A method for preparing high-solubility ultra-fine grain high-speed steel by using electric pulse

A technology of ultra-fine grain and high-speed steel, which is applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc., to achieve short process flow, improve hardness and toughness, and realize the effect of ultra-fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

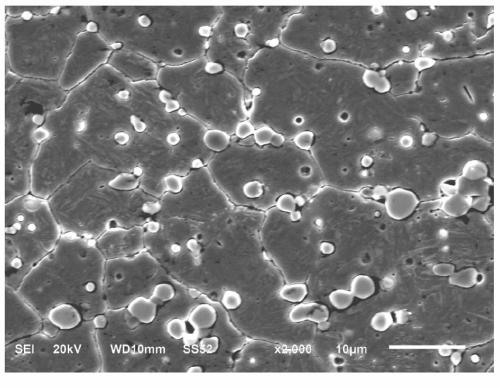

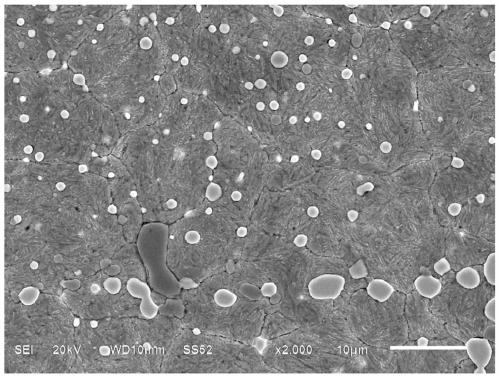

[0036] The material is M2 high-speed steel widely used in the market. A workpiece with a size of φ10x60mm is taken and heated to 1180°C in a vacuum tube furnace. After holding for 10 minutes, it is quenched and cooled to room temperature in quenching oil. figure 2 shown). Temper the pre-quenched high-speed steel workpiece at 550°C for 1 hour and then air-cool it to obtain the pre-heat treatment microstructure (such as image 3 shown). The average grain size of the preliminary heat treatment is 20 μm, and the matrix is distributed with eutectic carbides and fine secondary carbides precipitated by tempering.

[0037] Turn on the power supply 3 of the electric pulse device, and connect to the grid. Turn on the charging power supply 3, the transformer 4 and the energy storage 5 through the control system 1 to complete the energy storage charging process.

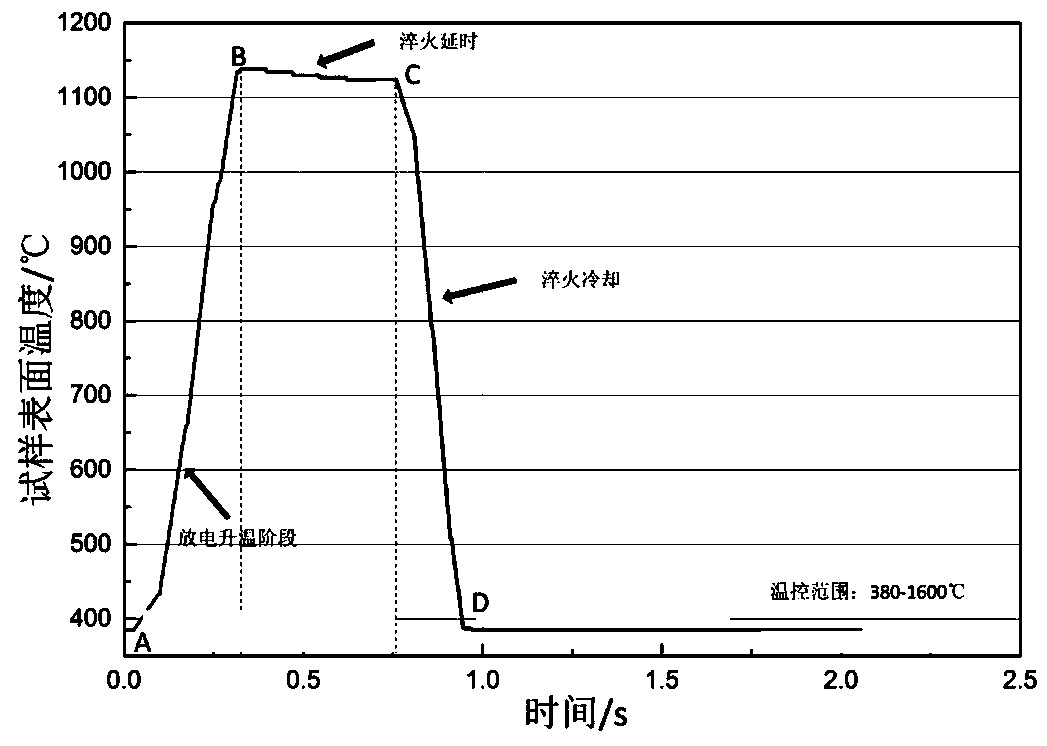

[0038] The high-speed steel workpiece 10 after preliminary heat treatment is polished smooth, and the two ends are clamp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com