Fluororubber composition, production method therefor, and molded crosslinked fluororubber article

A manufacturing method and fluororubber technology, applied in mechanical equipment, engine components, engine sealing, etc., can solve the problems of abnormal wear of sliding surfaces, sealing foaming, inability to obtain good sealing, and achieve excellent kneading, resistance to Excellent foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] 1st kneading process

[0091] No. 4 was used for the compounding recipe of the above-mentioned carbon nanotube masterbatch. In the first kneading, a carbon nanotube masterbatch containing a fluororubber polymer (20% by weight of CNT in the masterbatch) was produced by roller kneading. As the first kneading facility, an open roll kneading facility having a pair of two rolls was used. The distance between the first roll and the second roll was 1 mm, and the fluororubber polymer and CNT were kneaded to prepare a carbon nanotube masterbatch of formulation No. 4.

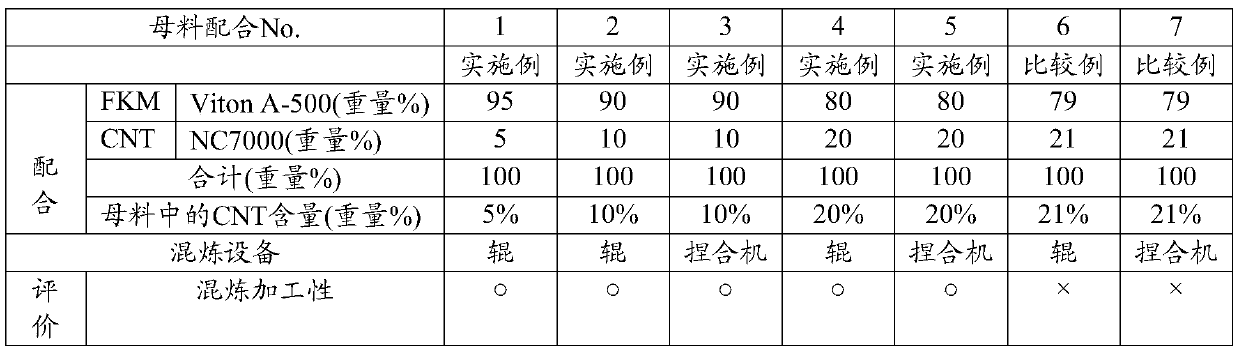

[0092] The kneading processability when kneading with an open roll to produce a carbon nanotube masterbatch was evaluated according to the following evaluation criteria, and the results are shown in Table 1 above.

[0093]

[0094] ○: Can be kneaded

[0095] ×: Not kneadable

[0096] 2nd kneading process

[0097] The carbon nanotube masterbatch obtained in the above-mentioned first kneading step was kneaded...

