High-calcium magnesia-calcium-carbon brick and manufacturing method thereof

A technology of high-calcium-magnesium-calcium-carbon bricks and calcium-magnesium-calcium-carbon bricks, which is applied in the field of refractory materials for steel ladles in the metallurgical industry, can solve problems such as inability to adapt to corrosion resistance, and improve spalling resistance, thermal shock resistance, and stability Good, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-calcium-magnesium-calcium-carbon brick made of the following raw materials in weight percentage:

[0030] 1-5mm magnesia calcium sand (CaO 58%, MgO 38%) 50.5%,

[0031] Magnesia-calcium sand (CaO 58%, MgO 38%) ≤1mm 10.4%,

[0032] ≤1mm magnesia (MgO 97%) 9.4%,

[0033] ≤0.088mm magnesia powder (MgO 97%) 20.2%,

[0034] Graphite 3.5%,

[0035] ≤0.088mm aluminum powder 1.0%,

[0036] Silicon powder ≤0.088mm 1.0%,

[0037] ≤0.088mm silicon carbide powder 1.0%,

[0038] Phenolic resin (moisture content 0.5%) 3.0%.

[0039] The manufacture method of above-mentioned high-calcium-magnesium-calcium-carbon brick is as follows:

[0040] 1) The magnesia and magnesia-calcium sand are mechanically crushed by a crusher, and sieved by a 5mm and 1mm sieve to make magnesia-calcium sand with a particle size of 1-5mm and a particle size of ≤1mm and magnesia with a particle size of ≤1mm. Part of the magnesia with particle size ≤ 1mm is processed into magnesia powder with par...

Embodiment 2

[0049] A high-calcium-magnesium-calcium-carbon brick made of the following raw materials in weight percentage:

[0050] 1-5mm magnesia calcium sand (CaO 56%, MgO 36%) 40%,

[0051] ≤1mm magnesia-calcium sand (CaO 56%, MgO 36%) 5%,

[0052] Magnesia (MgO 97.5%) ≤1mm 5%,

[0053] ≤0.088mm magnesia powder (MgO 97.5%) 30%,

[0054] Graphite 8%,

[0055] ≤0.088mm aluminum powder 3%,

[0056] Silicon powder ≤0.088mm 3%,

[0057] ≤0.088mm silicon carbide powder 3%,

[0058] Phenolic resin (moisture content 0.3%) 3%.

[0059] The manufacturing method of high calcium magnesium calcium carbon brick is as follows:

[0060] 1) The magnesia and magnesia-calcium sand are mechanically crushed by a crusher, and sieved by a 5mm and 1mm sieve to make magnesia-calcium sand with a particle size of 1-5mm and a particle size of ≤1mm and magnesia with a particle size of ≤1mm. Part of the magnesia with particle size ≤ 1mm is processed into magnesia powder with particle size ≤ 0.088mm by ball mi...

Embodiment 3

[0069] A high-calcium-magnesium-calcium-carbon brick made of the following raw materials in weight percentage:

[0070] 1-5mm magnesia calcium sand (CaO 56.5%, MgO 36.4%) 60%,

[0071] ≤1mm magnesia-calcium sand (CaO 56.5%, MgO 36.4%) 5%,

[0072] Magnesia (MgO 98%) ≤1mm 5%,

[0073] ≤0.088mm magnesia powder (MgO 98%) 20%,

[0074] Graphite 3%,

[0075] Aluminum powder ≤0.088mm 0.5%,

[0076] Silicon powder ≤0.088mm 0.5%,

[0077] Silicon carbide powder ≤0.088mm 0.5%,

[0078] Phenolic resin (moisture content 0.2%) 5.5%.

[0079] The manufacture method of high calcium magnesium calcium carbon brick is the same as embodiment 2.

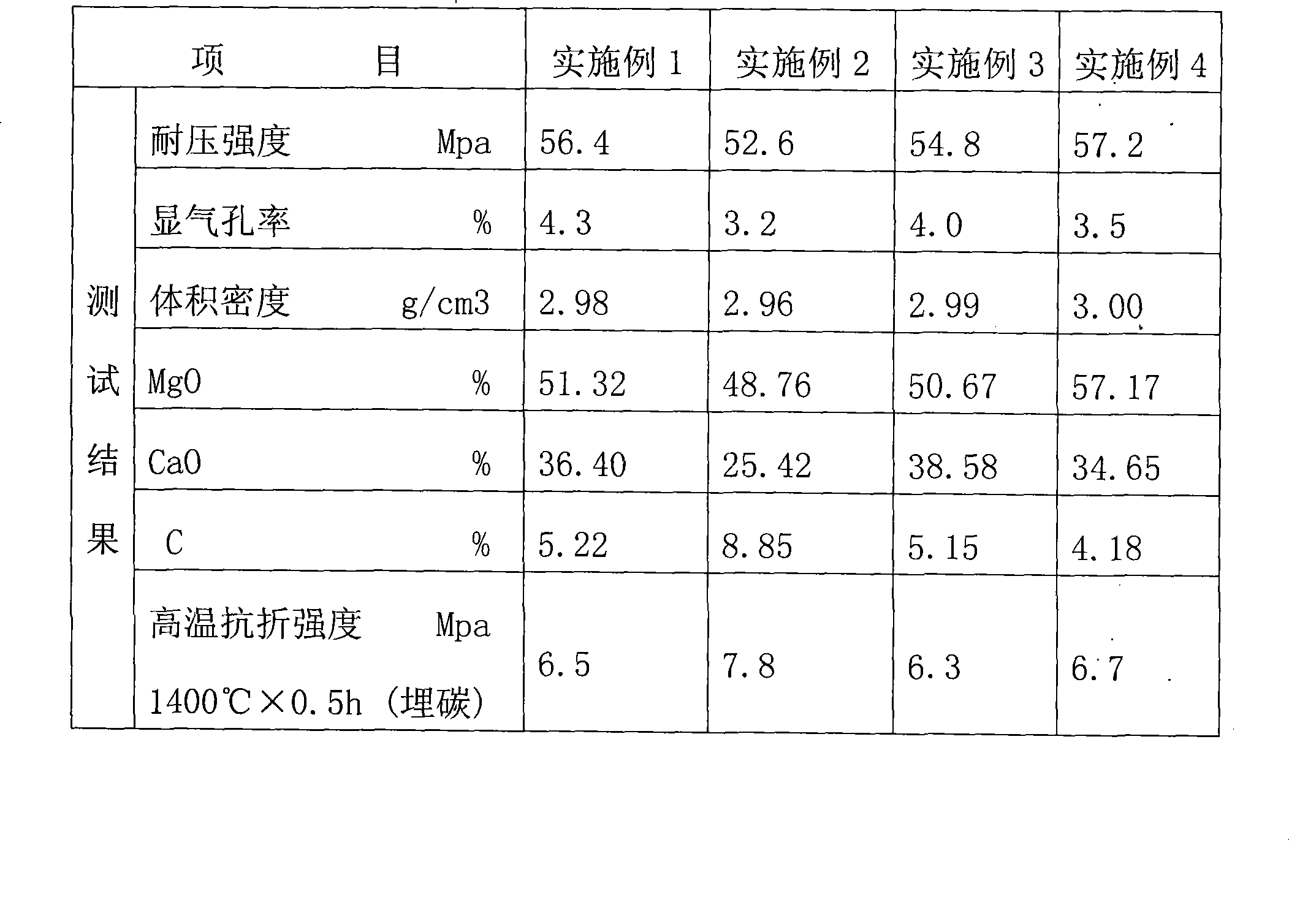

[0080] The product testing results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com