Preparation method of medium-strength corrosion-resistant aluminum alloy sheet materials

An aluminum alloy plate and aluminum alloy technology, applied in the field of metal materials and their processing and preparation, can solve the problems of difficulty in accurate monitoring of rolling temperature, difficulty in precise control of rolling temperature, reduction of alloy corrosion resistance, etc., and achieve excellent mechanical properties and corrosion resistance, improve solid solution strengthening effect, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

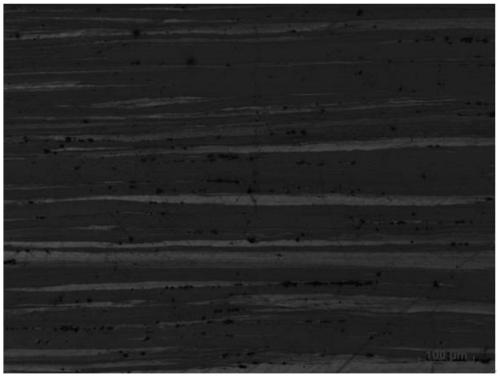

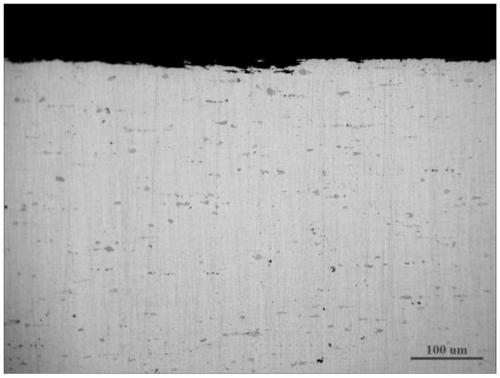

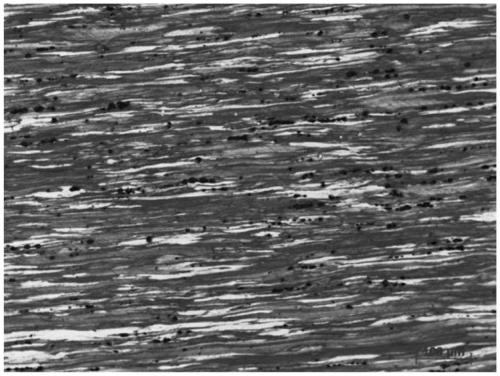

Image

Examples

Embodiment 1

[0043] A method for preparing a medium-strength corrosion-resistant aluminum alloy plate, comprising the following steps:

[0044] (1) Design the composition of aluminum alloy plates, including:

[0045] The content of Mg is 4.0%-5.0%, the content of Mn is 0.3%-1.0%, the content of Cr is 0-0.3%, the content of Zr is 0-0.4%, and the content of Fe is 0-0.35%.

[0046] In this example 1, for the preparation of the Al-4.5Mg-0.5Mn-0.15Cr alloy plate, according to the composition requirements, the master alloys are Al-Mn alloy Al-Mn and Al-Cr alloy Al-Cr alloy, and the pure magnesium is about 5%. The proportion of burning loss.

[0047] (2) Melting and casting:

[0048] The components are melted and cast into aluminum alloy slabs.

[0049] The melting temperature is set at 760°C-780°C, and the pure aluminum and the intermediate alloy are smelted at the same time. After the alloy is completely melted, the refining process is carried out. Among them, the refining process adopts arg...

Embodiment 2

[0072] A method for preparing a medium-strength corrosion-resistant aluminum alloy plate. For the preparation of Al-4.5Mg-0.5Mn-0.2Zr alloy plate, the master alloy is equipped with aluminum-manganese alloy Al-Mn and aluminum-zirconium alloy Al-Cr according to the composition requirements. Magnesium is proportioned according to the burning loss of about 5%. Melt pure aluminum and intermediate alloy at 780°C at the same time. After the alloy is completely melted, stir, degas, remove slag, and cool down to 730°C. Add pure magnesium. After the pure magnesium is completely melted, stir and remove slag. , poured at a temperature of 720°C to form an aluminum alloy flat ingot.

[0073] After removing the head and milling six sides of the aluminum alloy slab, heat it in a box-type resistance furnace at a heating temperature of 480°C and keep it warm for 8 hours. After coming out of the furnace, it will be rolled directly. The first rolling reduction is 10%. When the deformation reaches...

Embodiment 3

[0076] A method for preparing a medium-strength corrosion-resistant aluminum alloy plate. For the preparation of Al-4.5Mg-0.7Mn-0.15Cr-0.1Zr alloy plate, according to the composition requirements, the intermediate alloy is equipped with aluminum-manganese alloy Al-Mn, aluminum-chromium alloy Al- Cr and aluminum-zirconium alloy Al-Cr, pure magnesium according to the proportion of burning loss of about 5%, melting pure aluminum and intermediate alloy at a temperature of 780 ° C at the same time, after the alloy is completely melted, stirring, degassing, and slag removal , Stand still and cool down to 730°C, add pure magnesium, after the pure magnesium is completely melted, stir, remove slag, and pour at a temperature of 720°C to form an aluminum alloy flat ingot.

[0077] After removing the head and milling six sides of the aluminum alloy slab, heat it in a box-type resistance furnace at a heating temperature of 480°C and keep it warm for 8 hours. After coming out of the furnace,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com