A kind of cemented carbide for cold heading die and preparation method thereof

A cemented carbide and mold technology, applied in the field of cemented carbide preparation, can solve the problems of sacrificing wear resistance, limited alloy toughness, etc., and achieve the effects of increasing solid solution, long service life and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

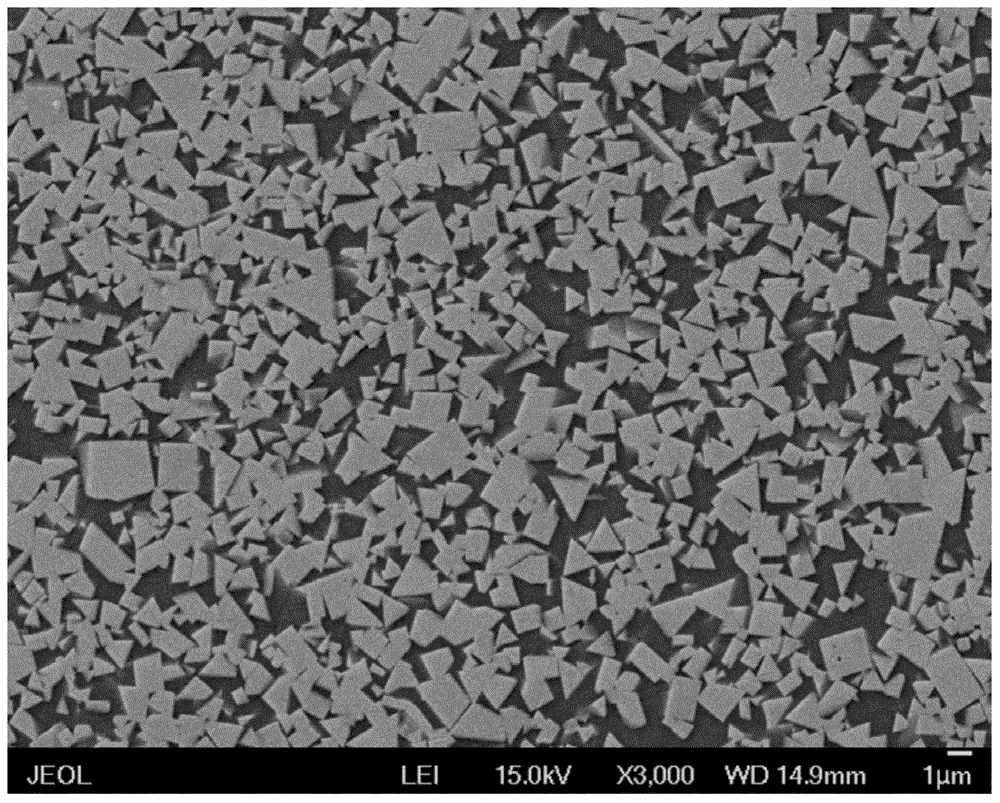

Embodiment 1

[0022] A hard alloy for cold heading dies, used for cold heading stainless steel Φ4.8 screw straight rods, the alloy and weight percentage of the composition are: Co powder 25%, WC powder with Fsss particle size 2.0-3.0μm 74%, 1.5μm Cr 3 C 2 1%.

[0023] The preparation method of above-mentioned cemented carbide for cold heading die: get above-mentioned raw material in proportion, and gross weight is 50KG, puts into 50 liters of tiltable ball mills, does wet-milling medium with alcohol and carries out wet-milling, and ball-to-material ratio is 4.3: 1. The liquid-solid ratio is 330ml / KG. Add paraffin wax molding agent according to 2% of the total weight of the raw materials. The wet grinding time is 50h. After the wet-milled slurry is spray-dried and pressed, it is sintered in a PVA furnace at 58bar. The temperature is 1410° C., and the holding time is 60 minutes to obtain a sintered cemented carbide.

[0024] Carry out heat treatment on the cemented carbide obtained after s...

