Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143 results about "Iron sulphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transdermal method and apparatus

Owner:ALDRED KATHERINE M

Method for preparing zinc-iron-selenium enriched bio-fertilizer and method of use thereof

InactiveCN101225006AImprove the level ofSimple methodBio-organic fraction processingFertilising methodsFermentationSe element

The invention relates to a preparation method for a zinc-iron-selenium-rich biological fertilizer and a usage, which belongs to the technical field of crop production. Water is added into pig manure, silkworm excrement, human excrement and colza cakes for a fermentation to get mother liquor of the biological fertilizer; zinc sulfate, green copperas, sodium selenite are added into the mother liquor for reactions to get zinc-iron-selenium-rich biological foliar fertilizer for the rice. The fertilizer is separately sprayed in the booting stage and the full heading stage of the rice, with an amount of 1000ml per mu. The function rice, with zinc content 19.4 to 28.7mg / kg, iron content 7.0 to 20.2mg / kg, and selenium content 0.08 to 0.15 mg / kg, measures up to the limit standards of zinc, iron, and selenium in the national food standards. Organic selenium accounts for more than 99% of the total selenium in the zinc-iron-selenium-rich function nutritive rice. The preparation method for the zinc-iron-selenium-rich biological fertilizer proves effective, economical, safe and non-polluted through twice foliage sprays with zinc-iron-selenium fertilizer for the rice as an experiment.

