Novel binding phase hard alloy and preparation method thereof

A cemented carbide and binder phase technology, applied in the field of cemented carbide, can solve the problems of easy agglomeration and limited strengthening effect, and achieve the effects of improving compatibility, increasing solid solution and obvious strengthening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

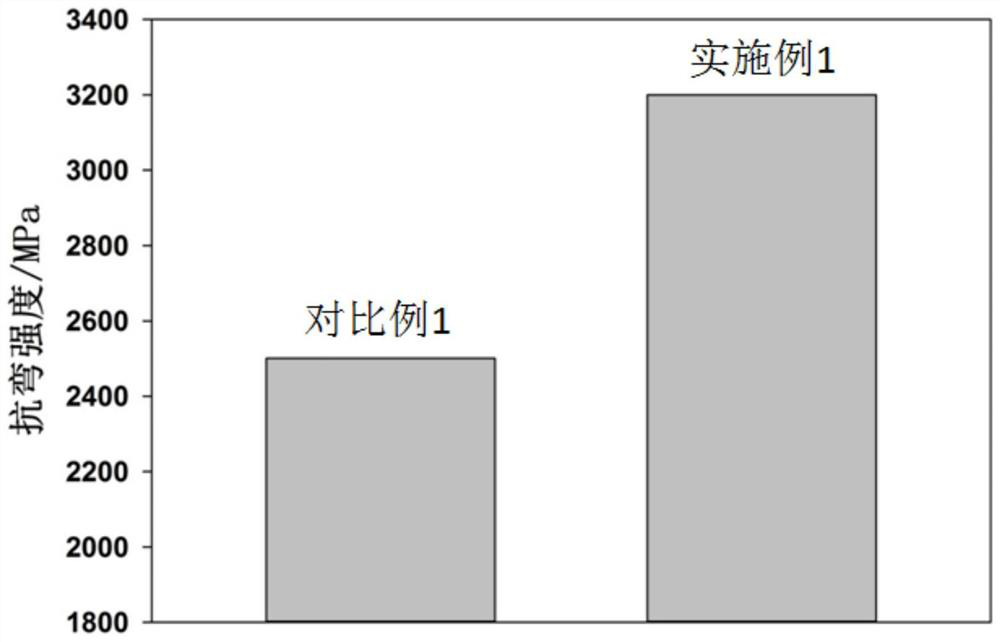

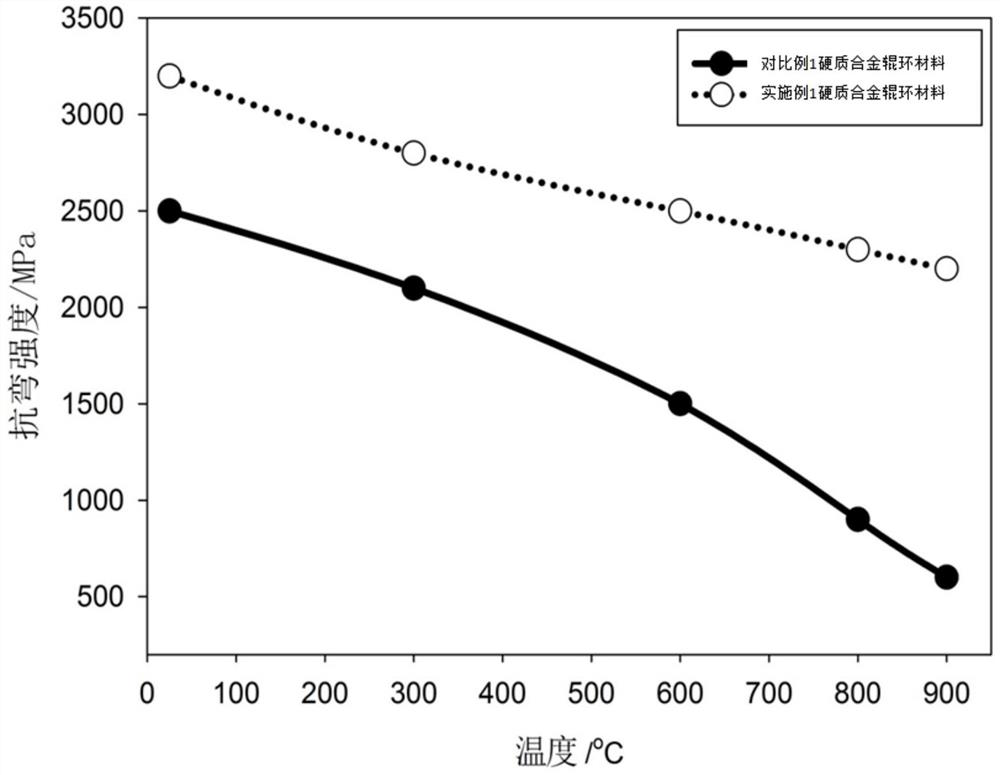

Embodiment 1

[0022] Pre-wet grinding 0.6wt% of the total weight of silicon carbide powder with a particle size of 0.6 μm for 6 hours, then adding 10wt% cobalt powder, 10wt% nickel powder and the remainder of tungsten carbide powder and then wet grinding for 18 hours, After the wet grinding mixture is spray-dried and pressed into shape; after the compact is sintered in the low-pressure liquid phase