Supporting structure with two rows of steel sheet piles and construction method of supporting structure

A technology of supporting structure and steel sheet pile, which is applied in foundation structure engineering, sheet pile wall, excavation, etc., can solve problems such as deformation, connection of pile top to foundation pit, seepage deformation of steel sheet pile, etc., to achieve low cost and reduce support. Deformation and seepage deformation, the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

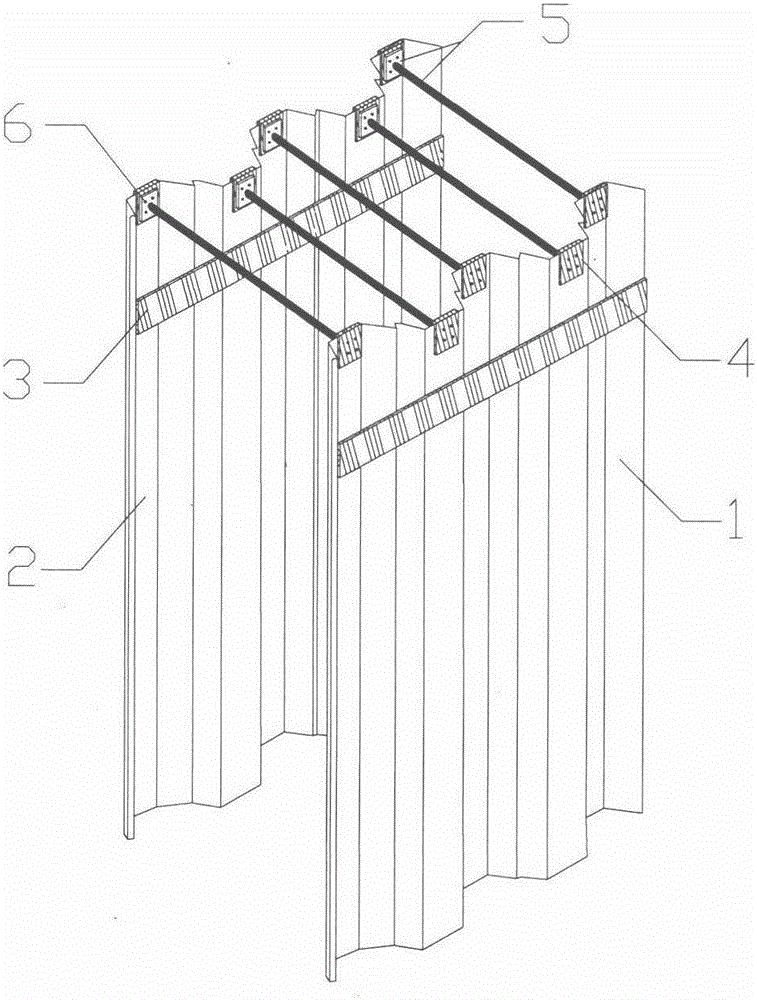

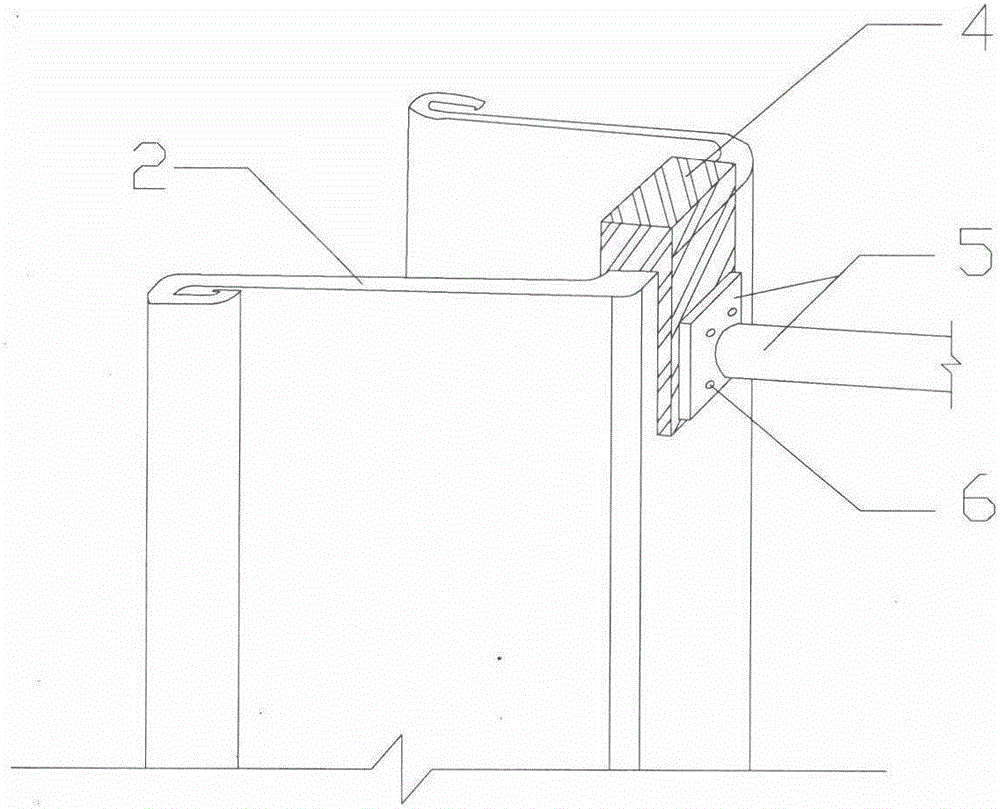

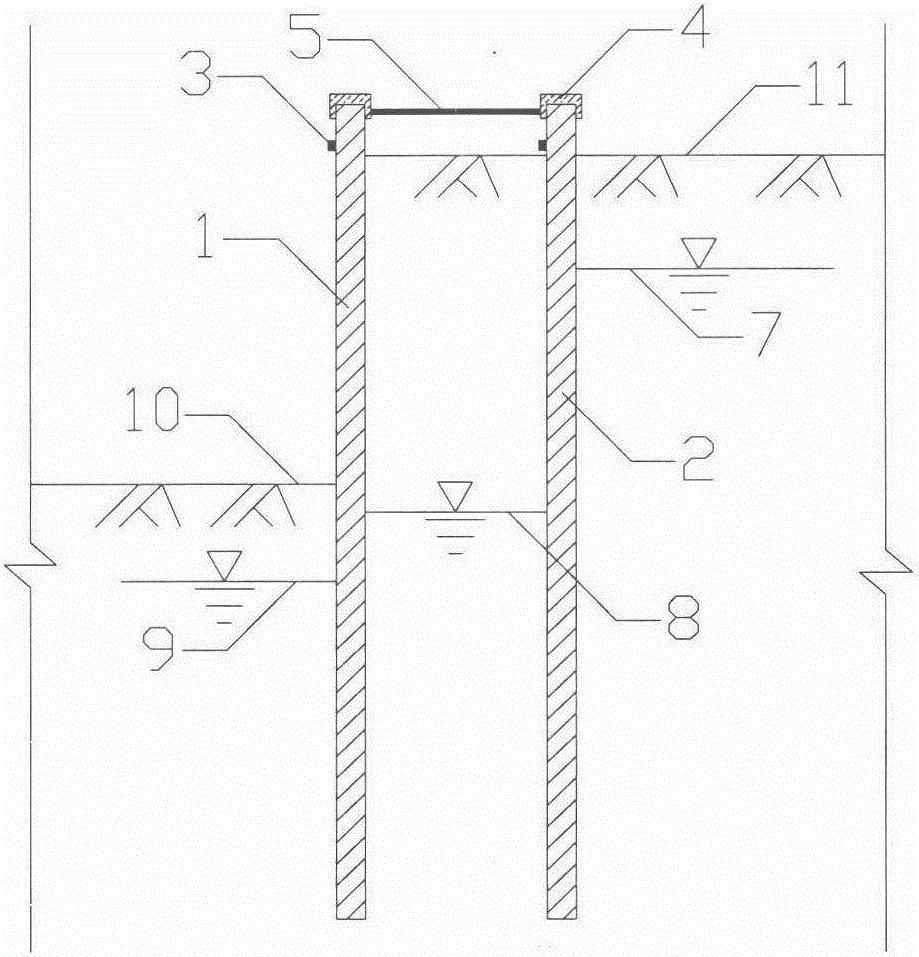

[0027] Examples see Figure 1-3 Shown: a support structure of double-row steel sheet piles, including a front row of steel sheet piles 1, a rear row of steel sheet piles 2, purlins 3, slots 4, connecting beams 5, and bolts 6, characterized in that: the surrounding The purlin 3 connects the steel sheet piles of each row into a whole, and the card slots 4 are respectively clipped into the front row of steel sheet piles 1 and the back row of steel sheet piles 2 at the straight tops of the piles. Alignment, the front row of steel sheet piles 1, the rear row of steel sheet piles 2, the card groove 4, and the connecting beam 5 all have bolt holes and are fixed by bolts 6 at one time.

[0028] The purlins 3 are double trusses, arranged on the side of each row of steel sheet piles close to the foundation pit and slightly higher than the ground 11 .

[0029] The clamping groove 4 is a U-shaped structure, the distance between the front and rear sides is the same as the thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com