Embodiment 2~6

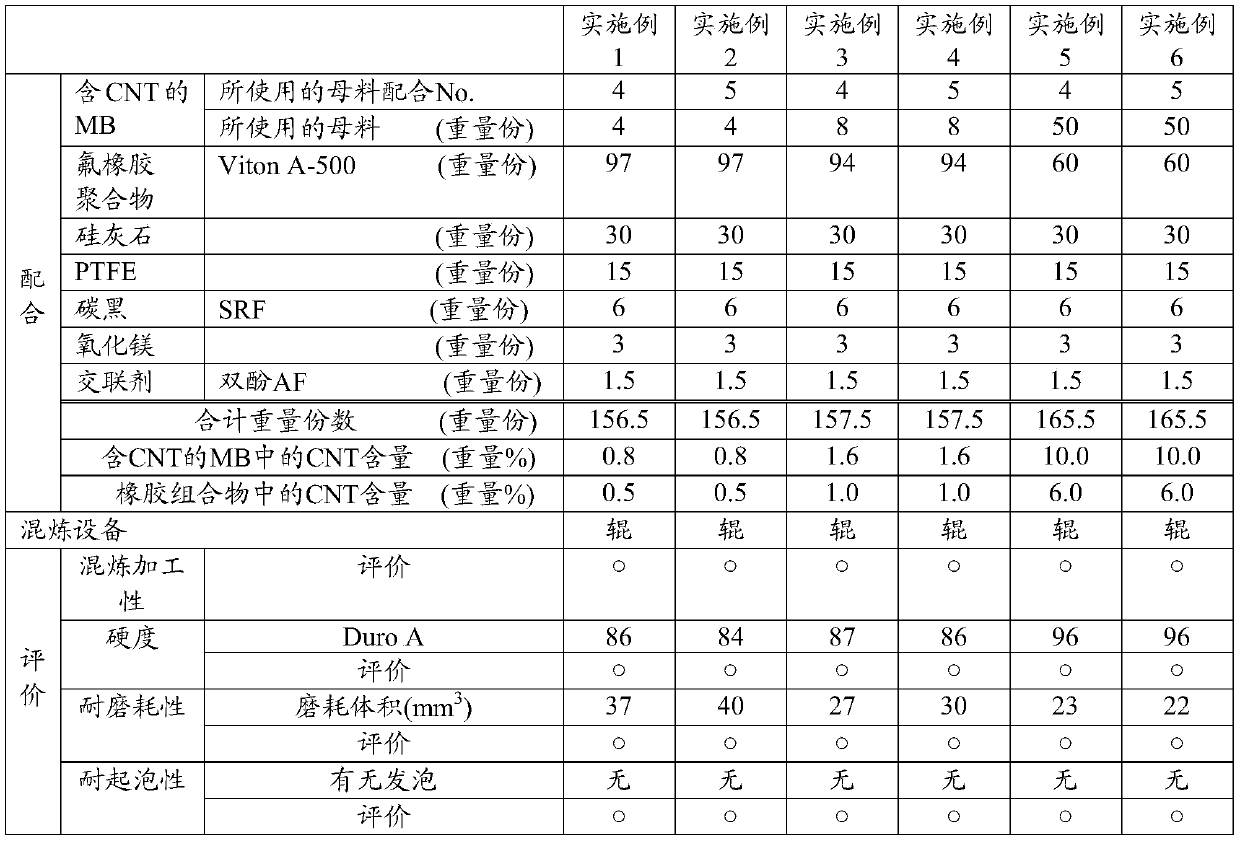

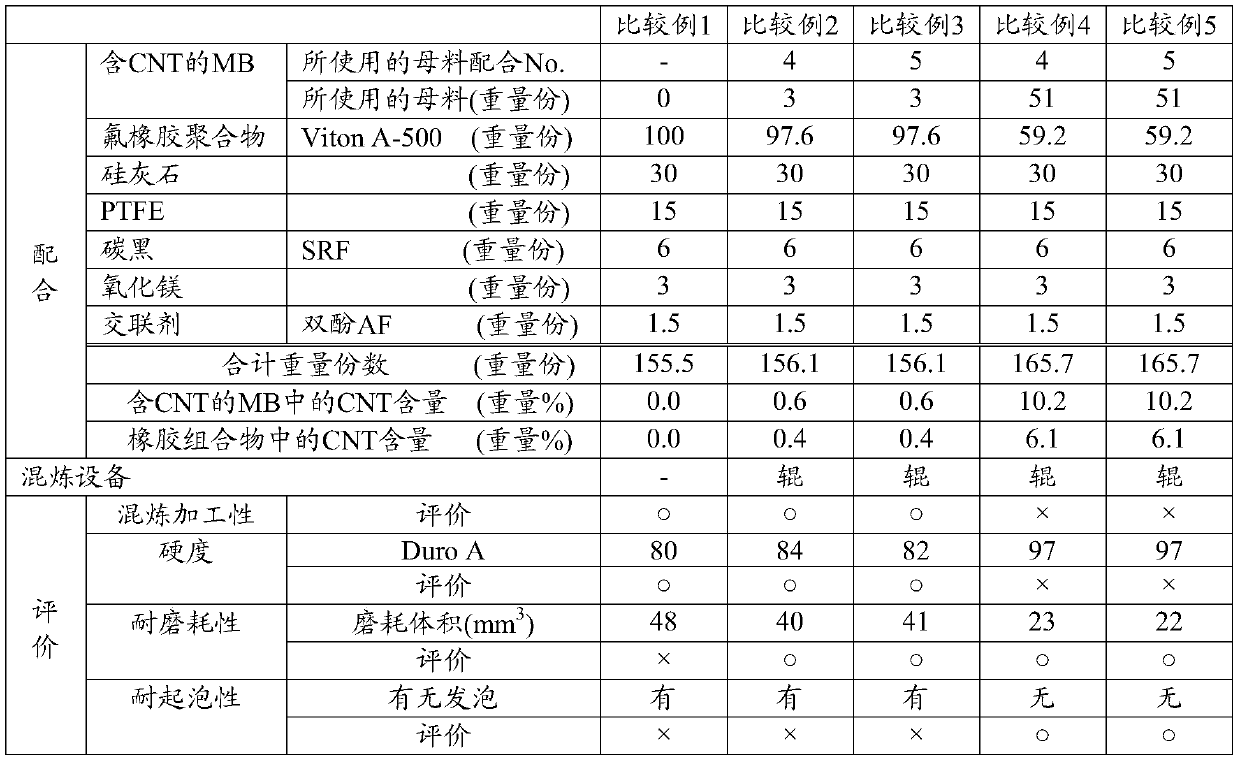

[0124] In Example 1, the carbon nanotube masterbatch No. 4 or No. 5 was used, and various compounding formulations were used to evaluate the kneading processability, hardness, abrasion resistance, and foaming resistance.

[0125] The results obtained in Examples 1 to 6 are shown in Table 2 below together with the compounding ratio.

[0126] Table 2 (Second Kneading Process)

[0127]

Embodiment 7

[0138] In Example 1, a fluororubber composition was produced in the same manner as in Example 1 except that "2. Second kneading step" was changed as shown below. The obtained fluororubber composition was evaluated for kneading processability, hardness, abrasion resistance, and foaming resistance.

[0139] "The second kneading process

[0140] The carbon nanotube masterbatch obtained in the first kneading step was introduced into a second kneading device which is a kneader kneading device.

[0141] In this second kneading facility, masterbatch No. 4 was kneaded with the fluororubber raw materials of the following recipe to produce a fluororubber composition. "

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com