Fabricated prefabricated shear wall and laminated slab node

A prefabricated shear and laminated slab technology, applied to walls, protective buildings/shelters, building components, etc., can solve the problems of cumbersome reinforcement, poor installation accuracy, and low construction efficiency, and improve integrity and earthquake resistance , reduce the difficulty of construction, and facilitate the effect of standardized production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

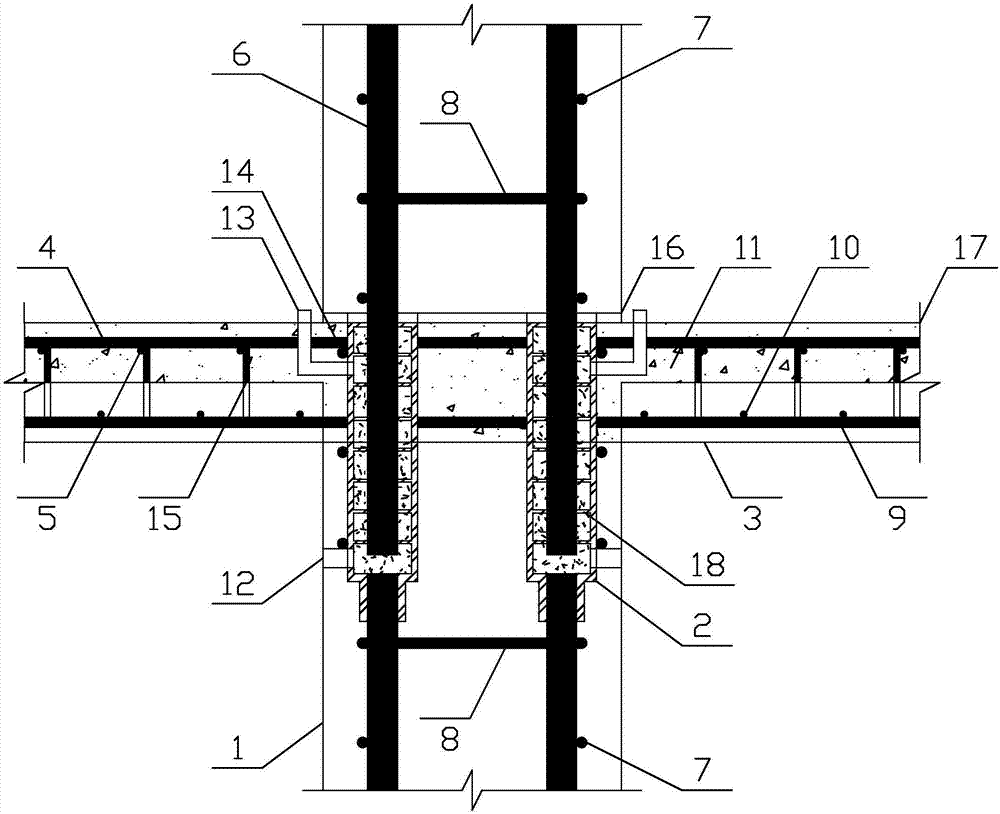

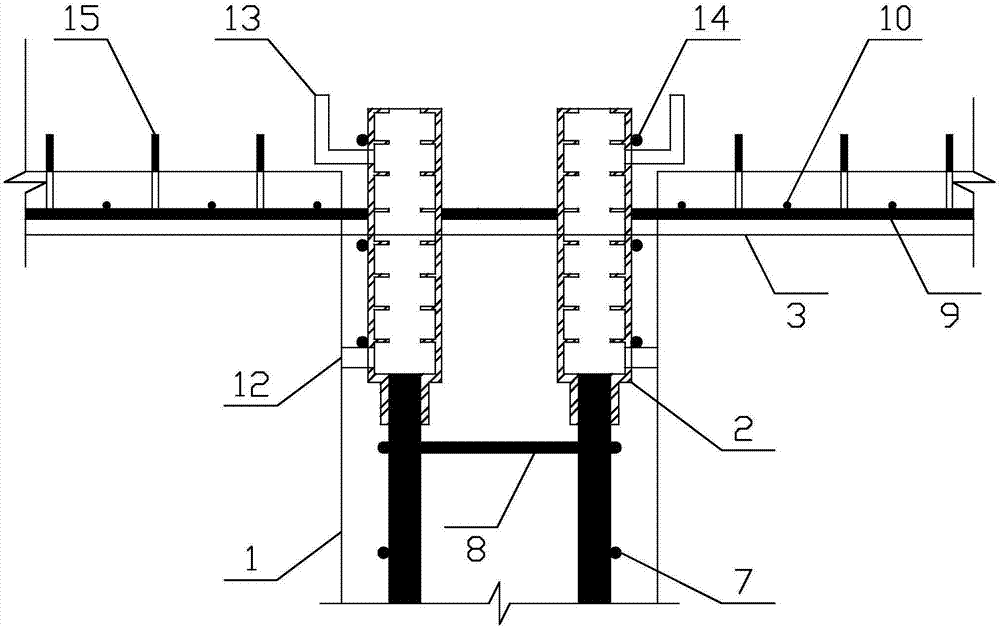

[0033] like Figure 1~4As shown, it is a prefabricated assembled shear wall and laminated slab joint of the present invention, including a prefabricated shear wall 1, a laminated slab 17 and a grouting sleeve 2, the prefabricated shear wall 1 is vertically arranged, and the prefabricated shear wall 1 is Reinforced concrete prefabricated wall, prefabricated shear wall 1 with grouting sleeve 2 extending from the upper end, and vertical steel bars 6 extending from the lower end; laminated slab 17 is mainly composed of prefabricated slab 3, steel mesh and post-cast concrete laminated layer 11, prefabricated slab 3 is set horizontally, the prefabricated slab 3 of the laminated slab is a reinforced concrete prefabricated slab, the steel bars are extended on both sides of the prefabricated slab 3, and the upper surface of the prefabricated slab 4 exposes the shear structural steel bars 15; the steel mesh is arranged horizontally above the prefabricated slab 3 And in the post-cast con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com