Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

144results about How to "Morph coordination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

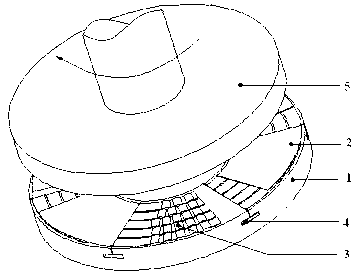

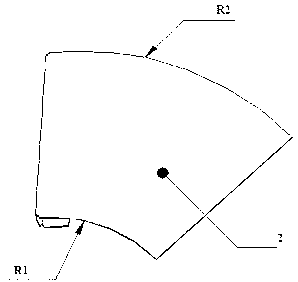

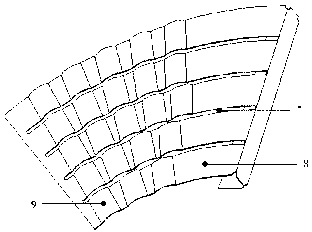

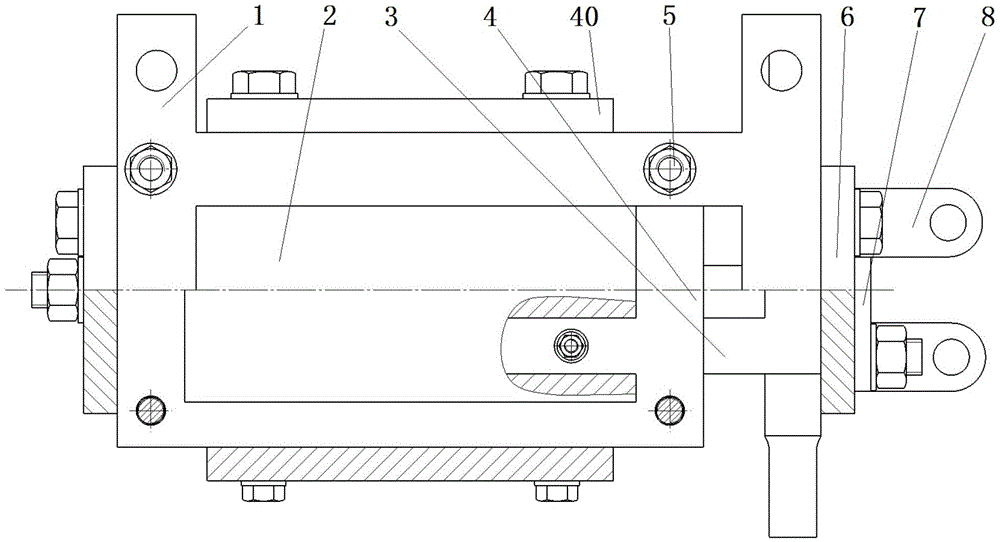

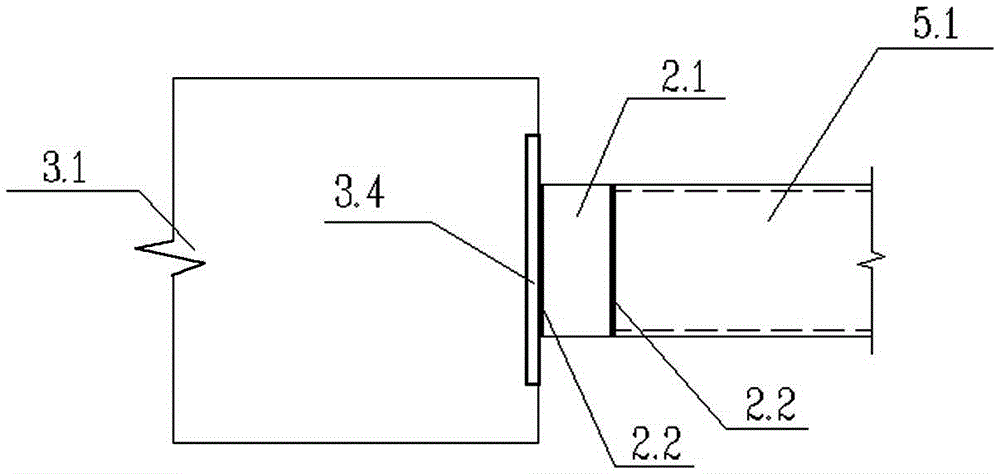

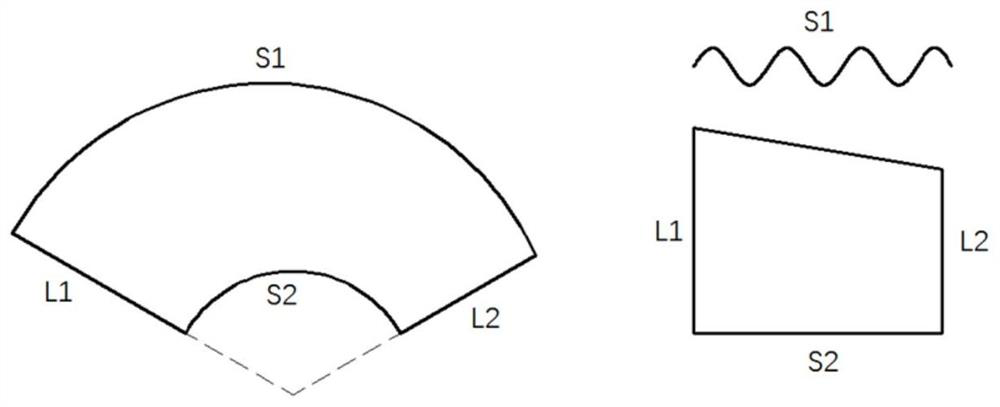

Separated-type wave foil dynamic pressure gas thrust bearing

InactiveCN103291745AMorph coordinationImprove carrying capacityBearing componentsSliding contact bearingsMembrane surfaceThermal deformation

The invention relates to a separated-type wave foil dynamic pressure gas thrust bearing capable of bearing certain axial load. The separated-type wave foil dynamic pressure gas thrust bearing comprises a bearing chassis, flat foil sheets, wave foil sheets and a gasket, wherein the circle of the bearing chassis is divided into a plurality of parts by clearances along the radius direction; the flat foil sheets and the wave foil sheets are inserted into the clearances; the gasket is inserted into a rectangular groove in the bearing chassis; a screw is screwed in a threaded hole at the rear part of the bearing chassis, and presses the gasket tightly so as to fix the foil sheets; the rigidity of the separated-type foil sheets can be changed along the radius direction and the circumference direction; the rigidity characteristic is beneficial to the adaptation of nonuniform pressure distribution for the bearing caused by velocity differences along the radius direction, so that the pressure can be homogenized, and the foil sheet deformation can be harmonized, and the bearing loading capability can be improved; slits among foil belts can ensure that the foil sheets prevent thermal deformation caused by nonuniform temperature distribution, and also can ensure that the bearing is adaptive to less axial deviation; the foil belts are connected integrally at free ends, and the damage on pressure air membrane surfaces caused by radial deviation of the foil sheets can be prevented.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

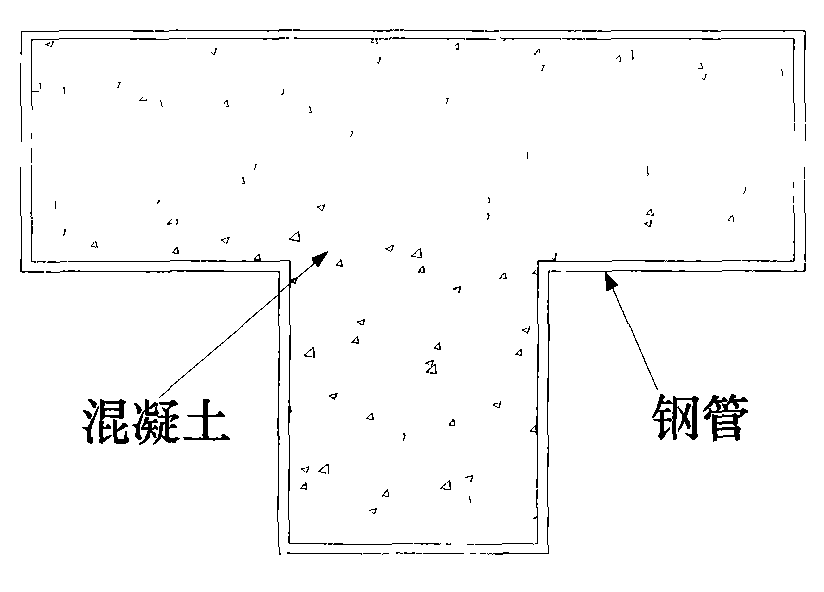

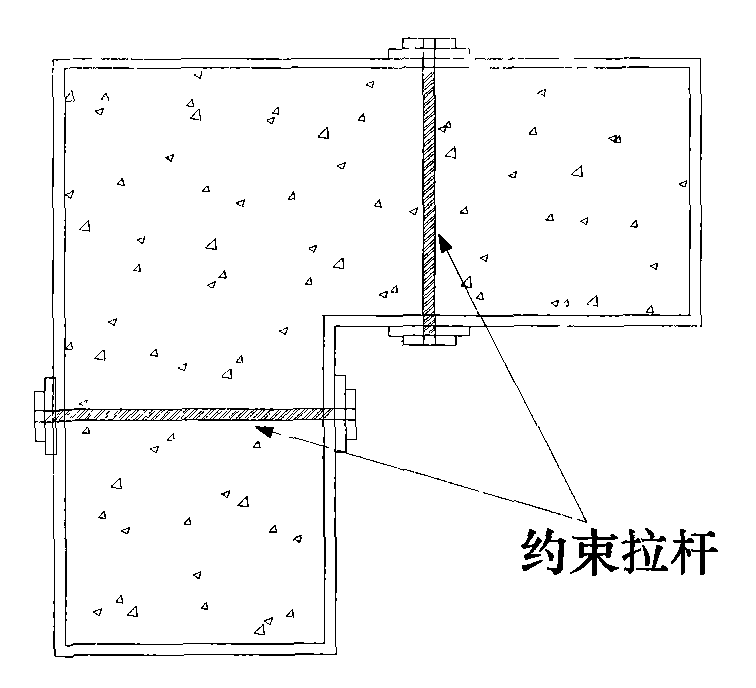

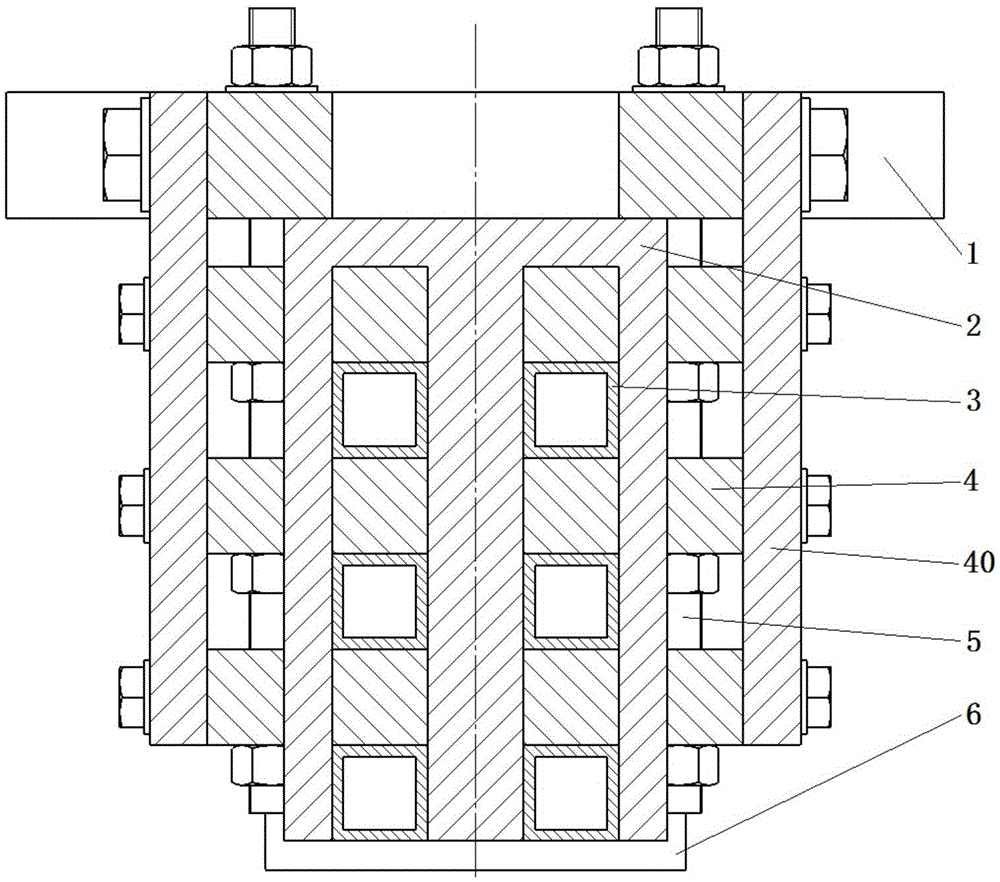

Multi-chamber type steel tube concrete special-shaped column

InactiveCN101555721AEnhanced interactionReduce aspect ratioStrutsPillarsSheet steelEconomic benefits

The invention discloses a multi-chamber type steel tube concrete special-shaped column, consisting of U-shaped steel, a rectangular steel tube and concrete cast in the tube. The U-shaped steel is mutually welded with the rectangular steel tube to form special-shaped columns with different sections. The whole section is divided into a plurality of chambers by the U-shaped steel and the rectangular steel tube, and the concrete is filled in the chambers. The U-shaped steel is formed by bending or welding a steel plate and the rectangular steel tube is formed by directly welding or first blending and then welding the steel plate. By dividing the section into a plurality of chambers, the special-shaped column can enhance the interaction between the steel and concrete, reduces the ratio of width to thickness of the steel plate and is beneficial to give full play of material performance and the improvement of section performance; and the directly stressed U-shaped steel and the directly stressed rectangular steel tube decrease the dimension of sections, eliminate the negative angle of 90 degrees, boost the bearing capacity of the special-shaped column and improve anti-seismic performance. The special-shaped column is simple in manufacture, guarantees the quality of concrete vibrating and casting, is convenient for construction and manufacture and has comparatively good economic benefits.