Owner:NANJING AGRICULTURAL UNIVERSITY

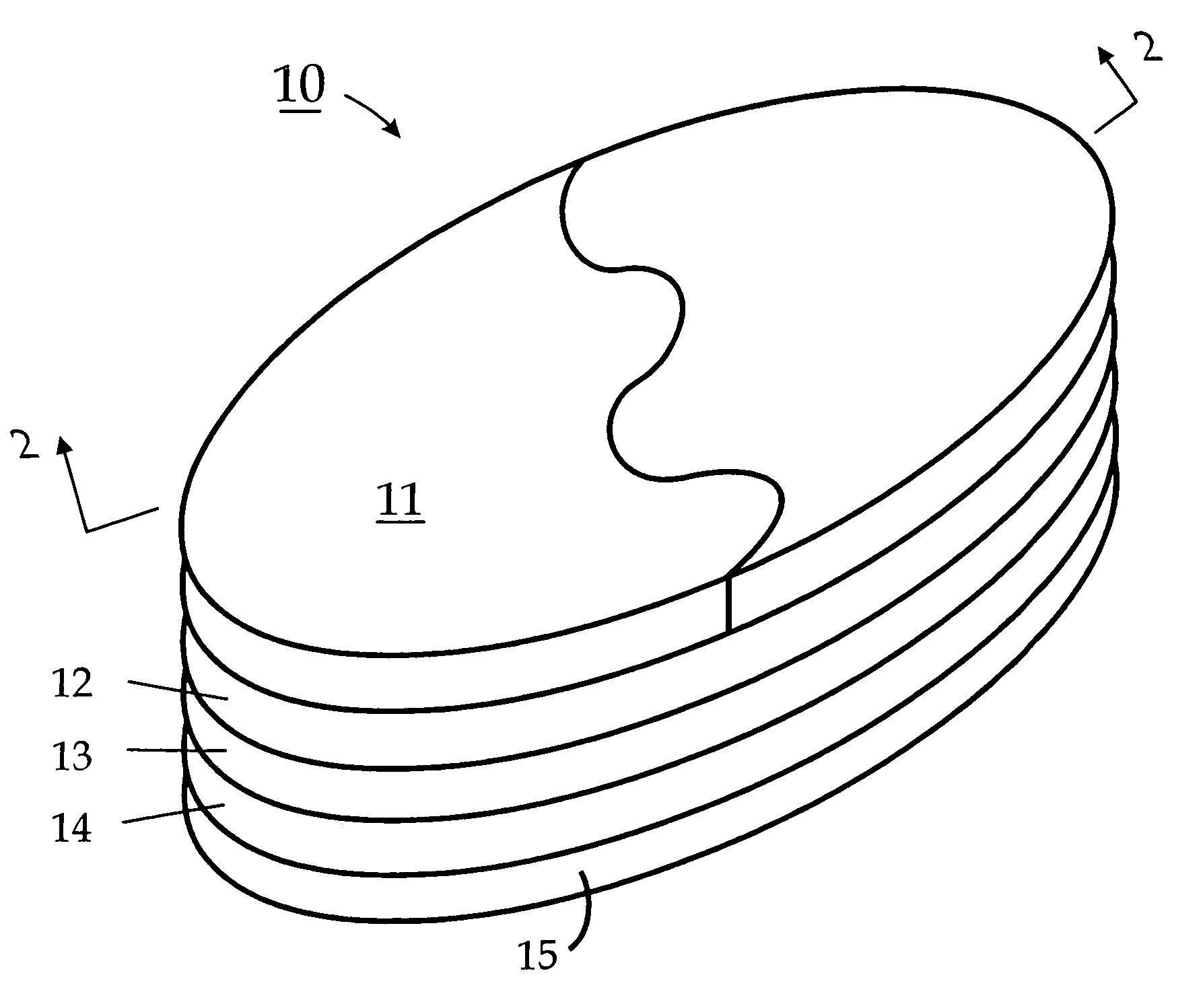

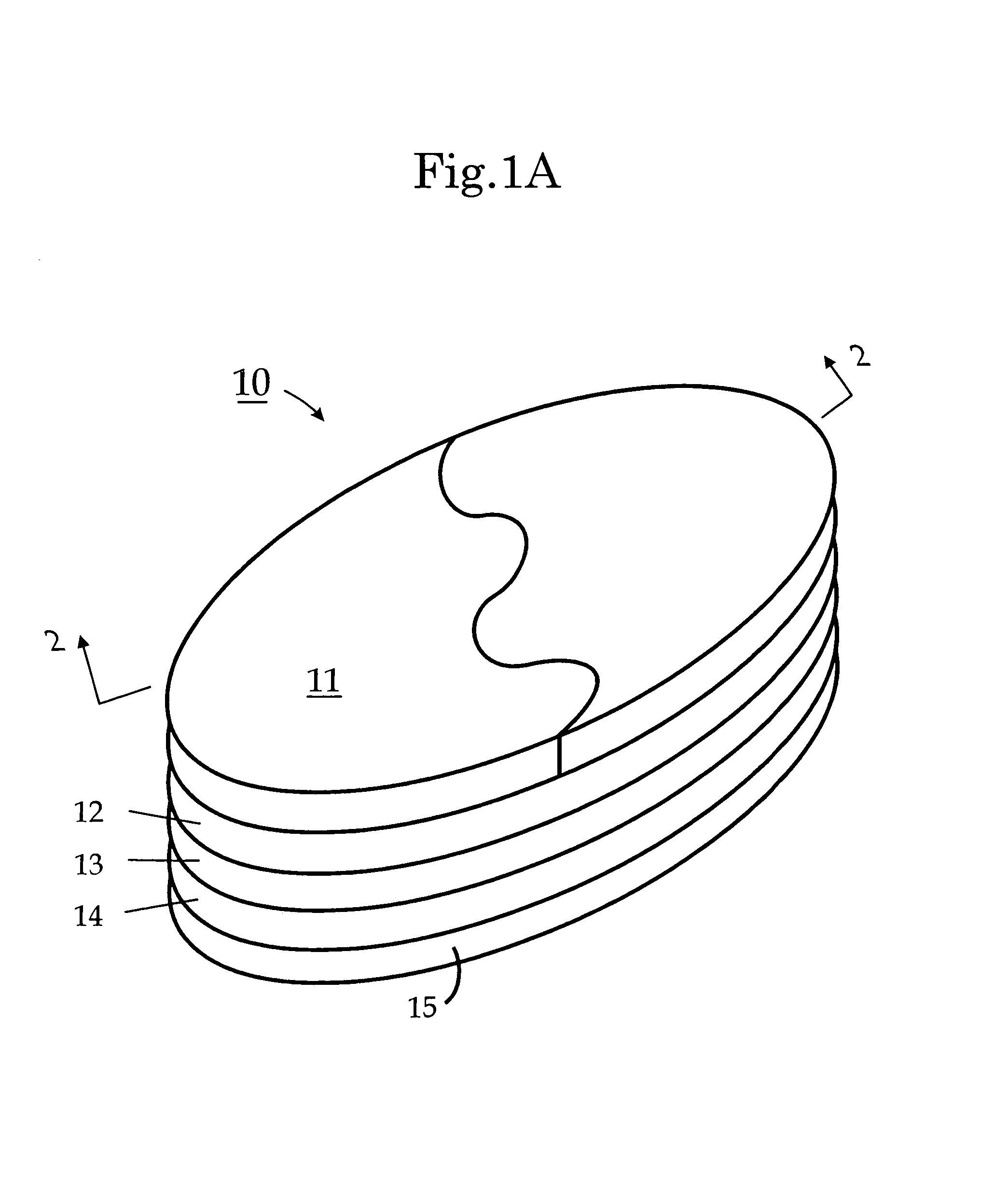

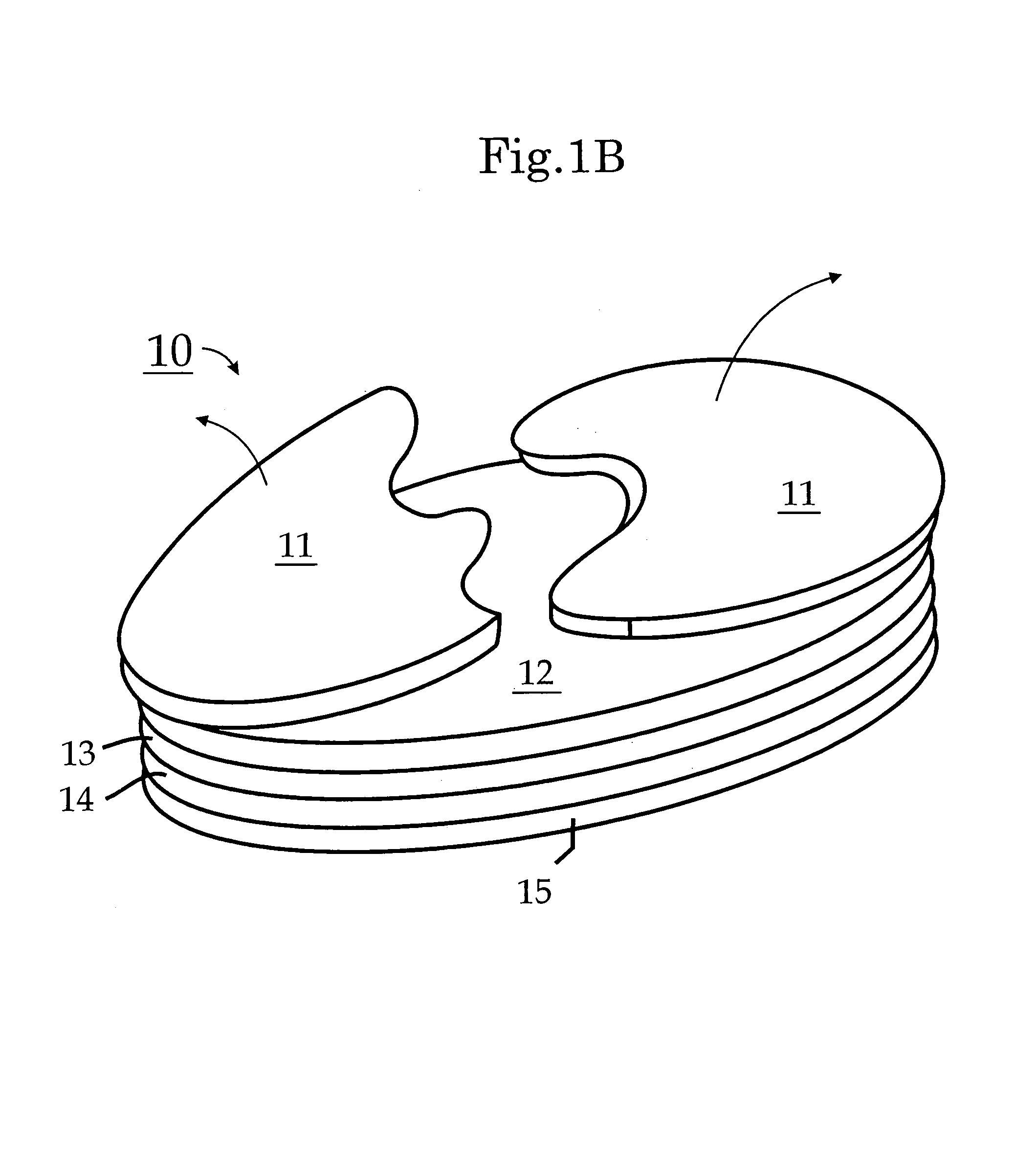

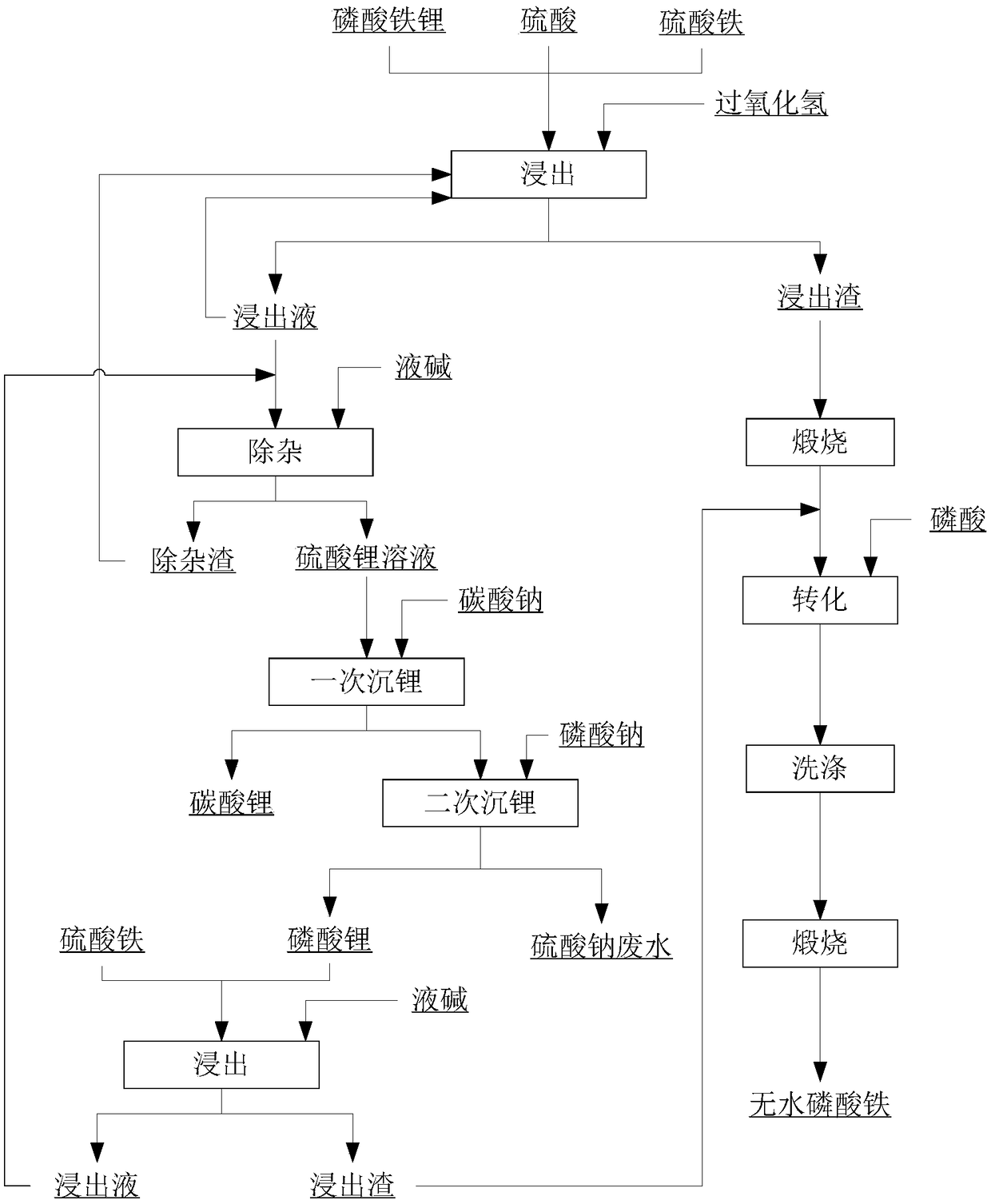

Method for recovering lithium from lithium iron phosphate

ActiveCN108899601ADoes not affect the leaching rateHigh purityWaste accumulators reclaimingProcess efficiency improvementFerric hydroxideIron sulphate

The invention discloses a method for recovering lithium from lithium iron phosphate. The method disclosed by the invention comprises the following steps: dissolving waste lithium iron phosphate slag with sulfuric acid and ferric sulfate, leaching iron, lithium and phosphorus, adding an oxidizing agent, reacting iron and phosphate radicals to produce an iron phosphate precipitate and a small amountof ferric hydroxide, converting lithium into a water-soluble lithium sulfate solution, filtering to obtain the lithium sulfate solution, adding sodium carbonate into the lithium sulfate solution to prepare a lithium carbonate product, and adding sodium phosphate or phosphoric acid to prepare lithium phosphate; dissolving the lithium phosphate with ferric sulfate again to obtain the lithium sulfate solution and a compound taking iron phosphate as a principle component, returning the lithium sulfate solution to the system to prepare lithium carbonate, and calcining the iron phosphate slag to remove organic matters and carbon in the slag; and slurrying to prepare cell grade iron phosphate. According to the method for recovering lithium