catalyst carriers and preparation and application methods thereof

InactiveCN109665821ALarge specific surface areaHigh porosityCatalyst carriersCatalyst activation/preparationPorositySlurry

The invention belongs to the technical field of catalyst carriers and particularly relates to a foamed ceramic for catalyst carriers and preparation and application methods thereof. The preparation method of the foamed ceramic comprises the following steps of, firstly, preparing primary suspension ceramic slurry and secondary suspension ceramic slurry; secondly, dipping polyurethane foam in the primary suspension ceramic slurry, and performing drying, curing and cooling to obtain primary slurry suspended foam; thirdly, applying the secondary suspension ceramic slurry onto the primary slurry suspended foam, and performing drying and cooling treatment to obtain secondary slurry suspended foam; fourthly, sintering the secondary slurry suspended foam at 600-700 DEG C and then at 1400-1600 DEGC to obtain the foamed ceramic for the catalyst carriers. The prepared foamed ceramic for the catalyst carriers solves the technical defects of small specific surface area and low porosity of catalystcarriers in the prior art.

Owner:GUANGDONG UNIV OF TECH

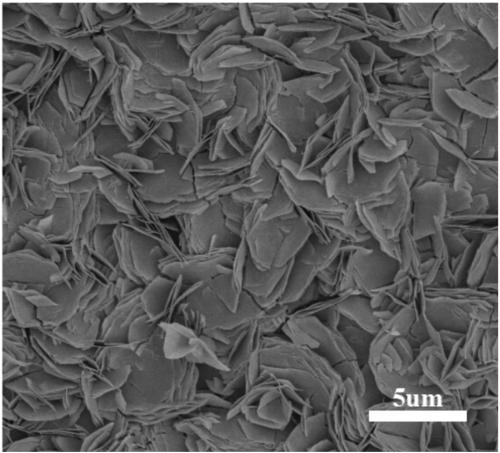

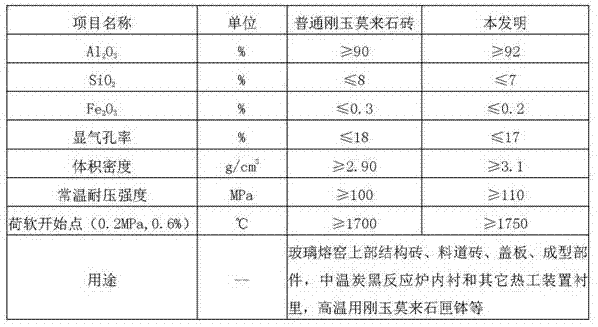

Corundum-mullite bricks capable of being used under high temperature and production method thereof

InactiveCN107056259AHigh hardnessImprove high temperature strengthCeramic shaping apparatusTunnel kilnBrick

The invention discloses corundum-mullite bricks capable of being used under high temperature. The corundum-mullite bricks comprise, by weight, 10-20 parts of fused white corundum granule, 5-10 parts of fused white corundum fine powder, 10-20 parts of fused mullite granule, 5-10 parts of fused mullite fine powder, 5-20 parts of alumina powder and 10-20 parts of kaolin. A production method of the corundum-mullite bricks includes: mixing and grinding raw materials, performing aging and back grinding, performing compression molding, sintering to obtain finished-product bricks and the like. Green bricks obtained after the compression molding are subjected to sintering and heat preservation under 1450-1500 DEG C in a high-temperature tunnel kiln for 10-20 hours, naturally cooled for 48-52 hours and discharged from the kiln to obtain the finished-product bricks. The produced corundum-mullite bricks have the advantages that the hardness, melting point, high-temperature strength, erosion resistance, thermal shock resistance, peeling off resistance and wear resistance of the bricks can be increased evidently, cracking and peeling off during high temperature and cooling can be prevented, and the service life of the corundum-mullite bricks is prolonged.