Owner:BEIHANG UNIV

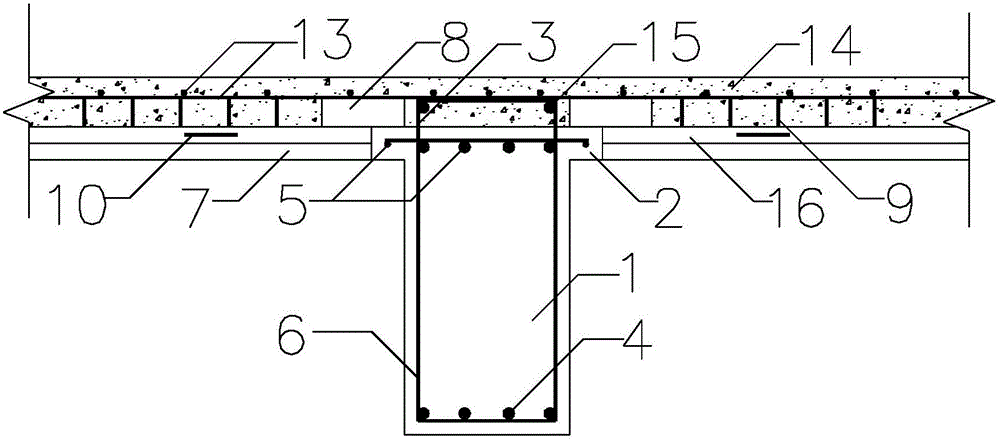

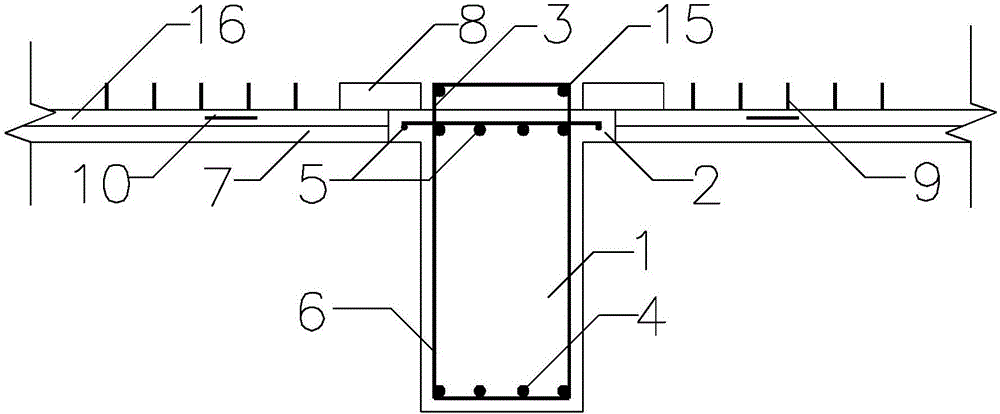

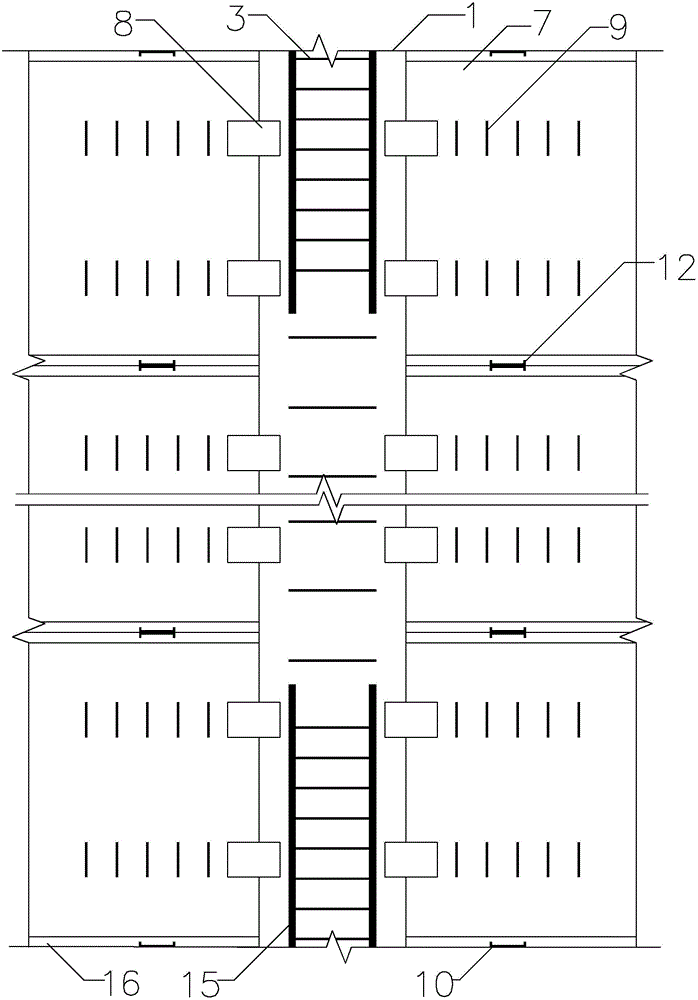

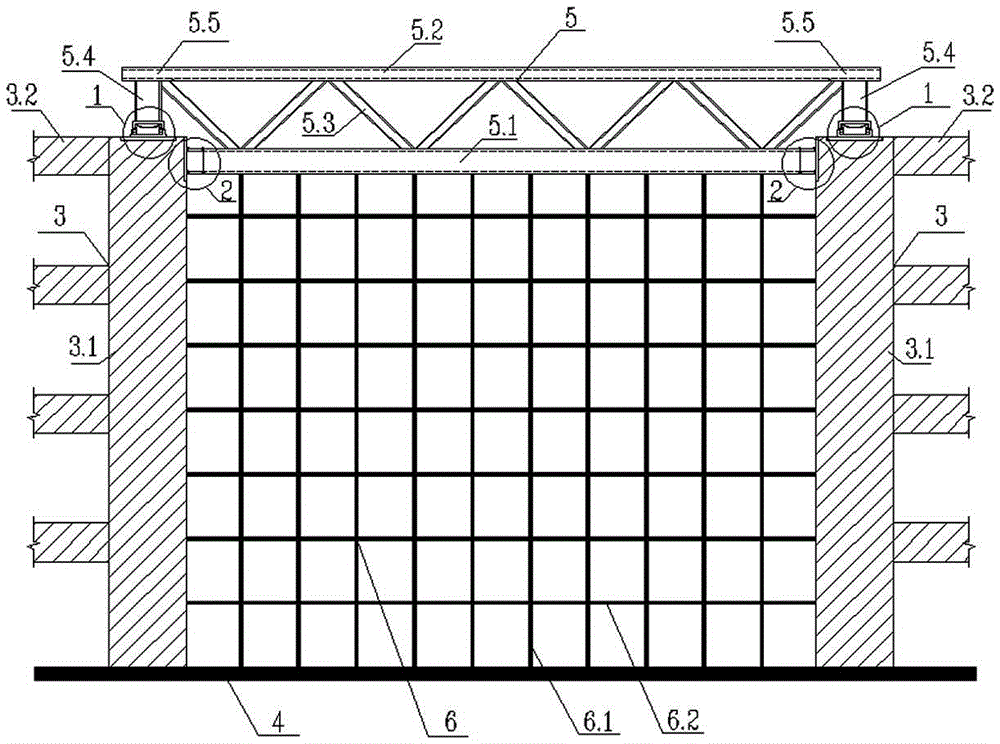

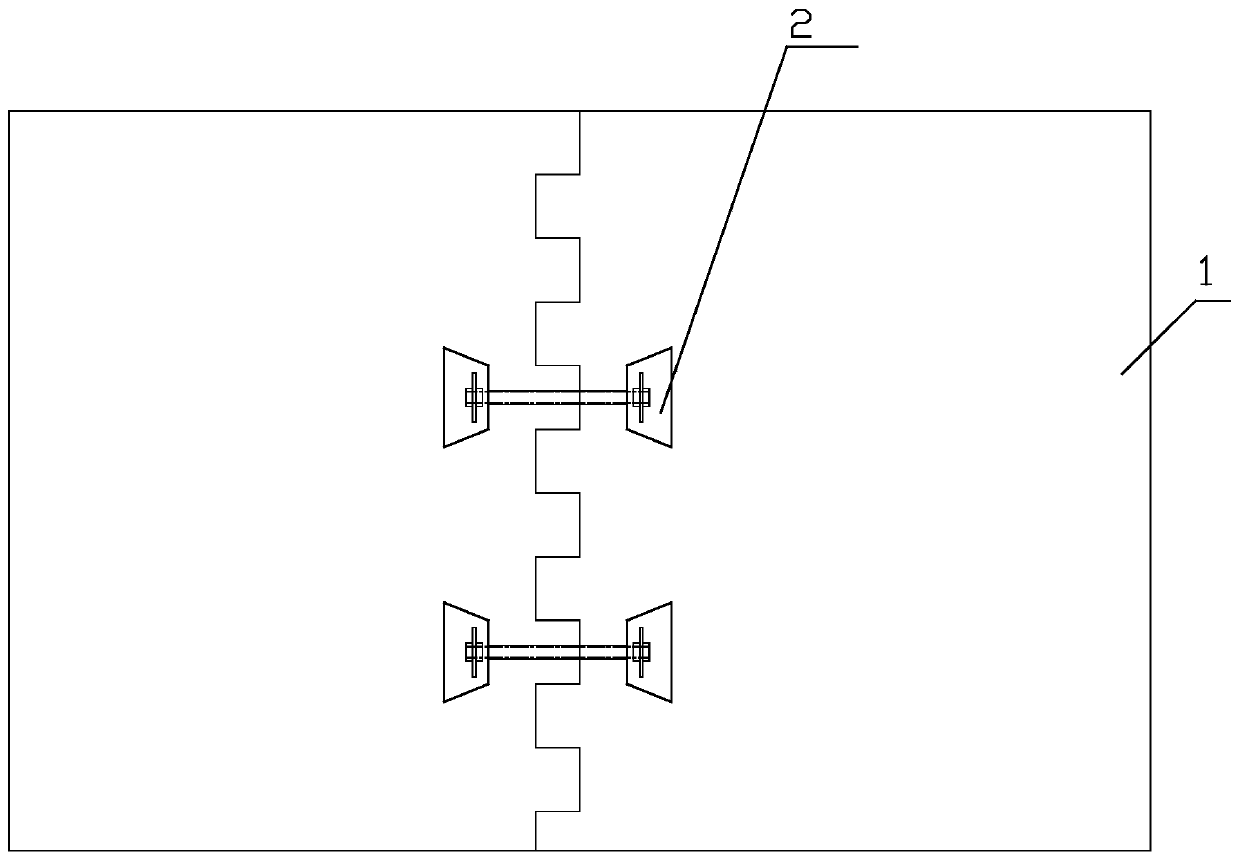

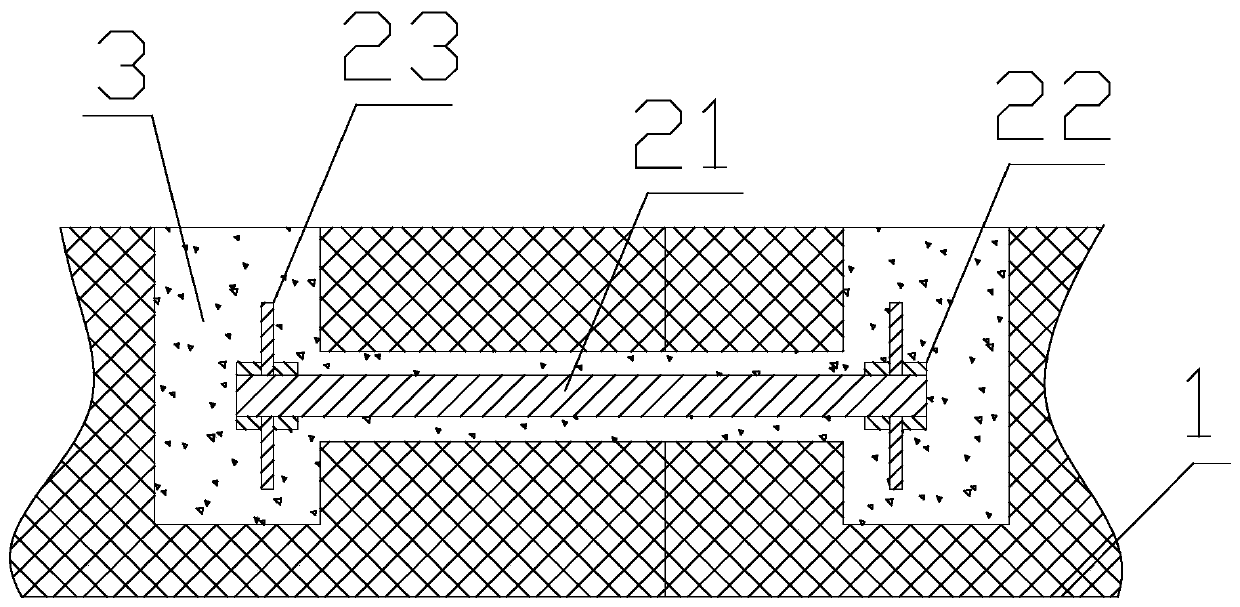

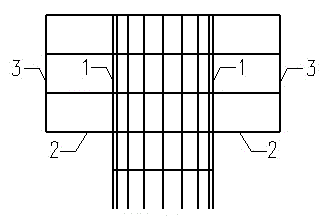

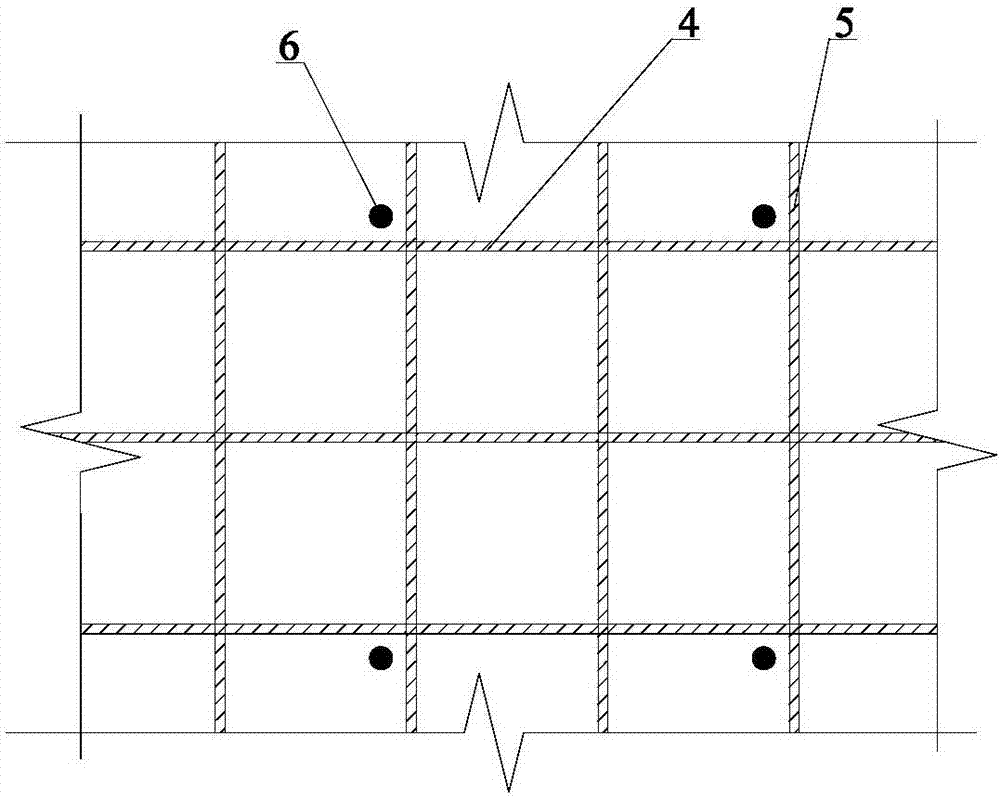

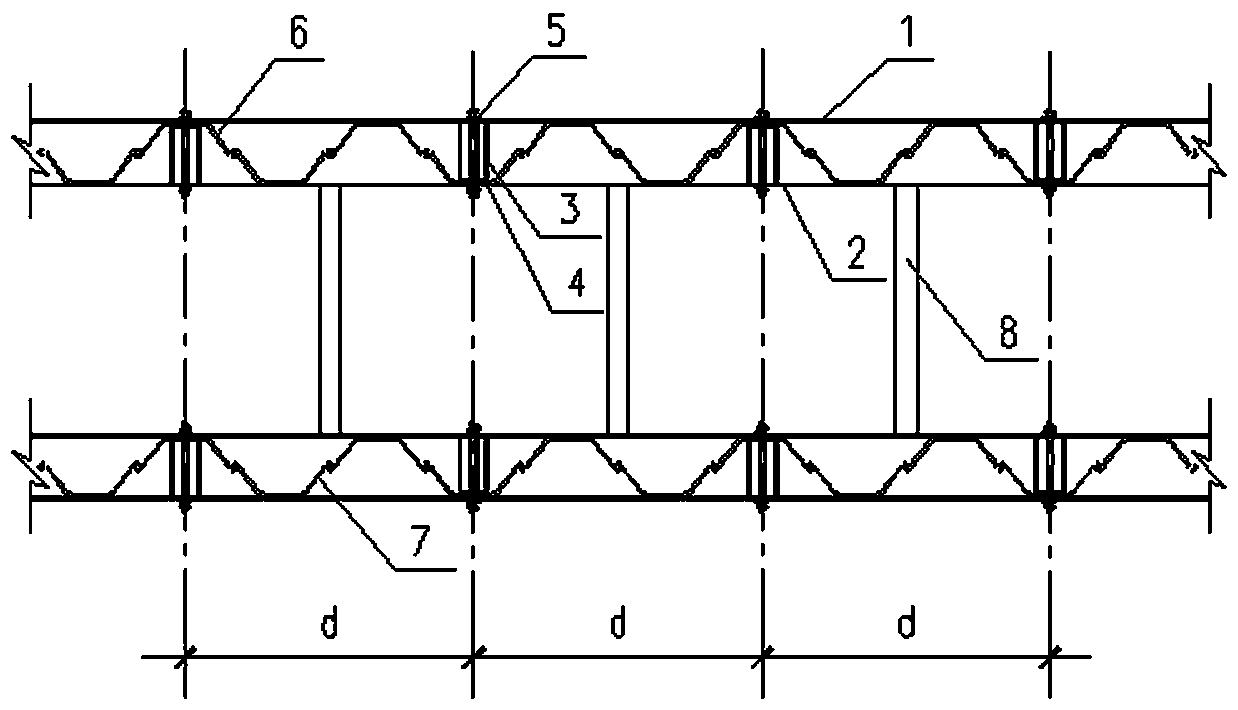

Assembled reinforced concrete beam-slab structural system with cast-in-situ layer in building structure

ActiveCN106065663AReduce workloadImprove standardizationFloorsLoad-supporting elementsReinforced concreteEngineering

The invention discloses an assembled reinforced concrete beam-slab structural system with a cast-in-situ layer in a building structure. The assembled reinforced concrete beam-slab structural system comprises a superposed beam, a superposed slab, reinforcing mesh pieces, the cast-in-situ concrete superposed layer and beam negative reinforcements, wherein the superposed beam is a reinforced concrete precast beam; outwardly projecting tongue-and-grooves are formed in two sides of the upper part of the superposed beam; the superposed slab is horizontally arranged and is a reinforced concrete precast slab; cover-plate-type tongue-and-grooves are formed at the positions, corresponding to the outwardly projecting tongue-and-grooves, on two sides of the superposed slab, and overlapped on the outwardly projecting tongue-and-grooves; the reinforcing mesh pieces and the beam negative reinforcements are horizontally arranged above the superposed beam and the superposed slab; the reinforcing mesh pieces are bundled up with corresponding reinforcements in the superposed beam and the superposed slab; the beam negative reinforcements are bundled up with corresponding reinforcements in the superposed beam; after arrangement of the reinforcing mesh pieces and the beam negative reinforcements, concrete is poured to form the cast-in-situ concrete superposed layer. The assembled reinforced concrete beam-slab structural system has favorable integrity and mechanical property, and the integrity and the anti-seismic property can be improved.

Owner:广东省建科建筑设计院有限公司

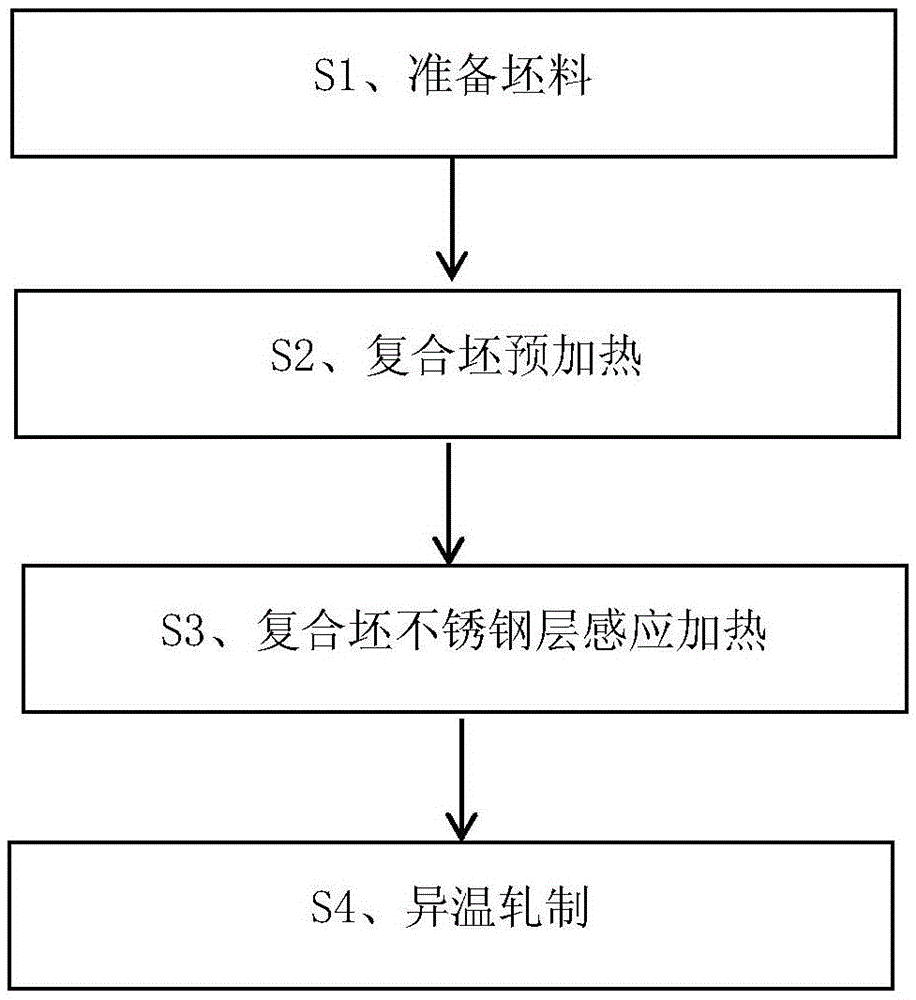

Different-temperature rolling method for preparing stainless steel and carbon steel composite board

ActiveCN105598166AReduce the difference in deformation resistanceMorph coordinationTemperature control deviceWork heating devicesTemperature differenceCarbon steel

The invention provides a different-temperature rolling method for preparing a stainless steel and carbon steel composite board. The different-temperature rolling method comprises the following steps: S1, blank preparation; S2, composite blank pre-heating; S3, composite blank induction-heating; S4, different-temperature rolling. An electromagnetic induction heating method is introduced into a hot-rolling composite process for preparing the stainless steel and carbon steel composite board to perform secondary heating on a stainless steel layer of an integrally-heated composite blank; the deformation resistance difference between the stainless steel layer and a carbon steel layer is reduced through controlling the temperature difference between the stainless steel layer and the carbon steel layer of the composite blank, so that the deformation of the stainless steel layer and the carbon steel layer in the rolling deformation process is more coordinated, therefore, the warping after a single-sided stainless steel composite blank is rolled can be reduced, even eliminated, and the internal residual stress after a double-sided stainless steel composite blank is rolled can be reduced.

