Low-precipitation super ferrite cast stainless steel and preparation method thereof

A technology of super ferrite and stainless steel, applied in the field of low precipitation super ferrite cast stainless steel and its preparation, can solve problems such as deterioration of mechanical properties, reduce the size and content of inclusions, purify grain boundaries, and reduce grain boundary distortion energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

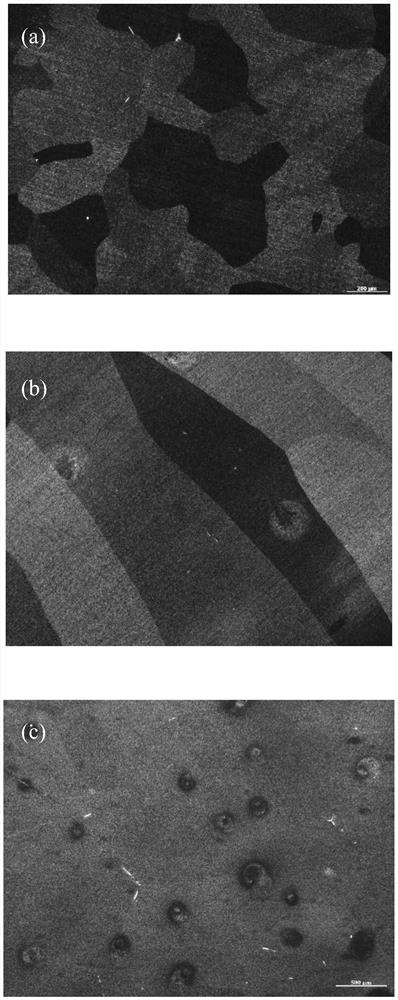

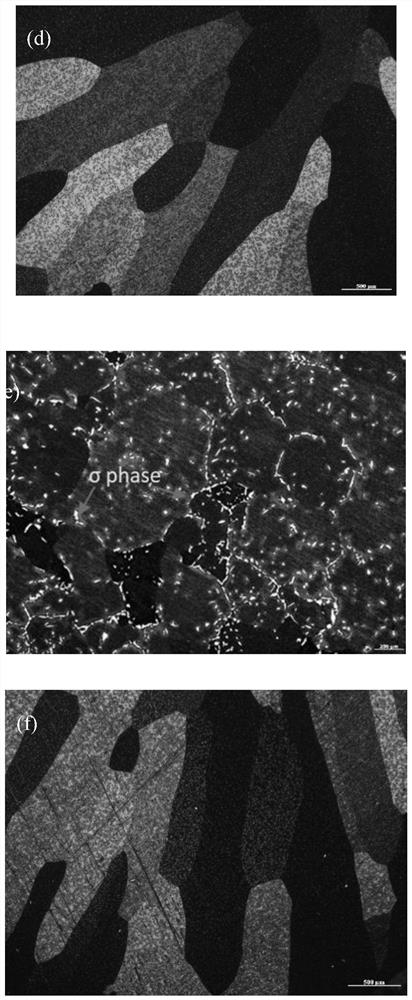

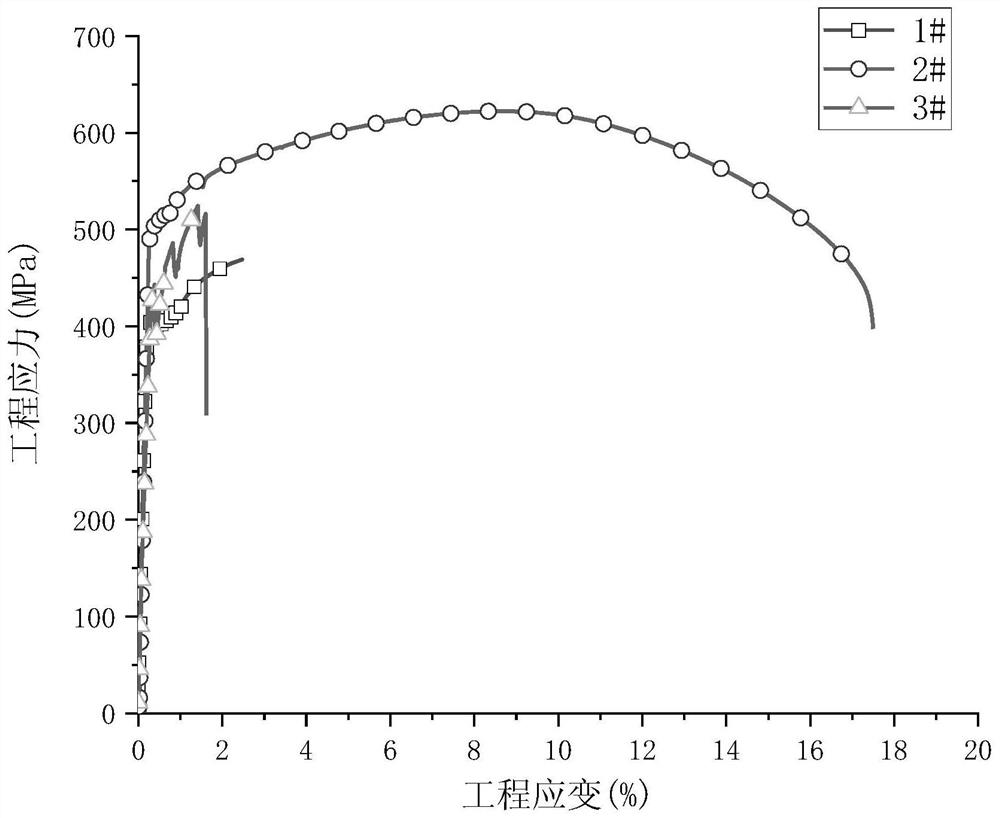

Embodiment 1

[0034] A method for preparing low-precipitation super ferritic cast stainless steel, using a 50KG vacuum induction smelting furnace to smelt the stainless steel described in the present invention, the content of each component of the stainless steel is Cr 25%, Mo 1%, Al 0.03%, Ce 0.03%, C0.0017%, N0.0031%, S 0.0020%, P 0.0080%, the balance is Fe, and the specific steps are as follows:

[0035] (1) Put 5KG super ferritic stainless steel alloy ingot into the crucible, and add Al and Ce by hanging method.

[0036] (2) Turn on the vacuum pump, when the vacuum is evacuated to 10 Pa, the power is 35KW, and when the vacuum reaches 0.1 Pa, increase the power to 40KW, and melt the material.

[0037] (3) Keep the vacuum constant, increase the temperature of molten steel to 1550°C for refining for 15 minutes, then turn off the power and cool down to 1506°C for part of the conjunctiva;

[0038] (4) Keep the vacuum constant, put Al into the molten steel, then increase the power to 40KW, h...

Embodiment 2

[0042] A method for preparing low-precipitation super ferritic cast stainless steel, using a 50KG vacuum induction smelting furnace to smelt the stainless steel described in the present invention, the content of each component of the stainless steel is Cr 30%, Mo 2.11%, Al 0.05%, Ce 0.05%, C0.0020%, N 0.0026%, S 0.0020%, P 0.0070%, the balance is Fe, and the specific steps are as follows:

