Ceramic fiber filtering tube, preparation method and pressurization and suction forming device

A ceramic fiber and molding device technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of high one-time investment in electrostatic dust removal, inability to purify toxic and harmful gases, and uneven density of large-sized products. Improve thermal shock performance and corrosion resistance, uniform density, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

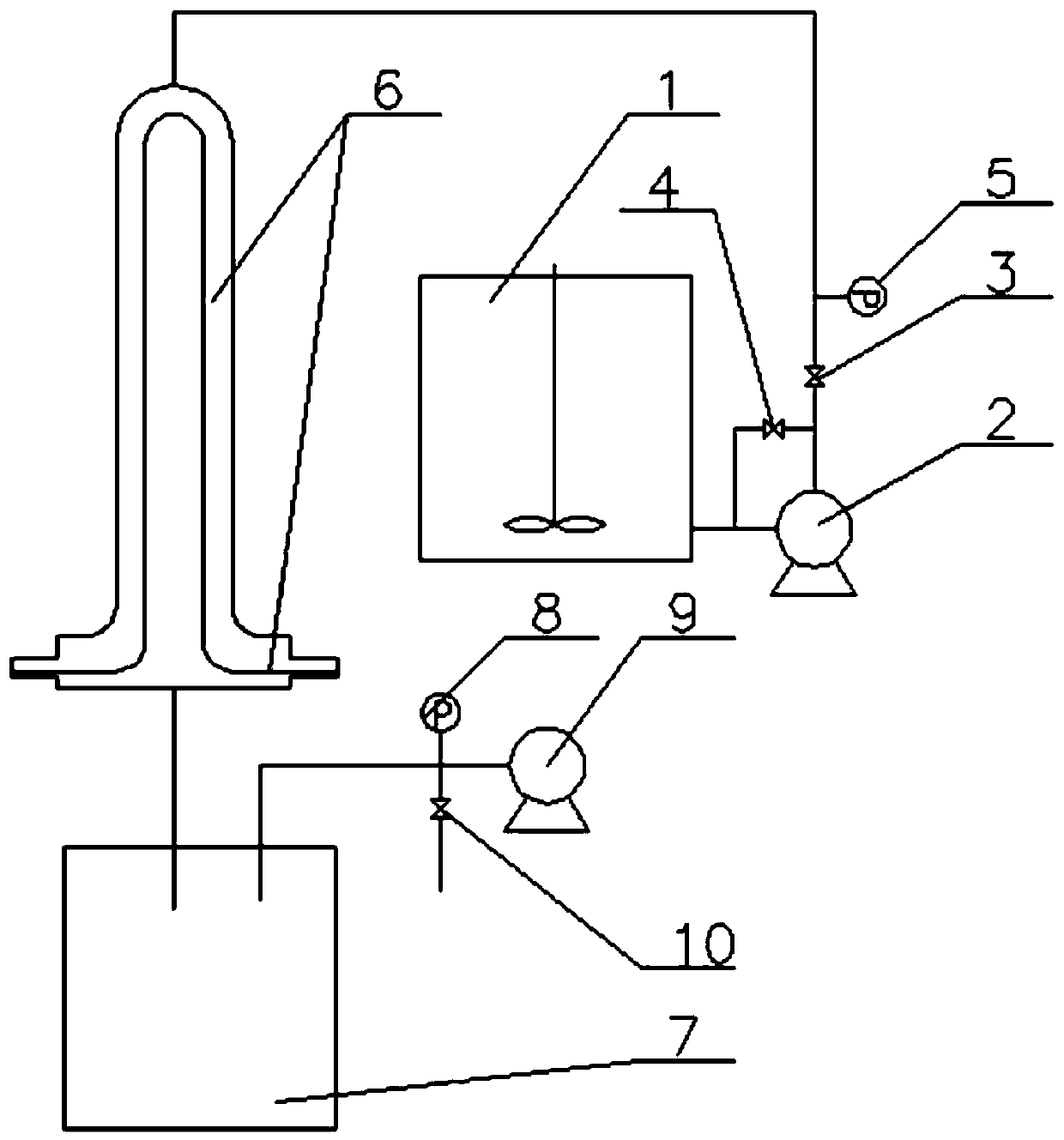

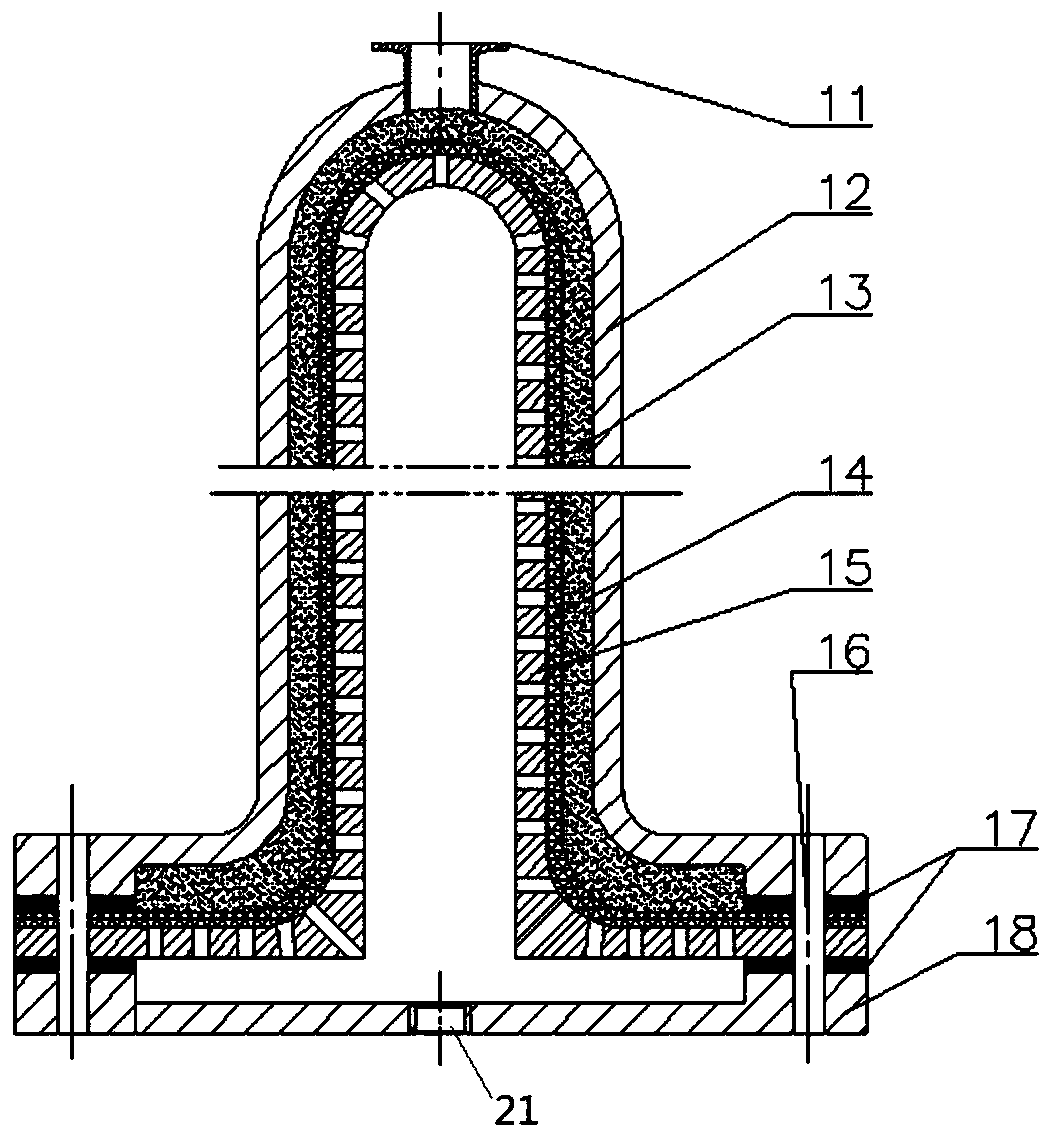

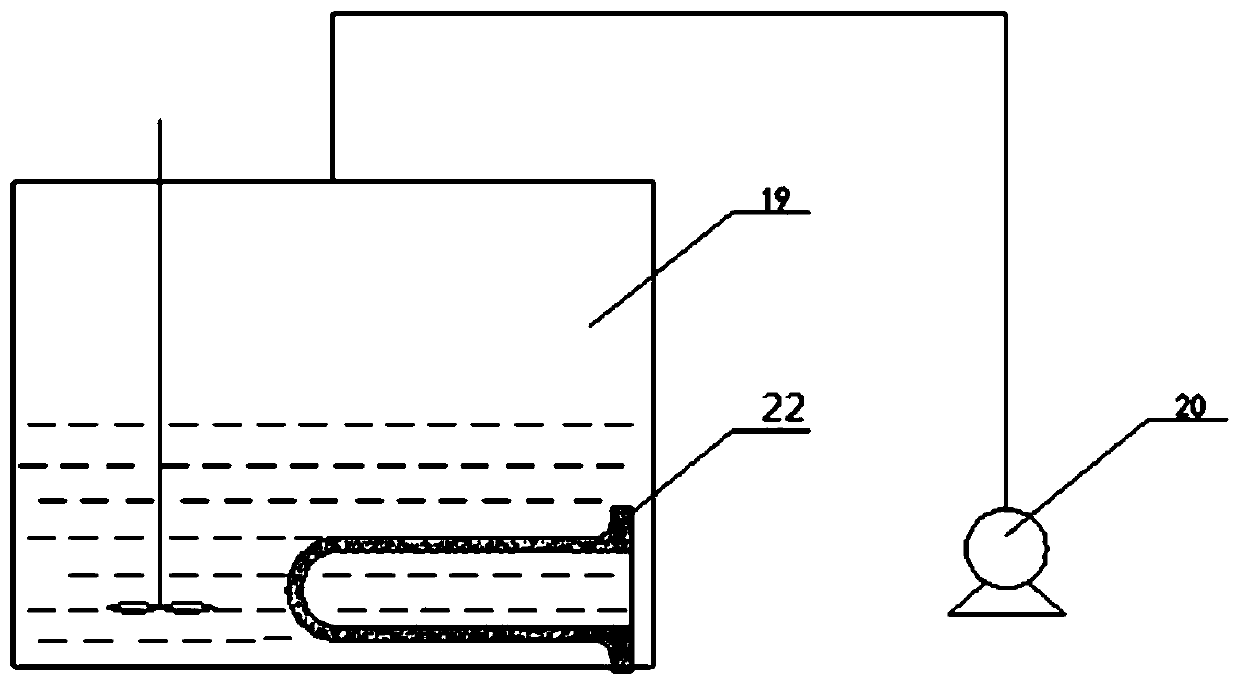

[0043] Such as figure 1 , figure 2As shown, a ceramic fiber filter tube pressurized suction forming device, the forming device includes a forming die 6, a pressurizing pump 2, a batching tank 1, a vacuum pump 9, a vacuum filtrate tank 7, and the forming die 6 includes Inner formwork 