Owner:YANSHAN UNIV

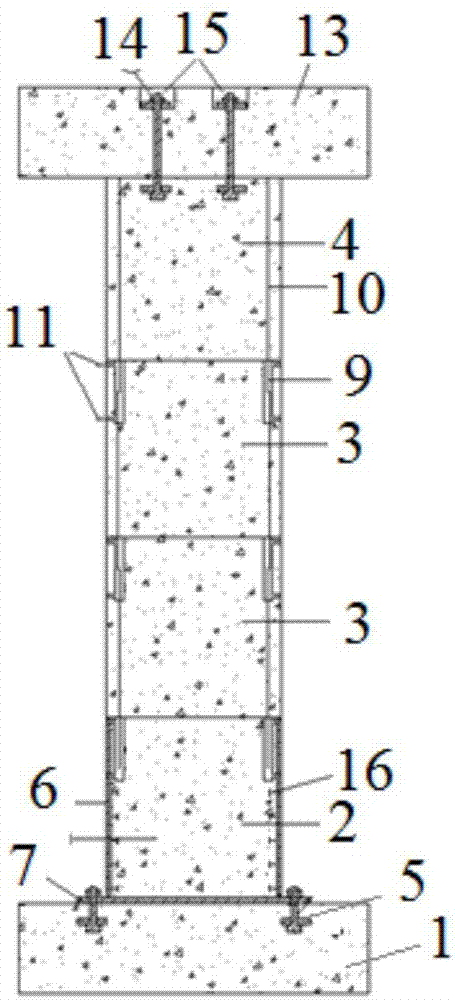

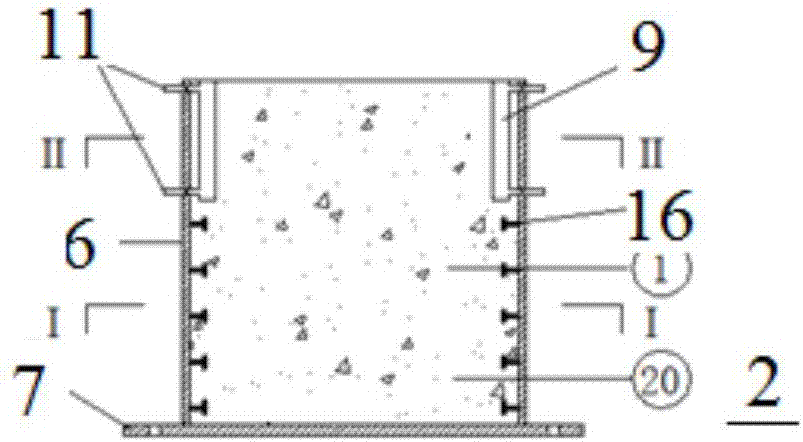

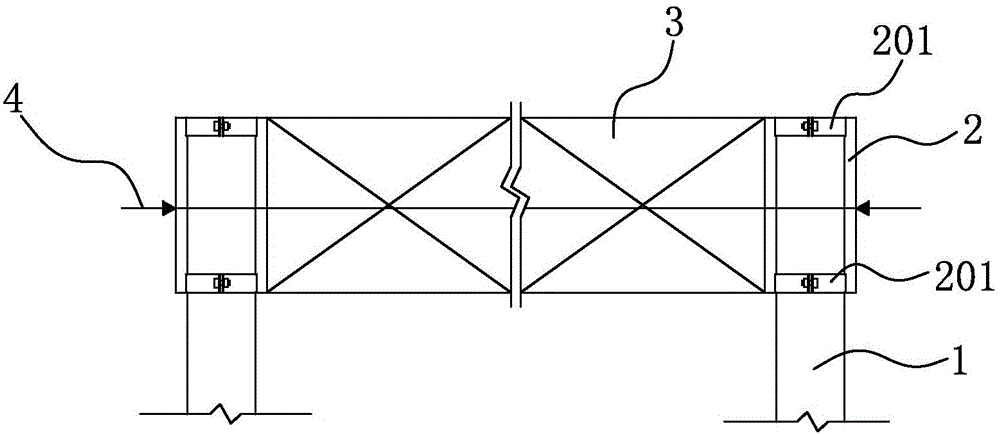

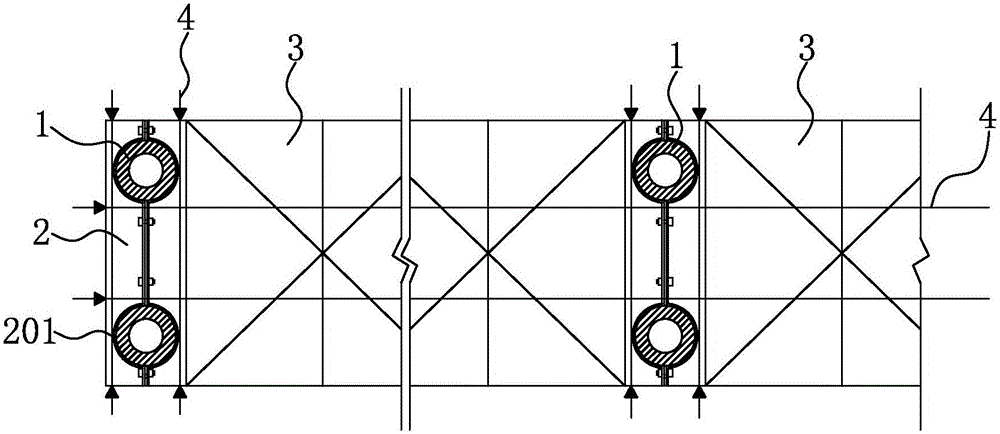

Prefabricated concrete-filled steel tube and concrete-filled steel tube splicing pier

ActiveCN107299588AImprove bearing capacityImprove stress resistanceBridge structural detailsBridge erection/assemblyReinforced concreteRebar

The invention relates to a prefabricated concrete-filled steel tube and a concrete-filled steel tube splicing pier. The concrete-filled steel tube assembling pier comprises a pier base, a prefabricating concrete-filled steel tube section, one or more concrete-filled steel tube middle sections and a prefabricating concrete-filled steel tube top section, wherein the pier base is fixedly connected with the prefabricating concrete-filled steel tube section through bottom anchoring bolts arranged on the pier base; the prefabricating concrete-filled steel tube section is fixedly connected with the concrete-filled steel tube middle sections through connecting units; every two concrete-filled steel tube middle sections are fixedly connected through the connecting units; and the concrete-filled steel tube middle sections are fixedly connected with the concrete-filled steel tube top section through the connecting units. According to the concrete-filled steel tube splicing pier disclosed by the invention, each part of assemblies is simple in structure, so that a plant can be convenient to prefabricate, and on-spot splicing is also convenient; the construction operation speed is increased, and on-spot operation strength can also be effectively reduced. The splicing piece disclosed by the invention has the advantages of being high in bearing force, good in compression resistance, good in bending resistance, good in shearing resistance, good in durability, good in vibration resistance and the like.

Owner:NORTHEASTERN UNIV

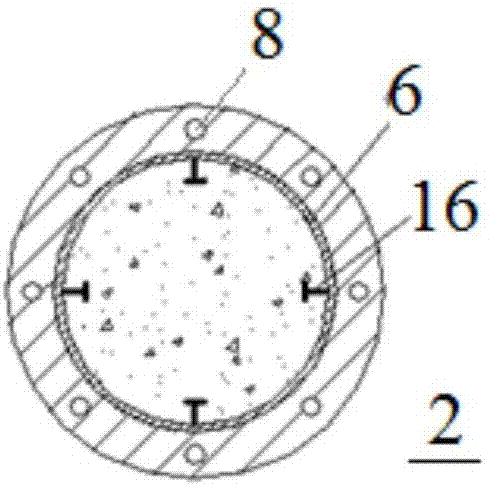

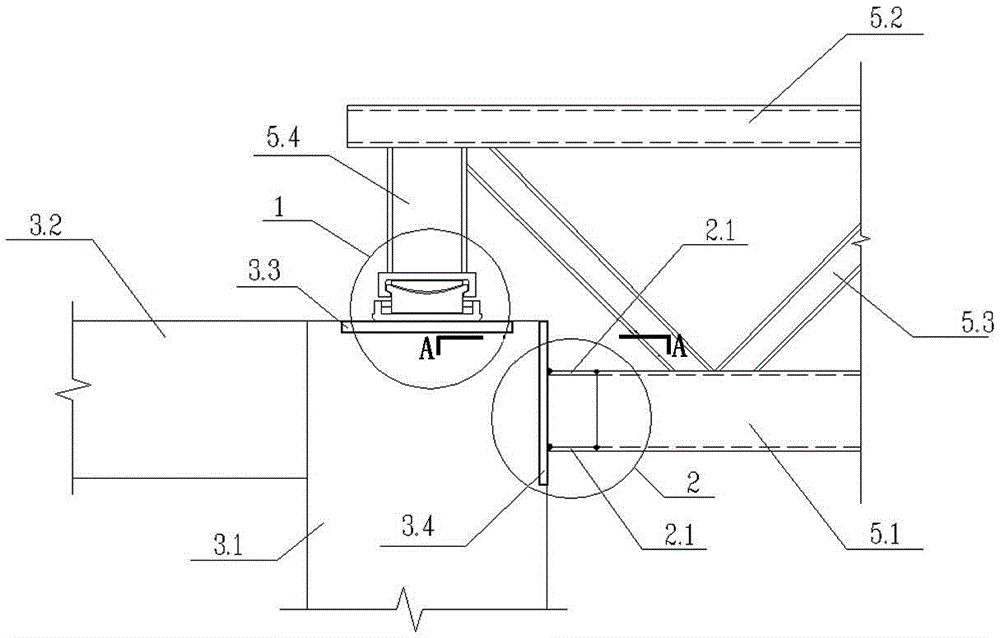

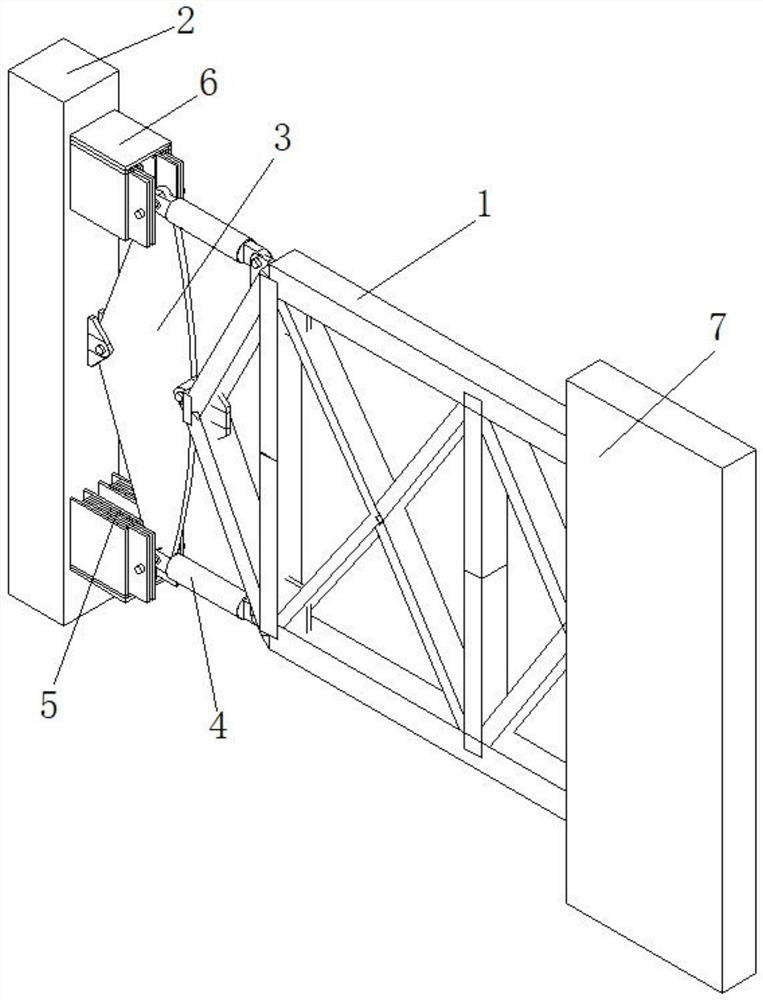

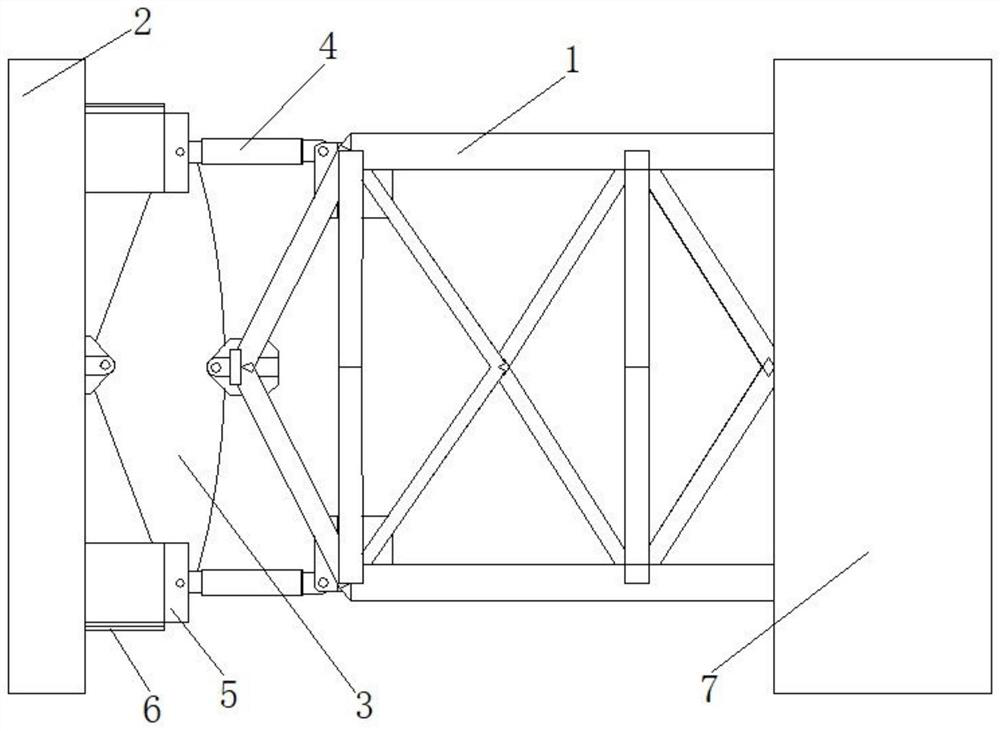

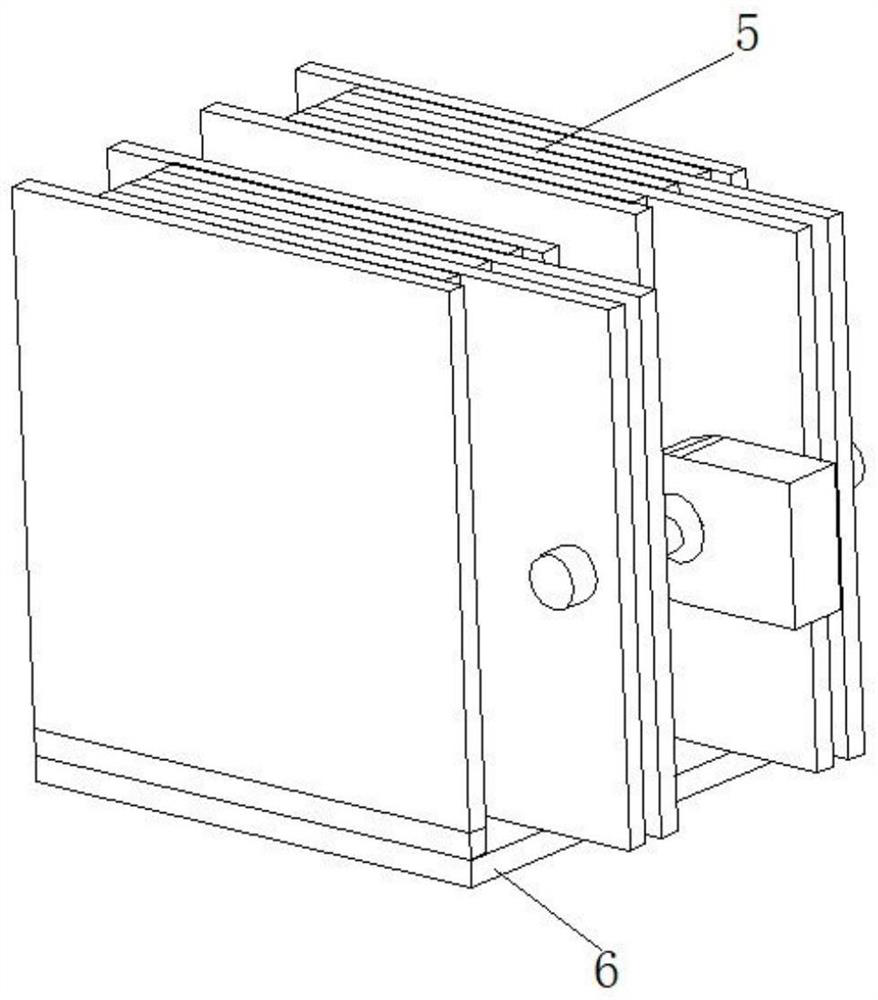

Dragline curtain wall support system with steel truss at top and construction method thereof

ActiveCN105332452ASolve processing problemsImprove structural strengthWallsBuilding material handlingSupporting systemPre stress

The invention provides a dragline curtain wall support system with a steel truss at the top and a construction method thereof. The dragline curtain wall support system comprises main building structures at two sides, a support structure at the lower part, the steel truss at the top and a curtain wall steel cable at the middle, wherein the main building structures provide left and right fixed points of the steel cable, and the steel truss and the support structure at the lower part provide upper and lower fixed points of the curtain wall steel cable; a two-direction fixed mode of horizontal connection and vertical connection is adopted at the two ends of the steel truss and between the main building structures; and the horizontal connection is realized through a horizontal bearing support, and the vertical connection is realized through a vertical bearing support. The dragline curtain wall support system is simple in structure and convenient in construction; by virtue of the two-direction support fixed mode, the structure strength is increased, the node structure is simplified, and the structure safety is greatly increased; The horizontal bearing support is installed after vertical steel cable prestress tension to enable the steel truss to freely rotate under the action of the vertical force, so that the secondary stress of buildings at two sides is reduced; and by transferring force by a horizontal steel plate, the bearing force is large, the stress is reliable, and micro-vertical deformation of the steel truss can also be applicable.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Fabricated prefabricated shear wall and laminated slab node

PendingCN107100290AAvoid the situation of pulling offImprove integrityWallsProtective buildings/sheltersSlurryShock resistance

The invention discloses a fabricated prefabricated shear wall and laminated slab node. The fabricated prefabricated shear wall and laminated slab node comprises a prefabricated shear wall and a laminated slab; a grouting sleeve is arranged at a node body of the prefabricated shear wall and the laminated slab, the lower portion of the grouting sleeve is buried in the upper end of the prefabricated shear wall, and the rest part of the grouting sleeve is located in a post-poured concrete laminated layer of the laminated slab; the bottom end of the grouting sleeve is arranged at the top ends of vertical steel bars located in the prefabricated shear wall, the vertical steel bars downwards and outwards extend out of a prefabricated shear wall located on an upper floor, and the vertical steel bars are inserted into the grouting sleeve from the top end of the grouting sleeve; and a slurry discharging pipe and a grouting pipe are arranged on the upper portion and the lower portion of the grouting sleeve correspondingly, and a grouting material is poured into the grouting sleeve from the grouting pipe till the grouting material overflows from the slurry discharging pipe to enable the grouting sleeve to be completely filled with the grouting material. The grouting sleeve is a connecting piece of the upper-layer shear wall and the lower-layer shear wall, and a plastic hinge is formed at the bottom of the grouting sleeve. The prefabricated shear wall and a prefabricated plate form the wall plate node in an engaged mode through mutual connecting and binding among the grouting sleeve, a steel bar net piece and the post-poured concrete, and integrality and shock resistance of the node are improved.

