Method for manufacturing high performance sinter Mo-Ti-Zr molybdenum alloy

A technology of powder metallurgy and molybdenum alloy, which is applied in the field of powder metallurgy, can solve the problems of low toughness alloys, etc., and achieve the effects of improved tensile strength, simple process and high alloy performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

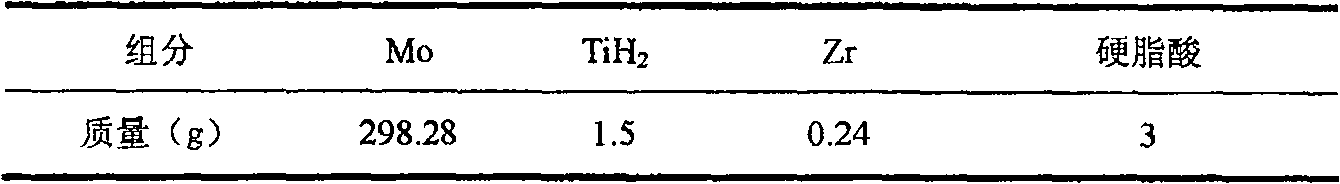

[0018] (1) Taking the preparation of 300g alloy powder as an example, weigh the mass of each component of the alloy powder according to mass percentage:

[0019]

[0020] Stearic acid is heated and dissolved in alcohol and put into the ball mill tube together with the powder, and the ball mill tube is filled with N 2 Set the milling time to 5h to prepare the pre-alloyed powder. Take out the powder, dry it, and pack it in a bag for later use.

[0021] (2) Press the prepared pre-alloy powder into a shape.

[0022] (3) Pre-sintering the prepared compact in a vacuum atmosphere, the process is as follows: from room temperature to 380°C for 45 minutes, then to 1100°C for 150 minutes;

[0023] (4) The obtained pre-fired billet is subjected to high-temperature sintering with hydrogen passing, and the process is as follows: from room temperature to 1450°C for 100 minutes, and finally to 1950°C for 200 minutes;

[0024] (5) Keep the obtained sintered compact in an Ar atmosphere at 1200°C ...

example 2

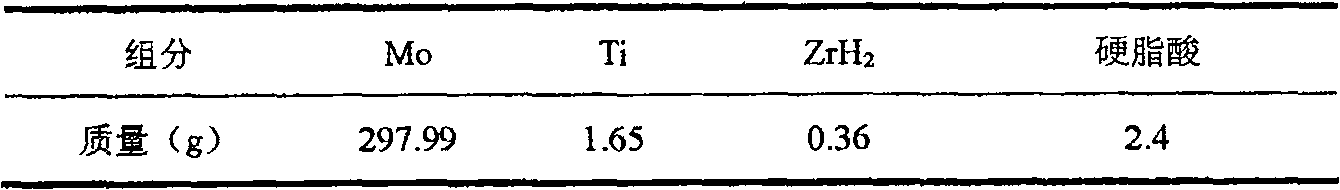

[0027] (1) Taking the preparation of 300g alloy powder as an example, weigh the mass of each component of the alloy powder according to mass percentage:

[0028]

[0029] Stearic acid is heated and dissolved in alcohol and put into the ball mill tube together with the powder, and the ball mill tube is filled with N 2 Set the milling time to 15h to prepare the pre-alloyed powder. Take out the powder, dry it, and pack it in a bag for later use.

[0030] (2) Pressing the prepared pre-alloy powder into a shape.

[0031] (3) Pre-sintering the formed compacts with hydrogen. The process is as follows: from room temperature to 450°C for 30 minutes, then to 1050°C for 120 minutes

[0032] (4) The pre-fired billet is sintered at a high temperature in an ammonia decomposing atmosphere. The process is as follows: the temperature is raised from room temperature to 1400°C for 100 minutes, and finally to 1920°C for 200 minutes.

[0033] (5) Keep the sintered compact in a vacuum atmosphere at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com