Silicon nitride heat generator and manufacturing method thereof

A technology of a silicon nitride heating element and a manufacturing method, which is applied in the direction of heating element materials, etc., can solve the problems of difficult atmosphere control, high defect rate, and low pass rate, and achieve the effects of high pass rate, high thermal efficiency, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its decorative effect, the following is a detailed description in conjunction with preferred embodiments of the present invention and accompanying drawings.

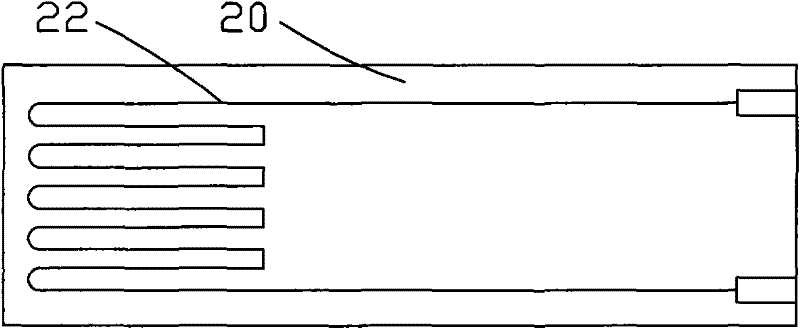

[0031] The invention provides a silicon nitride heating element, which includes: a heating source and a heating body, the heating source is a tungsten wire, and the components and contents of the heating body are as follows, in parts by weight: 88 to 92 parts of silicon nitride , 6.5-8.5 parts of aluminum oxide, 1.5-3.5 parts of diyttrium oxide

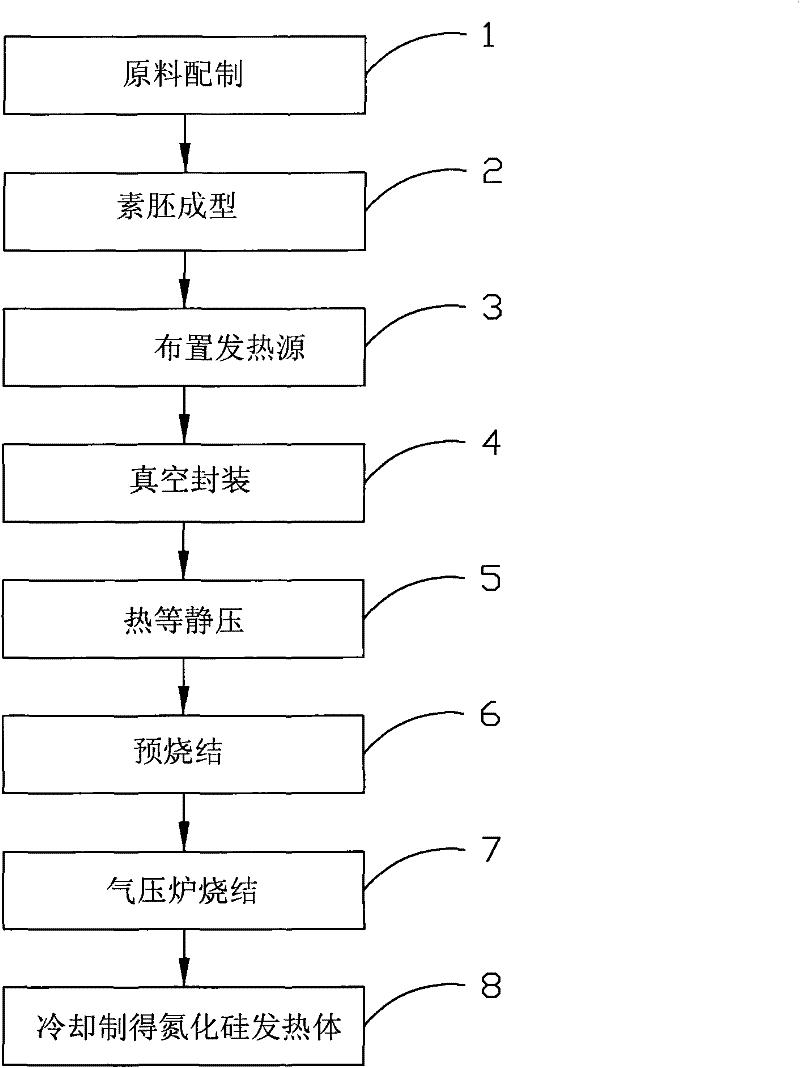

[0032] figure 1 Shown), the present invention also provides a kind of manufacture method of silicon nitride heating element (the method comprises:

[0033] Step 1. Raw material preparation: Provide raw materials for making the heating body and make slurry. Wherein, the raw material components and contents of the heating body are as follows, in parts by weight: 88-92 parts of silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com