Owner:广东省建科建筑设计院有限公司 +1

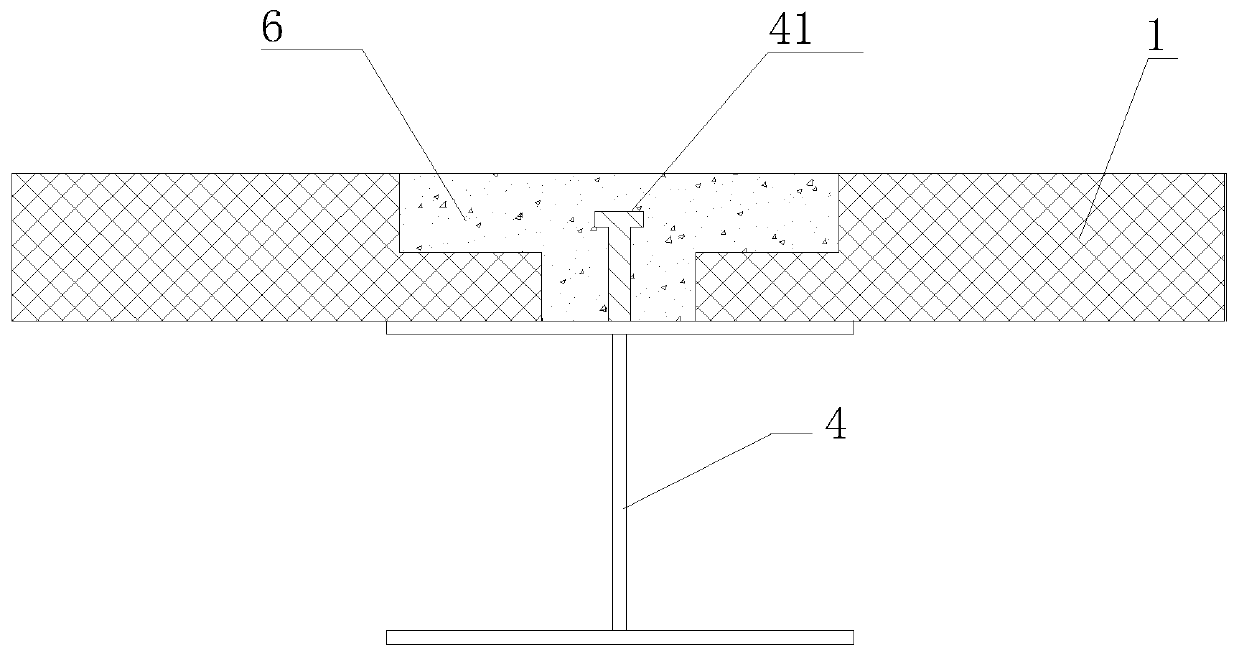

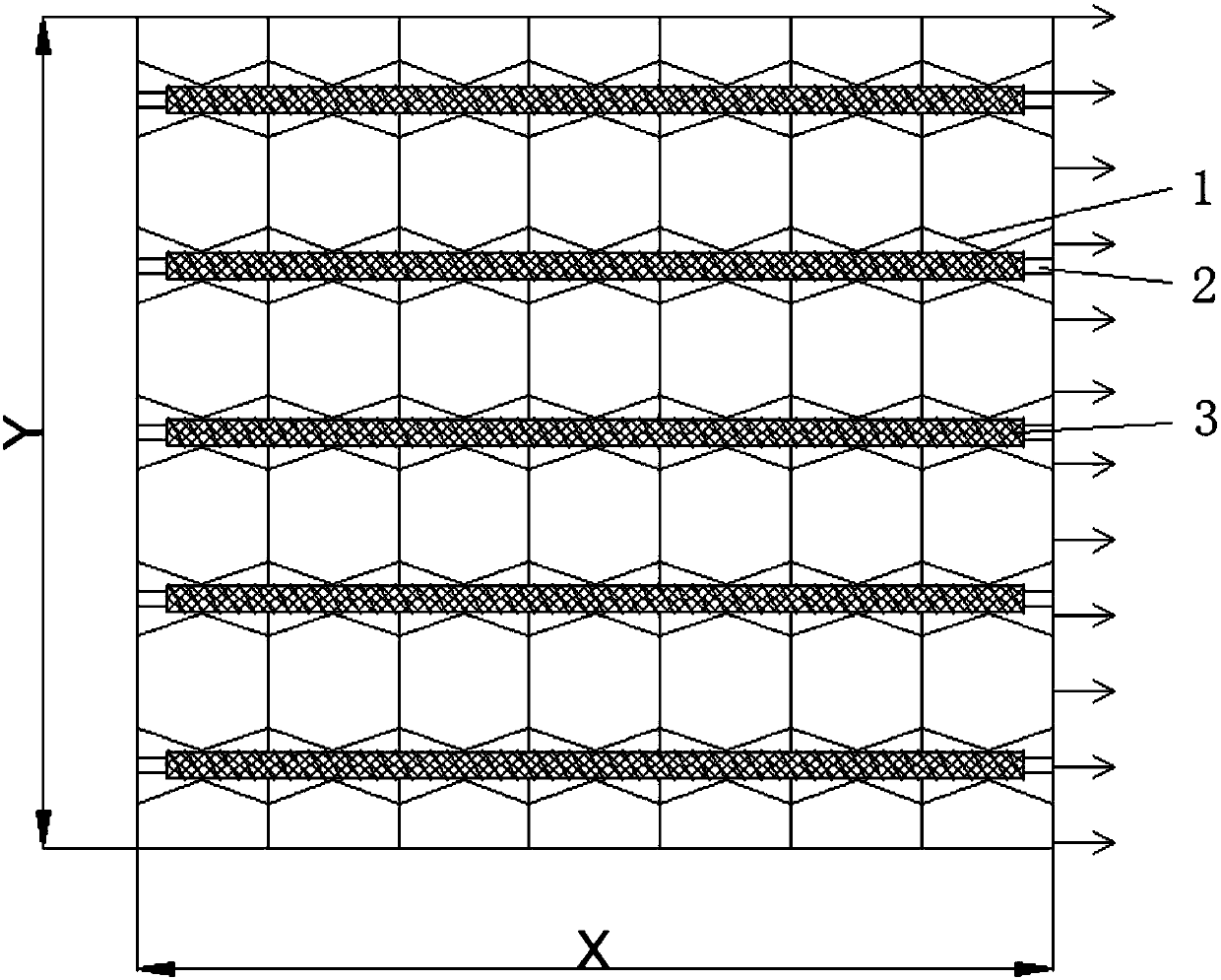

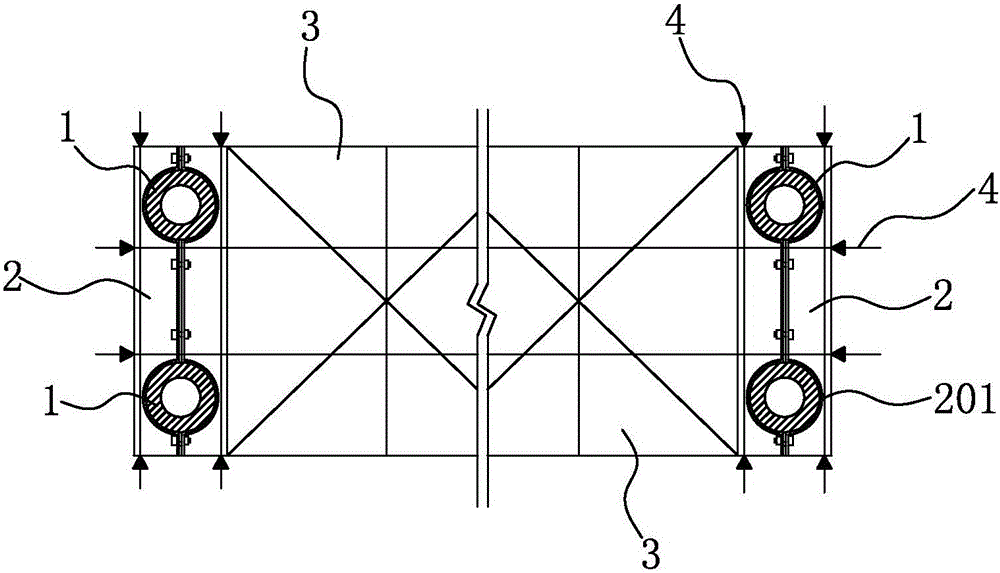

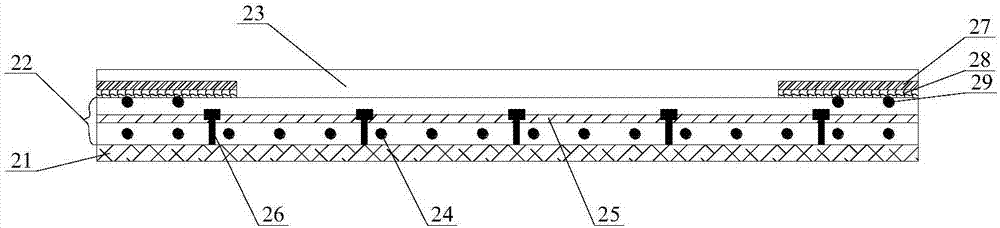

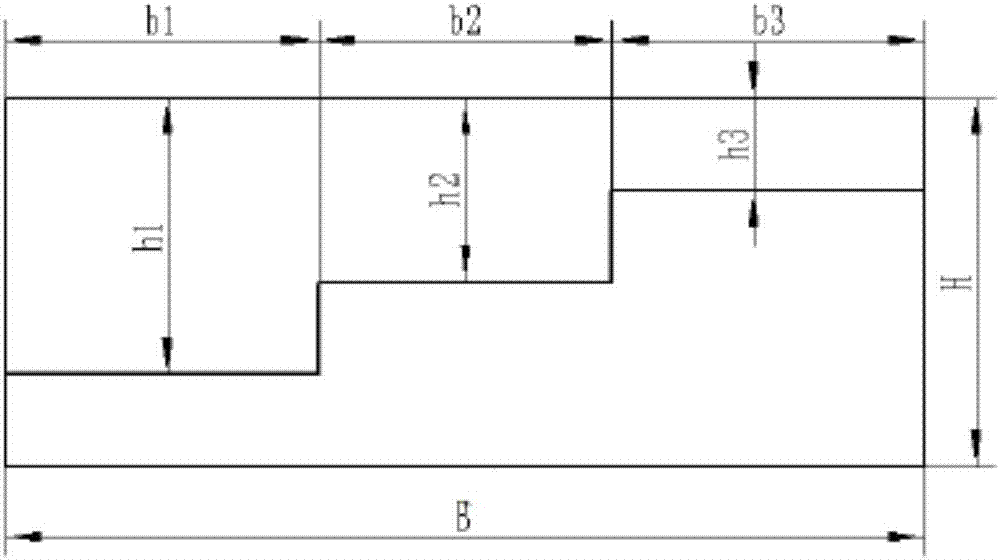

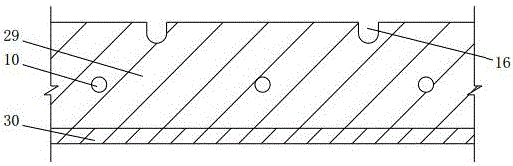

Full-fabricated floor slab assembled-type steel-concrete combined floor

PendingCN110847463ASimple structureImprove performanceClimate change adaptationFloorsFloor slabArchitectural engineering

The invention discloses a full-fabricated floor slab assembled-type steel-concrete combined floor. The floor comprises an H-shaped steel beam and floor slabs which are disposed on the beam. One or more rows of connection studs or other connectors are disposed on the H-shaped steel beam; the two adjacent floor slabs in the steel beam-floor slab connection position are placed on the two sides of theupper flange of the steel beam; the sections, in the joint connection position on the beam, of the floor slabs are in a step shape; V-shaped notches are formed in the lower portions of the steps in the spliced joint connection positions of the floor slabs; shear reinforcements are put in the notches, in the two sides of the spliced joints, of the floor slabs; reinforcements on the upper portionsof the steps in the spliced joint connection positions of the floor slabs extend out, and lap joint reinforcements are placed to be connected with the extend-out reinforcements of the floor slabs on the two sides of the spliced joints; and UHPC or ECC concrete materials fill in the space between the floor slabs on the two sides of the spliced joints and the steel beam. According to the floor, thestud connectors, the V-shaped notches in the floor slabs, the shear reinforcements, the lap joint reinforcement structure and the post-cast UHPC or ECC concrete materials are skillfully utilized, andreliable connection between the floor slabs and the steel beam is formed.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

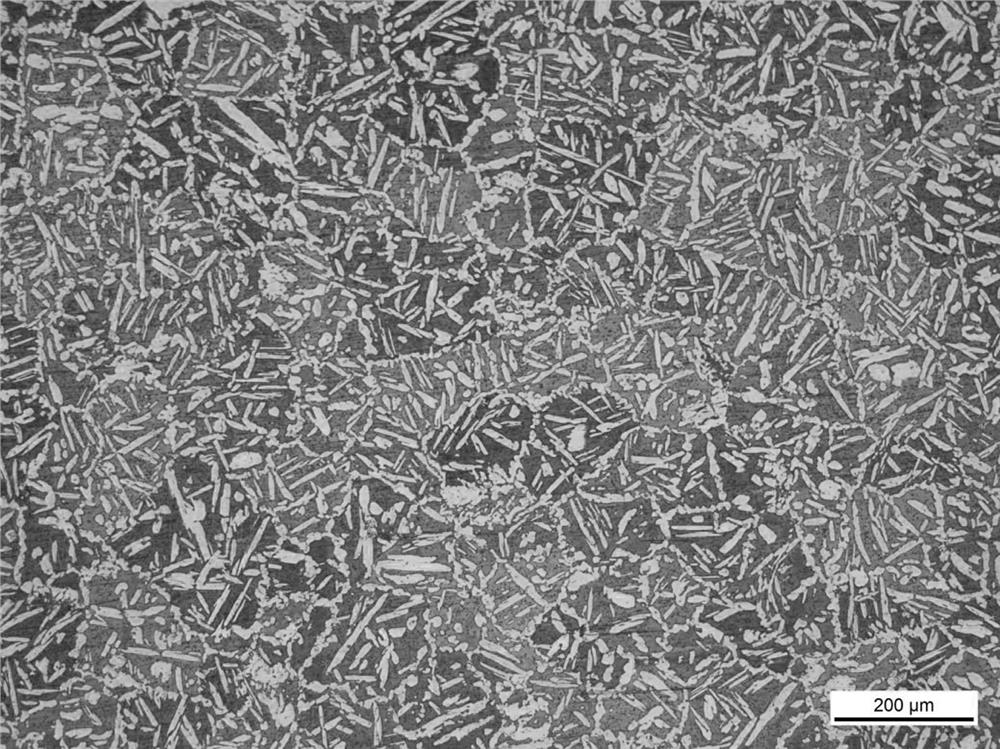

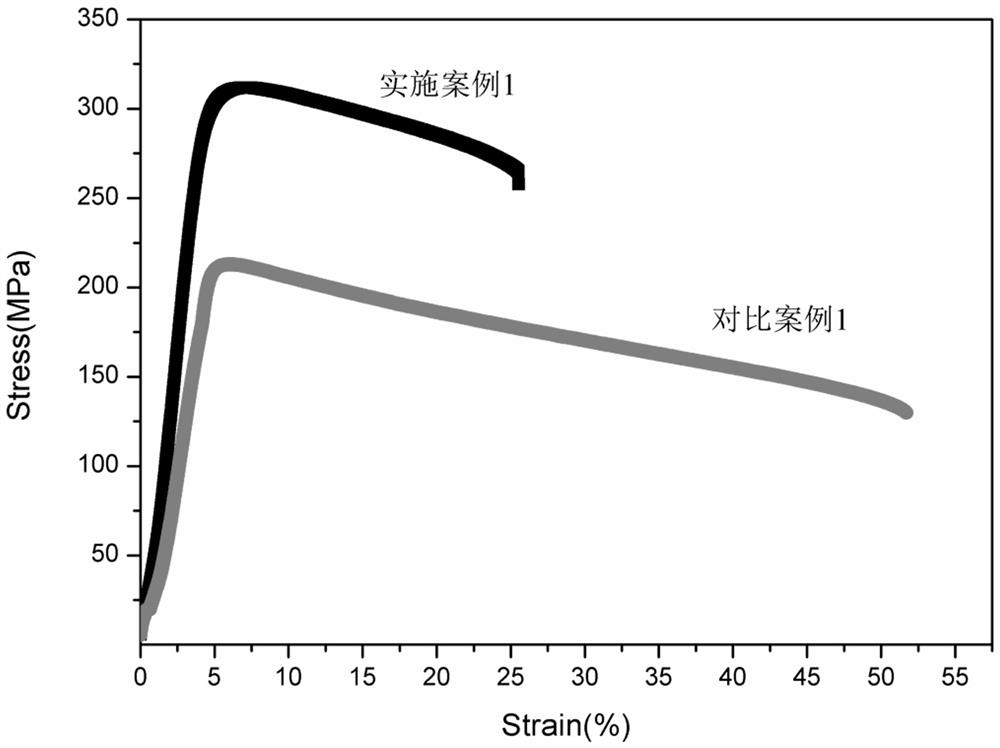

High-strength high-plasticity high-yield-ratio magnesium-lithium alloy and preparation method and application thereof

ActiveCN112593131AGood solid solution strengthening effectMorph coordinationDigital processing power distributionVacuum castingSolution treatment

The invention belongs to the technical field of magnesium-lithium alloy material preparation, and particularly relates to a high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and apreparation method and application thereof. The high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and the preparation method and application thereof are used for solving the problems of low absolute strength, difficult matching of strong plasticity and yield ratio of the magnesium-lithium alloy, the high-strength high-plasticity high-yield-ratio magnesium-lithium alloy material with high yield ratio, good plasticity, stable quality and high purity is obtained by designing the components of the magnesium-lithium alloy, optimizing a vacuum casting process and adopting a novel deformation heat treatment process, and the magnesium-lithium alloy has an industrialized practical application prospect. According to the preparation method of the high-strength, high-plasticity and high-yield-ratio magnesium-lithium alloy, the plastic processing procedure is simple, the maneuverability is high, only medium-high temperature solution treatment and medium-low temperature deformation are needed, intermediate process annealing is not needed, the yield is high, the economical efficiency is high, and the magnesium-lithium alloy product with the tensile strength of 330 MPa, the yield strength of 314 MPa, the elongation of 16% and the yield ratio of up to 95% or above can be obtained through the method.

Owner:郑州轻研合金科技有限公司

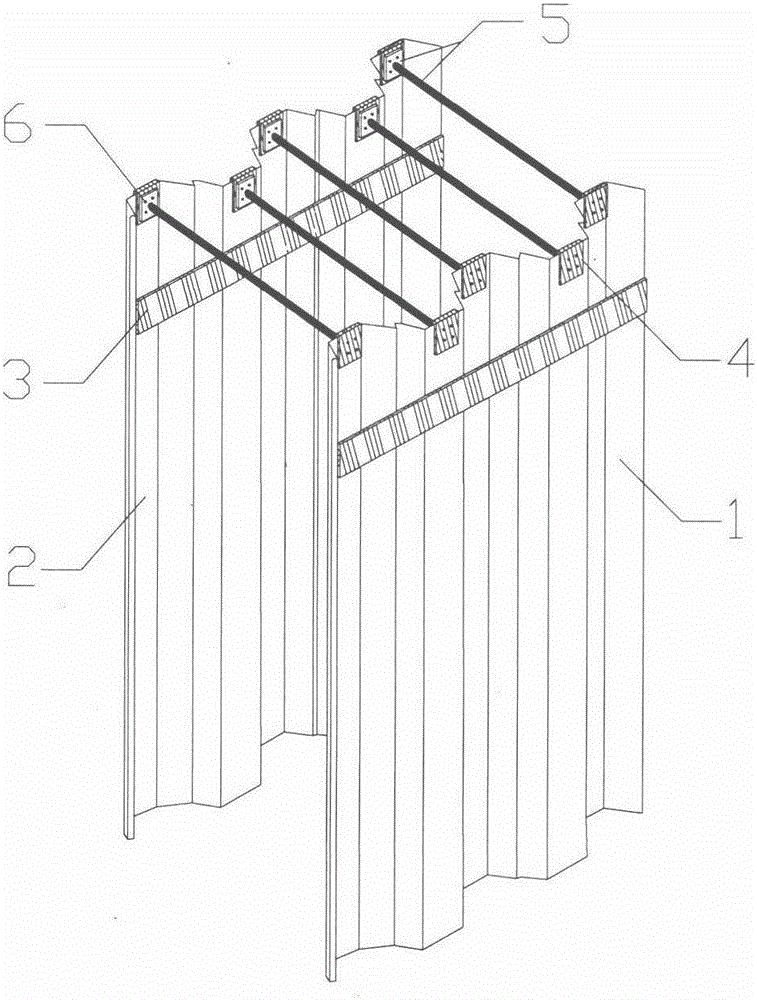

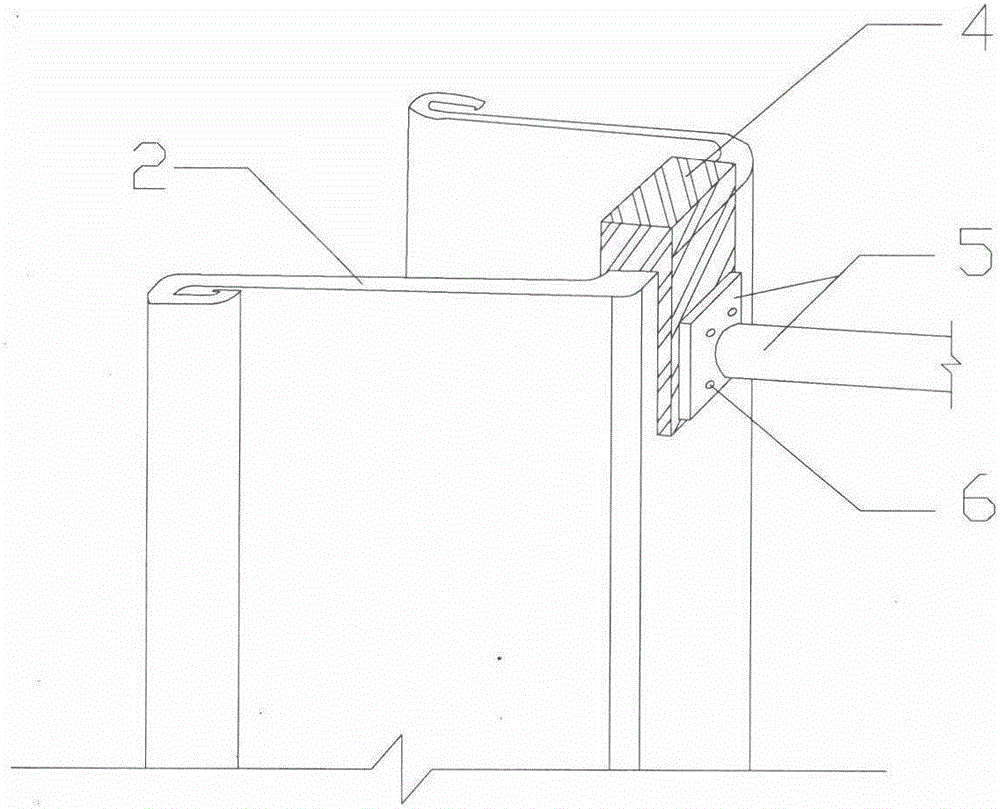

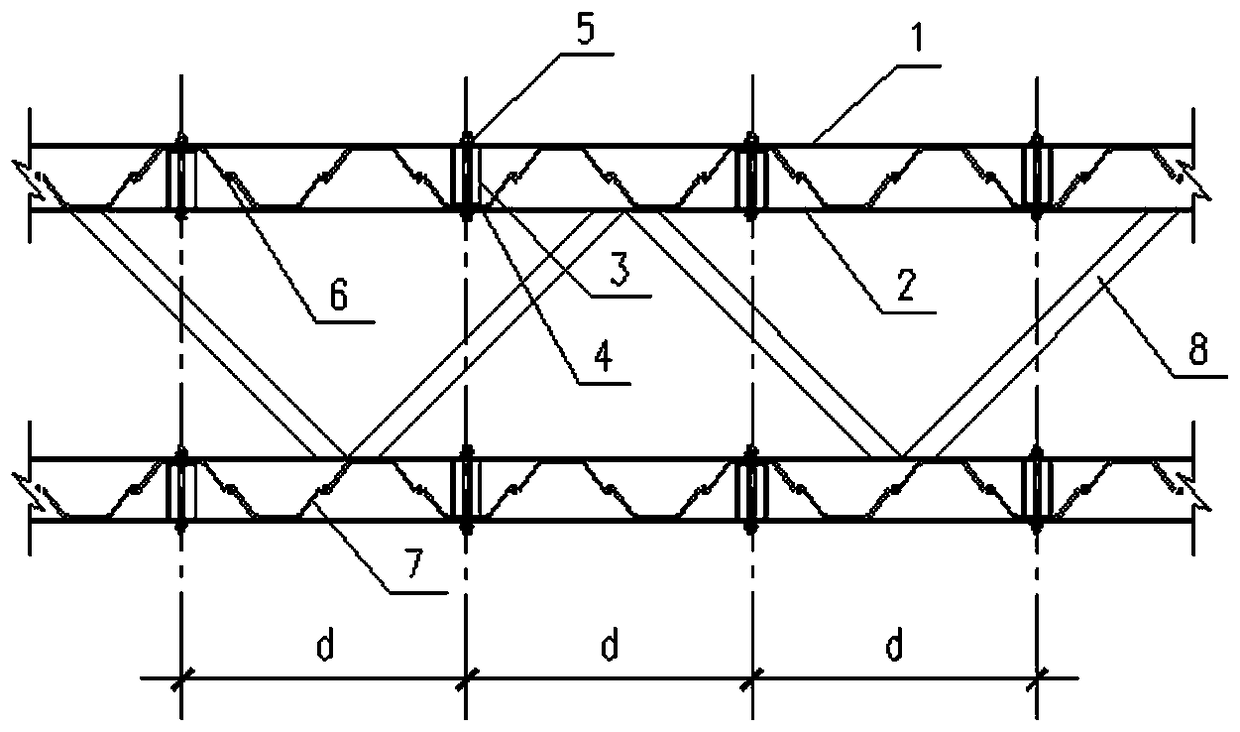

Supporting structure with two rows of steel sheet piles and construction method of supporting structure

