A low heat input dual DC pulse compound arc welding method for thin-walled metal pipes

An arc welding method and DC pulse technology, which is applied in arc welding equipment, metal processing, welding equipment, etc., can solve the problems of long residence time of metal at high temperature, grain growth of welded joints, and reduction of mechanical properties of welded seams, etc. The existence time of molten pool, the effect of reducing corrosion resistance and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

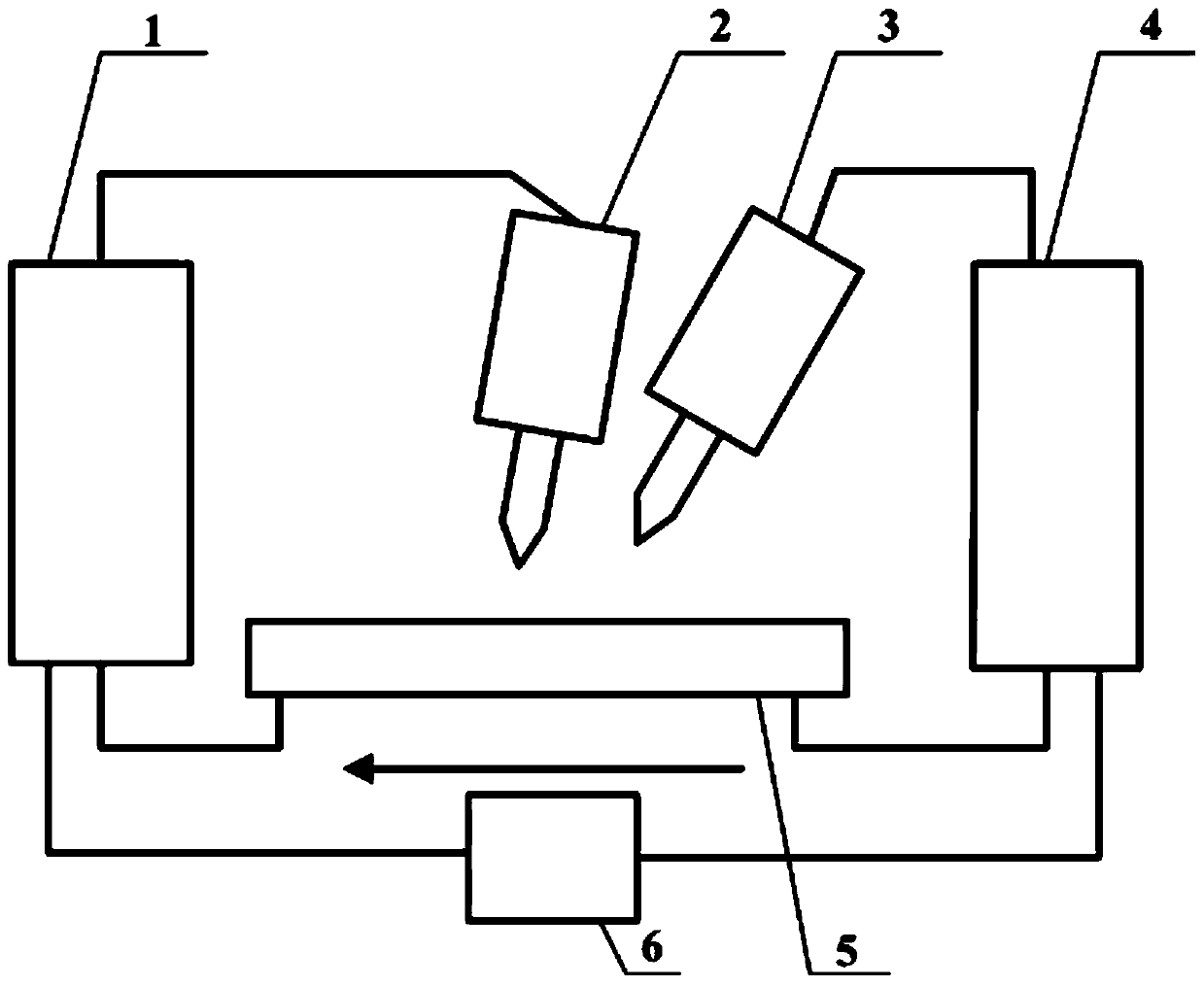

[0028] Taking the production of Φ48×1.5mm 409L ferritic stainless steel pipe as an example, the implementation of the DC pulse double TIG arc high-speed welding process is illustrated.

