Reinforced concrete structure containing early strength type ultra-high performance concrete

A reinforced concrete, ultra-high-performance technology, applied in buildings, bridges, bridge parts, etc., can solve the problems affecting the service life of ultra-high-performance concrete, affecting the safety of building structures, and cumbersome construction in high-temperature steam curing, so as to improve the structural stress. performance, extended fatigue life, the effect of a reliable shear connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example is the preparation of early-strength ultra-high performance concrete.

[0031] Described early-strength ultra-high performance concrete comprises raw material and its volume percentage is:

[0032]

[0033] Wherein, the aspect ratio of the steel fiber is 50, and the above-mentioned raw materials are mixed evenly to obtain the early-strength ultra-high performance concrete.

Embodiment 2

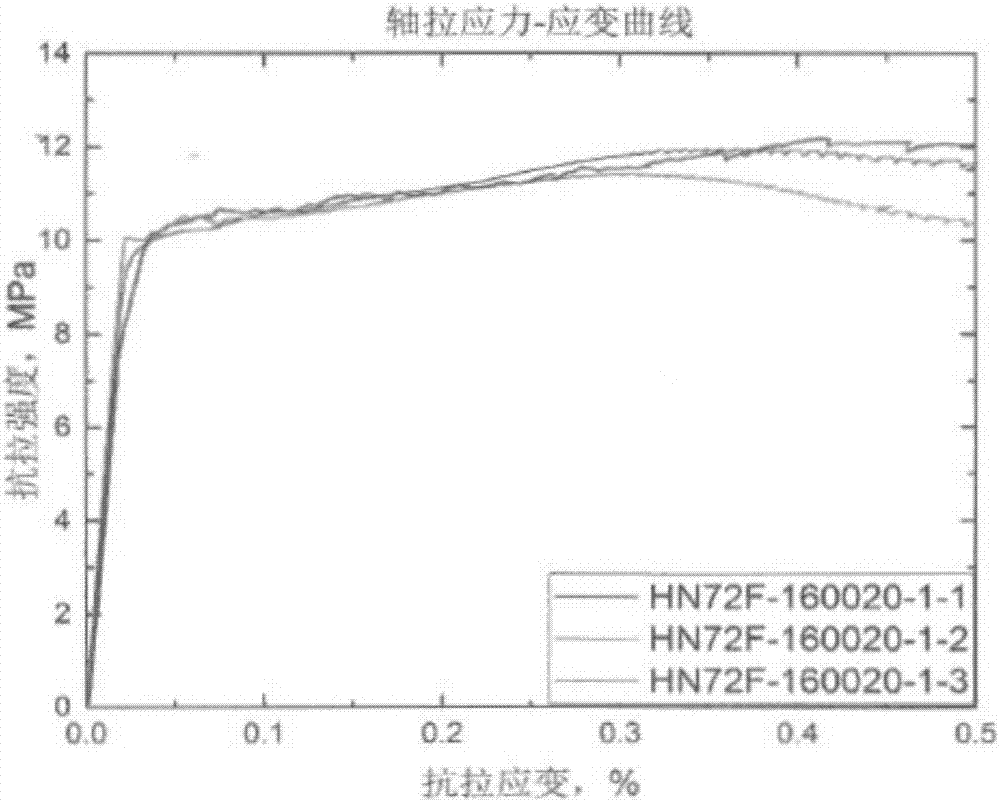

[0035] This example is the performance test result of the early-strength ultra-high performance concrete prepared in Implementation 1.

[0036] The tensile bending strength adopts the test method specified in GB / T 31387, the flexural strength adopts the test method specified in GB / T 17671, the compressive strength adopts the test method specified in GB / T 17671 and GB / T 31387 respectively, and the ultimate tensile strength adopts the test method specified in GB / T 17671 and ultimate tensile strain are entrusted to Shanghai Academy of Building Research for testing, and the test methods are in accordance with the regulations of CECS 13.

[0037] like image 3 As shown, the test results of the Shanghai Institute of Building Research show that the 28d ultimate tensile strength is 11.9MPa, and the 28d ultimate tensile strain is 0.35% (ie 3500με).

[0038] The performance testing result of the early-strength type ultra-high performance concrete of the present invention is shown in th...