Embodiment 2

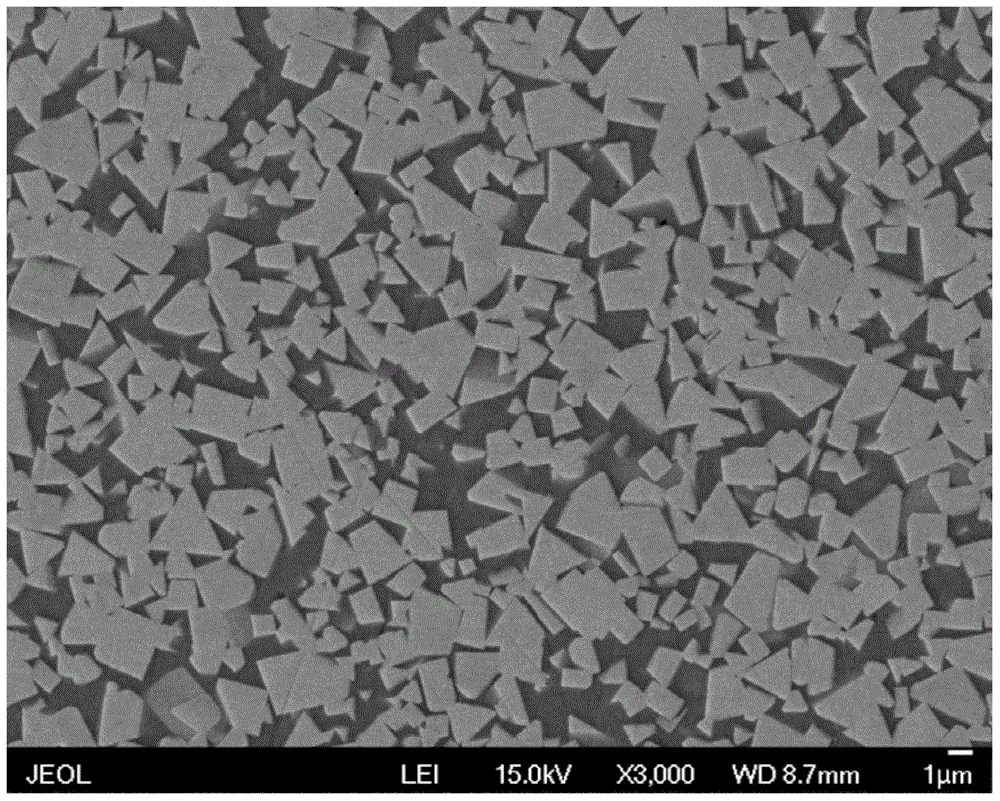

[0026] A hard alloy for cold heading dies, used for cold heading carbon steel Φ3.8 screw straight rods, the alloy and weight percentage of the composition are: Co powder 22%, WC powder with Fsss particle size of 5.0-6.0μm 77.5%, 1.5 μm Cr 3 C 2 0.5%.

[0027] The preparation method of above-mentioned cemented carbide for cold heading mold: get above-mentioned raw material in proportion, and gross weight is 50KG, puts into 50 liters in the tiltable ball mill, does wet-milling medium with alcohol and carries out wet-milling, and ball-to-material ratio is 3.4: 1. The liquid-solid ratio is 320ml / KG. Add paraffin wax molding agent according to 2% of the total weight of the raw materials. The wet grinding time is 36 hours. After the wet-milled slurry is spray-dried and pressed, it is sintered in a PVA pressure furnace at 58bar. The sintering temperature is 1450° C., and the holding time is 60 minutes to obtain a sintered cemented carbide.

[0028] Carry out heat treatment on the ...

Embodiment 3

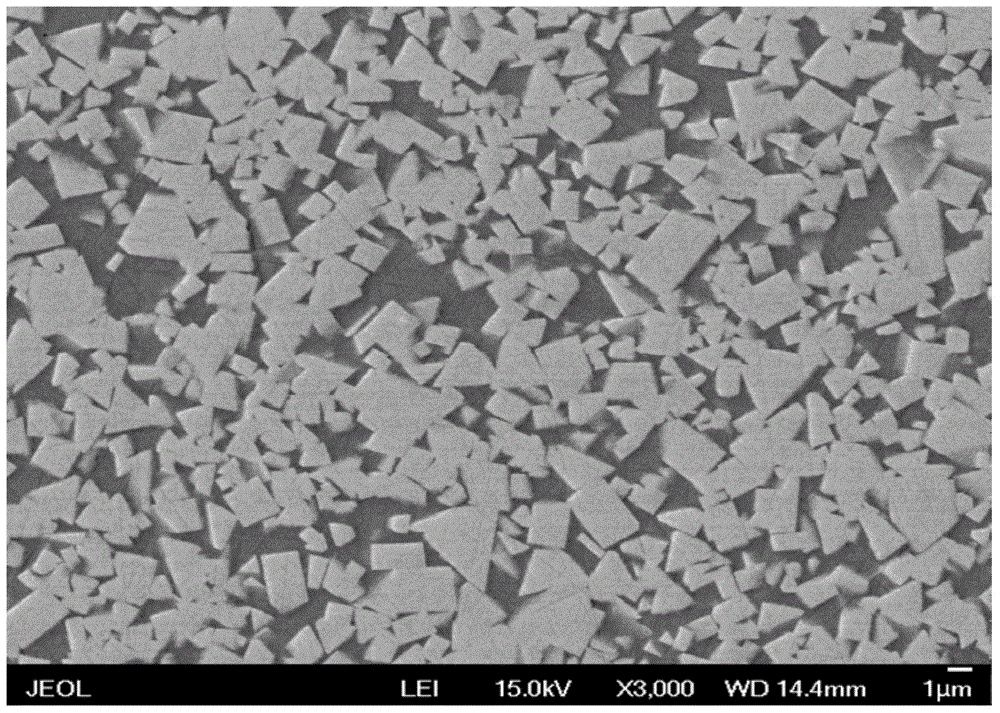

[0030] A hard alloy for cold heading dies, used for cold heading stainless steel Φ8 screw straight rods, the alloy and weight percentage of the composition are: 28% Co powder, 70.5% WC powder with Fsss particle size of 3.0-4.0 μm, 1.5 μm Cr 3 C 2 1.5%.

[0031] The preparation method of above-mentioned cemented carbide for cold heading mold: get above-mentioned raw material in proportion, gross weight is 50KG, puts into 50 liters in the tiltable ball mill, does wet-milling medium with alcohol and carries out wet-milling, and ball-to-material ratio is 4.5: 1. The liquid-solid ratio is 350ml / KG. Add paraffin wax molding agent according to 2% of the total weight of raw materials. The wet grinding time is 52 hours. After the wet-milled slurry is spray-dried and pressed, it is sintered in a TP furnace (no pressure). The sintering temperature is 1400° C., and the holding time is 60 minutes to obtain a sintered cemented carbide.

[0032] Carry out heat treatment on the cemented car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com