Multi-chamber type steel tube concrete special-shaped column

A technology of steel tube concrete and special-shaped columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of increasing the difficulty of construction and design of special-shaped columns, reducing the overall performance of components, and prone to premature buckling, so as to achieve better cross-section performance and benefit The effect that up, construction making is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

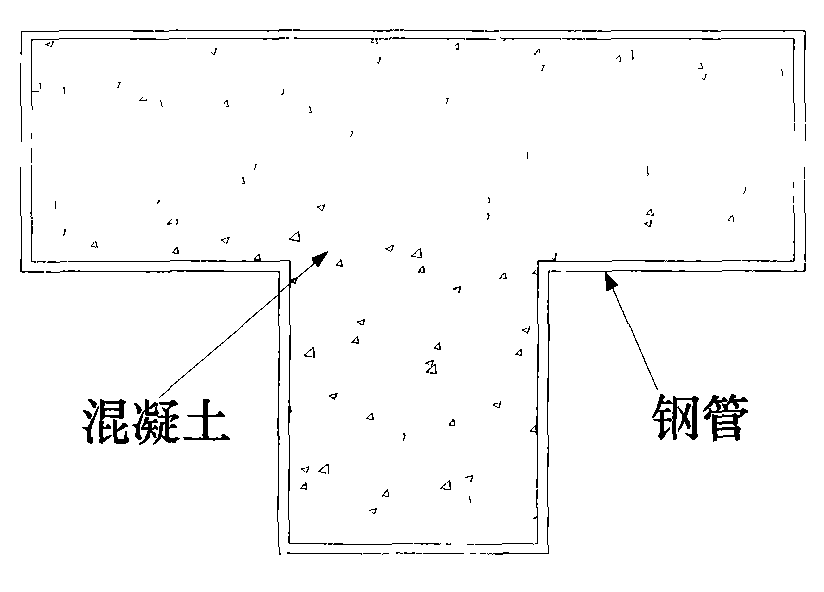

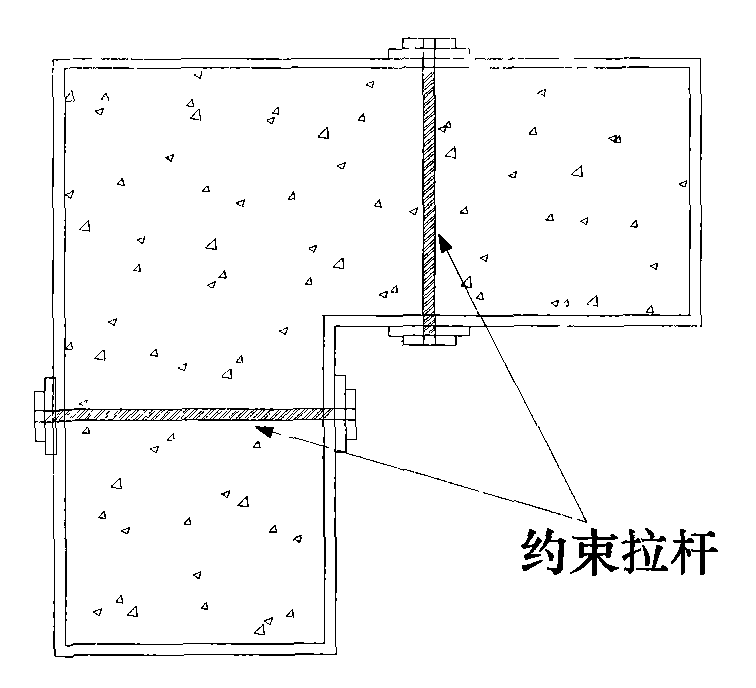

[0024] The invention is a multi-chamber concrete-filled special-shaped column, which is composed of U-shaped steel 1, rectangular steel pipe 2 and concrete 3 poured into it. The U-shaped steel 1 and rectangular steel pipe 2 are welded together to form a special-shaped column with different sections. Column, the entire special-shaped column section is divided into multiple chambers by U-shaped steel 1 and rectangular steel pipe 2, and concrete 3 is filled into U-shaped steel 1 and rectangular steel pipe 2.

[0025] Such as Figure 5a As shown, the U-shaped steel 1 is bent or welded by steel plates, such as Figure 5b As shown, the rectangular steel pipe 2 is formed by bending a steel plate and then welding it or directly welding a steel plate.

[0026] The special-shaped column mentioned in the present invention refers to that the cross-sectional form of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com