Embodiment 3

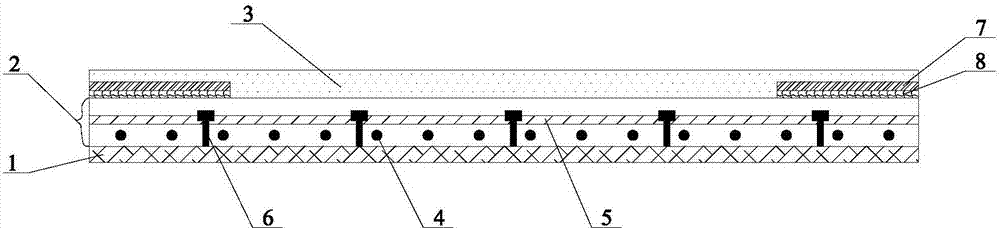

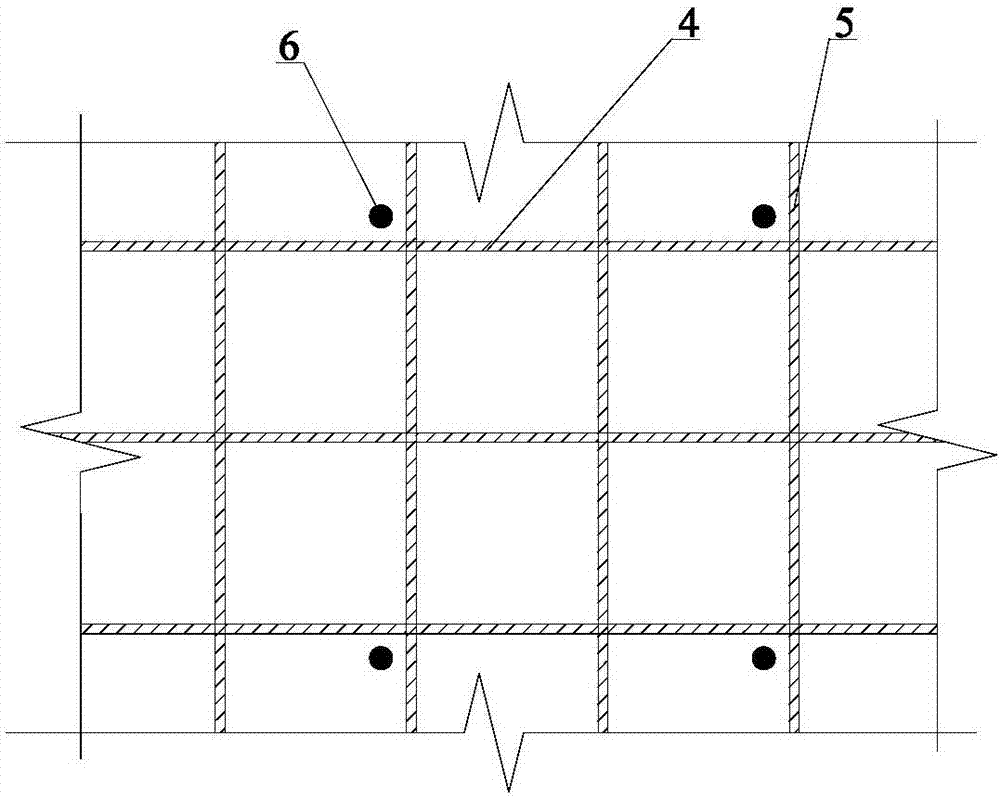

[0043] This embodiment is a reinforced concrete structure containing the early-strength ultra-high performance concrete described in Embodiment 1, such as figure 1 and figure 2 As shown, it includes a construction panel 1 and a reinforced concrete structure body 2. The reinforced concrete structure body 2 includes a steel skeleton and early-strength ultra-high performance concrete poured in the steel skeleton. The reinforced concrete structure body 2 is provided with a wear layer 3; the steel skeleton is a multi-layer superimposed steel bar composite structure, which includes a longitudinal bar distribution layer composed of longitudinal bars 5 and a transverse bar distribution layer composed of transverse bars 4, and the longitudinal bar distribution layer Intersecting with the horizontal reinforcement distribution layer to form a reinforced mesh structure, the longitudinal reinforcement distribution layer is located below the horizontal reinforcement distribution layer, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com