from lithium iron phosphate disclosed by the invention,the lithium is totally converted into the product lithium carbonate in the method, the process flow is short, the cost is low, the lithium recovery rate is 97%, the metal lithium in the lithium iron phosphate can be effectively recovered, and all the slag is converted into the cell grade iron phosphate.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Nourishing type multiple stems panax growth promoter

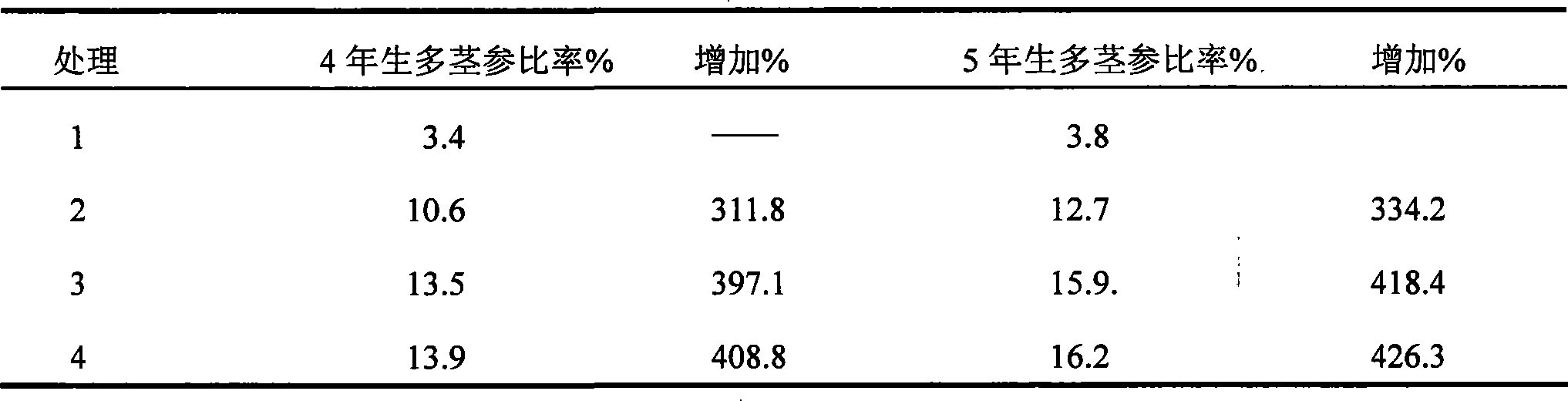

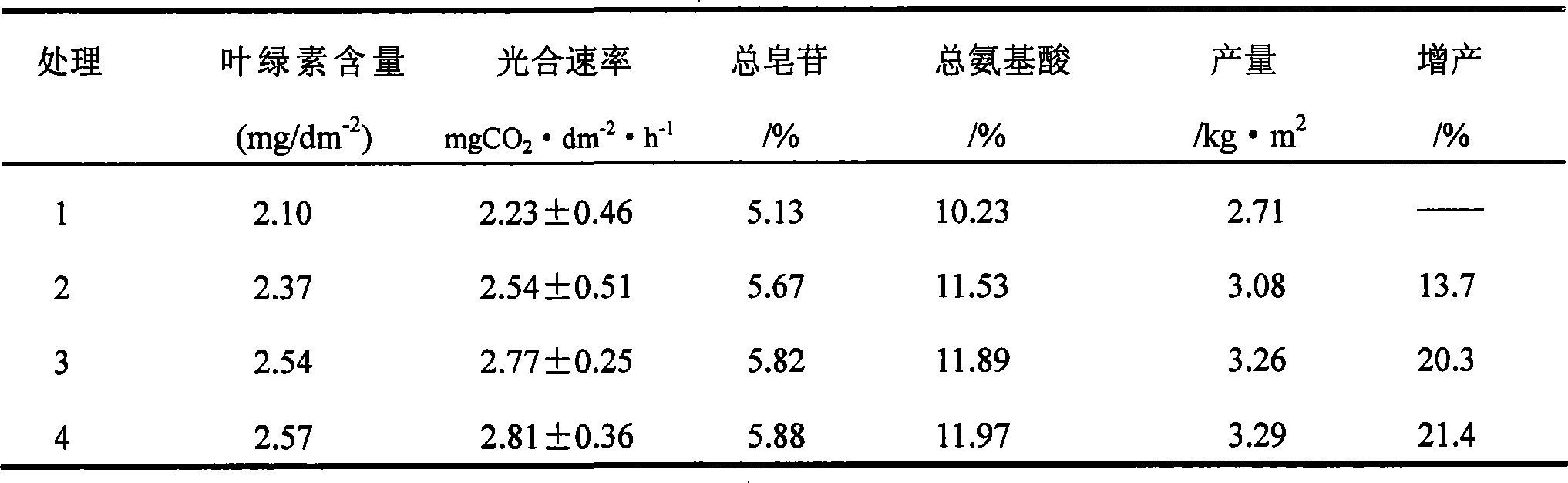

A nutritional growth promoter for multi-stem ginseng belongs to the agricultural technology field. The invention solves the problem of changing ginseng from single-stem to multi-stem. The invention can be prepared according to the weight percentages as follows: B9 0.10%-0.40%, chito-oligosaccharides 0.30%-1.00%, compound amino acid 0.50%-1.50%, monopotassium phosphate 0.10%-0.20%, ferrisulphas 0.02%-0.08%, boric acid 0.05%-0.15%, manganous sulfate 0.05%-0.15%, copper sulfate 0.02%-0.08%, zinc sulfate 0.10%-0.20%, ammonium molybdate 0.05%-0.10%, and water 100.0%. B9, chito-oligosaccharides, compound amino acid, monopotassium phosphate, ferrisulphas, boric acid, manganous sulfate, copper sulfate, zinc sulfate, and ammonium molybdate are respectively dissolved in little water, and then mixed with the rest water to prepare nutrient solution which is used in foliage spraying. The nutritional growth promoter is used for cultivating multi-stem ginseng with increased production and improved quality.

