Prefabricated double-row pile and water-stop curtain integrated foundation pit supporting structure and construction method thereof

A technology of foundation pit support and water-stop curtain, which is applied in foundation structure engineering, excavation, construction, etc., can solve the problems of inconvenient recycling, high input cost of foundation pit support structure, environmental pollution, etc., and achieves convenient foundation pit excavation. , force coordination, good economy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with accompanying drawing, the present invention will be further described.

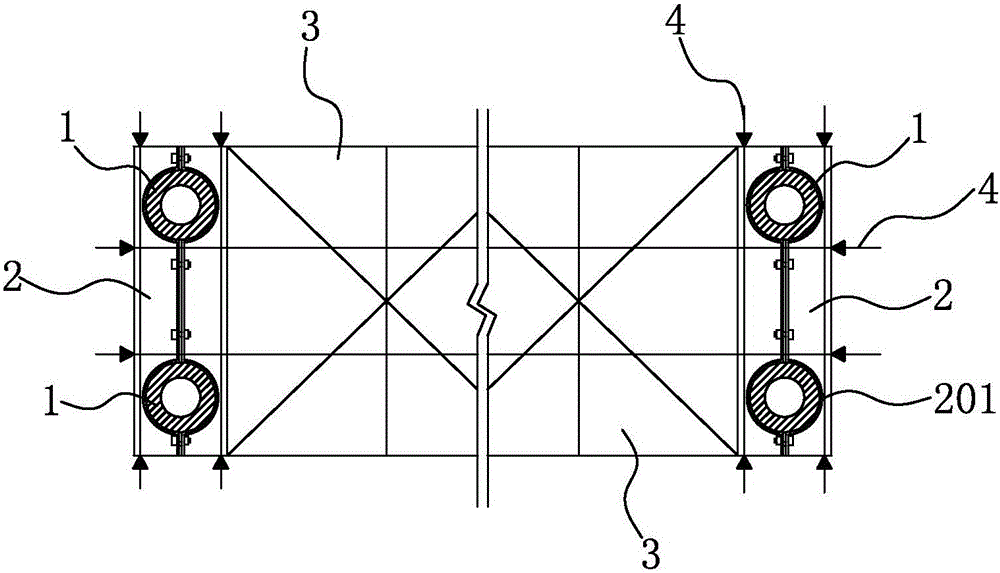

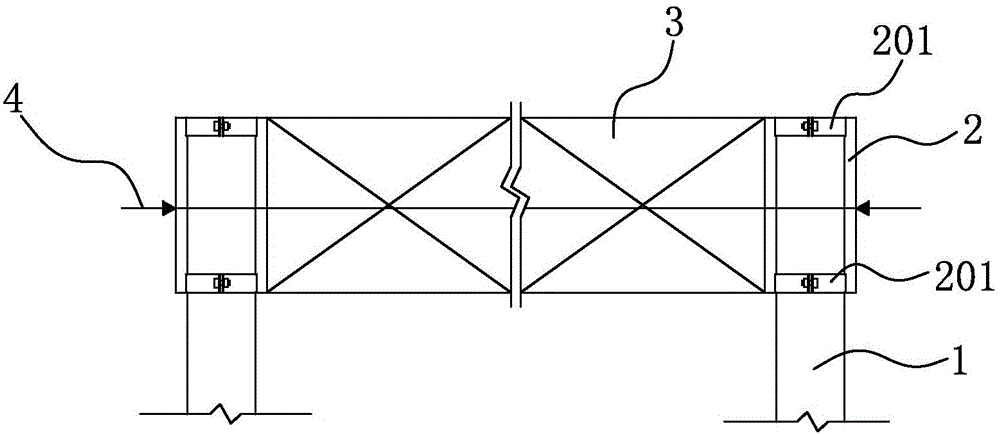

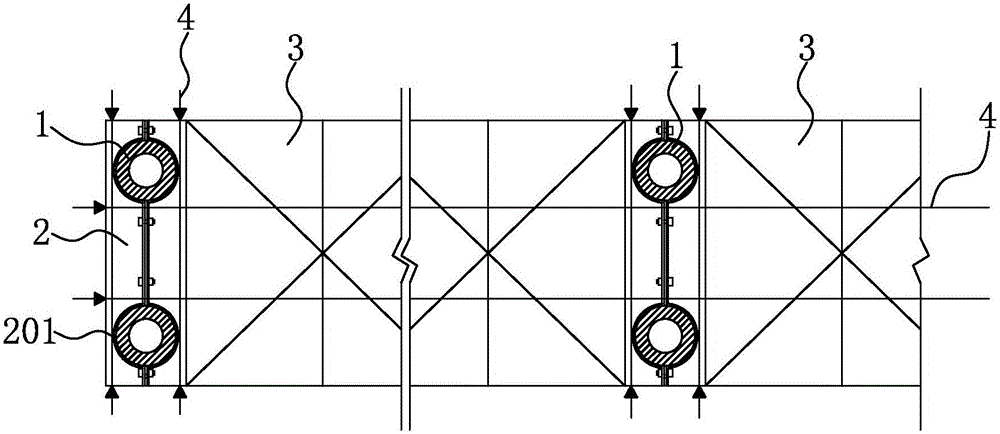

[0020] Such as Figure 1-4 As shown, the prefabricated double-row pile and water-stop curtain integrated foundation pit support structure includes double-row piles, steel frame beams 2, crown beams 3, and cement-soil mixing piles 5, in which the double-row piles are made of pre-tensioned prestressed concrete Pipe pile 1, two concrete pipe piles arranged at intervals in the front and rear as a unit, the unit is evenly arranged along the edge of the foundation pit to form two rows of concrete pipe piles in the front and rear, and the front row of concrete pipe piles is located at the boundary of the foundation pit range , the rear row of concrete pipe piles is located outside the scope of the foundation pit. The tops of the two concrete pipe piles of each unit of the double-row pile are fixedly connected to the steel frame beam, and the connection between the steel frame beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com