at 1450°C, the pressure is 0.6MPa, and the holding time is 1h, the Si-enhanced Co-Ni binder phase of the present invention can be obtained. quality alloy.

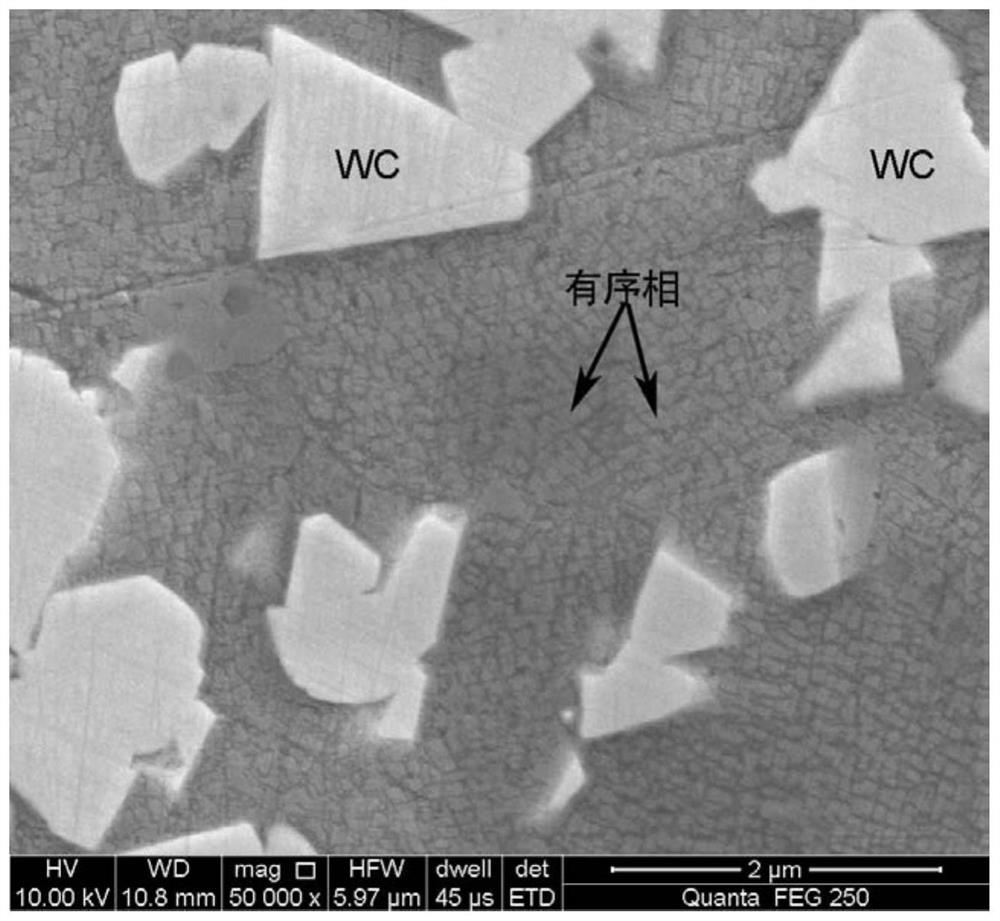

[0023] Characterize the microstructure of the cemented carbide prepared in this embodiment, its structure is as follows figure 1 As shown, the ordered phase is the strengthening phase, and the phase structure is A 3 B (wherein A represents Co and / Ni element, B represents Si element).

Embodiment 2~9

[0033] The preparation process of Examples 2-9 is basically the same as that of Examples, and their specific proportions and process parameters are shown in Table 1.

[0034] The preparation parameter of the cemented carbide regeneration process of table 1 embodiment 1-embodiment 9 and part comparative examples

[0035]

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com