Owner:JILIN AGRICULTURAL UNIV

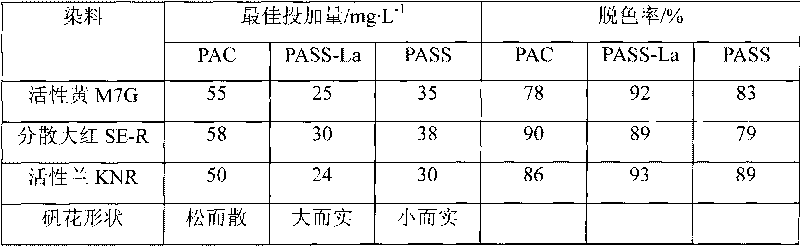

Composite flocculant and preparation method and application thereof

InactiveCN101734774AGood effectLow costWater/sewage treatment by flocculation/precipitationIron sulphateRare earth

The invention discloses a composite flocculant and a preparation method and application thereof. The flocculant is prepared from rare-earth carbonate, sodium silicate and ferric sulfate / aluminum sulfate serving as raw materials by a composite copolymerization method. The effect of the composite flocculant of the invention is superior to that of the conventional polymeric ferric / aluminum silicate sulfate; the chroma removal rate of wastewater reaches over 90 percent; the COD Cr removal rate reaches over 65 percent; the removal rate of total phosphorus reaches over 88 percent; and the expense of a wastewater treatment medicament is reduced by 10 to 20 percent compared with PASS. The composite flocculant has rapid, large and solid alumen ustum, reduces the use amount of a single dye wastewater coagulating agent by over one half compared with PAC and by over 20 percent compared with PASS, improves the chroma removal rate of the wastewater by about 10 percent, has low processing cost, and improves the processing effect.

Owner:GUANGDONG UNIV OF TECH

Clear liquid complex fertilizer special for high concentration drip irrigation and method of preparing the same

ActiveCN101318858ALower pHImprove utilizationOrganic fertilisersUrea compound fertilisersHigh concentrationPhosphoric acid

The invention relates to a high-concentration clear liquid compound fertilizer special for drop irrigation and a production method thereof. The fertilizer is prepared by dissolving urea, liquid phosphoric acid and potassium chloride, green vitriol, zinc vitriol, boric acid and fulvic acid in water with different temperatures in two steps and then mixing the compositions. The liquid compound fertilizer has the advantages that: the liquid compound fertilizer has good physical characteristics, can not deposit for long-term storage, has full nutrients to fully supplement various elements required by crops, can accelerate the growth of a crop root system and prevent precipitation reaction from blocking drop holes, in particular, the liquid compound fertilizer can obviously activate inorganic phosphorus pool of soil and reduce pH value of limy soil so as to greatly improve utilization efficiency of nitrogen and phosphorus nutrient resources. The clear liquid compound fertilizer can be separately applied for basal application and dressing, also can be used as a foliar fertilizer after diluted, and also can be mixed with other fertilizers for application, in particular has wide application respect in drop irrigation areas with the limy soil.

Owner:沃达农业科技股份有限公司

Technology for preparing iron phosphate through hydrolytic method

The invention provides a technology for preparing iron phosphate through a hydrolytic method. The technology for preparing the iron phosphate through the hydrolytic method comprises the steps that 1 aqueous solution of the iron phosphate and phosphoric acid are added, an oxidizing agent is added while stirring is conducted, and the temperature is heated to 90 to 95 DEG C; 2 deionized water is added in a hydrolyzing tank, then the temperature is heated to 90 to 95 DEG C, the solution obtained in the step 1 is totally added into the hot water while stirring is conducted, and sediment of the iron phosphate is generated; 3 the mixing solution obtained in the step 2 is filtered immediately, and primary iron phosphate product sediment A and mother solution A are obtained; 4 according to inversion, all the sediment A obtained in the step 3 are added into 0.5 mol / L iron phosphate solution and is stirred, the temperature is heated to 90 to 95 DEG C, the temperature is maintained for 1 hour, filtering is conducted, and sediment B and mother solution B are obtained. The mother solution B acts on the step 4 of a product in a next batch, a filter cake is pulped and washed by the deionized water in the normal temperature, drying in 100 to 120 DEG C is conducted, and the product is obtained. The technology for preparing the iron phosphate through the hydrolytic method has the advantages that water treatment in the technology is simplified and circulative, and lowering the cost is facilitated.

Owner:徐源庆

Metal alloy electroplating liquid

The invention discloses a metal alloy electroplating liquid. The metal alloy electroplating liquid is composed of the following raw material components in parts: 30-40 parts of copper sulphate, 30-50 parts of aluminium sulphate, 50-60 parts of copper chloride, 50-60 parts of nickel hydroxide, 20-30 parts of cobalt sulphate, 30-40 parts of cobalt chloride, 10-15 parts of iron sulphate, 30-35 parts of ferrous chloride, 50-58 parts of cuprous oxide, 16-18 parts of hydrochloric acid, 15-20 parts of acetic acid, 3-4 parts of Tween-60, 4-5 parts of sodium hydroxyethyl sulfonate, 5-6 parts of allyl polyethenoxy ether, 6-7 parts of polyethylene glycol, 3-4 parts of ammonium lauryl sulphate, 5-8 parts of sodium lauryl sulphate and 200-300 parts of deionized water. The metal alloy electroplating liquid is good in stability, the surface of a plated film is high in brightness and smoothness, the flexibility of a plated layer is obviously improved, and the defects of burrs, roughness and the like on the outer surface of a plated part are basically eliminated.

Owner:梁胜光

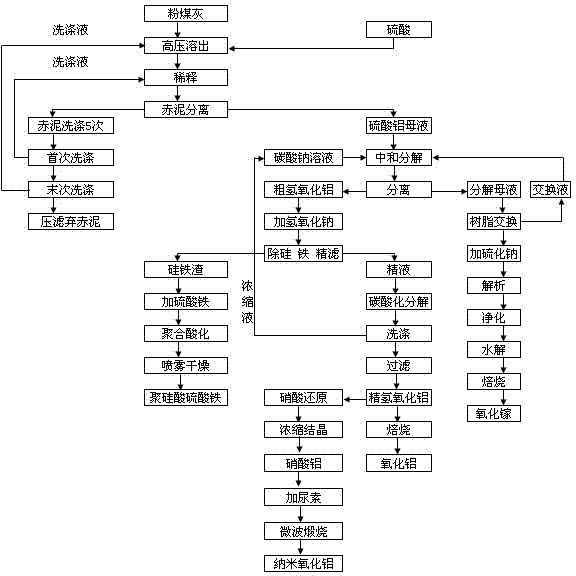

Method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate

InactiveCN102515220AImprove use valueReduce manufacturing costSolid waste disposalGallium/indium/thallium compoundsSlurryMaterials science

Provided is a method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate. Pulverized fuel ash and sulfuric acid are sent to a high-pressure autoclave to react by heating and pressurizing so as to generate slurry, and after dilution separation, neutralization desilicication of iron, carbonation decomposition, washing and dehydration and roasting, aluminum oxide is obtained. Nitric acid is added to the prepared aluminium hydroxide for reduction to prepare aluminium nitrate. The aluminium nitrate is added with carbamide and enters a microwave oven to be roasted to ashes, and aluminum oxide nanometer is obtained. Aluminum sulfate solution which has subjected to separation is added to sodium carbonate for neutralization and decomposition, and filtrated stock is sent to an ion resin exchange column to extract gallium oxide. Aluminum hydroxide is added to sodium hydroxide, and then silicon iron filter residue is obtained by filtering. Ferric sulfate is added for polymerization reaction to obtain polymeric ferric silicate sulfate. By adopting the technique of decomposing pulverized fuel ash with sulfuric acid in a high-temperature high-pressure mode, a plurality of industrial products are can be obtained respectively. Compared with an existing hydrochloric acid decomposition method, the method for extracting alumina and gallium oxide from pulverized fuel ash to prepare aluminum oxide nanometer and polymeric ferric silicate sulfate increases comprehensive utilization value of pulverized fuel ashand has great economic benefits.