Owner:辉县市东方耐火材料有限公司

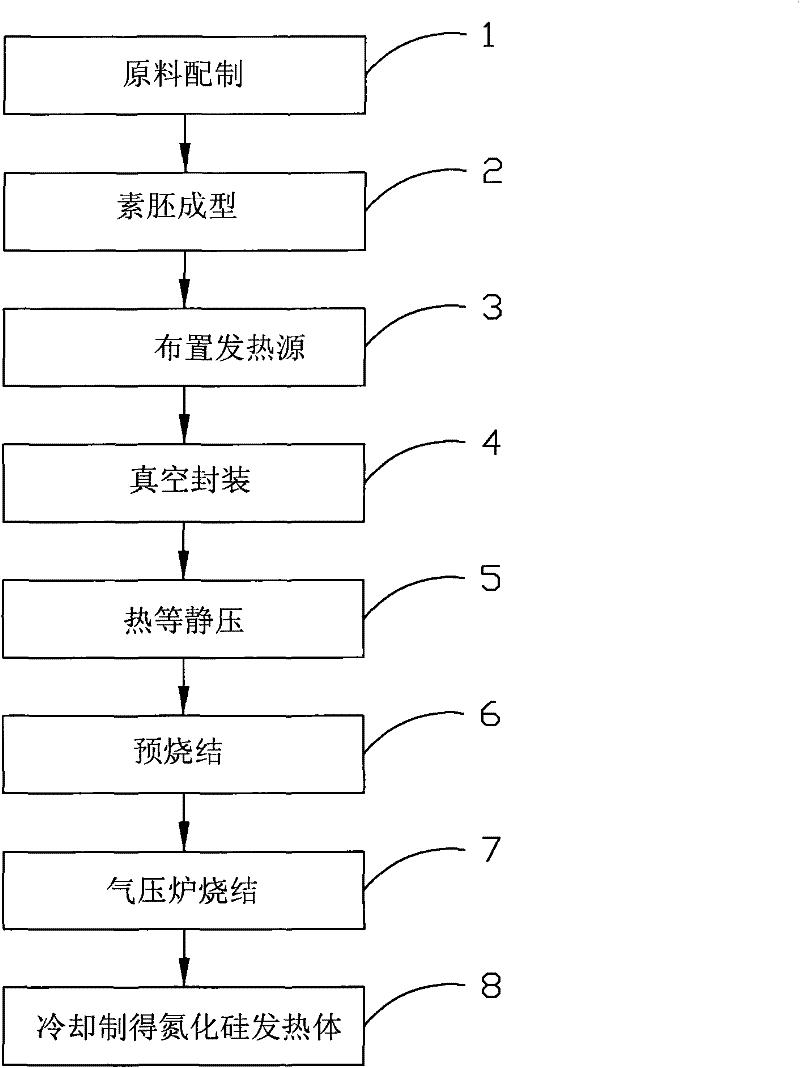

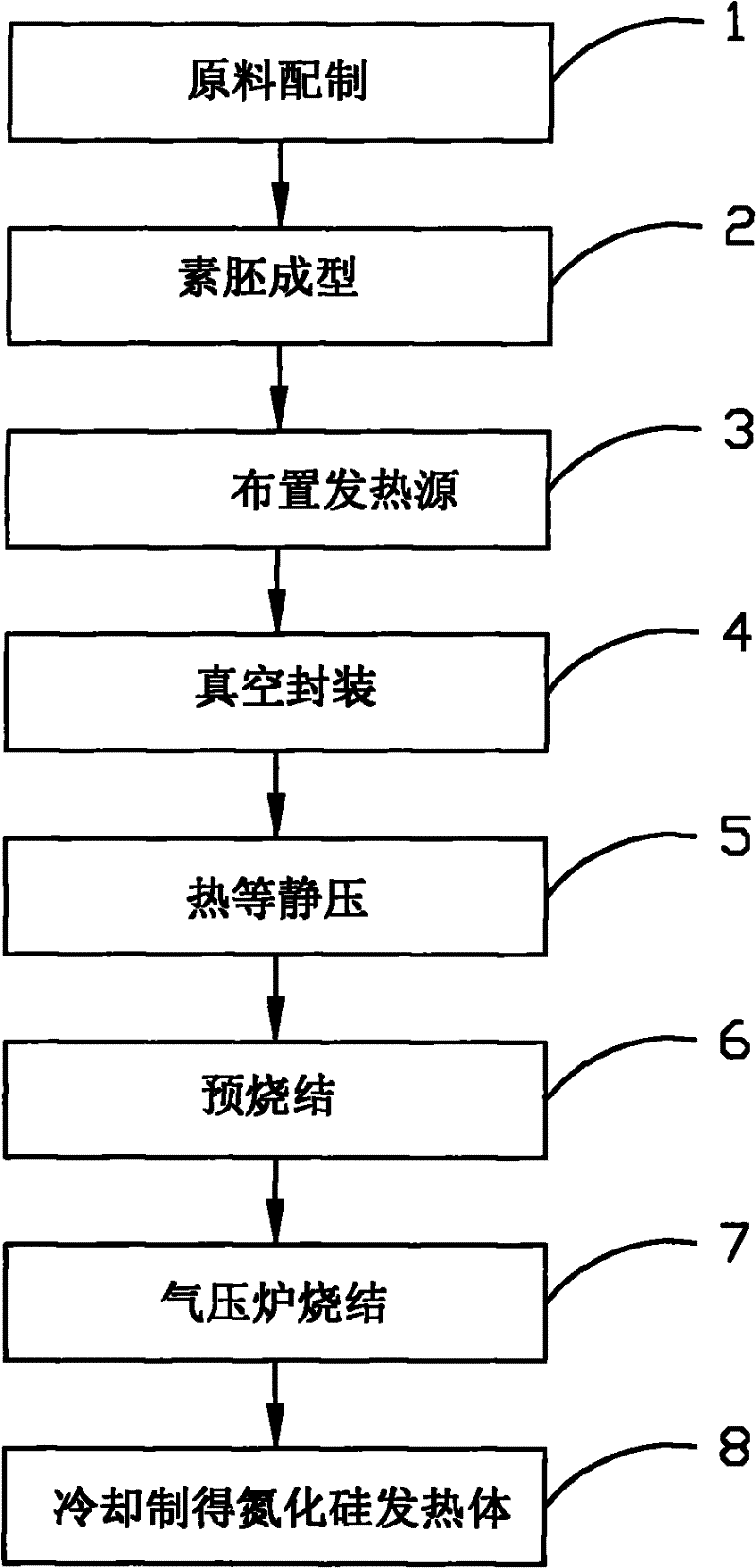

Silicon nitride heat generator and manufacturing method thereof

InactiveCN101754497AImprove thermal shock performanceImprove pass rateHeating element materialsHeat conductingTungsten filament

The invention provides a silicon nitride heat generator and a manufacturing method thereof. The silicon nitride heat generator comprises a heat generating source and a heat generating main body, wherein the heat generating source is a tungsten filament; the heat generating main body is prepared from the following components in part by weight: 88-92 parts of silicon nitride, 6.5-8.5 parts of aluminum oxide and 1.5-3.5 parts of yttrium oxide. The invention has the advantages that the manufacture processing is simple, and the operation process is easy to control; the silicon nitride heat generator manufactured by the method has higher qualified rate of the finished product, higher heat conducting property and higher heat efficiency; and the silicon nitride also has good thermal shock property.

