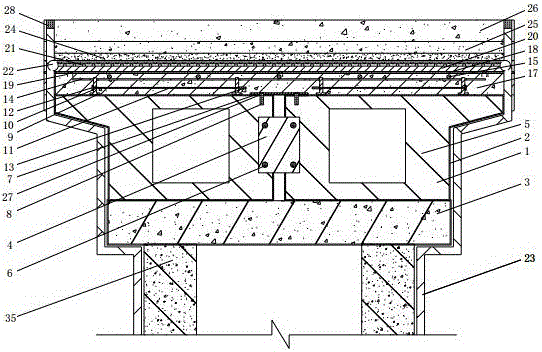

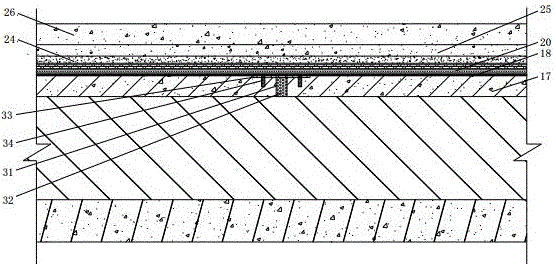

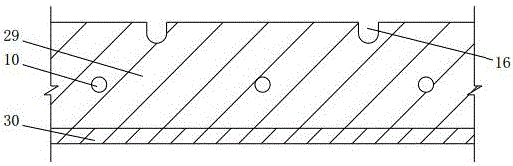

Large-span steel box girder rigidity coordination type composite bridge deck pavement layer structure and construction method thereof

A bridge deck pavement and steel box girder technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of inability to effectively reduce vehicle shear force damage to the overlay structure, and difficulty in achieving coordination of the stiffness of the pavement structure layer. Achieve the effects of improving the mechanical performance of the structure, improving the ability to resist diseases, and improving the ability to resist shear damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not intended to limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0048] The present invention relates to the technical requirements for the design and manufacture of shear strips, the technical requirements for the surface treatment of steel box girders, the technical requirements for concrete pouring, the technical requirements for the design and construction of SMA asphalt concrete layers, the technical requirements for the binding or welding of steel bars, and the stress-absorbing layer The technical requirements for design and construction, the production of tie bars and the technical requirements for construction, etc. all belong to conventional technologies, so this embodiment will not repeat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com