Owner:潘安标

Method for recovering iron, vanadium and chromium in vanadium-titanium magnetite concentrate

ActiveCN102041377AImplement synchronous recyclingHigh recovery rateProcess efficiency improvementIron sulphateMagnetite

The invention provides a method for recovering iron, vanadium and chromium in vanadium-titanium magnetite concentrate, which comprises the following steps: milling the vanadium-titanium magnetite concentrate, carrying out magnetic separation, directly reducing iron, milling, carrying out magnetic separation to obtain an iron powder product and tailings, and treating the tailings by the following steps: pelletizing, roasting, leaching while stirring, boiling the leaching liquor, simultaneously adding sulfates, cooling to crystallize and precipitate to obtain polyvanadates and liquor containing chromium, adding ferric sulfate into the liquor containing chromium to reduce chromium, and adding Ca(OH)2 to generate Cr(OH)3 precipitate. The method can be used for synchronously and effectively recovering multiple valuable metals, such as iron, titanium, vanadium and chromium, in the vanadium-titanium magnetite concentrate so as to produce products with high added value, such as high-quality reduced iron powder, red vanadium, chromium, titanium and the like, thereby sufficiently and effectively utilizing the limited ore resources in a reasonable way. The metal recovery rate of the method is high, wherein the recovery rate of iron is higher than 90%, the recovery rate of vanadium is higher than 80%, the recovery rate of chromium is higher than 78%, and the recovery rate of titanium is higher than 90%. The method is not involved with the use of coke, and has the advantages of low power consumption and no environment pollution.

Owner:WUKUN STEEL

Treatment method of industrial arsenic wastewater

InactiveCN104787932ARaw materials are easy to getReduce processing costsMultistage water/sewage treatmentArsenateIron sulphate

The invention relates to a treatment method of industrial arsenic wastewater, which comprises the following steps: neutralizing industrial arsenic wastewater with an antalkali to control the end pH value to be greater than or equal to 5.0, and carrying out solid-liquid separation to obtain primary treated water; adding polyferric sulfate and H2O2 into the primary treated water to control the end pH value to be greater than or equal to 5.0, wherein the polyferric sulfate accounts for 0.01-1 wt% of the arsenic wastewater to be treated, and the H2O2 accounts for 0.01-1 wt% of the arsenic wastewater to be treated; and carrying out solid-liquid separation on the product to obtain secondary treated water with the arsenium content of less than 0.5 ppm. The primary treatment adopts lime or any other antalkali, and thus, has the advantages of accessible raw material and low treatment cost. The secondary treatment adopts the H2O2 and polyferric sulfate as reagents, and can convert residual arsenium in the primary treated water into an insoluble ferric arsenate precipitate, thereby achieving the effect of deep dearsenication. The secondary treated water can be further treated by a sewage treatment cyclic utilization system, thereby reducing the subsequent treatment cost for arsenic wastewater.

Owner:TONGLING CHEM IND GRP

Efficient fruits nutrition physiology hyperchromic fertilizer and preparation thereof

InactiveCN101274864ANon-toxicNo pollution in the processOrganic fertilisersPotassium fertilisersNutritionAdditive ingredient

The invention relates to a high-efficiency fruit-nutritive physiological hyperchromic fertilizer and a preparation method thereof. Currently, the hyperchromic products in the market such as phytohormone, including products of ethane, abscisic acid, daminozide, most of such products adopt or contain hormone, have instable effect and easily cause adverse side effects, thus leading fruits to be soft and lowered in bin stability. The invention is a high-efficiency fruit-nutritive physiological hyperchromic fertilizer, the active ingredients of which comprise aminofusin, potassium sulfate, potassium chloride, borax, zinc vitriol, iron vitriol (FeSO4 question mark 7H2O), compound sodium nitrophenolate, chlormequat chloride with 50 percent of aqua and white sugar; the ingredients do not contain hormone, are non-poisonous and pollution-free, and have no adverse side effects. The high-efficiency fruit-nutritive physiological hyperchromic fertilizer contains various aminophenols, active substances for plant growth, a plurality of major elements and chelate trace elements, which are necessary for the growth and development of the fruit trees and vegetables, and is a novel organic and inorganic hyperchromic product integrating the advantages of various foliar fertilizers of inorganic nutrition type, organic type and growth conditioner type, etc. into a whole.

Owner:翟丙年

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:WR GRACE & CO CONN

Potassium sulfate and magnesium sulfate fertilizer production process having extrusion prilling step and no drying step

InactiveCN101298393AReduce releaseIncrease profitMagnesium fertilisersPotassium fertilisersIron sulphateBiology

The invention relates to a technique for manufacturing magnesium potassium sulfate fertilizer by extrusion pelleting with no drying, which is characterized by: mixing lemery, anhydrous magnesium sulfate, water retention agent as well as medium elements and microelements according to the weight portions of 46:35:0.6:18.4; transmitting the mixture to a feed hopper after being fully stirred, then packaging the mixture into a finished product by rolling, cutting up, pelleting and sieving; the medium elements and the microelements include: zeolite powder, borax, zinc sulfate, bluestone and green copperas which are uniformly mixed according to the weight portions of 10 to 20: 1 to 3: 1 to 2.5: 0.1 to 1.5 : 0.1 to 1. The invention adopts the technique of extrusion pelleting and is added with a drought control water retention growth promoting agent; the produced multi-element magnesium potassium sulfate water retention fertilizer has the advantages of slow nutrient release, high fertilizer operating factor, easing resource shortage, reducing soil nutrient losing, protecting the underground water environment as well as being safe and environment protective. During the whole manufacture process, no water and no drying processes are educed, thus reducing power consumption and coal consumption during the drying and cooling processes; no contaminations of the three wastes are discharged during the manufacture process.

Owner:郭瑞

Method for treating wastewater containing anilines

InactiveCN103663831AReduce contentSimple processWater contaminantsMultistage water/sewage treatmentIron sulfateActivated carbon

The invention discloses a method for treating wastewater containing anilines, belonging to the field of environmental protection. The method comprises the following processing steps: (1) carrying out primary treatment on the wastewater, carrying out direct heating and air stripping by steam, cooling, absorbing and reusing the steam containing ammonia, and enabling the pH value of the wastewater to be less than 9; (2) after cooling the wastewater subjected to ammonia removal to 51-60 DEG C, adding acid to regulate the pH value of the wastewater to be 3.5-5; (3) adding industrial grade iron sulfate and hydrogen peroxide in sequence under the condition of stirring the wastewater, and reacting for 61-90 minutes; (4) finally adsorbing the wastewater subjected to catalytic oxidation with a 4-7g / mL activated carbon tower. The method can enable the contents of COD (chemical oxygen demand) and anilines in original wastewater to be reduced below the national emission standards, and has the characteristics of simple process, convenience in operation and good treatment effect.