Owner:贺连英

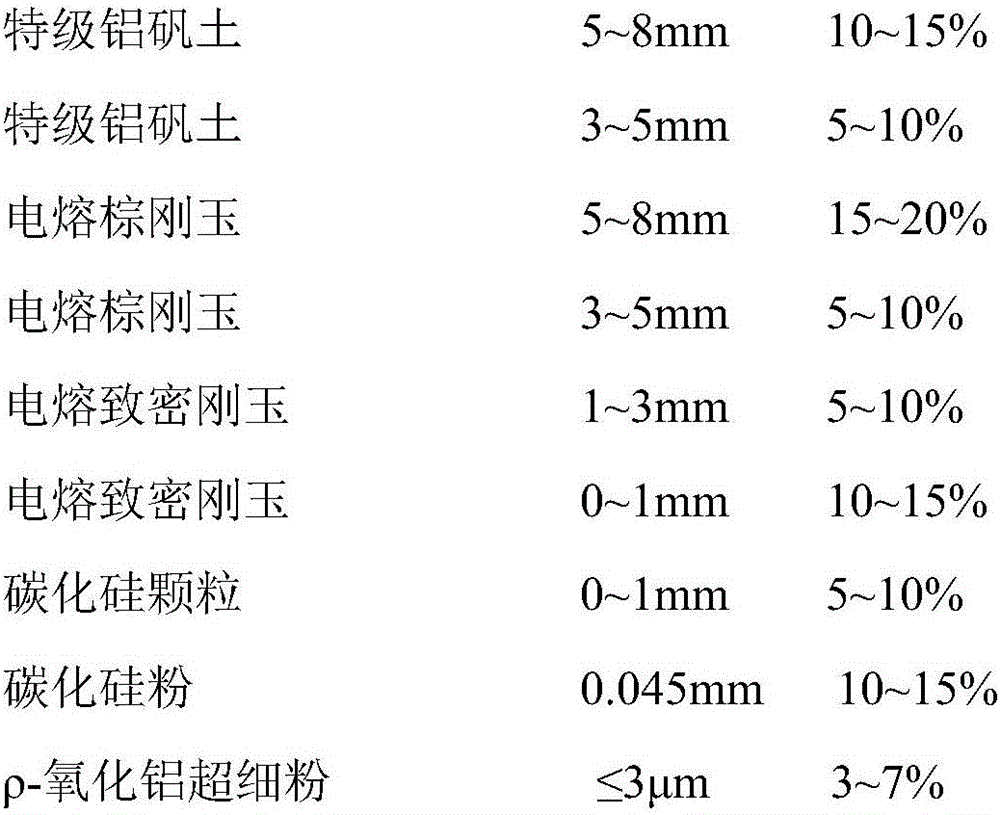

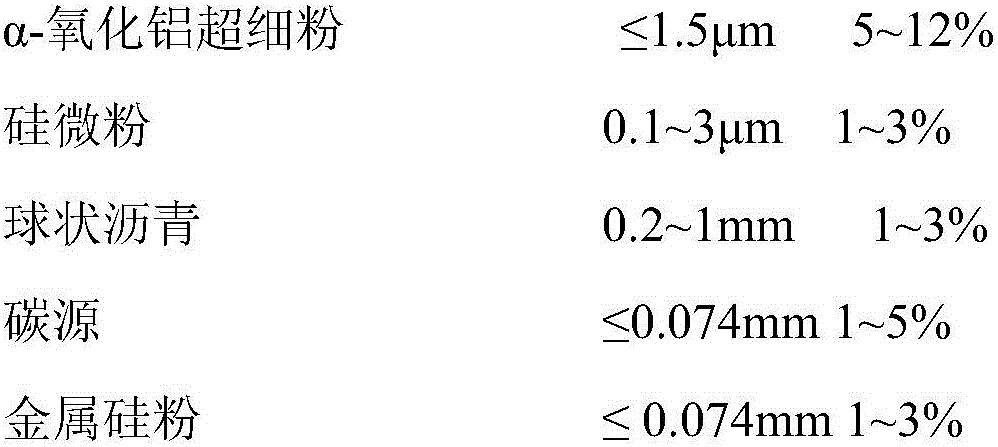

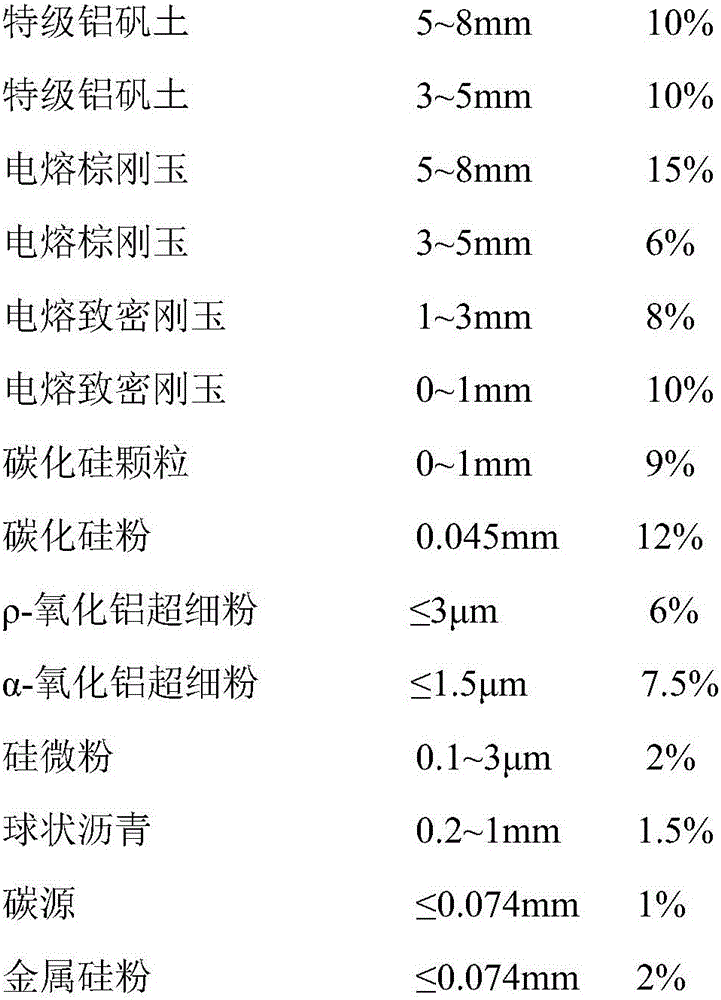

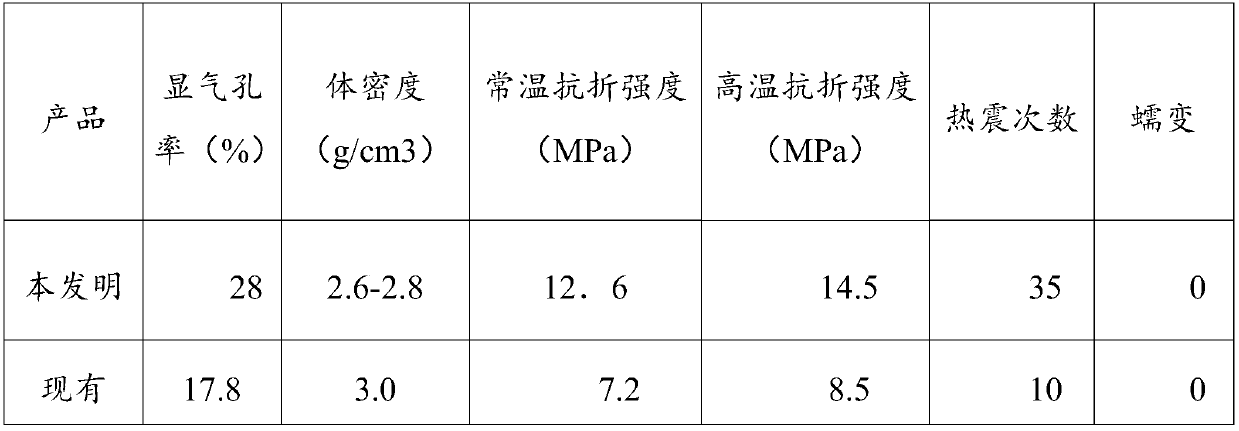

Cement-free iron trough castable for blast-furnace tapping and preparation method of cement-free iron trough castable

The invention discloses a cement-free iron trough castable for blast-furnace tapping. The castable is prepared from special-grade bauxite, fused brown corundum, fused dense corundum, silicon carbide particles, silicon carbide powder, rho-aluminum oxide ultrafine powder, alpha-aluminum oxide ultrafine powder, silicon micropowder, spherical asphalt, a carbon source, metal silicon powder and an efficient water reducing agent. The preparation method includes: proportionally adding the raw materials into a stirring machine, performing dry mixing and stirring for 1-2min, adding water accounting for 4.5-5.5% of the amount of the raw materials, and stirring for 3-5min. Under the condition of freeness of cement addition, fused brown corundum is substituted by part of special-grade bauxite, and raw material cost is reduced while high iron influx is achieved; excellent normal-temperature and high-temperature performances are realized.

Owner:巩义市科正冶金材料有限公司

Sagger used for high-temperature firing and preparation method of sagger

The invention relates to a sagger used for high-temperature firing and a preparation method of the sagger. The sagger used for high-temperature firing is formed by performing mixing forming by using aluminum oxide powder, kaolin powder, clay powder, white corundum, quartz and mullite as raw materials and performing high-temperature firing. The sagger used for high-temperature firing provided by the invention has a good thermal shock effect, low costs and long service life, and can maintain the crack resistance, uniformity and quality stability of a product during mass production, and is suitable for use in environments with larger temperature differences; the sagger used for high-temperature firing provided by the invention is produced during high-temperature firing, and compared with a sagger formed by synthesizing quartz and mullite in advance and performing mixing forming on the market, the sagger provided by the invention has a more uniform finished-product phase, better color andthermal shock stability, and a small phase thermal expansion coefficient, thereby having extremely high thermal shock stability; and the quartz is added, so that the thermal shock performance can be improved.