15, upper formwork 12, lower formwork 18, filter cloth 14, blank tube cavity 13, described filter cloth 14, blank tube cavity 13 are arranged between inner formwork 15, upper formwork 12 respectively, described filter cloth 14 is arranged on the inner formwork 15, the lower formwork 18 and the upper formwork 12 are connected by threads, the upper and lower flange surfaces of the inner formwork 15 are respectively provided with sealing gaskets 17, and the top of the upper formwork 12 A quick fitting 11 is provided for adding water or slurry. The quick fitting 11 is connected to the booster pump 2, and the booster pump 2 is connected to the batching tank 1, and is adjusted by the return valve 4 and...

Embodiment 2

[0059] In this embodiment, a ceramic fiber filter tube with high temperature resistance, corrosion resistance and catalytic function is prepared, and the specific process is as follows:

[0060] (1) Fiber pretreatment:

[0061] The aluminum silicate fibers and zirconia fibers were sheared and crushed respectively, sieved to obtain short fibers with a length of 300 μm, and then washed with 5% sodium hydroxide solution at 35°C, filtered and rinsed with pure water until neutral, 110 ℃ drying hour stand-by.

[0062] (2) Preparation of slurry:

[0063] In the batching tank 1 with stirring, add 25kg of pure water, then add 10.5kg of nano-silica sol with a solid content of 20% and a particle size of 20nm, and 4kg of nano-zirconia sol with a solid content of 15% and a particle size of 20nm , the solid content is 20%, the particle diameter is 20nm catalytic gamma nano-alumina sol 10kg, PAA1.5kg, antifoamer 0.2kg specially for ceramics, stirring down to pH=3, adding the zirconia of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com