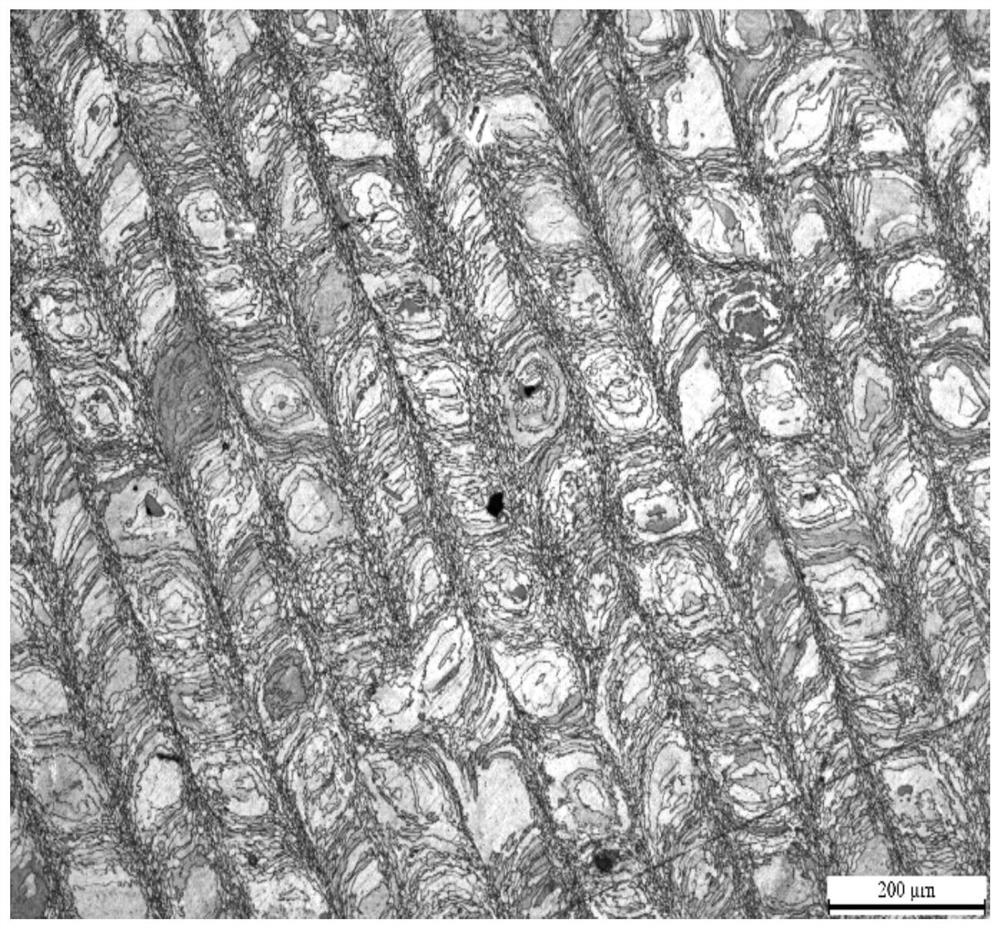

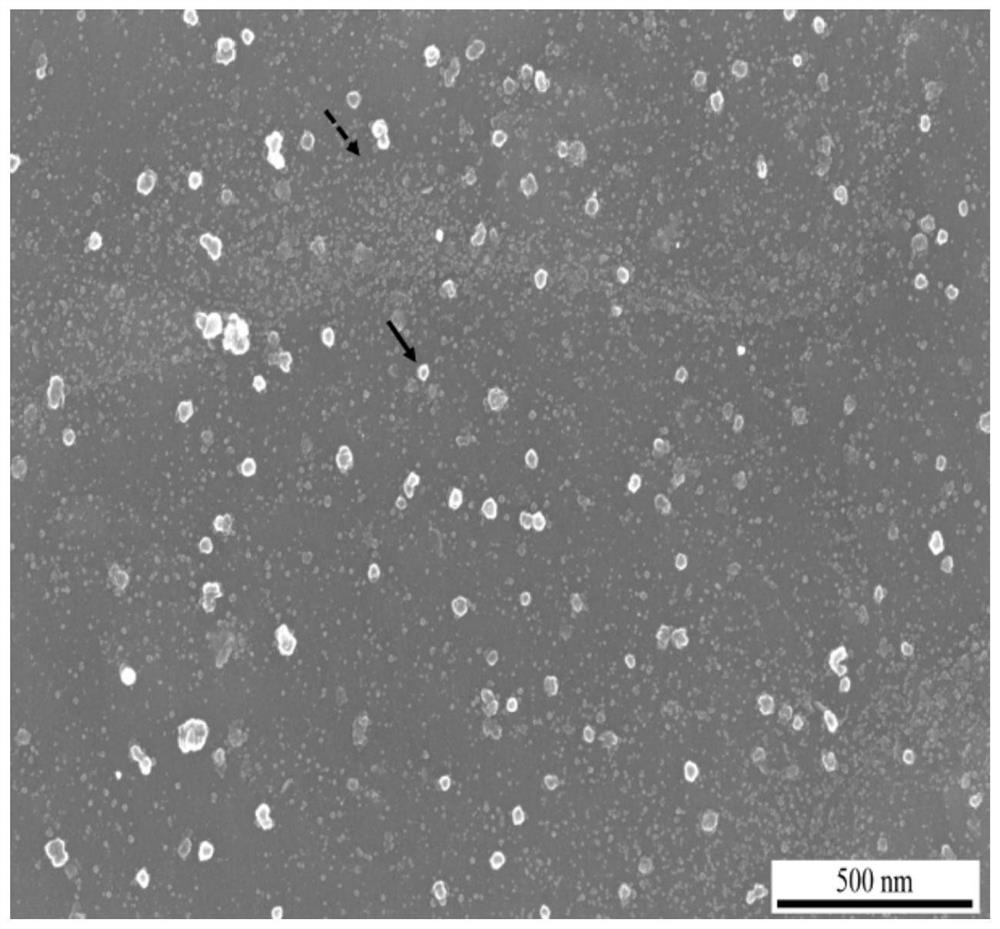

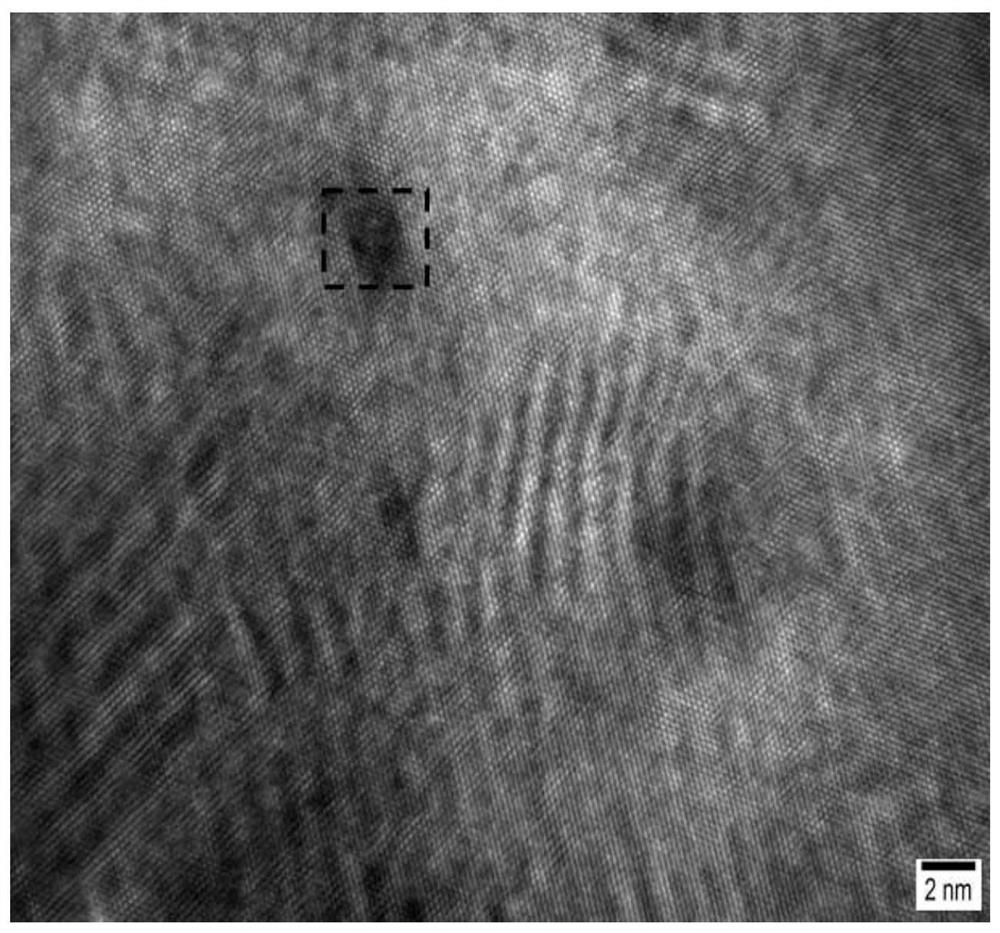

High-strength and high-conductivity Cu-Cr-Nb alloy with double-peak grain size and double-scale nano-phase reinforcing function

A cu-cr-nb, grain size technology, applied in metal processing equipment, additive manufacturing, transportation and packaging, etc. The effect of high electrical conductivity and high plastic electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of copper alloy powder suitable for SLM

[0046] Put electrolytic pure copper and Cr-Nb intermediate alloy raw materials into a vacuum induction melting furnace for melting; when the raw materials are melted and completely alloyed, vacuum degassing is carried out at 1580 ° C for 10 minutes, and then the fully alloyed melt is melted at 3.5kg / The flow rate of min is introduced into the close-coupled gas atomization furnace through the guide tube, the atomization temperature is controlled at 1600°C, the atomization medium pressure is 3.5MPa, and high-purity argon (purity 99.99wt%) is used as the atomization medium to spray The liquid flow is crushed into fine droplets, and