Owner:山东莱科陶瓷材料有限公司

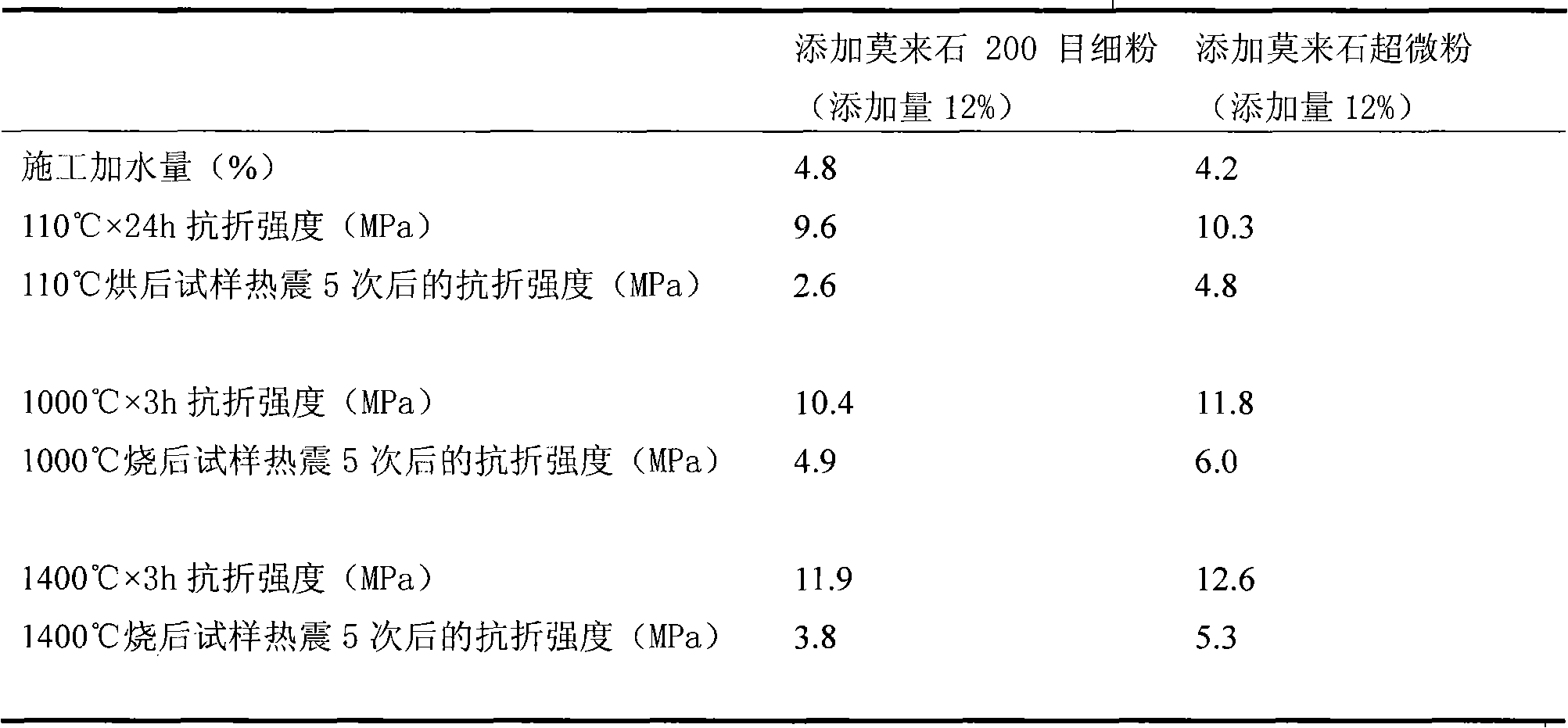

Refractory castable for desulfurizing spray gun for pretreating molten iron

The invention provides a refractory castable for a desulfurizing spray gun for pretreating molten iron, which has lower thermal conductivity and higher thermal shock resistance. The invention is characterized in that 10-50% of flint clay and 5-40% of andalusite are added to aggregate, and 2-15% of mullite ultramicro powder is also added to the aggregate. Thus, on the premise of ensuring that the refractory castable has sufficient corrosion resistance and high strength, the invention further reduces the thermal conductivity of the refractory castable, enhances the shock resistance of the refractory matter, reduces the possibility of cracking, prevents cracks from expanding and greatly prolongs the service life of the desulfurizing spray gun from 18 kilns to about 35 kilns.

Owner:上海彭浦特种耐火材料厂有限公司

Dedicated pouring material for cement kiln outlet and jetting coal pipe and preparation method thereof

InactiveCN101445379BImprove thermal shock performanceGood alkali resistanceCarbide siliconCement factory

The invention discloses a dedicated pouring material for a cement kiln outlet and a jetting coal pipe, which comprises the following components by the weight percentage: 20 to 30 percent of sintered plate-shaped corundum, 20 to 30 percent of sintered and synthesized mullite, 10 to 15 percent of chrome corundum, 5 to 10 percent of silicon carbide, 3 to 5 percent of silicon carbide superfine powder, 3 to 5 percent of magnesia alumina spinel, 5 to 8 percent of zircon sand, 2 to 5 percent of activated Al2O3 micro powder, 2 to 5 percent of silicon micro powder, 3 to 5 percent of pure calcium aluminate cement, 1 to 2 percent of stainless steel fiber, 5 to 10 percent of synthesized zirconium mullite grinding powder, 0.1 to 0.15 percent of composite additives and 0.01 to 0.1 percent of explosion proof fiber. The invention further discloses a method for preparing the pouring material. The pouring material is applicable to the dry-process cement kiln outlets and the jetting coal pipes in large-scale cement plants and has the advantages of high wear resistance, good anti-stripping resistance and long service life.

