Bidirectional U-shaped coal-mining method of thick coal bed by gateway layout along stability layer

A coal mining method and thick coal seam technology, applied in ground mining, mining equipment, earthwork drilling and mining, etc., can solve the problems of increased section coal pillar width, difficulty in roadway excavation and support, and influence on roadway excavation speed, etc., to achieve improved The effect of improving the recovery rate, reducing the loss of coal pillars, and speeding up the excavation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

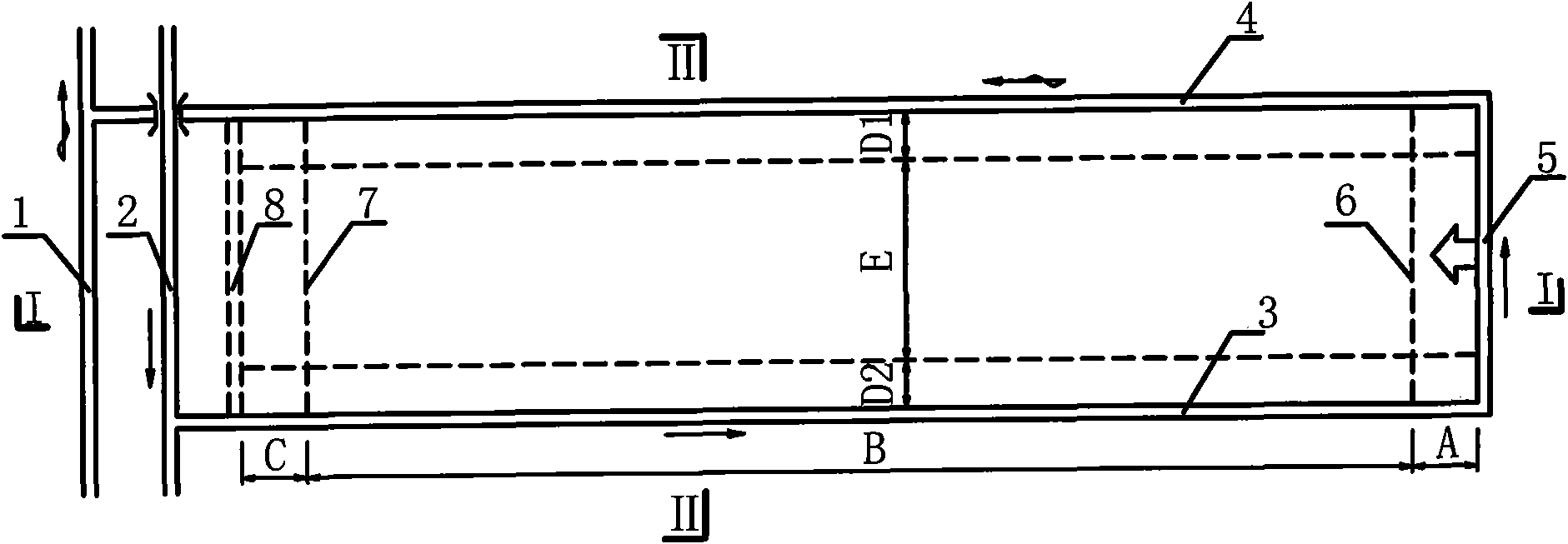

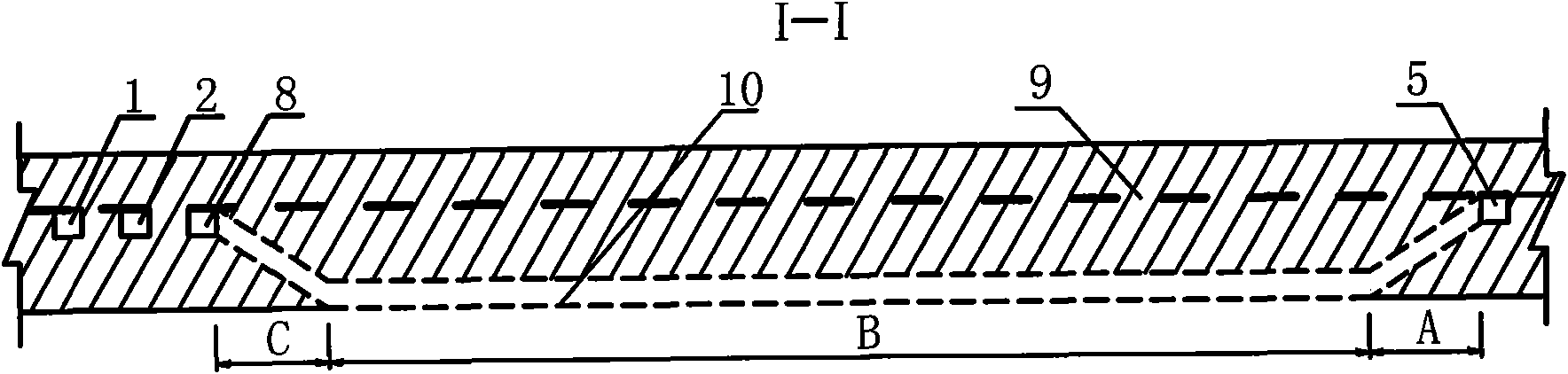

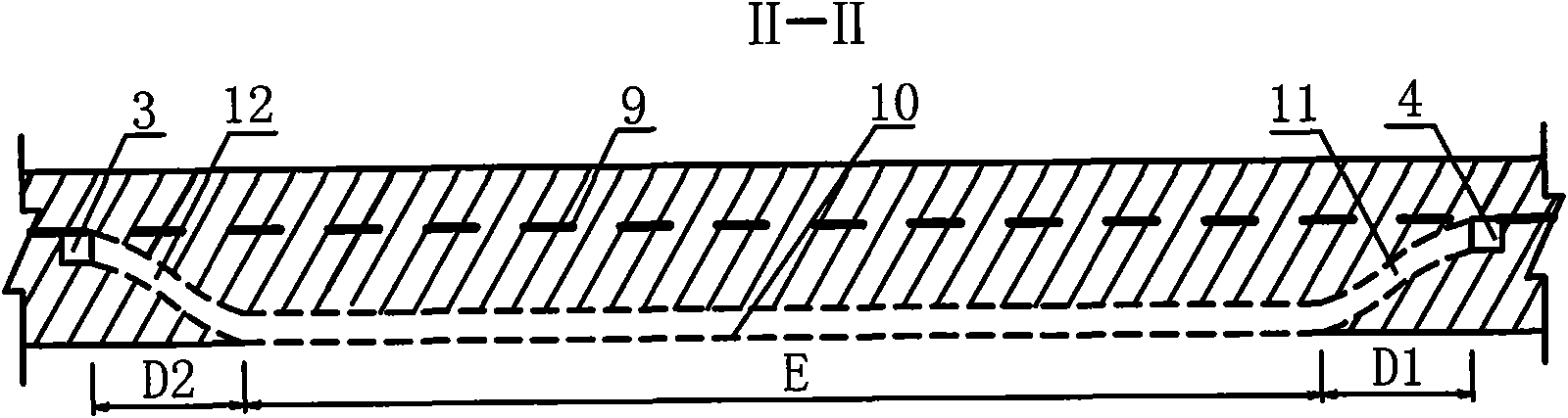

[0021] Such as figure 1 , 2 As described in 3, a schematic diagram of the mining method system of the two-way "concave" type top-coal caving working face of the present invention along the stable layer roadway distribution in thick coal seams. The roadway layout and mining technology of the two-way "concave" type top-coal caving face mining system along the stable layer with thick coal seams are as follows:

[0022] 1. Excavate along the stable layer of the thick coal seam into the air entry lane 2 of the mining area, 1 of the return air lane of the mining area, 3 of the transport trough, 4 of the return air trough, and 5 of the cutting eye, so that the roof of these roadways is a stable layer, and the mining area enters When the air lane 2 intersects with the return air channel 4, the roof of the return air channel 4 will intersect three-dimensionally above the inlet air channel 2 in the mining area to form a working face production system.

[0023] 2. The mining face forms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com