ActiveCN106284296AMorph coordinationReduce horizontal forceExcavationsBulkheads/pilesPurlinPrecipitation

The invention discloses a supporting structure with two rows of steel sheet piles and a construction method of the supporting structure. The supporting structure comprises the front-row steel sheet piles, the back-row steel sheet piles, enclosing purlins, clamping grooves, connecting beams and bolts; each row of the steel sheet piles are connected into a whole through the corresponding enclosing purlin, the clamping grooves are formed in the pile tops of the steel sheet piles, the ends of the connecting beams are aligned with the clamping grooves, and the steel sheet piles, the clamping grooves and the connecting beams are all provided with bolt holes and fixed through the bolts for one time. The construction method comprises the steps that firstly, the front-row steel sheet piles and the back-row steel sheet piles are driven, and the enclosing purlins are erected; secondly, the clamping grooves are formed, the connecting beams are fixed, and precipitation is conducted on soil masses and foundation pits which are located between the pile rows; lastly, the foundation pits are excavated, and underground structures are constructed. According to the supporting structure and the construction method, steel structures can be recycled, and the pile tops of the front-row steel sheet piles and the pile tops of the back-row steel sheet piles achieve deformation coordination by fixing the connecting beams; by conducting precipitation on the soil masses between the pile rows, the horizontal borne force of the front-row steel sheet piles is greatly decreased, the seepage path is widened, the foundation pit excavation safety is improved, and the construction cost is reduced.

Owner:NANJING UNIV OF TECH

Extra-large-span truss string off-site hoisting construction method

ActiveCN107338963AEvenly loadedMorph coordinationBuilding material handlingEconomic benefitsEngineering

The invention discloses an extra-large-span truss string off-site hoisting construction method. The method comprises the steps that accurate blanking and machining are carried out, and single trusses are spliced; a sliding track is laid, and a supporting jig frame and a temporary supporting frame are built; a track hoist is used for hoisting the first truss to the temporary supporting frame and hoisting the second truss to the supporting jig frame, and the second truss and the first truss are connected into a rigid whole; an in-situ synchronous symmetrical graded tensioning method is adopted for detecting that tension slow coordinated deformation achieves the self-balance system deformation of a truss string; the temporary supporting frame is detached after an auxiliary truss is installed; the first truss and the second truss are integrally moved forwards by one unit through a hydraulic crawl device; in the same way, all the following trusses are installed one by one in an accumulated sliding mode; and finally unloading is carried out. Splicing is carried out outside a building site and does not affect other professional synchronous construction; hoisting and sliding construction is adopted, the number of the supporting jig frames and large hoisting machines is reduced, and economic benefits are remarkable.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD +1

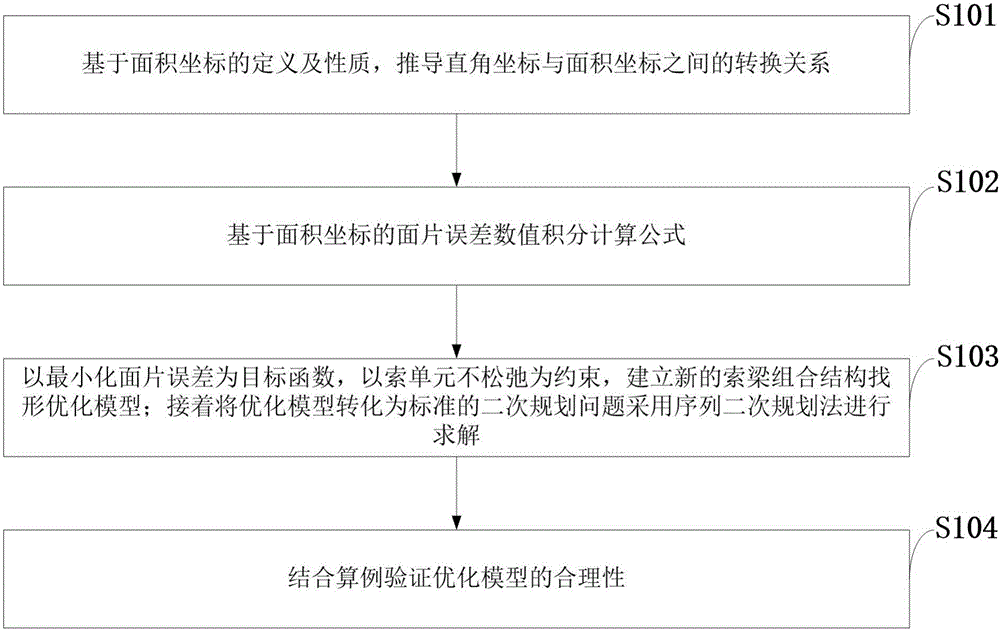

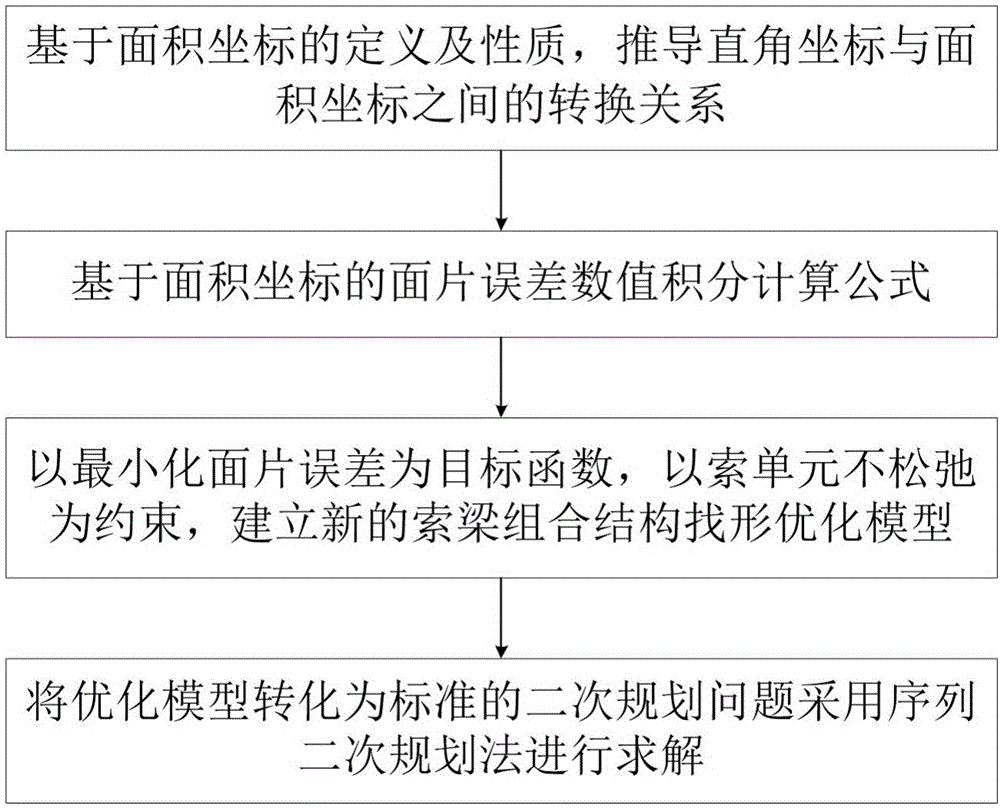

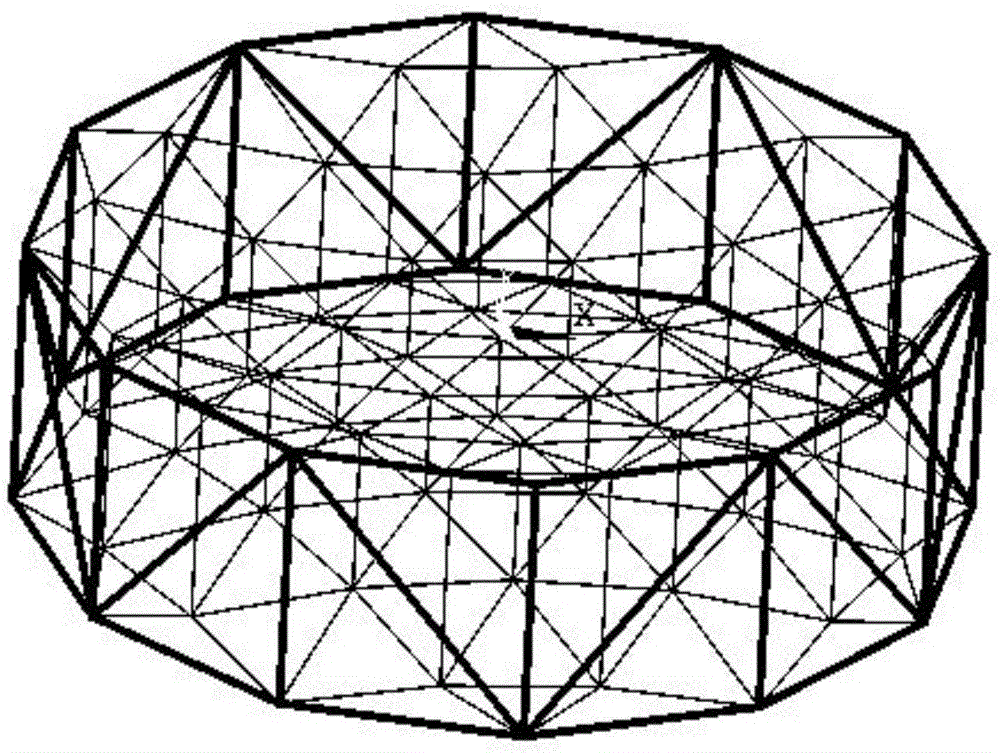

Mesh-shaped extendible antenna shape-finding method based on triangular patch errors

ActiveCN106354906AMeet the hard requirementsImprove surface accuracyDesign optimisation/simulationMulti-objective optimisationRectangular coordinatesPlanning method

The invention discloses a mesh-shaped extendible antenna shape-finding method based on triangular patch errors. The method includes the steps of deducing the conversion relation between rectangular coordinates and area coordinates on the basis of definition and property of the area coordinates, establishing a new cable and beam combination structure shape-finding optimizing model on the basis of a patch error numerical value integral calculating formula of the area coordinates with the minimized patch errors as the target function and the cable unit non-looseness as the constraint, and converting an optimization model into a standard secondary planning problem to be solved by means of a sequence secondary planning method. The shape surface precision of a reflection surface can be improved when it is ensured that a cable section is free of looseness, and meanwhile the mechanical property of an antenna structure is improved compared with a traditional shape-finding method; the precision of the reflection surface can be accurately represented, and the result is more reliable; meanwhile, the patch errors should be considered in the shape-finding process, and the shape-finding result better than that obtained with the minimized node root-mean-square error as the target can be obtained with the minimized reflection surface patch error as the target.

Owner:XIDIAN UNIV

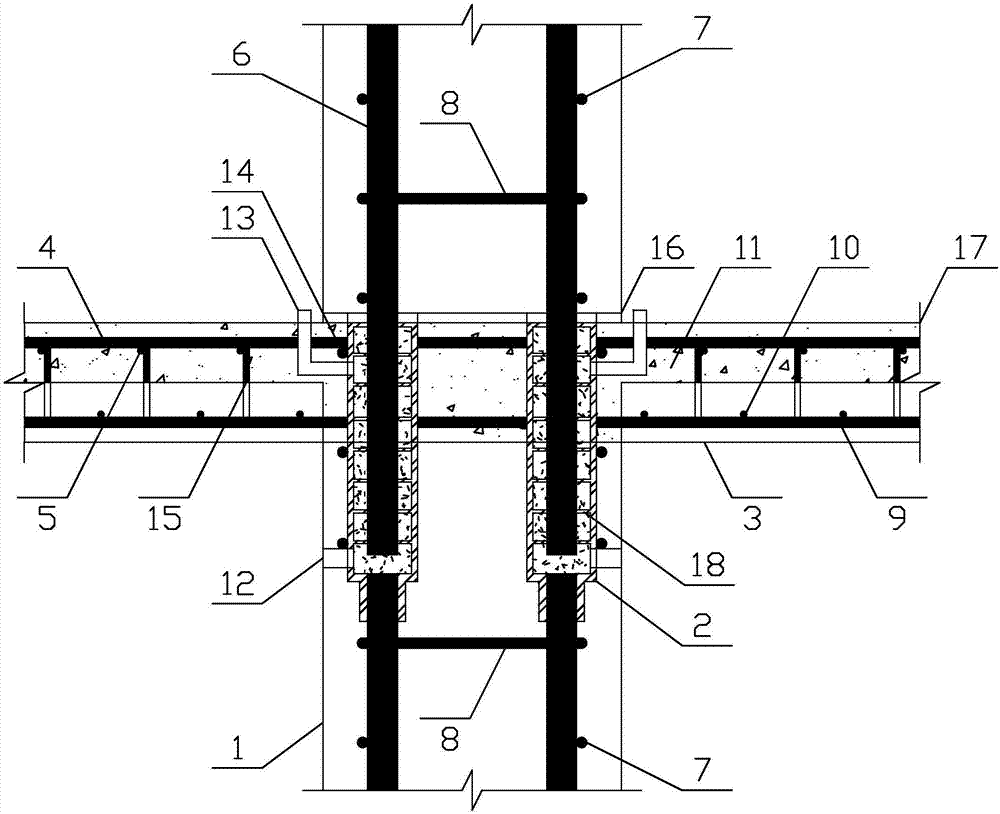

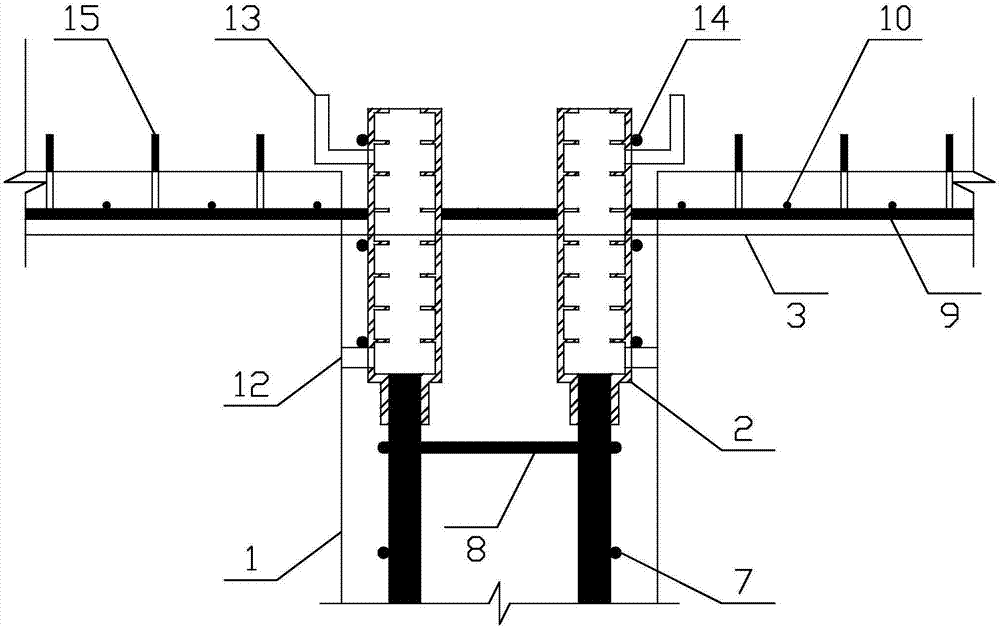

Joint of fabricated precast shear wall and laminated slab connected with fabricated precast shear wall by combined grouting sleeves

PendingCN106968381AImprove seismic performanceIncrease production capacityFloorsBuilding reinforcementsSteel barPlastic hinge

The invention discloses a joint of a fabricated precast shear wall and a laminated slab connected with the fabricated precast shear wall by combined grouting sleeves. The combined grouting sleeves are arranged at the joint. Each combined grouting sleeve comprises a first section sleeve body and a second section sleeve body; the top ends of the first section sleeve bodies are connected with the bottom ends of the second section sleeve bodies; the bottom ends of the first section sleeve bodies are connected on the top ends of vertical steel bars in the precast shear wall and completely pre-buried in the top ends of the precast shear wall, and the second section sleeve bodies are pre-buried in post-poured concrete laminated layers; the vertical steel bars extend downward out of the precast shear wall on the last storey, the vertical steel bars are inserted in the second section sleeve bodies from the top ends of the second section sleeve bodies and extend into the first section sleeve bodies; and mortar discharging pipes are arranged on the upper portions of the second section sleeve bodies, and grouting pipes are arranged on the lower portions of the first section sleeve bodies. The combined grouting sleeves serve as connecting pieces of the shear wall on the upper layer and the shear wall on the lower layer. Shear wall members form plastic hinges at the bottom. The shear wall and the precast slab form the joint through mutual connection and bonding occlusion among the sleeve bodies, steel bar meshes and post-poured concrete, and the integrity and anti-seismic performance of the joint are improved.

Owner:广东省建科建筑设计院有限公司 +1

Active deformation honeycomb structure skin based on pneumatic muscle

The invention discloses active deformation honeycomb structure skin based on a pneumatic muscle, belongs to the field of deformation aircrafts, and aims to solve the problem of poor deformation performance of the conventional skin structure. The active deformation honeycomb structure skin based on the pneumatic muscle comprises a silicon rubber material, the pneumatic muscle, a spring and a zero-Poisson-ratio honeycomb structure, wherein the outer surface of the pneumatic muscle is sleeved with the spring; the pneumatic muscle sleeved with the spring is inserted into the zero-Poisson-ratio honeycomb structure; the pneumatic muscle passes through a rib piece of each honeycomb unit in the zero-Poisson-ratio honeycomb structure; two ends of pneumatic muscle are fixedly arranged on boundary rib pieces of the zero-Poisson-ratio honeycomb structure respectively; the silicon rubber material is attached to the surface of the zero-Poisson-ratio honeycomb structure to serve as a skin material. The active deformation honeycomb structure skin based on the pneumatic muscle disclosed by the invention has the advantages of high carrying capability along a vertical direction, large deformation being up to 30 to 40 percent in a deformation direction, coordinated deformation of a honeycomb and the pneumatic muscle, and easiness in control.