Owner:JIANGSU GUOHAO REFRACTORY TECH

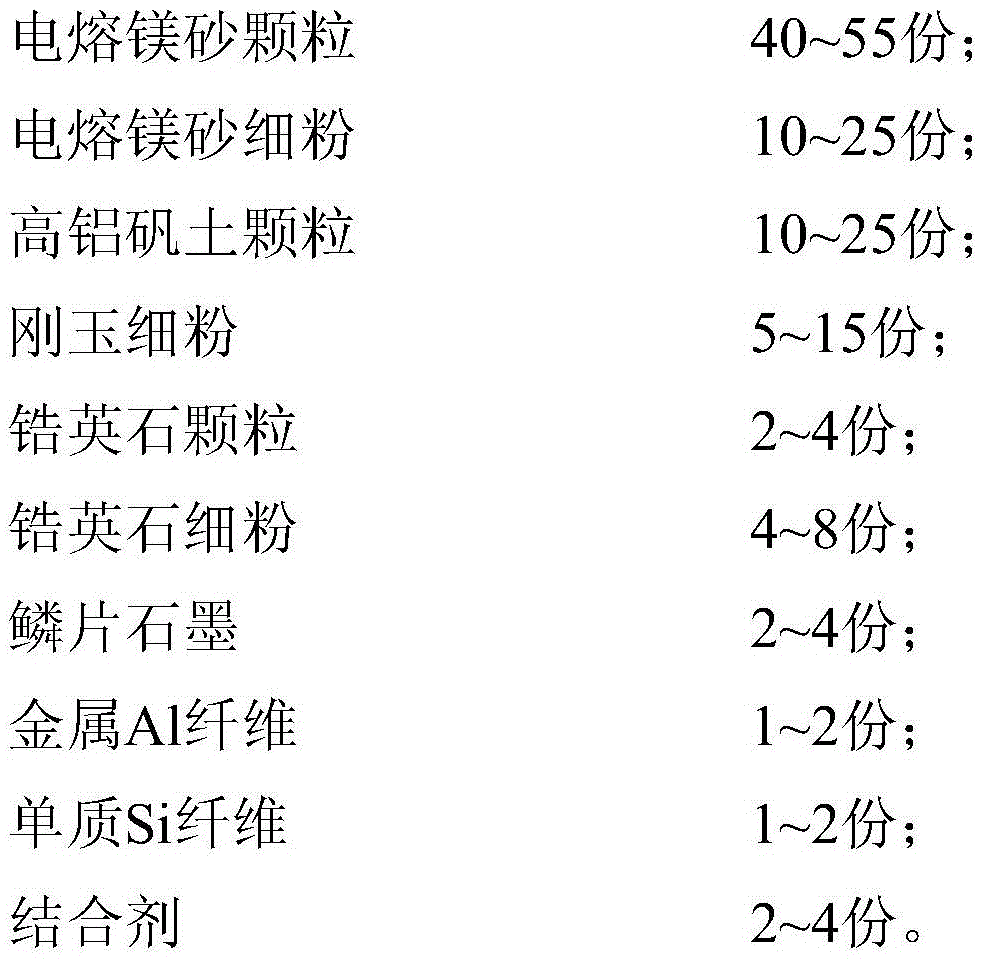

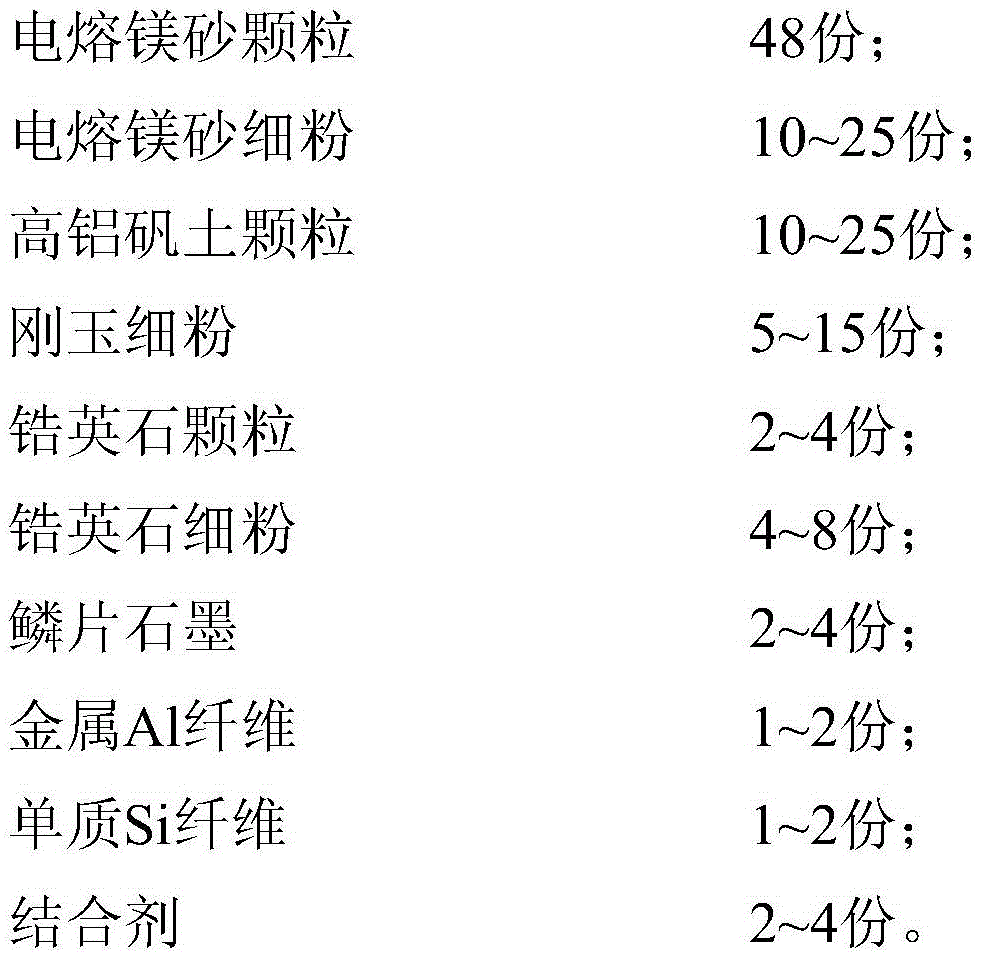

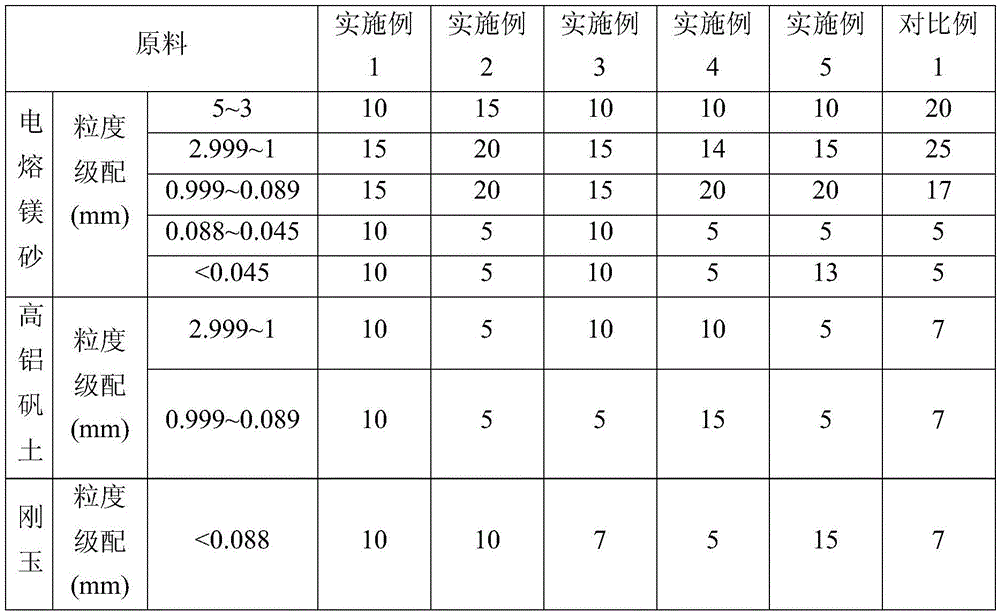

Low carbon magnesia-alumina-carbon brick combining ceramics at high temperature and preparation method thereof

