Processes and apparatuses for removing mercaptans from a feed stream

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

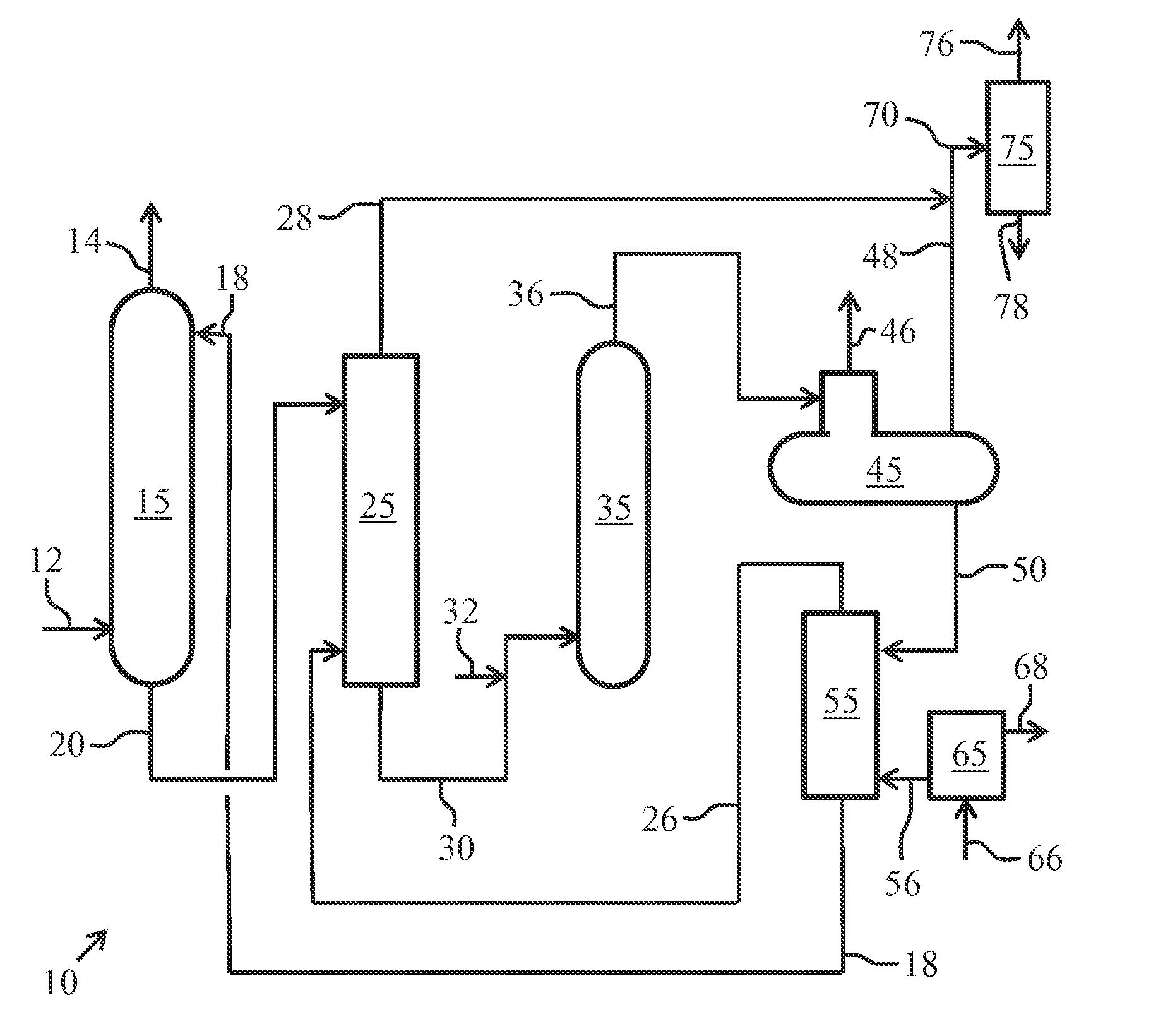

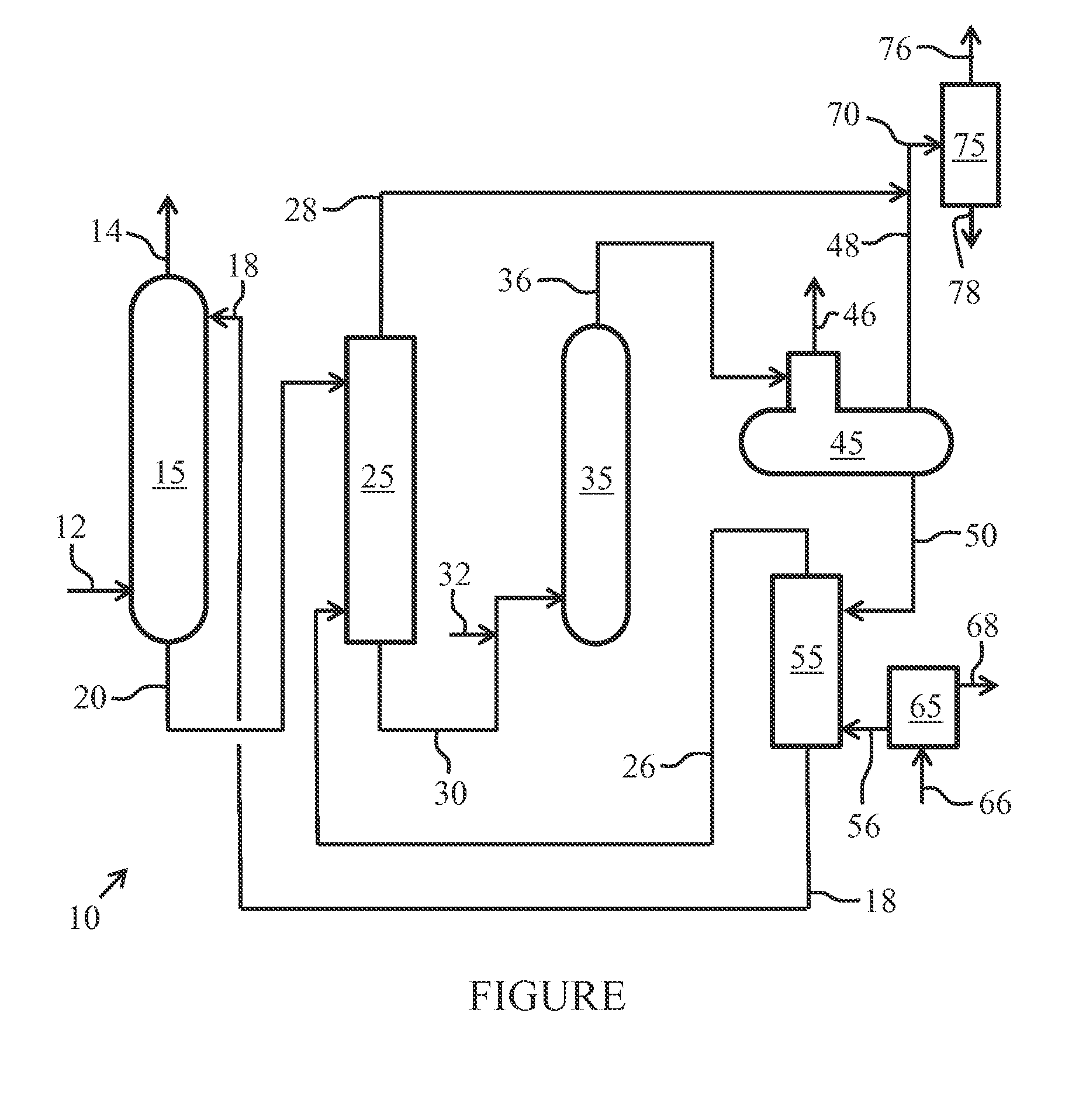

Image

Examples

Embodiment Construction

[0011]The following detailed description is merely exemplary in nature and is not intended to limit the processes and apparatuses for removing mercaptans from feed streams. Furthermore, there is no intention to be bound by any expressed or implied theory presented in the preceding technical field, background or brief summary, or in the following detailed description.

[0012]Most distillate hydrocarbon streams produced from crude oil contain some amount of sulfur in one form or another unless these streams have been subjected to extensive sulfur removal procedures such as hydrotreating. Often a major amount of this sulfur is present in the form of mercaptans. Mercaptan sulfur content must be reduced in the hydrocarbon distillate stream in order to meet certain product specifications such as a limitation on the total sulfur content of a product. It may also be desirable to remove mercaptan compounds from a hydrocarbon stream for the purpose of eliminating the rather malodorous mercaptan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com