Owner:苏州因诺威汽车科技有限公司

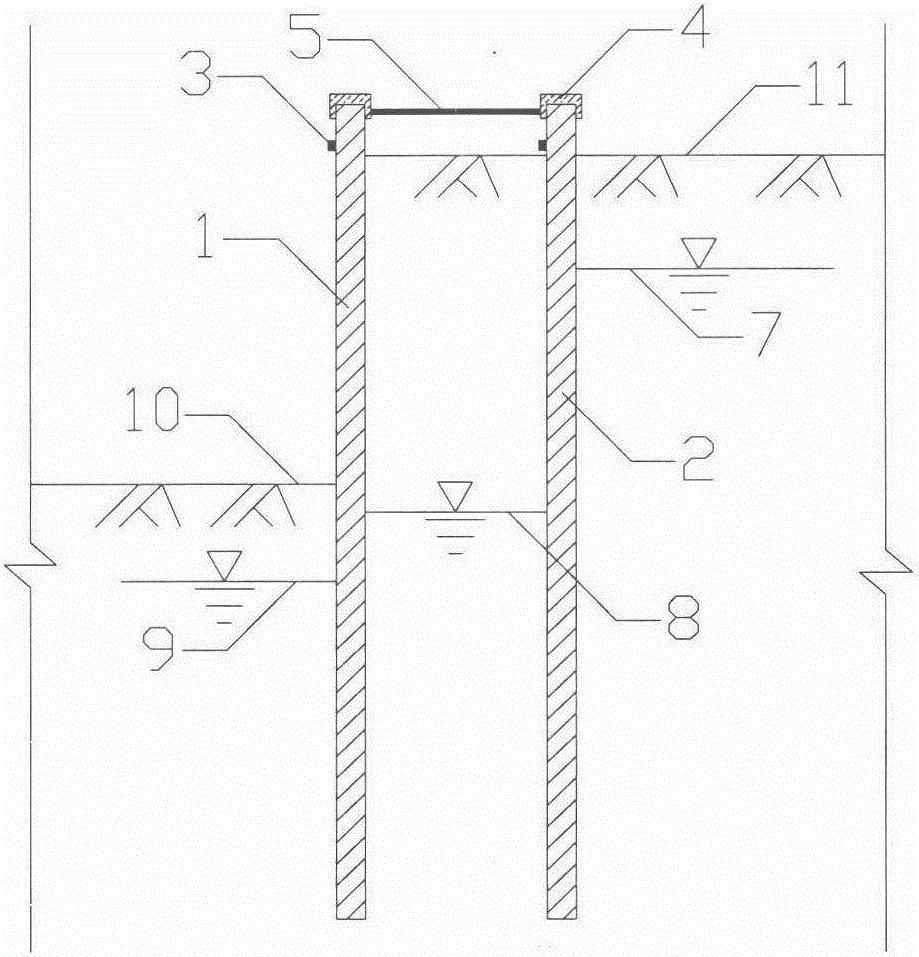

Prefabricated double-row pile and water-stop curtain integrated foundation pit supporting structure and construction method thereof

The invention relates to a prefabricated double-row pile and water-stop curtain integrated foundation pit supporting structure and a construction method thereof. The structure comprises double rows of piles, steel frame beams, crown beams and cemented soil stirring piles; the double rows of piles comprise the front row of piles and the rear row of piles formed through the manner that a front concrete pipe pile and a rear concrete pipe pile which are arranged at an interval serve as a unit, and the units are evenly arranged along the edge of a foundation pit; the corresponding detachable steel frame beam is connected between the tops of two concrete pipe piles in each unit; the detachable crown beams are fixedly connected between adjacent steel frame beams of the double rows of piles; and the cemented soil stirring piles are arranged between the front row of concrete pile piles of the double rows of piles and between the front row of piles and the rear row of piles, and a water-stop curtain is formed. The construction method comprises the steps that the positions of the double rows of piles and the positions of the cemented soil stirring piles forming the water-stop curtain are subject to division and piling, cemented soil is poured into the positions, the prefabricated concrete pipe piles are inserted into the corresponding positions of the double rows of piles, the corresponding steel frame beam is fixedly connected between two concrete pipe piles of each unit, the corresponding crown beam is fixedly connected between two steel frame beams, and after cemented soil materials are solidified, construction is completed.

Owner:NINGBO CONSTR ENG GROUP

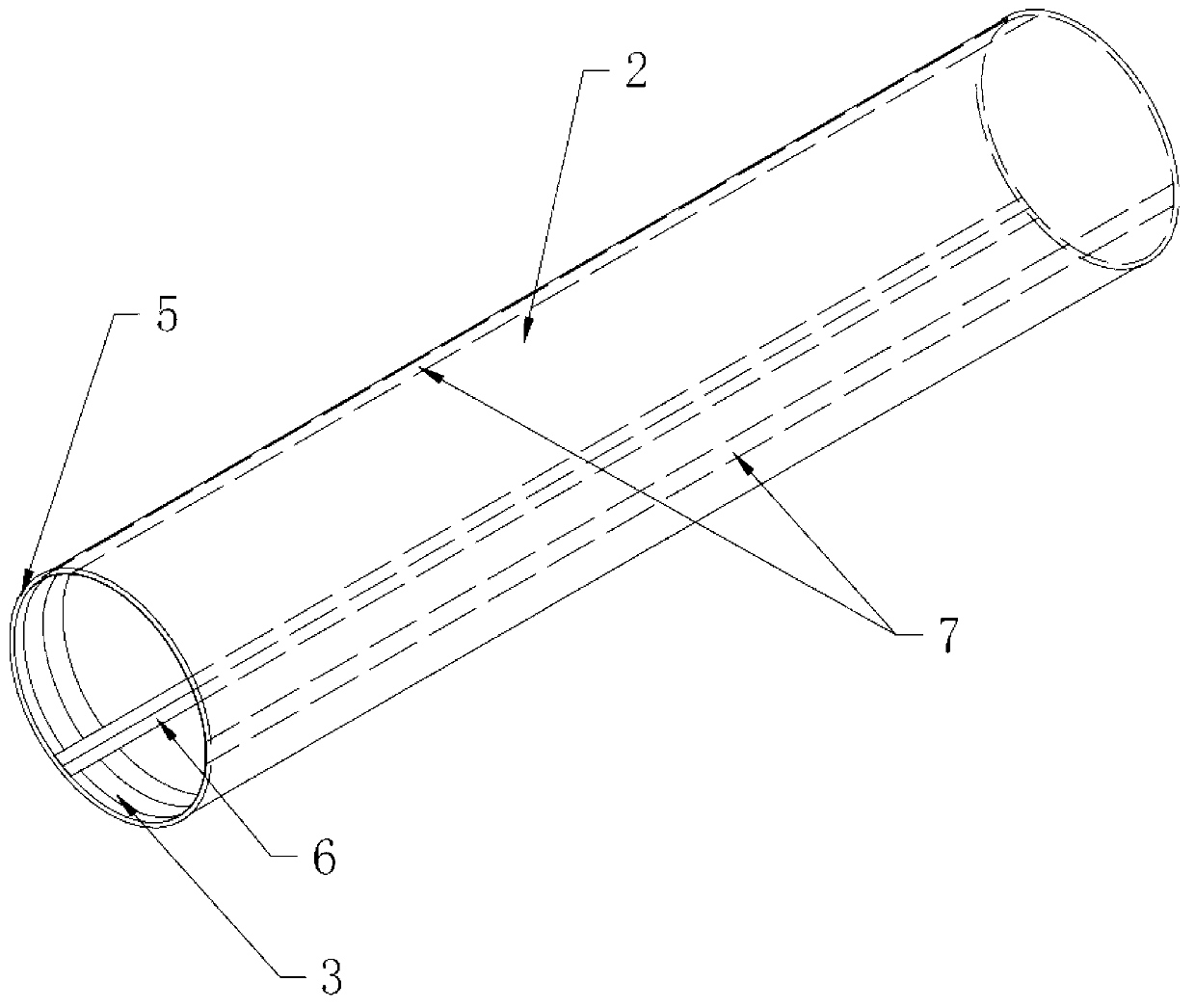

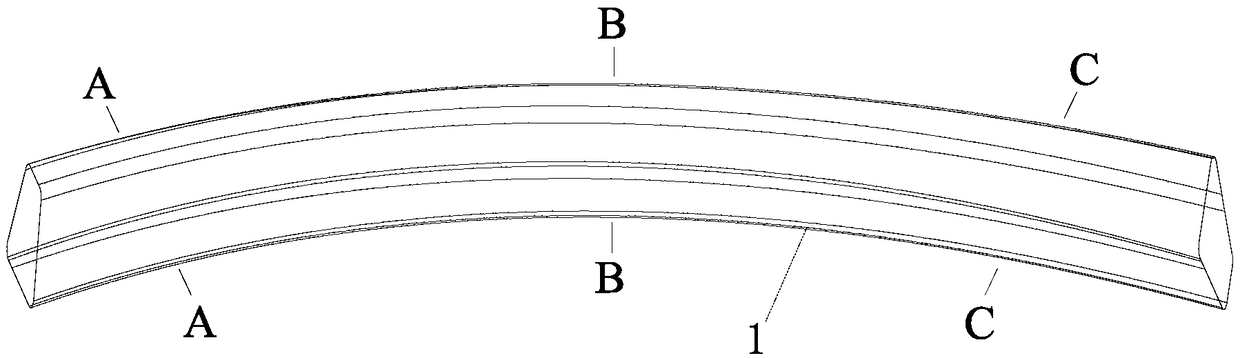

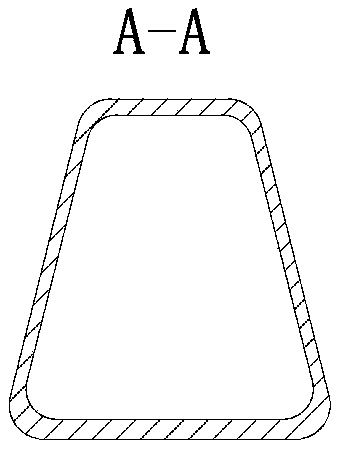

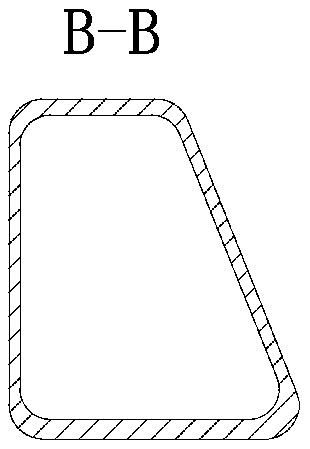

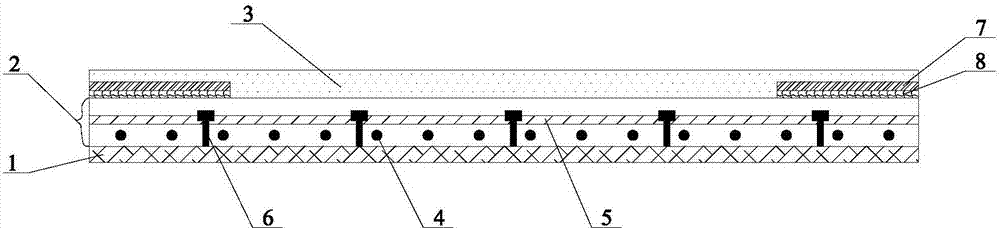

Pneumatic membrane compression bar and manufacturing method thereof

ActiveCN102995748AImprove air tightnessLight in massExtraordinary structuresRubber ringMechanical engineering

The invention discloses a pneumatic membrane compression bar and a manufacturing method thereof and belongs to the field of pneumatic membrane structures. The pneumatic membrane compression bar comprises a bar end enclosure (1), a tubular air bag (2), reinforcing membrane materials (3), a sealing rubber ring (4), buried ropes (5), a thermal bonding seam rib (6), a balancing rib (7), an air inlet (8), an air outlet (9), a bar end steel hoop (10) and a sealing rubber pad (11). The pneumatic membrane compression bar is characterized in that a membrane material and the thermal bonding seam rib (6) are connected to form the tubular air bag (2), and meanwhile, the tubular air bag (2) is internally provided with the balancing rib (7); the inner walls at two ends of the air bag are additionally provided with the reinforcing membrane materials (3), and the buried ropes (5) are embedded in the ends of the air bag; and the tubular air bag (2) is connected with the bar end enclosure (1) by using the bar end steel hoop (10), and meanwhile, construction measures including the sealing rubber ring (4), the sealing rubber pad (11) and the buried ropes (5) are adopted between the tubular air bag (2) and the bar end enclosure (1) so that the pneumatic membrane compression bar is assembled. The pneumatic membrane compression bar has the characteristics of high compression resistant rigidity, light weight, high bearing capability and convenience in deformation compatibility, manufacture and installation.

Owner:BEIJING UNIV OF TECH

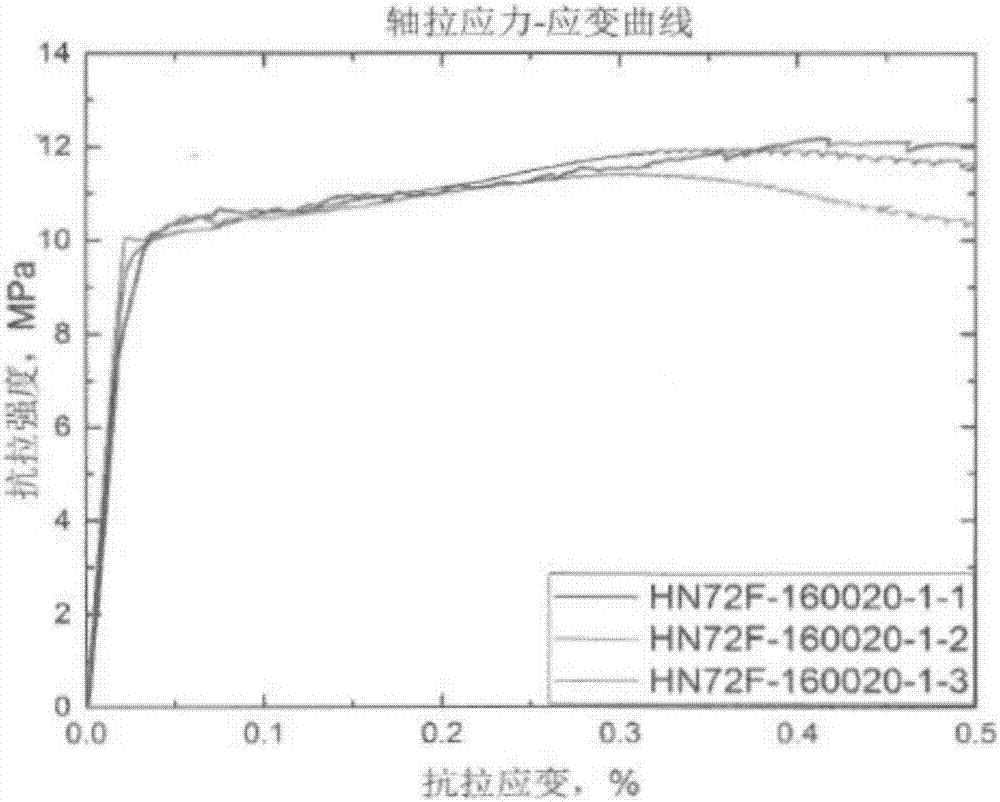

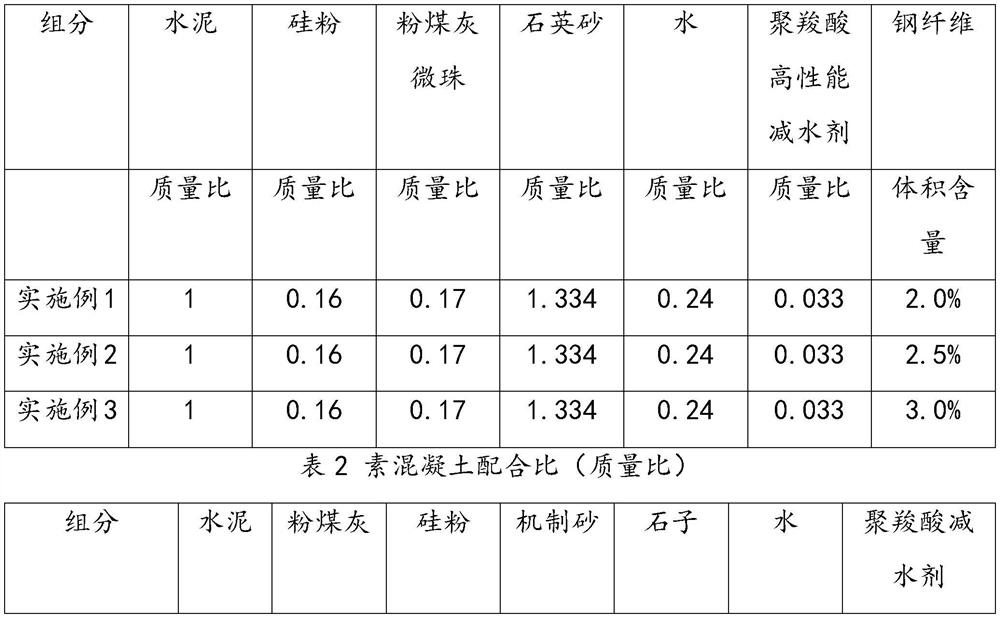

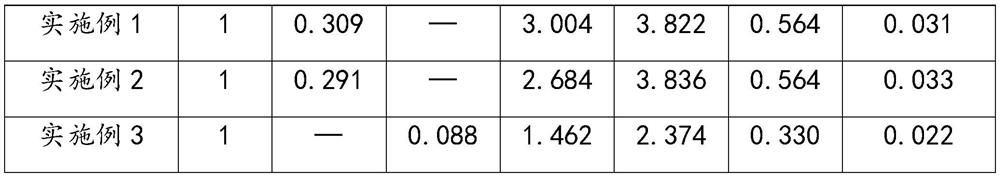

Normal temperature curing type ultrahigh-performance concrete and application thereof

InactiveCN107129237ASolve the problem of long curing time in high temperature steam curingExtended service lifeBuilding componentsBridge structural detailsFiberDefoaming Agents

The invention relates to normal temperature curing type ultrahigh-performance concrete and an application thereof. The concrete per cubic meter comprises, by weight, 600-1200kg of cement, 50-200kg of mineral additives, 800-1200kg of fine aggregate, 78-300kg of steel fiber, 3-15kg of a water reducing agent (solid content), 0.6-5kg of a defoaming agent, 60-129kg of an expanding agent and 100-250kg of water. Compared with the prior art, the normal temperature curing type ultrahigh-performance concrete has the advantages of good ductility, less proneness to cracking, coordination deformation with construction panels and improvement of structural tension performance; the normal temperature curing type ultrahigh-performance concrete is short in curing time, 3 hours is enough for completion of curing, construction time can be effectively reduced, compressive strength is not less than 120Mpa, and service life of the ultrasonic-performance concrete is prolonged.

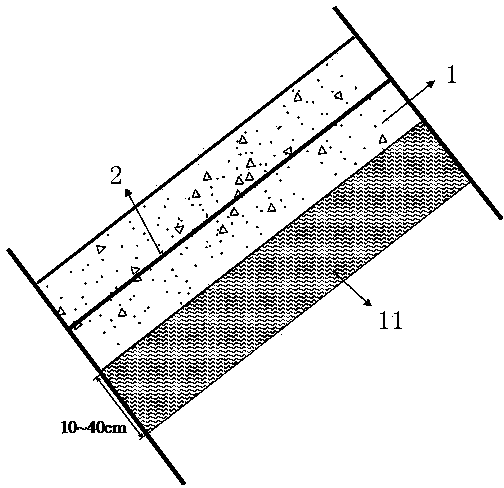

Anti-seismic face plate structure for rock-fill dam with concrete face plate and method for constructing face plate anti-seismic structure

InactiveCN103422473AImprove panel stressPrevent leakageBarrages/weirsEarth-fill damsEarthquake resistantEarth quake

The invention discloses an anti-seismic face plate structure for a rock-fill dam with a concrete face plate and a method for constructing the anti-seismic face plate structure. The method includes that a middle sandwich layer is laid along an area between the concrete face plate and a cushion of the rock-fill dam with the concrete face plate within the dam height range 0-H of a rock-fill dam body with the concrete face plate, and the H represents the dam height; the middle sandwich layer is an asphalt concrete face plate layer or a plastic concrete face plate layer, and perpendicular open seams are reserved in the plastic concrete face plate layer; when the middle sandwich layer is the plastic concrete face plate layer, the perpendicular open seams reserved in the plastic concrete face plate layer and perpendicular open seams reserved in the concrete face plate are staggered from one another, and a protective layer is coated on a surface layer of the middle sandwich layer. The anti-seismic face plate structure and the method have the advantages that the middle sandwich layer is laid between the original concrete face plate and the cushion, the anti-seismic face plate structure is in such a face plate structure form that stress conditions of the face plate in an operating period and an earthquake period are sufficiently improved by the aid of asphalt concrete and plastic concrete, and a project can be advantageously constructed efficiently, conveniently and quickly; the plastic concrete or the asphalt concrete is particularly laid, deformation among the original concrete face plate and cushion materials is coordinated, and leakage due to the fact that the face plate cracks in tension can be prevented.