The invention discloses a low carbon magnesia-alumina-carbon brick combining ceramics at a high temperature and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing raw materials in the low-carbon magnesia-alumina-carbon brick, pressing to form a green body, and then baking the green body for 6 to 12 hours at 150 to 220 DEG C. The low carbon magnesia-alumina-carbon brick is prepared from the following raw materials in parts by weight: 40 to 50 parts of fused magnesite particles, 10 to 25 parts of fused magnesite fine powder, 10 to 25 parts of high-alumina bauxite particles, 5 to 15 parts of corundum fine powder, 2 to 4 parts of zirconite particles, 4 to 8 parts of zirconite fine powder, 2 to 4 parts of crystalline flake graphite, 1 to 2 parts of metal Al fibers, 1 to 2 parts of elementary substance Si fibers and 2 to 4 parts of binding agents. Compared with the traditional carbon-combined low carbon magnesia-alumina-carbon brick, the low carbon magnesia-alumina-carbon brick is excellent in medium-high-temperature strength, thermal shock resistance and oxidation resistance.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

Coal gasifier for slag granulation and coal gas preparation process

ActiveCN104593085AReduce oxygen concentrationReduce the temperatureCombined combustion mitigationGranular/pulverulent flues gasificationCoal waterSlag

The invention discloses a coal gasifier for slag granulation and a coal gas preparation process. The coal gasifier is mainly composed of a pressure-bearing housing, a slag film gasification device, an annular chamber structure slag basin, a quenching chamber, a conduit, a convection cooling section and the like. The process comprises the following steps: with pulverized dry coal or coal water slurry as a raw material, feeding the raw material to a gasification chamber to burn and gasify together with a gasifying agent from a vortex gasification burner; enabling formed liquid slag to collide with the wall surface of the gasification chamber under the vortex action, and flowing from bottom to top under the action of gravity; feeding to the slag basin of the annular chamber structure, carrying out further gasification reaction together with oxygen fed from the upper part of the slag basin, and discharging from a slag discharge hole; feeding coal gas main airflow to the quenching chamber together with liquid drops, cooling to a specific temperature, and then conveying to the convection cooling section to further lower temperature through the conduit; finally removing dust, purifying and then outputting. The liquid slag drops penetrating through the slag basin are cooled to form solid particles and are collected by a dry slag collector; and the heat is recovered by a slag cooler.