Owner:QINGDAO WINCHANCE TECH

Method for repairing cadmium-lead composite polluted calcareous soil

ActiveCN102615098AReduce heavy metal contentThe problem of secondary pollutionContaminated soil reclamationIron sulphateSoil properties

The invention discloses a method for repairing cadmium-lead composite polluted calcareous soil. Heavy metals of cadmium and lead in the calcareous soil mainly exist in a carbonate combined state and an organic combined state which are more stable, treatment requirements are difficultly met by a chemical fixation method, and a conventional leaching repair method has the problems of serious damage to soil property and difficulty in leaching liquid treatment. In order to solve the problems, Al2(SO4)3 18H2O and polymeric ferric sulfate (PFS) are uniformly mixed with the soil according to a certain molar ratio and are soaked with water, filtrate is collected, the heavy metals in the filtrate are settled, and the soil can be circularly leached by supernate. The removal rate of available Cd in the polluted soil reaches 84.02%, the removal rate of available Pb in the polluted soil reaches 79.47%, and the repaired soil is beneficial to crop plantation.

Owner:CENT SOUTH UNIV +1

Special water soluble fertilizer for amphisarca vegetables

The invention provides a special water soluble fertilizer for amphisarca vegetables. The special water soluble fertilizer comprises the following components in parts by weight: 4-10 parts of humic acid ammonium, 20-50 parts of carbamide, 20-30 parts of calcium superphosphate, 20-30 parts of potassium sulphate, 1-2 parts of boric fertilizer, 1-2 parts of ferrous sulfate, 1-2 parts of zinc sulfate, 1-2 parts of cupric sulfate, 1-2 parts of manganese sulfate and 1-2 parts of ammonium molybdate. The special water soluble fertilizer has the following technical effects: the special water soluble fertilizer can be used for drip irrigation, spray irrigation, soilless culture, soil watering and foliage dressing, realizes water and fertilizer integration, achieves the efficiency of saving water, fertilizer and labor, and increasing yield, can enable amphisarca vegetables to acquire required nutritional ingredients quickly and fully in each growing period, maintains nutrition balance, ensures leaves, flowers and fruits of the amphisarca vegetables to grow normally, and improves yield and quality of the fruits.

Owner:南通宏洋化工有限公司

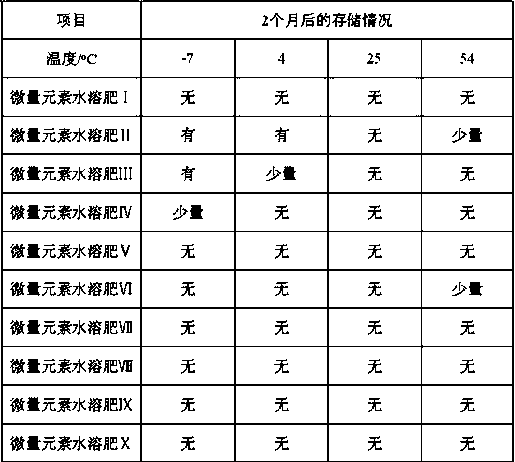

Trace element water-soluble fertilizer capable of enhancing wetting performance and preparation method thereof

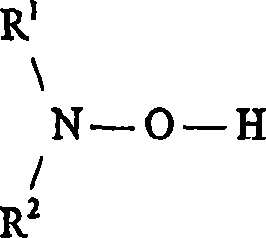

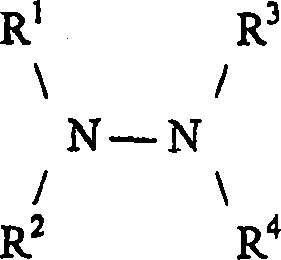

ActiveCN107746331AImprove oxidation capacityNot easy to absorbBioloigcal waste fertilisersLiquid fertilisersIron sulfateAnti oxidant

The invention relates to a preparation method of a trace element water-soluble fertilizer capable of enhancing wetting performance. The method comprises the following steps: taking a humic acid reagent, EM bacteria, water-soluble starch, rice bran, wheat bran and water, fermenting the materials for 15-20 days in a sealing mode at the temperature of 45-65 DEG C, uniformly stirring the materials every three days, and performing constant-temperature drying at the temperature of 75 DEG C to obtain the modified humic acid reagent; taking water and heating water to the temperature of 30-40 DEG C, adding a chelating agent and an anti-oxidant, then adding trace elements, using boric acid and borax to adjust the pH value of a solution to 4.0-5.5, adding the modified humic acid reagent and a silicone surfactant, adding an antifoaming agent and the anti-oxidant, then adding iron sulfate heptahydrate, supplying water, stirring the materials while adding the materials, and after stirring, filteringinsoluble substances to obtain the trace element water-soluble fertilizer capable of enhancing wetting performance. The trace element water-soluble fertilizer capable of enhancing wetting performancehas good moistening performance on plants leaves, and has the advantages of high utilization rate, antioxidation, simple preparation method, low cost, and easy operation.

Owner:安徽乾丰新型肥料有限公司

Production process of calcium iron zinc and selenium nutrition enhanced germinant long-shaped rice coarse rice powder

The invention relates to a production process of calcium iron zinc and selenium nutrition enhanced germinant long-shaped rice coarse rice powder, which is characterized in that: high quality long-shaped rice coarse rice is selected to guarantee the germinant rate, the high quality long-shaped rice coarse rice is sent into a classificator to remove weak and broken particles and to remove foreign matters such as stone, dust and the like; the selected coarse rice is washed by flowing water containing 0.5% sodium hypochlorite for three times so as to remove surface microorganisms, and then the coarse rice is washed by pure water for five times; the washed coarse rice is immersed in immersion solution at the room temperature for 9 hours, every liter of coarse rice immersion liquid contains 2g of calcium chloride, 0.25g of green copperas, 0.2g of zinc sulfate and 0.25mg of sodium selenite, the immersion liquid is replaced twice during the period of 9 hours so as to prevent the pollution of the microorganisms; the coarse rice is moisturized at 30 DEG C to germinate for 20 hours; the coarse rice is washed with pure water for five times to prevent the pollution of the microorganisms during the period of 20 hours; the coarse rice is re-washed with pure water for three times after the germination is ended; and then the coarse rice is swelled, smashed, screened and packed. The rice powder can also provide necessary trace elements of the human body such as selenium, calcium, iron, zinc and the like on the premise of improving the nutrient substances such as gamma-propalanine and the like.

Owner:NANCHANG UNIV

Treatment agent for printing and dyeing wastewater

InactiveCN105884047AEasy to handleWater contaminantsWater/sewage treatment by flocculation/precipitationPotassium persulfatePolyethylene glycol

The invention discloses a treatment agent for printing and dyeing wastewater. The treatment agent is prepared from the following materials in parts by weight: 21 parts of menthone, 10 parts of silicon dioxide, 20 parts of zeolite minerals, 5 parts of powdered activated carbon, 5 parts of sodium silicate, 12 parts of diatomite, 5 parts of potassium persulfate, 5 parts of dibenzoyl peroxide, 15 parts of reductase peroxide, 12 parts of basic aluminum chloride, 8 parts of polyacrylamide, 30 parts of polyferric sulfate, 18 parts of polyaluminium chloride, 2 parts of polysorbate, 20 parts of polyimide, 1 part of polyethylene glycol, 8 parts of polyethyleneimine, 5 parts of thiocarbamate, 8 parts of zinc sulfate, 18 parts of expanded graphite, 5 parts of strong base, 5 parts of hydroxypropyl methyl cellulose sodium, 18 parts of calcium hydroxide, 85 parts of polyacrylamide, 20 parts of aluminum oxide and 5 parts of dodecyl diethylenetriamine.