Owner:DALIAN UNIV OF TECH

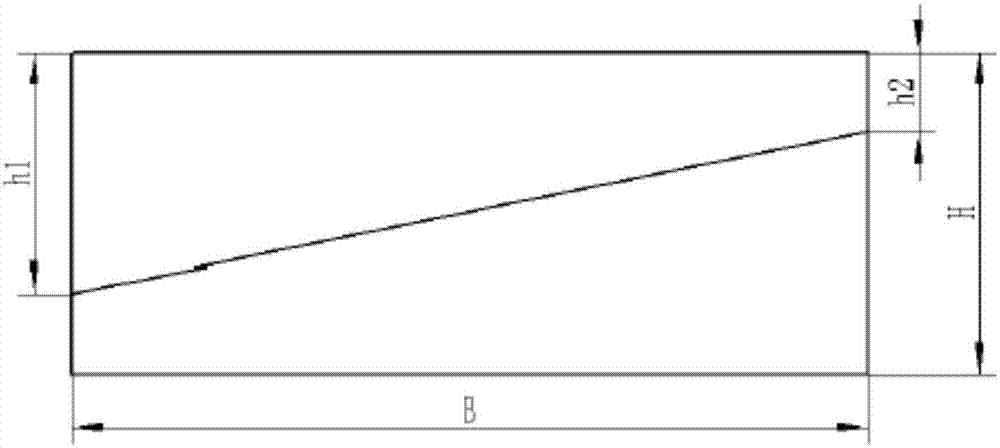

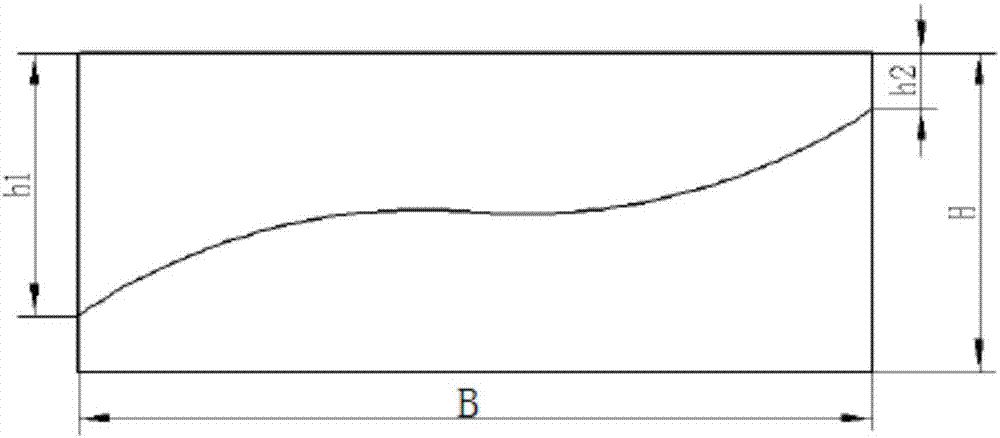

Ply rolling method for utilizing point symmetry to prepare transverse variable thickness plate strips

InactiveCN107999536AMeet different needsGood for weight lossAuxillary arrangementsMetal rolling arrangementsVariable thicknessMetallic materials

The invention belongs to the technical field of metal material deep processing and particularly relates to a ply rolling method for utilizing point symmetry to prepare transverse variable thickness plate strips. According to the method, the point symmetry is utilized for preparing the transverse variable thickness plate strips, the defects of waves, curve, torsion and the like caused by uneven andasymmetrical deformation in the variable thickness plate strip rolling process can be overcome, and the method can be used for preparing the various metal material transverse variable thickness platestrips. The method has the beneficial effects that adaptability to raw material texture and shape size is high, the flexibility of thickness changing of products is improved remarkably, flat rollerscan be used for carrying out rolling, the expense generated by using milling roller types is saved, the defects of waves, curve, torsion and the like caused by uneven deformation of variable thicknessrolling can be avoided, whether transition areas between thick areas and thin areas exist on the transverse variable thickness plate strips or not can be selected and designed, the shape and the position of the transition areas can selected and designed, and the best weight reducing and load bearing effects are achieved.

Owner:NORTHEASTERN UNIV

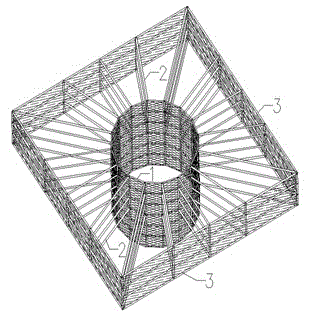

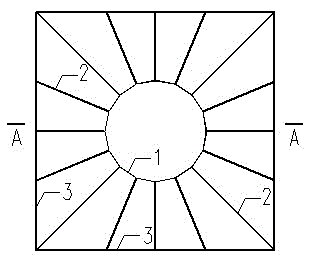

Multilayer cantilever rigid cylindrical structure system

ActiveCN102720269AReduce braid effectImprove staticExtraordinary structuresShock proofingClassical mechanicsCantilever

The invention relates to a combination system of a multilayer cantilever structure and a cylinder structure. The structure system consists of an inner cylinder structure (1), a cantilever structure (2), and an outer cylinder structure (3). The combination system of the multilayer cantilever structure and the cylinder structure involved in the invention is applicable to a multilayer cantilever structure, and is especially applicable to a multilayer cantilever constructional engineering which has the requirement of large space utilization on a cantilever floor. Through the cooperation of the outer cylinder structure and the cantilever structure, the system can solves technical problems with existing multilayer cantilever structure systems, realizes security, rationality, economy of the multilayer cantilever structure, and meets the requirement of large cantilever modeling construction and the requirement of multilayer large space utilization.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Axial differential-pressure heat-state internal-pressure forming method of special-shaped variable-cross-section pipe fitting

The invention relates to an axial differential-pressure heat-state internal-pressure forming method of a special-shaped variable-cross-section pipe fitting, and relates to a forming method of the pipefitting. In order to solve the problems that during the process of an existing heat-state internal-pressure forming method of the special-shaped variable-cross-section pipe fitting, the pressure on the pipe fitting cannot be controlled in a zoning way, so that the deformation of zones and the wall thickness distribution cannot be effectively and reasonably controlled, the method comprises the following steps of (1) heating a mold; (2) placing an original pipe blank into the heat-state mold; (3) moving a punch to contact the pipe blank, sealing, and then filling a heat-state fluid medium intothe pipe blank through an internal pipeline; (4) starting a supercharger for controlling the internal pressure of the pipe blank so as to separate and seal the zones in the axial direction; (5) starting a supercharger for controlling the external pressure of the pipe blank, and filling pressure media with different sizes into the axial zones of the pipe blank; and (6) controlling the internal pressure and the external pressure of the pipe blank, enabling the pipe blank to deform, and obtaining the required special-shaped variable-cross-section pipe fitting. The axial differential-pressure heat-state internal-pressure forming method of the special-shaped variable-cross-section pipe fitting provided by the invention is used for forming the special-shaped variable-cross-section pipe fitting.

Owner:HARBIN INST OF TECH

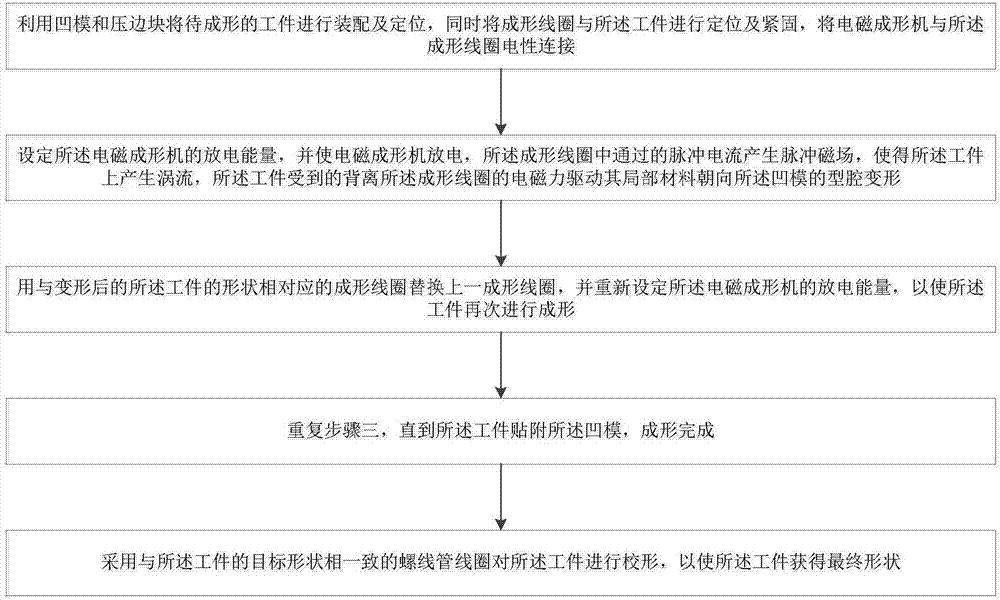

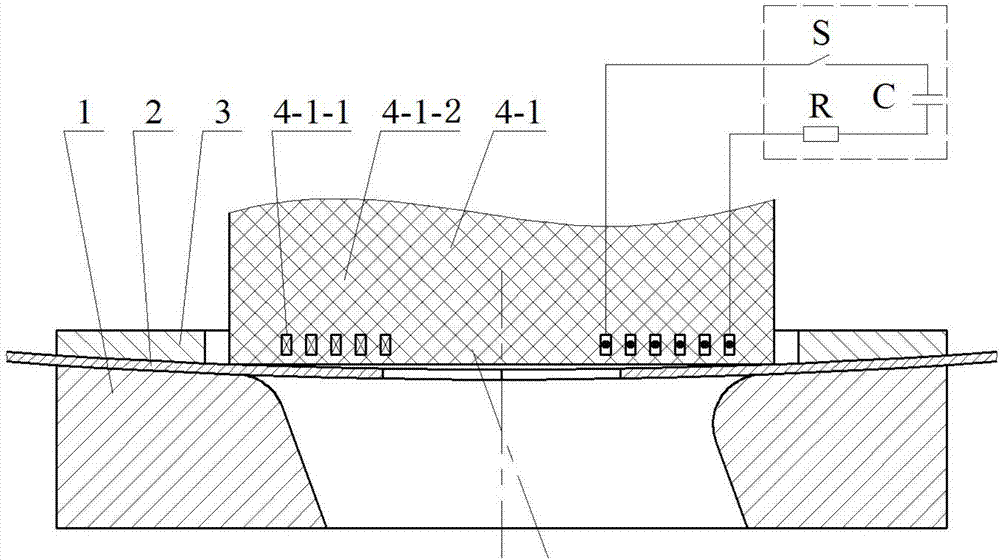

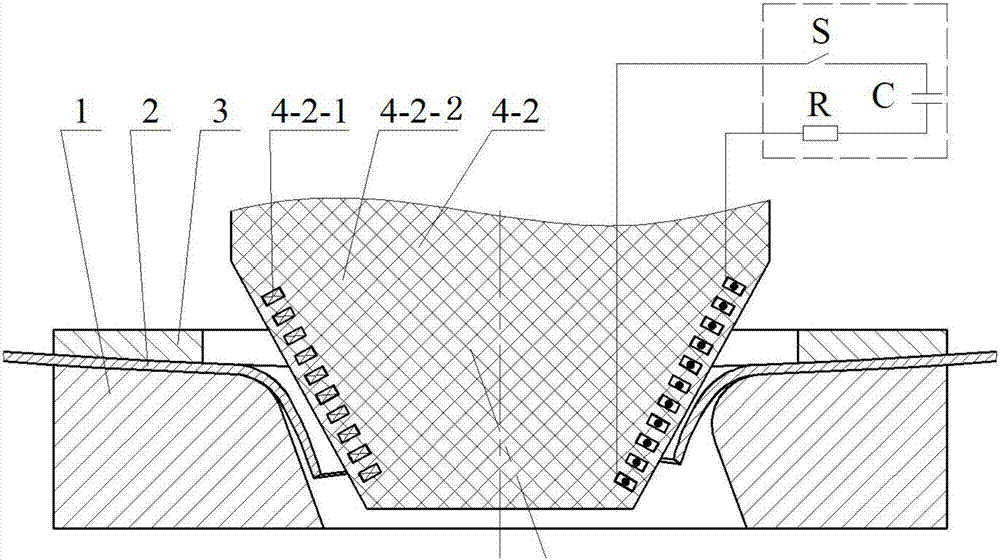

Composite multi-step local plastic electromagnetic forming method for sheet workpiece

The invention belongs to the technical field of workpiece forming and manufacturing, and discloses a composite multi-step local plastic electromagnetic forming method for a sheet workpiece. The composite multi-step local plastic electromagnetic forming method comprises the steps that (1) the to-be-formed workpiece is fabricated and positioned by utilizing a concave mold and a blank pressing block, meanwhile, a forming coil and the workpiece are positioned and fastened, and an electromagnetic forming machine is connected with the forming coil; (2) the electromagnetic forming machine is discharged, and the workpiece is driven by an electromagnetic force deviating from the forming coil, so that partial material is deformed towards a mold cavity of the concave mold; (3) the forming coil is replaced by a forming coil suitable for the shape of the workpiece after deforming, and the discharge energy of the electromagnetic forming machine is reset for forming the workpiece again; and (4) step (3) is repeated until the workpiece attaches the concave mold. According to the composite multi-step local plastic electromagnetic forming method for the sheet workpiece, nonuniform deformation of the partial material in a deformation area of the workpiece is controlled, and requirements of tooling and fabricating precision are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

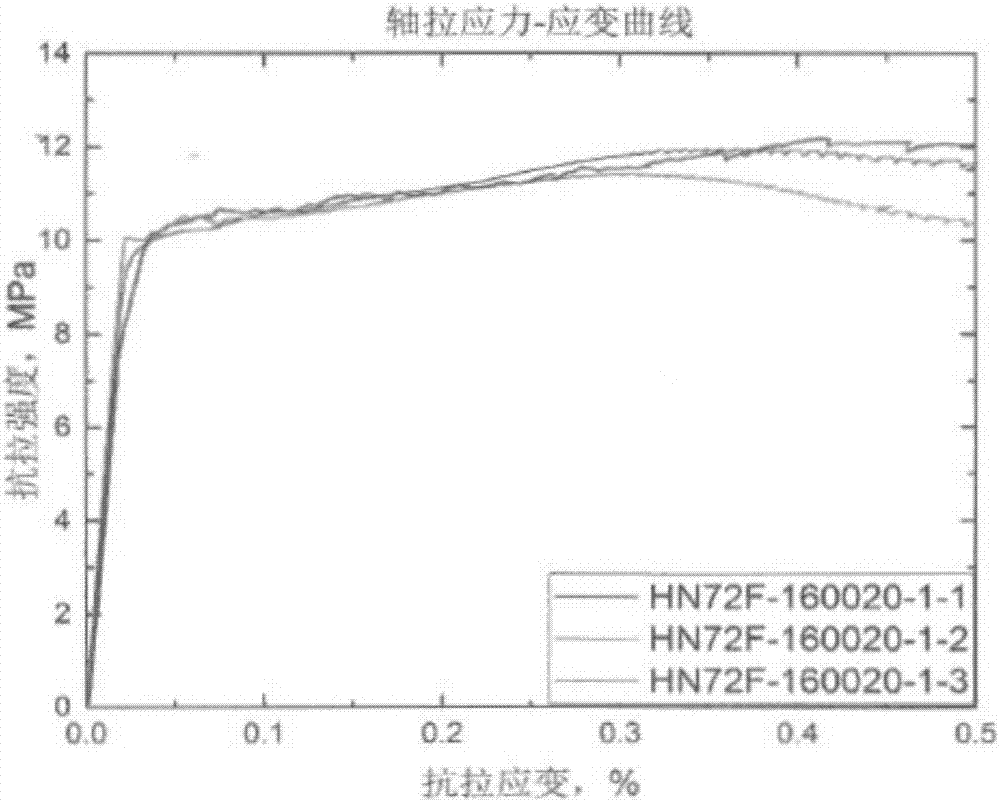

Reinforced concrete structure containing early strength type ultra-high performance concrete

InactiveCN107245947ASolve the problem of long curing time in high temperature steam curingReduce the impactBridge structural detailsBridge erection/assemblyTensile strainFiber

The invention relates to a reinforced concrete structure containing early-strength ultra-high-performance concrete, which includes a construction panel and a reinforced concrete structure body. The reinforced concrete structure body includes a steel skeleton and early-strength ultra-high-performance concrete poured into the steel skeleton , the upper part of the reinforced concrete structure body is provided with a wear layer, and the early-strength ultra-high performance concrete is composed of cement, fine admixtures, aggregates, admixtures, fibers and water, and has the following properties: 3h compressive strength is less than Less than 30MPa, 28d ultimate tensile strain not less than 3000με. Compared with the prior art, the early-strength ultra-high-performance concrete of the present invention has good ductility and is not easy to crack. It can coordinate deformation with the construction panel and improve the mechanical performance of the structure; the steel skeleton is a steel mesh shear structure, reducing The stress range in the construction panel under the action of the vehicle is reduced, and its durability is improved; the reinforced concrete structure is suitable for rapid maintenance of the bridge deck structure, and the impact of construction on traffic is minimized.

