Method and apparatus for biological treatment of spent caustic

A biological treatment and bioreactor technology, applied in biological water/sewage treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as large reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

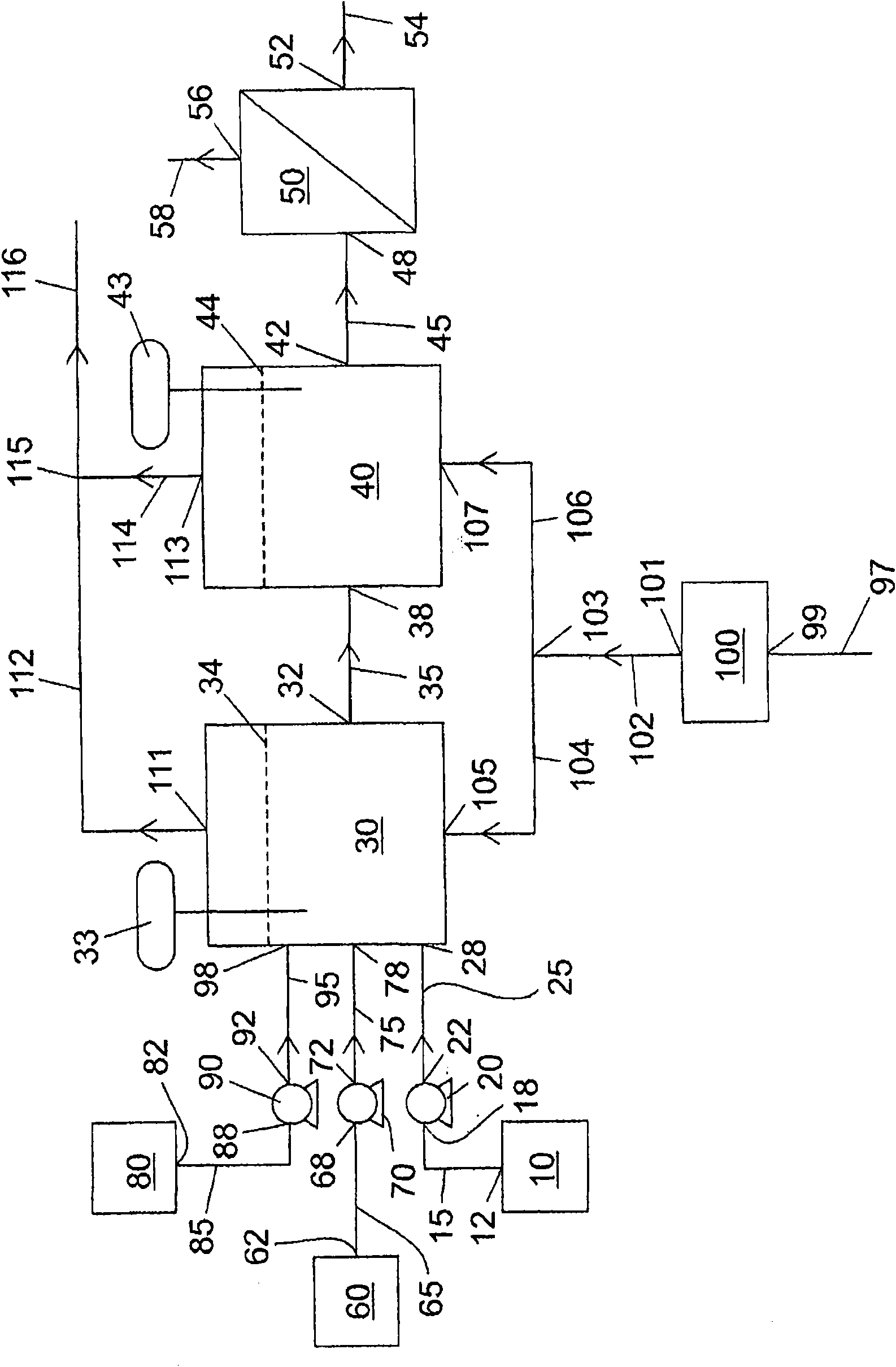

Method used

Image

Examples

Embodiment 1

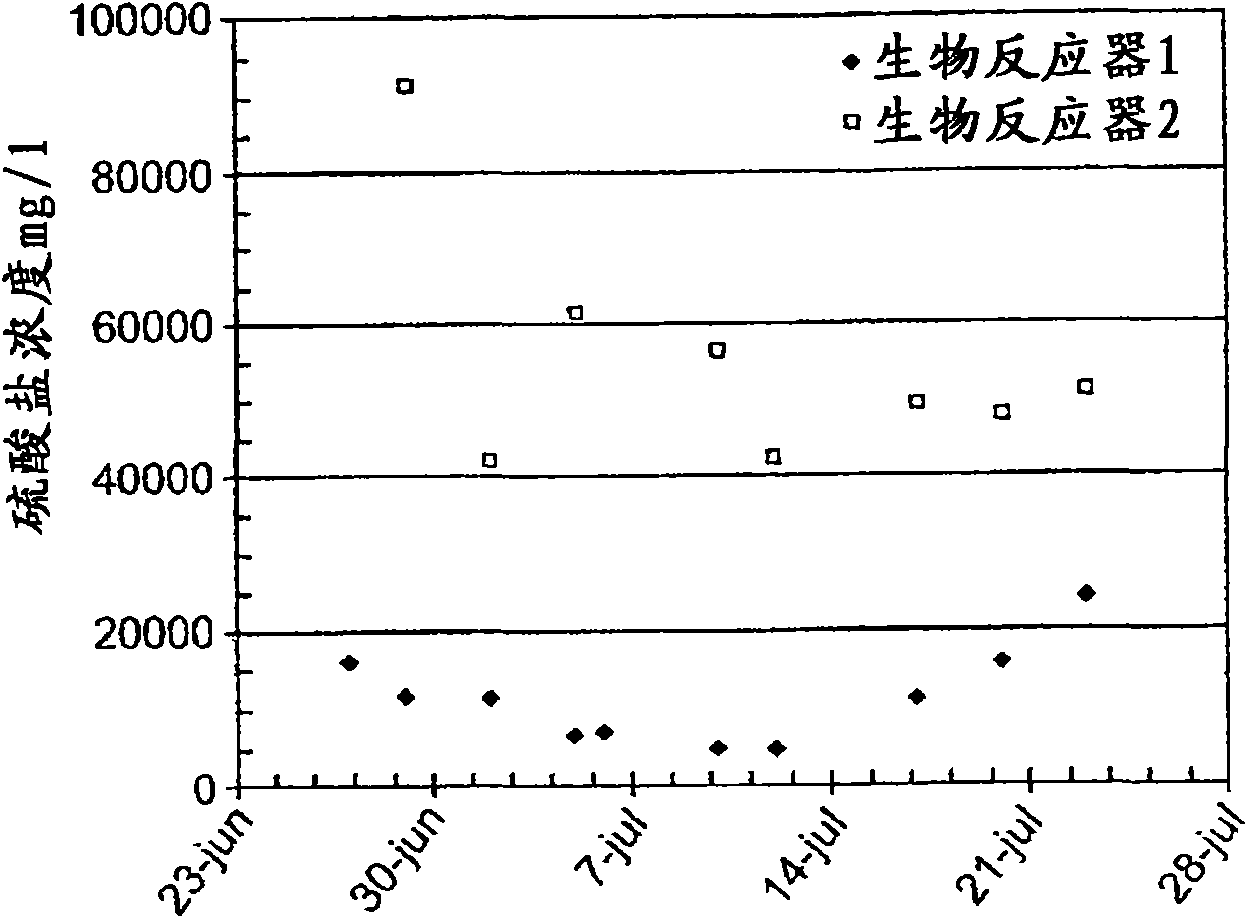

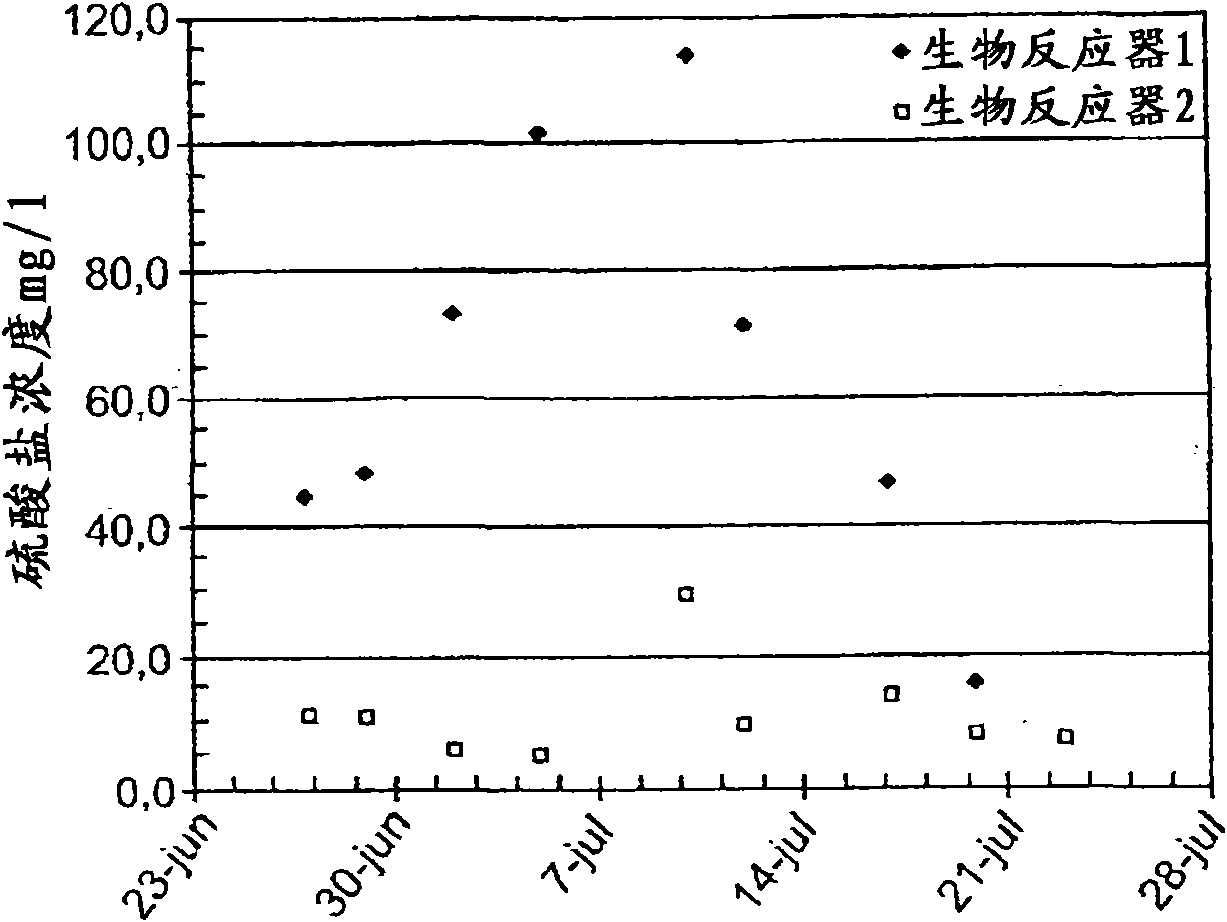

[0089] Two standard bioreactors of 2 l working volume each were provided and configured to work as continuous cultures. Inoculate the bioreactor with sludge. SOB is taken from full size H mixed with SOB from soda lake 2 S oxidation device. The temperature of the bioreactor was controlled at 30°C by a water jacket, providing an internal temperature of 28±1°C in both reactors.

[0090] The redox potential and pH of each bioreactor were measured online using the redox potential. Nutrients are supplied intermittently by pulse / intermittent pumps or manually. An air supply was provided to the bioreactor to aerate the solution. Set the aeration level so that the redox potential is greater than -100 mV / cm. The air supply is adjusted using a humidifier so that humid air is supplied to the bioreactor. The humidity level of the air supply was set to maintain the liquid level in the bioreactor at a constant level.

[0091] Table 2 shows the composition of the synthetic spent causti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com