Owner:王瑞明

Method of polymerization and coagulation for treating sewage participating of heavy concentration acrylonitrile

InactiveCN1500739AReduce governance costsEasy to operateWater/sewage treatment by flocculation/precipitationHigh concentrationPotassium persulfate

The pollutant acrylonitrile in high concentration waste water with acrylonitrile content of 2800-7603 mg / L is polymerized with solid ammonium persulfate, solid potassium persulfate, solid sodium chlorate or hydrogen peroxide as polymerization initiator at the reaction temperature of 10-70 deg.c while stirring electromagnetically or mechanically. The polymerized pollutant acrylonitrile is then eliminated through coagulation with polyaluminium chloride or polyferric sulfate as coagulant. When the polymerization time is 105 min, acrylonitrile eliminating rate as high as 96 % may be obtained and CODCr eliminating rate is 66-99 %. The present invention has simple and reasonable technological process, high waste water treating effect and low treating cost.

Owner:ZHEJIANG UNIV OF TECH

A novel compound method of copolymerized silicate flocculating agent

InactiveCN101531371ARapid destabilizationImprove the coagulation effectWater/sewage treatment by flocculation/precipitationSilicon compoundsIron sulphateAluminium chlorohydrate

The invention discloses a novel compound method of copolymerized silicate flocculating agent. The method compounds middle and later stage of polyaluminium chloride, polyaluminium ferric chloride, polymerized ferric chloride, or polymerized ferric sulfate and the like flocculating agents, or adding high chloro-silicane together with polyaluminium chloride, polyaluminium ferric chloride, polymerized ferric chloride, or polymerized ferric sulfate and the like liquid flocculating agents to perform copolymerization reaction with the polymer to compound the copolymerized silicate flocculating agent. The invention overcomes the problem of using traditional acidified method for preparing polysilicate flocculating agent, simplifies the synthetic process route for providing facilitation to the large-scale production of copolymerized silicate flocculating agent, and reduces fabricating cost.

Owner:李绍通

Iron mineral inhibitor and production method thereof

ActiveCN106824550AImprove acceleration performanceHigh selectivityFlotationSodium acetateSodium chloroacetate

The invention discloses a production method of an iron mineral inhibitor. The production method comprises the following steps: step I, enabling a mixture of following components in parts by weight to react for 1 to 4 hours at 60 to 90 DEC to obtain an additive (1): 100 parts of corn starch, cassava starch or wheat starch, 0.5 to 4.0 parts of sodium ethoxide or sodium hydroxide and 5 to 15 parts of sodium chloroacetate; step II, enabling a mixture of following components in parts by weight to react for 3 to 6 hours at 50 to 80 DEG C to obtain an additive (2): 100 parts of the additive (1) obtained in the step I, 5 to 15 parts of ethylene oxide, and 0.2 to 1.0 part of sodium carbonate or sodium acetate; and step III, enabling a mixture of the following components in parts by weight to react for 1 to 3 hours at 30 to 60 DEG C to obtain an inhibitor finished product: 100 parts of the additive (2) obtained in the step II, 1 to 12 parts of sodium periodate or hydrogen peroxide, and 0.2 to 1.0 part of ferrous sulfate or cupric sulfate.

Owner:天津天宝翔科技有限公司

Method for recovering iron from sulphuric acid leachate through extraction

InactiveCN104164561AAchieve separationAchieve recyclingProcess efficiency improvementIron sulphateFree acid

The invention discloses a method for recovering iron from sulphuric acid leachate through extraction. The sulphuric acid leachate contains greater than 14g / L of iron and 0.3-4.0mol / L of free acids, and has a pH value of less than 0.5. The method is characterized by comprising the following steps of: adding an oxidant to oxidize divalent iron in the sulphuric acid leachate; extracting the sulphuric acid leachate by an extractant to obtain deacidified raffinate; extracting iron from the deacidified raffinate by using the extractant; extracting the previous raffinate by the extractant, repeating for 2-5 times in this way, and mixing iron-loaded organic phases; re-extracting the mixed iron-loaded organic phase by using a sulphuric acid solution to obtain iron sulphate solution and an organic phase; mixing an acid-loaded organic phase and the organic phase, neutralizing acid by a basic solution, and recycling the extractant. The invention discloses a method for recovering iron, which is low in cost, simple in process and operation and environment-friendly and can be put into industrialization.

Owner:广东省工业技术研究院(广州有色金属研究院)

Disease-resistant macroelement liquid water-soluble fertilizer and preparation method thereof

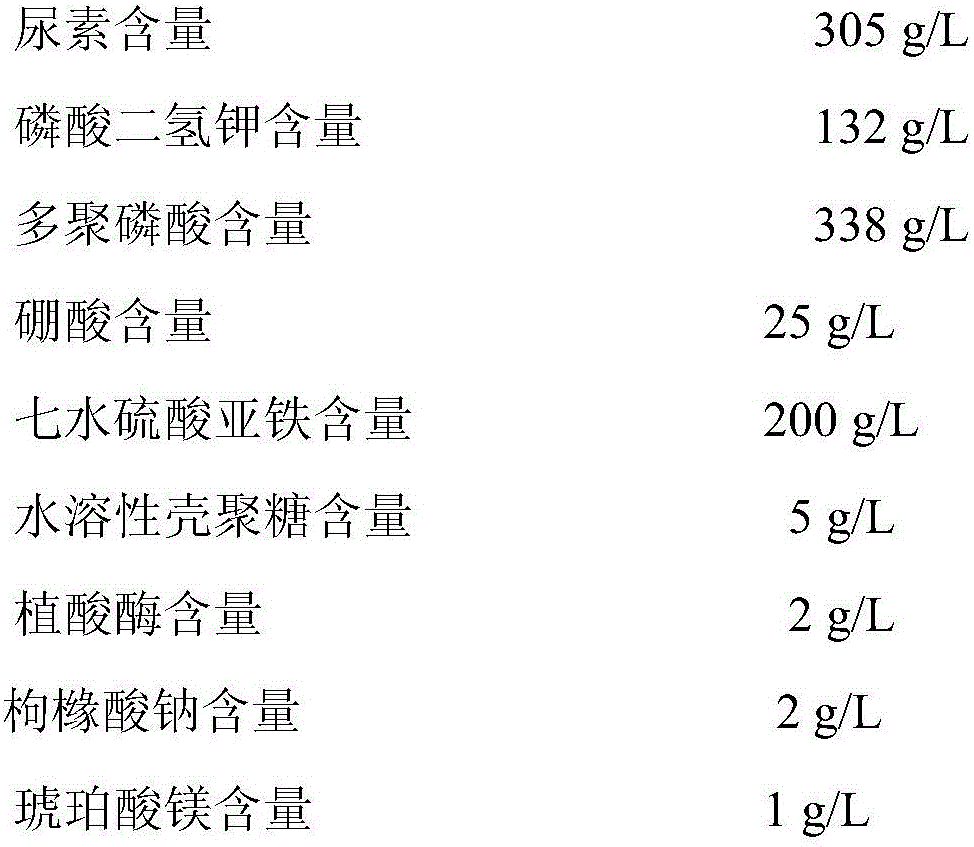

ActiveCN106380323AGuaranteed SolubilityLow costAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersIron sulfateSolubility

The invention relates to disease-resistant macroelement liquid water-soluble fertilizer and a preparation method thereof. In the liquid water-soluble fertilizer, the urea content is 300 to 310g / L; the content of phosphorus-containing polymers is 333 to 343 g / L; the content of monopotassium phosphate is 127 to 137g / L; the content of boracic acid is 23 to 37g / L; the content of iron sulfate heptahydrate is 180 to 220g / L; the content of water-soluble chitosan is 3 to 8g / L; the content of phytase is 1 to 3g / L; the content of antiflocculating agents is 2 to 4g / L. During the preparation, firstly, iron and the phosphorus-containing polymers are chelated; macroelements and trace elements are sequentially dissolved and are then mixed with a solution containing additives. The additives such as the water-soluble chitosan, the phytase and the antiflocculating agents are added into the water-soluble fertilizer, so that the obtained macroelement liquid water-soluble fertilizer has the advantages of high nutrition content and full water solubility and also has the characteristics of resisting flocculating and improving crop disease resistant capability.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

