Prefabricated concrete-filled steel tube and concrete-filled steel tube splicing pier

A technology of reinforced concrete and steel pipe concrete, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., which can solve traffic flow, work area safety and environmental impact, affect the progress of bridge construction, and have less seismic performance of the whole pier column, etc. problems, to achieve the effect of not affecting normal traffic, low construction noise, and easy on-site splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

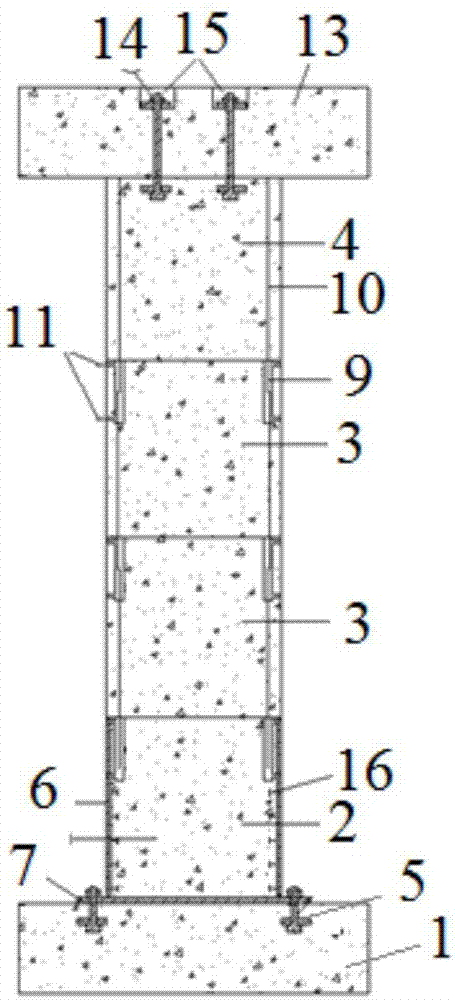

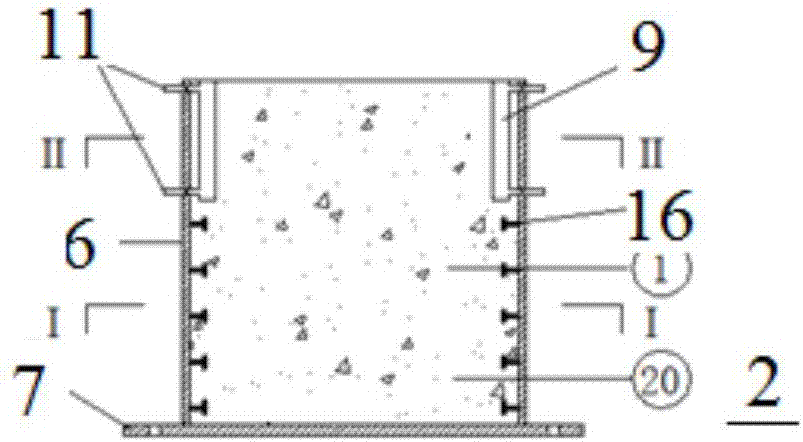

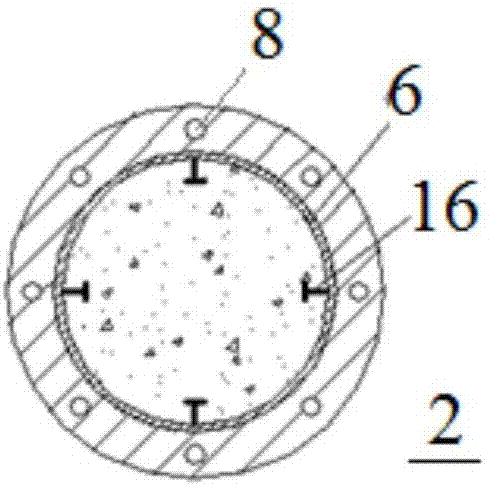

[0069] A prefabricated steel pipe concrete and reinforced concrete bridge pier, such as figure 1 As shown, it includes, from bottom to top, the pier foundation 1, the prefabricated steel pipe concrete section 2, one or more prefabricated reinforced concrete middle sections 3 and the prefabricated reinforced concrete top section 4, wherein the bridge pier foundation 1 and the prefabricated steel pipe concrete The segment 2 is fixedly connected by means of the bottom anchor bolt 5 arranged on the pier foundation 1, between the prefabricated steel pipe concrete segment 2 and the prefabricated reinforced concrete intermediate segment 3, and between a plurality of prefabricated reinforced concrete intermediate segments 3, The prefabricated reinforced concrete middle section 3 and the prefabricated reinforced concrete top section 4 are fixedly connected by means of connecting units.

[0070] Specifically, such as Figure 2-Figure 4 shown, where image 3 with Figure 4 for figur...

Embodiment 2

[0093] This embodiment is based on embodiment 1, as shown in the figure, it is different from embodiment 1 in that the cross-sections of prefabricated steel pipe concrete segment 2, prefabricated reinforced concrete middle segment 3 and prefabricated reinforced concrete top segment 4 are all square , that is, the steel pipes in the prefabricated steel pipe concrete segment 2 are also set in a square shape, and of course they can be set in other shapes as required.

[0094] The connecting unit in this embodiment is different from that in Embodiment 1, such as Figure 9 As shown, its connecting unit includes connecting bolts 17, connecting steel plates 18 and connecting anchor tendons 19. Connecting bolt 17 is the top that is embedded in the lower segment, and is arranged at intervals along the edge of the segment. Connecting steel plate 18 is arranged at the lower end of the upper segment. hole, the top of the through hole is reserved with a joint and then poured concrete cavi...

Embodiment 3

[0112] In this embodiment, on the basis of Embodiment 1, the shear connector 16 is set as a steel plate with holes, such as Figure 15 As shown, the steel plate with holes is a strip-shaped steel plate 27 with through holes 21 at equal intervals. The setting of the through holes is conducive to strengthening the connection between the shear connector 16 and the concrete, and improving the ability to work together and coordinate deformation. , steel plates with holes are welded parallel to the inner wall of the steel pipe and arranged at intervals on the inner wall of the steel pipe. Further, steel bars can be arranged in the through holes for better connection, and steel bars are penetrated in the through holes of the perforated steel plates at the same horizontal position along the inner circumference of the steel pipe to form a circle of steel bars around the inner wall or outer wall of the steel pipe. , steel bars can be welded in the through holes to further strengthen the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com