[0043] (1) Put 5KG super ferritic stainless steel alloy ingot into the crucible, and add Al and Ce by hanging method.

[0044] (2) Turn on the vacuum pump, when the vacuum is evacuated to 10 Pa, the power is 35KW, and when the vacuum reaches 0.1 Pa, increase the power to 40KW, and melt the material.

[0045] (3) Keep the vacuum constant, increase the temperature of the molten steel to 1600°C for refining for 10 minutes, then turn off the power and cool down to 1506°C for part of the conjunctiva;

[0046] (4) Keep the vacuum constant, put Al into the molten steel, then increase the power to...

Embodiment 3

[0056] A method for preparing low-precipitation super ferritic cast stainless steel, using a 50KG vacuum induction smelting furnace to smelt the stainless steel described in the present invention, the content of each component of the stainless steel is Cr 28%, Mo 4%, Al 0.04%, Ce 0.08%, C0.0020%, N0.0026%, S 0.0020%, P 0.0070%, the balance is Fe, and the specific steps are as follows:

[0057] (1) Put 5KG super ferritic stainless steel alloy ingot into the crucible, and add Al and Ce by hanging method.

[0058] (2) Turn on the vacuum pump, when the vacuum is evacuated to 10 Pa, the power is 35KW, and when the vacuum reaches 0.1 Pa, increase the power to 40KW, and melt the material.

[0059] (3) Keep the vacuum constant, increase the temperature of molten steel to 1650°C for refining for 8 minutes, then turn off the power and cool down to 1506°C for part of the conjunctiva;

[0060] (4) Keep the vacuum constant, put Al into the molten steel, then increase the power to 40KW, he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com