Anti-seismic face plate structure for rock-fill dam with concrete face plate and method for constructing face plate anti-seismic structure

A technology for concrete panels and earthquake-resistant structures, applied in dams, barrages, water conservancy projects, etc., can solve problems such as large tensile stress, panel failure, panel voiding, etc., so as to improve the stress condition of panels, facilitate engineering implementation, and simple construction methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: In the case where the interlayer 9 adopts an asphalt concrete panel:

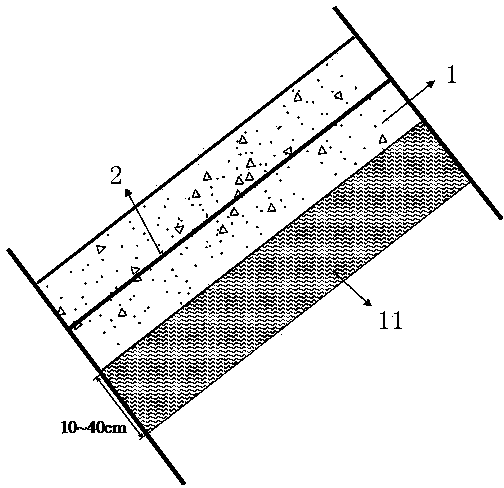

[0025] figure 1 It is a schematic diagram of the panel structure of a panel anti-seismic structure for a concrete face rockfill dam of the present invention. A face anti-seismic structure for a concrete face rockfill dam, comprising a concrete face rockfill dam main body, a concrete face rockfill dam cushion 6, and the concrete face rockfill dam cushion 6 is laid with concrete with preset vertical splits 101 Panel 1, the interior of concrete panel 1 is penetrated by steel bars 2, such as figure 2 As shown, the top of the vertical split 101 is provided with a flexible packing layer 3, and the bottom of the vertical split 101 is provided with a mortar cushion 4 and a pair of water-stop copper sheets 5, and the water-stop copper sheets 5 are perpendicular to the mortar cushion 4 and It is arranged symmetrically on the mortar cushion 4, wherein, the width of the vertical split 101 is 1-2...

Embodiment 2

[0033] Embodiment 2: In the case where the interlayer 9 adopts multiple plastic concrete panel layers:

[0034] figure 1It is a schematic diagram of the panel structure of a panel anti-seismic structure for a concrete face rockfill dam of the present invention. A face anti-seismic structure for a concrete face rockfill dam, comprising a concrete face rockfill dam main body, a concrete face rockfill dam cushion 6, and concrete face rockfill dam cushion 6 laid with concrete with reserved vertical splits 101 Panel 1, steel bars 2 are arranged inside the concrete panel 1, such as Figure 5 As shown, the top of the vertical split 101 is provided with a flexible packing layer 3, and the bottom of the vertical split 101 is provided with a mortar cushion 4 and a pair of water-stop copper sheets 5, and the water-stop copper sheets 5 are arranged perpendicular to the mortar cushion 4 and Symmetrically arranged on the mortar cushion 4, an intermediate interlayer 9 is laid between the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com