Owner:XI AN JIAOTONG UNIV +1

High-temperature alloy protecting coating and method of preparing the same

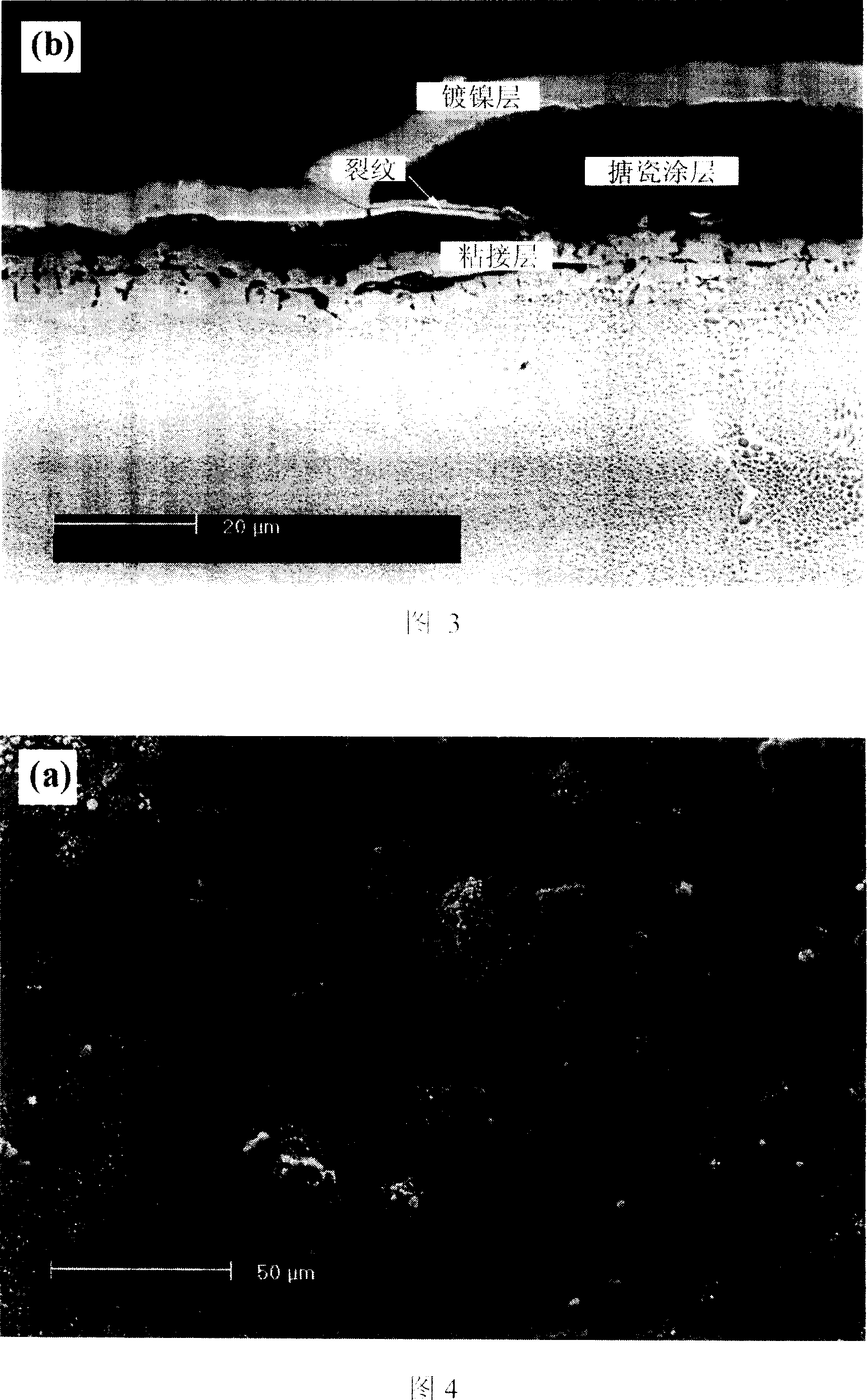

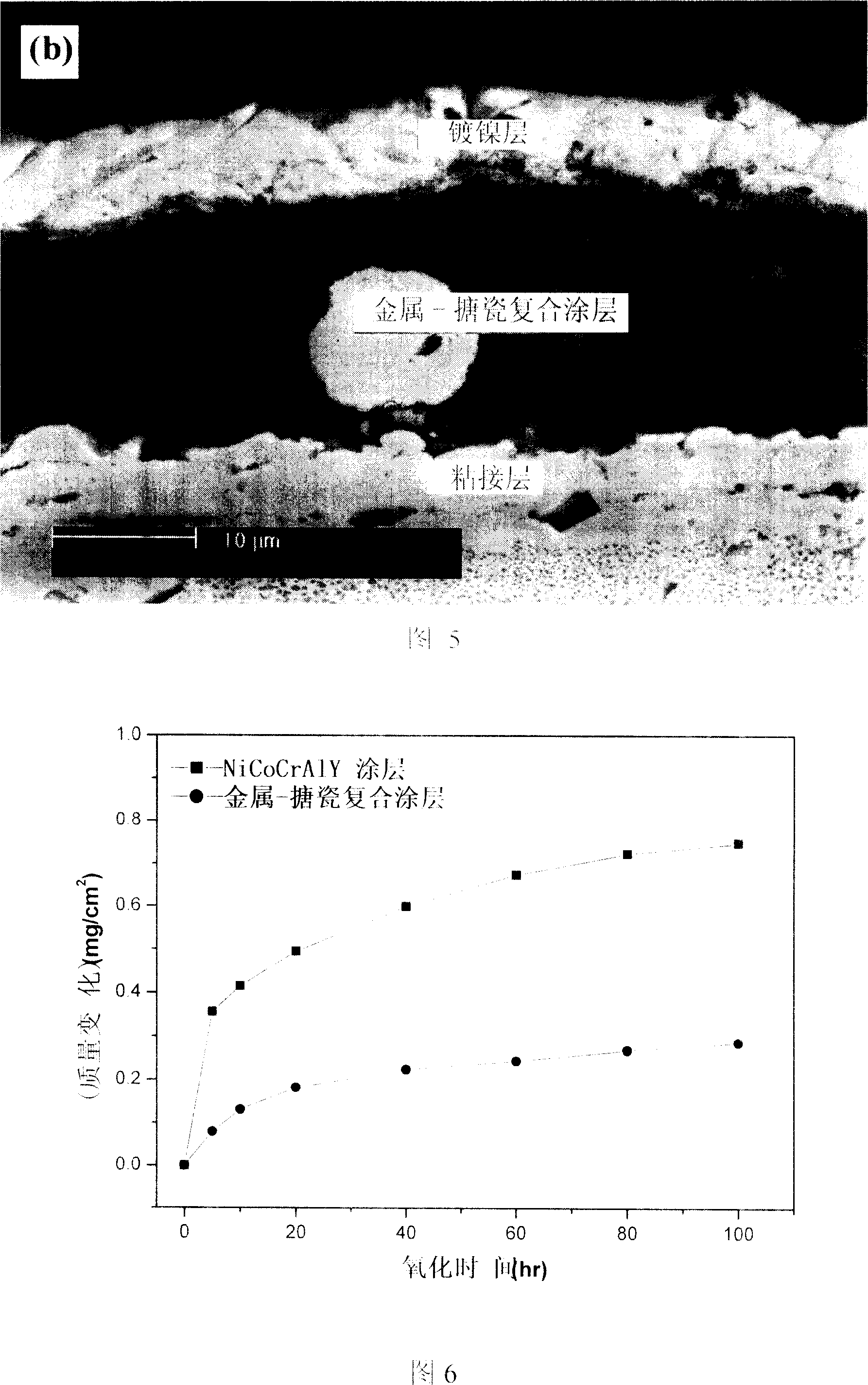

InactiveCN101109086AImprove thermal shock resistanceImprove thermal shock performanceThermal expansionSuperalloy

A protection coating for a hi-temp alloy is characterized in that, the coating is a compound coating of metal and enamel formed by spreading some metallic powder on an enamel substrate. Wherein, the metallic powder is MCrAlY powder of high thermal expansion rate coefficient and good resistance to hi-temp corrosion, M is one from Ni, Co, NiCo or any combination of them. Way for preparing the protection coating for hi-temp alloy is: first of all the metallic powder is fully mixed with the enamel powder, then the mixed powder is sprayed on the surface of a specimen, still then a metal-enamel compound coating spread on the enamel substrate is formed by high temperature sintering. The metal-enamel compound coating prepared by the invention is not only furnished with excellent resistance to hi-temp corrosion, but also highly improved thermal expansion rate coefficient because of the addition of plastic metallic powder, and greatly improved thermal vibration property.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Reaction diffusion connection method of ceramic composite material and metal

The invention relates to a reaction diffusion connection method of ceramic composite material and metal, which belongs to the technical field of connection of ceramic material and metal material, and is characterized in that corresponding mixed powder is added between the ceramic composite material and the metal, combustion reaction heat is generated under the activation of an electric field, and the ceramic composite material and the metal material are locally smelted respectively and generate diffusion reaction to form connection. The combustion synthesis of the metal powder forms an intermetallic compound with the performance between ceramic and metal, thus alleviating the problem of mismatching between the metal and the ceramic; and the action of the electric field causes elements between interfaces to diffuse mutually, thus being beneficial to improving the strength of the connecting interfaces. By combustion heat release, the method realizes the synthesis of an intermediate layer and the connection of metal and ceramic simultaneously, and has the characteristics of being low in energy consumption and high in connection strength.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com