Owner:浙江宏日泰耐克新材料科技有限公司

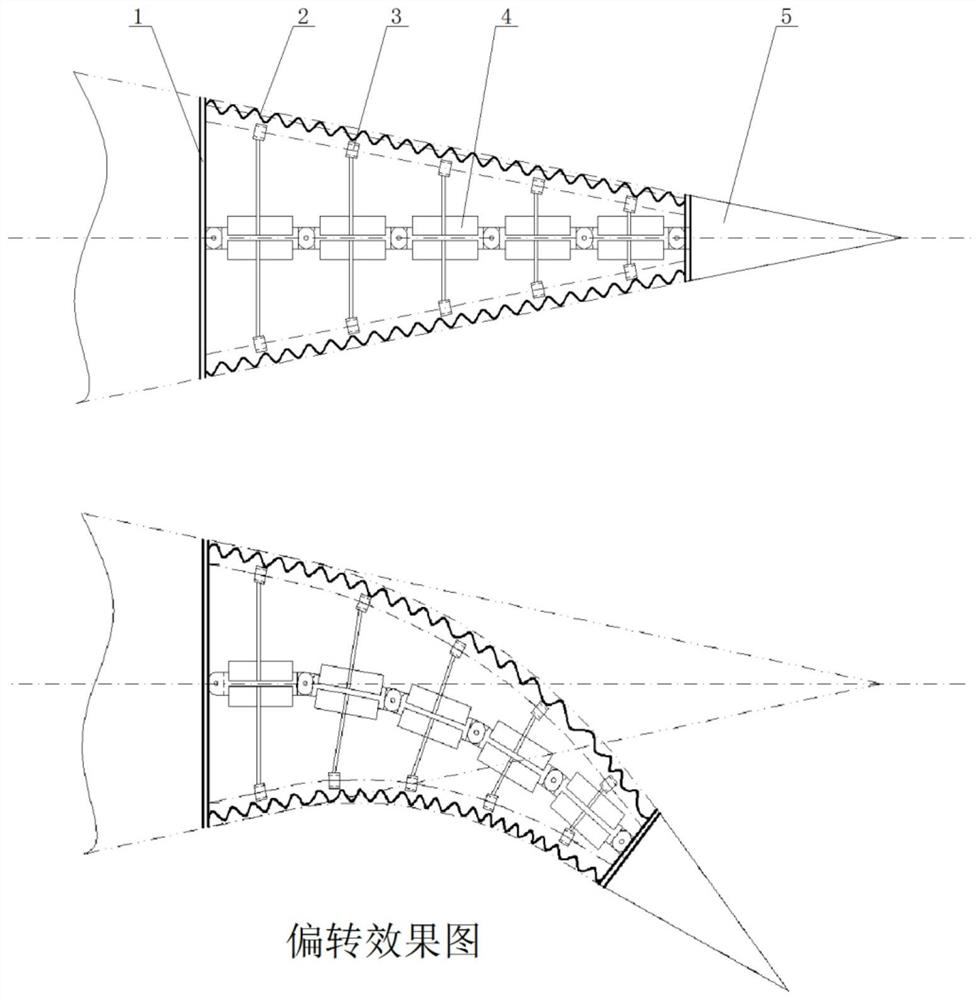

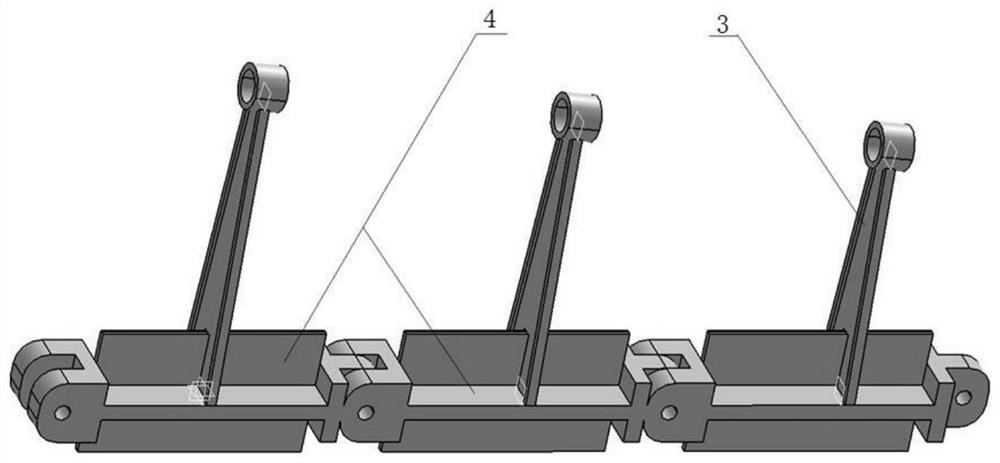

Variable-camber trailing edge sectional type wing rib and flexible skin supporting and connecting structure

The invention discloses a variable-camber trailing edge sectional type wing rib and flexible skin supporting and connecting structure, and belongs to the field of structural design of morphing aircrafts. A variable-camber trailing edge structure of a flexible wing consists of a corrugated structure flexible skin, sectional type wing ribs, a supporting plate, distributed drivers and a rear end conebody. The distributed drivers are arranged below the flexible skin and supported on the sectional type wing ribs through driver supports, mutual deflection between rib sections is caused by stretching and retracting of the drivers, and the flexible skin stretches and retracts under the action of driving force so as to achieve trailing edge camber changing. When an upper wing surface extends, a lower wing surface is shortened, the rib sections deflects downwards, and a trailing edge is bent downwards. According to the device, the flexible skin can be uniformly supported to transmit loads, anduniform and harmonious deformation of the flexible skin can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

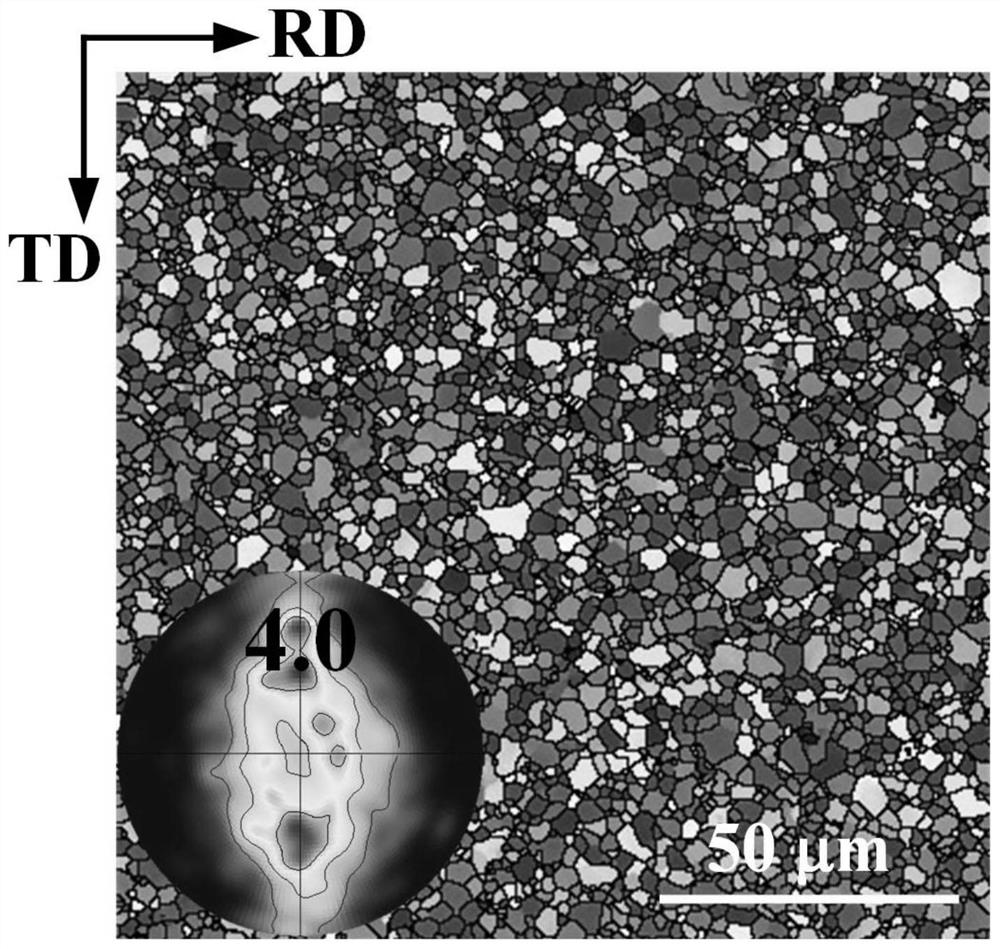

Rapid age hardening multi-element microalloy weak texture magnesium alloy and preparation method thereof

ActiveCN112899541AHigh strengthNo addedFurnace typesMetal rolling arrangementsPre deformationManganese

The invention relates to the field of metal material magnesium alloys, in particular to a rapid age hardening multi-element microalloy weak texture magnesium alloy and a preparation method thereof. The alloy comprises the following components of 0.5 wt.%-2.0 wt.% of Zn, 0.1 wt.%-1.0 wt.% of Ca, 0 wt.%-1 wt.% of Sn, 0.05 wt.%-1 wt.% of manganese, and the balance commercial pure Mg and inevitable impurities, wherein the content of the impurities is less than 0.02%. The preparation method of the alloy comprises the steps of smelting, hot extrusion, multi-pass controlled rolling, recrystallization treatment, low-temperature aging and the like, wherein the low-temperature aging comprises low-temperature aging after pre-deformation stretching and low-temperature aging after cold rolling. The magnesium alloy subjected to recrystallization treatment is subjected to pre-deformation stretching and low-temperature aging treatment, the average size of alloy grains is 2-7 micrometers, in addition, the obtained magnesium alloy has a good age hardening effect, and it can be seen from an EBSD diagram that the alloy shows weak texture characteristics distributed in the TD direction, and the electrode density is 4.0; and in addition, the magnesium alloy has good mechanical properties, the yield strength of the alloy is larger than or equal to 300 MPa, and the ductility is larger than or equal to 15%.

Owner:JILIN UNIV

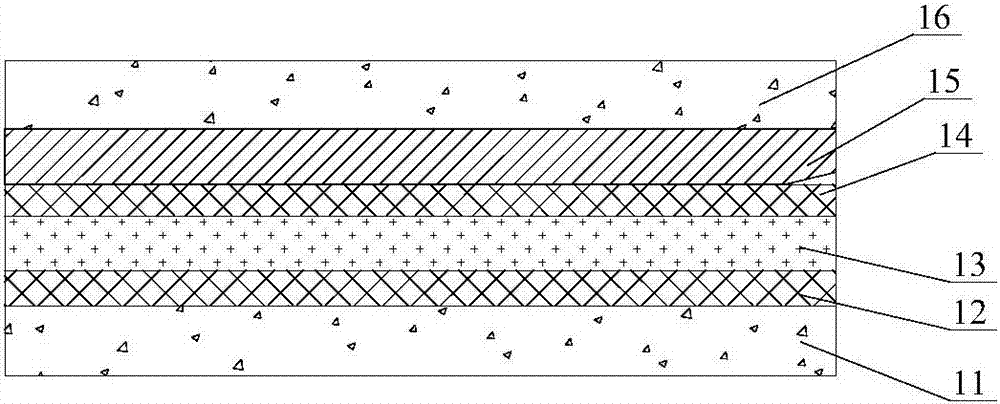

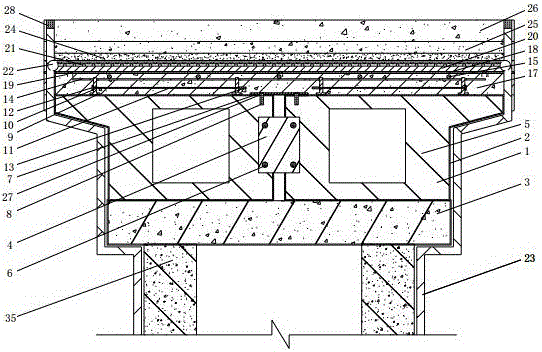

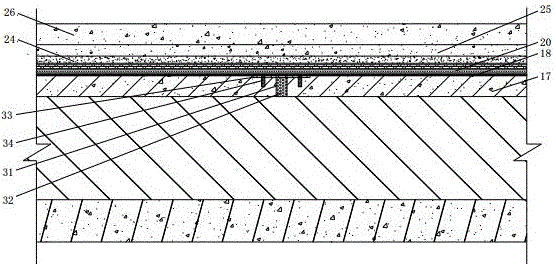

Large-span steel box girder rigidity coordination type composite bridge deck pavement layer structure and construction method thereof

ActiveCN105937204AHigh strengthIncreased resistance to shear damageBridge structural detailsCoordination typeThermal insulation

The present invention relates to a large-span steel box girder rigidity coordination type composite bridge deck pavement layer structure and a construction method thereof. The construction method comprises painting anticorrosion thermal insulation layer coating along the periphery of a steel box girder; setting a side surface connecting plate and a top overlapping plate at seaming positions of the steel box girder, longitudinally welding shearing-resistant strips at an upper surface of the box girder, setting a shearing-resistant strip binding bar between the adjacent shearing-resistant strips, and setting a horizontal negative moment reinforcement and a longitudinal negative moment reinforcement at a bridge pier position; erecting a template to perform concrete pouring and maintenance of a rigid reinforcement layer; successively constructing a reinforcement mesh layer, a waterproof layer and a stress absorbing layer after intensity of the concrete is formed, and laying a drainage strip in a road camber direction; and finally laying a fine-grained SMA asphalt concrete layer and a medium-grained SMA asphalt concrete layer. Deformation and rigidity coordination of an upper structure layer of the steel box girder can be achieved, the steel box girder can also be effectively prevented from being influenced by pavement water seepage and temperature gradient, and the influence of the negative moment at the bridge pier on the structure can also be reduced.

Owner:ANHUI HIGHWAY ENG CORP

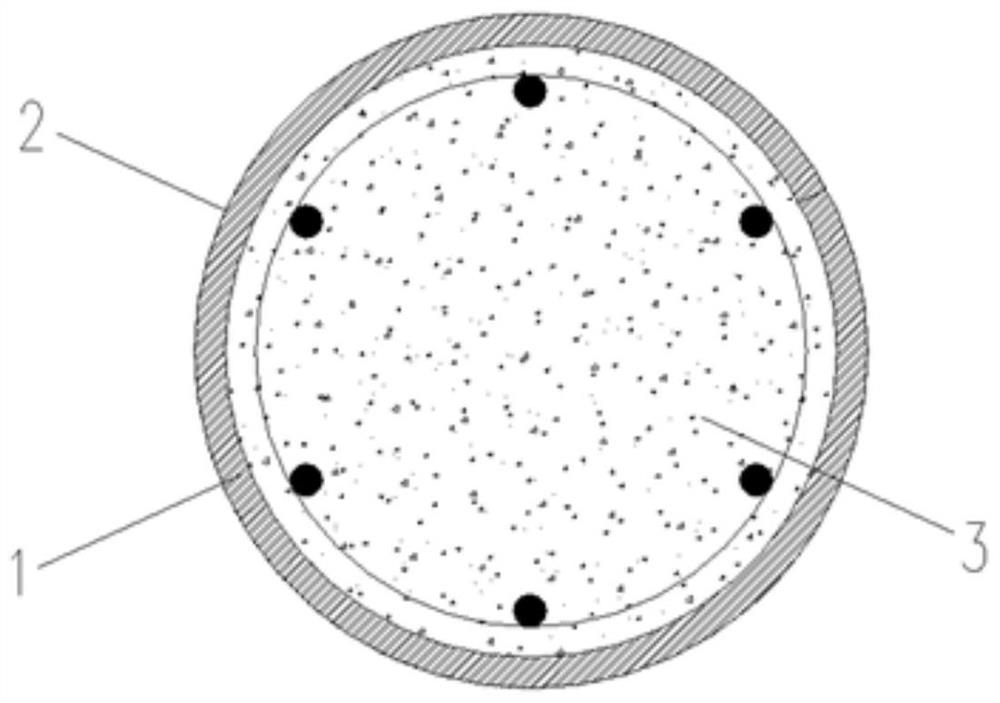

Fiber reinforced plastic and ultra-high performance concrete pipe filled common concrete combined column and production method thereof

InactiveCN112695953AImprove adhesionAvoid risk of local buckling failureStrutsPillarsEarthquake resistanceMaterials science

Owner:WUHAN UNIV

Seesaw type amplification type energy dissipation extending arm capable of preventing out-of-plane instability

PendingCN113374109AEffectively dissipateReduced seismic responseProtective buildings/sheltersShock proofingEngineeringShock absorber

The invention discloses a seesaw type amplification type energy dissipation extending arm capable of preventing out-of-plane instability. The extending arm comprises an extending arm truss, an outer frame column, a seesaw type amplification device, a viscous fluid damper, a viscoelastic damper and out-of-plane instability preventing connecting steel plates. The seesaw type amplification device is hinged to the outer frame column through a left hinge point, and the seesaw type amplification device is hinged to the extending arm truss through a right hinge point; the seesaw type amplification device is respectively hinged with one end of the viscous fluid damper through the upper hinge point and the lower hinge point, and the other end of the viscous fluid damper is hinged with the extending arm truss; and the out-of-plane instability preventing connecting steel plates are fixed to the upper end and the lower end of the outer frame column and fixedly connected with the viscoelastic damper, and the viscoelastic damper is fixedly connected with a pin shaft of the upper hinge point or the lower hinge point. The energy dissipation extending arm is high in feasibility, the key technical problem of an existing energy dissipation extending arm with an amplifying device is solved, and the energy dissipation and shock absorption effects and the capacity of coordinating deformation of an inner cylinder and an outer frame are superior to those of an existing technical scheme.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

Double-row larssen steel sheet pile rigid-frame beam and mounting method thereof

The invention relates to a double-row larssen steel sheet pile rigid-frame beam. A double-row larssen steel sheet pile is composed a front-row larssen steel sheet pile unit and a rear-row larssen steel sheet pile unit, and the upper portions of both the front-row larssen steel sheet pile unit and the rear-row larssen steel sheet pile unit are provided with crown beams; the double-row larssen steelsheet pile is characterized in that each crown beam is composed of steel sheets arranged at the front and the rear of the corresponding larssen steel sheet pile unit, and the steel plates are provided with reinforcing ribs, which extend into grooves formed in the corresponding larssen steel sheet pile unit and connect the steel plates at the front and the rear of the larssen steel sheet pile unitinto the crown beam; the crown beam of the front-row larssen steel sheet pile unit and the crown beam of the rear-row larssen steel sheet pile unit are connected through horizontal supports to form ahorizontal rigid-frame beam. The double-row larssen steel sheet pile rigid-frame beam can enhance integrity of the steel sheet pile, coordinates deformation of the front-row larssen steel sheet pileunit and the rear-row larssen steel sheet pile unit, and greatly improves the rigidity; after being used, the double-row larssen steel sheet pile rigid-frame beam can be disassembled for recycling andreutilization.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

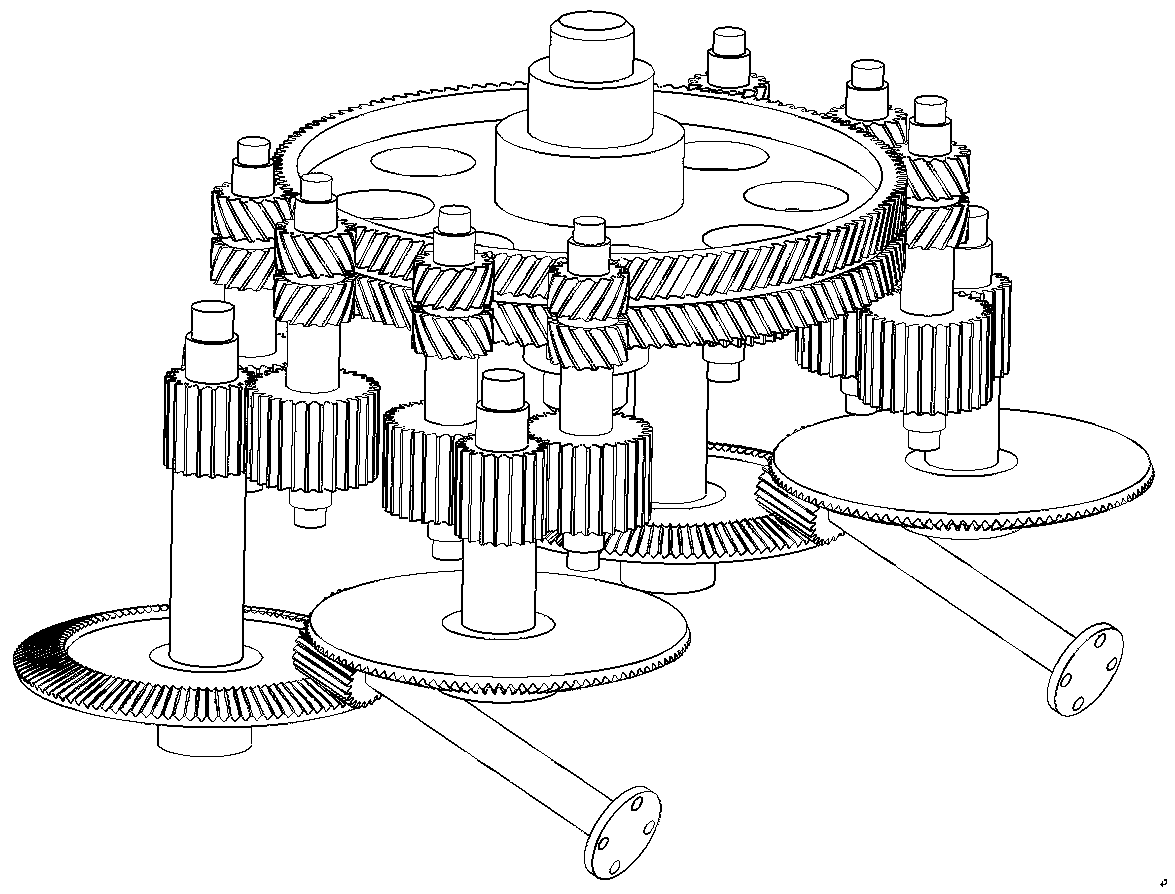

Two-time power dividing transmission system configuration

The invention discloses a two-time power dividing transmission system configuration which comprises a power input part and a power output part. At the input stage, surface gears are adopted for dividing transmission, meanwhile, reversing and power dividing are achieved, one-stage transmission in a whole transmission system is omitted, and the error generated by axial movement of the surface gearsnearly has no influence on transmission performance. Cylindrical gears are adopted for dividing and parallel operation transmission, the transmission ratio is large, and flexibility is good. Only a pair of gears on the cylindrical gears is adopted for power dividing, the structure is simple, the design space is large, moreover, when dual gear shafts all adopt the elastic shaft structures, the length of the dual gear shafts is large, flexibility is good, and deformation coordination and uniform load achievement are more facilitated. Two-time power dividing transmission is adopted, and thus theload borne by the gears is reduced, so that the sizes of the gears are decreased, and the line speed of the gears is decreased. The transmission system all adopts simple fixed-shaft gear trains for transmission, and thus achievement is easy in technology. The transmission configuration can be widely applied to the fields such as medium-heavy helicopter transmission systems and ship transmission systems.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com