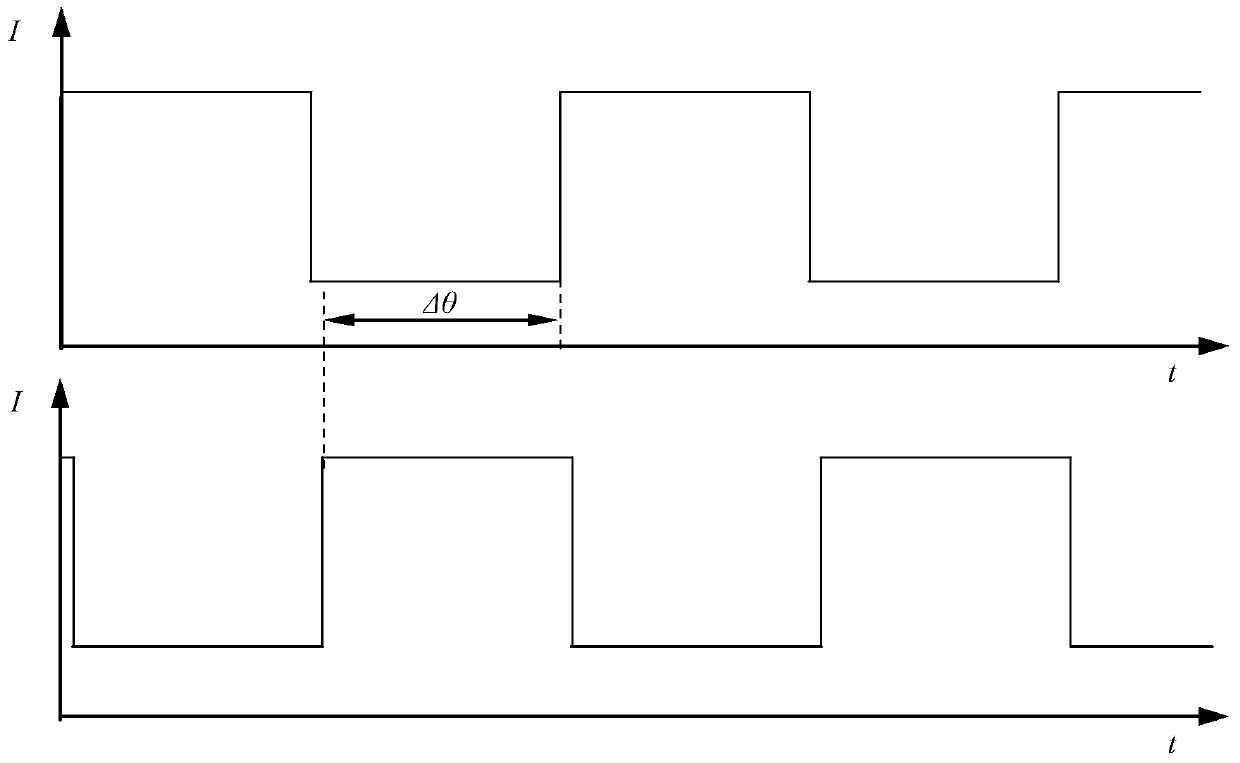

[0029] Two identical digital inverter DC pulse TIG power supplies are selected as the first DC pulse power supply 1 and the second DC pulse power supply 4, the pulse waveform is square wave, and the pulse duty cycle is 50%. The average welding current of the first DC pulse power supply 1 is set to 240A, and the pulse frequency is 20Hz. The average current of the second DC pulse power supply 4 is set to 160A, and the pulse frequency is also 20Hz. The angle of the main welding torch 2 is 80°. The angle of the auxiliary welding torch 3 is 65°, the distance between the two tungsten electrodes is 21mm, the distance between the tungsten electrode tip of the main welding torch 2 and the workpiece is 1.2mm, the distance between the tungsten electrode tip of the auxiliary welding torch 3 and the workpie...

Embodiment 2

[0032] Taking the production of Φ32×1.2mm 409L ferritic stainless steel pipe as an example, the implementation of DC pulsed double TIG arc high-speed welding process is illustrated.

[0033] Two identical digital inverter DC pulse TIG power supplies are selected as the first DC pulse power supply 1 and the second DC pulse power supply 4, the pulse waveform is a sawtooth wave, and the pulse duty cycle is 30%. The average welding current of the first DC pulse power supply 1 is set to 300A, and the pulse frequency is 30Hz. The average current of the second DC pulse power supply 4 is set to 150A, and the pulse frequency is also 30Hz. The angle of the main welding torch 2 is 80°. The angle of the auxiliary torch 3 is 65°, the distance between the two tungsten electrodes is 21mm, the distance between the tip of the tungsten electrode of the main welding torch 2 and the workpiece is 1.2mm, the distance between the tip of the tungsten electrode of the auxiliary welding torch 3 and the ...

Embodiment 3

[0036] Taking the welding of 2.0mm thick 409L ferritic stainless steel sheet as an example to illustrate the implementation of DC pulse double TIG arc high-speed welding process.

[0037] Two identical digital inverter DC pulse TIG power supplies are selected as the first DC pulse power supply 1 and the second DC pulse power supply 4. The pulse waveform is a ladder wave and the pulse duty cycle is 40%. The average welding current of the first DC pulse power supply 1 is set to 300A, and the pulse frequency is 10Hz. The average current of the second DC pulse power supply 4 is set to 200A, and the pulse frequency is also 10Hz. The angle of the main welding torch 2 is 80°. The angle of the auxiliary welding torch 3 is 65°, the distance between the two tungsten electrodes is 21mm, the distance between the tungsten electrode tip of the main welding torch 2 and the workpiece is 1.2mm, the distance between the tungsten electrode tip of the auxiliary welding torch 3 and the workpiece is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com