after cooling and rapid solidification, Cu-Cr-Nb alloy powder is formed; finally, the required Cu-Cr- Nb alloy powder, packaged in a reducing atmosphere with a hydrogen content of 3v% and an argon content of 97v%. The content of Cr in the alloy powder is 2.3 at%, the content of Nb is 1 a...

Embodiment 2

[0056] (1) Preparation of copper alloy powder suitable for SLM

[0057] Put the electrolytic pure copper and Cr-Nb intermediate alloy into the vacuum induction melting furnace for melting; when the raw materials are melted and completely alloyed, carry out vacuum degassing at 1590°C for 10 minutes, and then melt the fully alloyed melt at 3.5kg / min The flow rate is introduced into the close-coupled gas atomization furnace through the guide tube, the atomization temperature is controlled at 1600°C, the atomization medium pressure is 3.5MPa, and high-purity argon (purity 99.99wt%) is used as the atomization medium to spray the metal liquid The flow breaks into fine droplets, and after cooling and rapid solidification, Cu-Cr-Nb alloy powder is formed; finally, the required Cu-Cr-Nb is screened out by using a nitrogen screening device and ultrasonic vibration screening at low temperature. The alloy powder is packaged in a reducing atmosphere with a hydrogen content of 2v% and an ar...

Embodiment 3

[0067] (1) Preparation of copper alloy powder suitable for SLM

[0068] Put the electrolytic pure copper and Cr-Nb intermediate alloy into the vacuum induction melting furnace for melting; when the raw materials are melted and completely alloyed, carry out vacuum degassing at 1580°C for 10 minutes, and then melt the fully alloyed melt at 3.5kg / min The flow rate is introduced into the close-coupled gas atomization furnace through the guide tube, the atomization temperature is controlled at 1600°C, the atomization medium pressure is 3.5MPa, and high-purity argon (purity 99.99wt%) is used as the atomization medium to spray the metal liquid The flow breaks into fine droplets, and after cooling and rapid solidification, Cu-Cr-Nb alloy powder is formed; finally, the required Cu-Cr-Nb is screened out by using a nitrogen screening device and ultrasonic vibration screening at low temperature. The alloy powder is packaged in a reducing atmosphere with a hydrogen content of 2v% and an ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com