Nickel-iron-phosphorus/nano V8C7 composite electroplating solution

The invention discloses a nickel-iron-phosphorus / nano V8C7 composite electroplating solution. According to a formula, the composite electroplating solution comprises 70-120g / L of nickel sulfate, 10-20g / L of nickel chloride, 40-80g / L of iron sulfate, 10-20g / L of iron chloride, 20-40g / L of sodium hypophosphite, 10-25g / L of boric acid, 0.1-0.5g / L of a complexing agent, 0.1-0.5g / L of a brightener, 2-5g / L of a stabilizer and 5-20g / L of nano V8C7. Compared with the prior art, the composite electroplating solution disclosed by the invention has the advantages that a composite coating with nickel-iron-phosphorus amorphous alloy as a matrix and nano V8C7 as a second phase can be prepared, and the composite coating is free of microcracks on the surface and high in wear and corrosion resistance. The composite electroplating solution is simple in component; environmental hazards of all reagents are low; the process is stable and simple in operation; and the current efficiency is high.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for preparing demulsification clarifier

InactiveCN101113028AImprove adsorption capacityChange hydrophilicityTransportation and packagingWater/sewage treatment by ion-exchangeSolid componentIron sulphate

The invention relates to a demulsification purifying agent and is characterized in that the purifying agent is composed by the components and proportions: 2-68 percent of sewage purifier, 2-37 percent of polymeric ferric sulfate, 5-45 percent of aluminum polychlorid, 6-57 percent of calcium chloride, and 19-47 percent of ferric chloride. The preparation steps are that: sewage purifier, polymeric ferric sulfate and aluminum polychlorid are dumped into a mixer and then calcium chloride and last water of 50 percent of the four raw materials are added; the mixture is stirred fully at a rate of 60 rpm for two to three hours to ensure the solid components are completely dissolved; the ferric chloride is added and the mixture is mixed continuously but at a rate of 50-80 rpm for half an hour to one hour; the mixture is filtered and packed into package buckles after the mixer is stopped for six to ten hours. The invention has excellent sewage treatment effect with low investment.

Owner:SHANGHAI ZHONGCHENG ENVIRONMENTAL SCI & TECH

Chinese caterpillar fungus liquid bacterial cultivating matrix

InactiveCN101260368AReduce dosageNo reduction in efficacyFungiMicroorganism based processesPotassium iodineCalcium hypochlorite

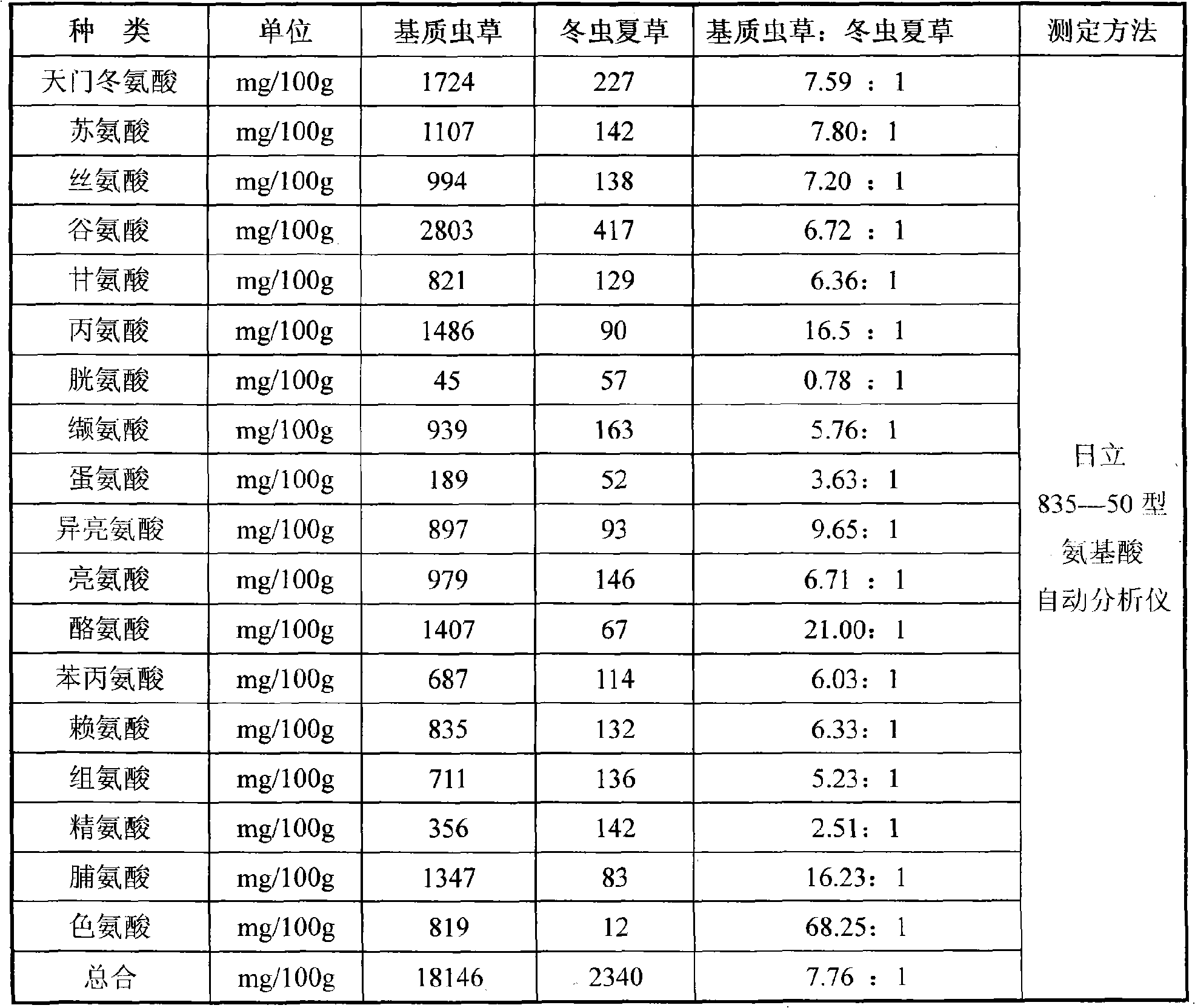

The invention relates to a cordyceps liquid spawn culture medium, which is mixed and prepared by 30 to 100 gram glucose, 3 to 10 gram peptone, 0.5 to 1.1 gram multiplex vitamin, 5 to 12 gram multiplex mineral matters and 961.5 to 876.9 gram water, wherein, the vitamin mainly comprises VA, VB1, VB2, VB5, VB12, VC and VE which are prepared according to the ratio of 1 to 1; the mineral matters mainly comprise calcium hypochlorite, green vitriol, zinc selenides, sodium chlorides, potassium nitrates, magnesium sulphates, manganese sulphates, ammonia sulphates and potassium iodides which are prepared according to the ratio of 1 to 1 or are mixed and prepared by 2 gram calcium hypochlorite, 0.2 gram green vitriol, 0.2 gram zinc selenides, 0.5 to 1 gram sodium chlorides, 3 gram potassium nitrates, 3 gram magnesium sulphates, 0.2 gram manganese sulphates, 0.3 gram potassium iodides and 2 gram ammonia sulphates. The invention concentrates effective nutrition and medicinal compositions in cordyceps, and reduces the dosage but does not reduce the effect. The cordyceps liquid spawn culture medium can save 90 percent labor and save 90 percent energy, is environment-friendly without refuses; moreover, the seed production technology is simplified, which contributes to the popularity and promotion of cordyceps seed production and culture technologies and is favorable for the development of cordyceps project and simultaneously avoids large-area pollution loss due to various reasons of liquid spawn.

Owner:董亚贤

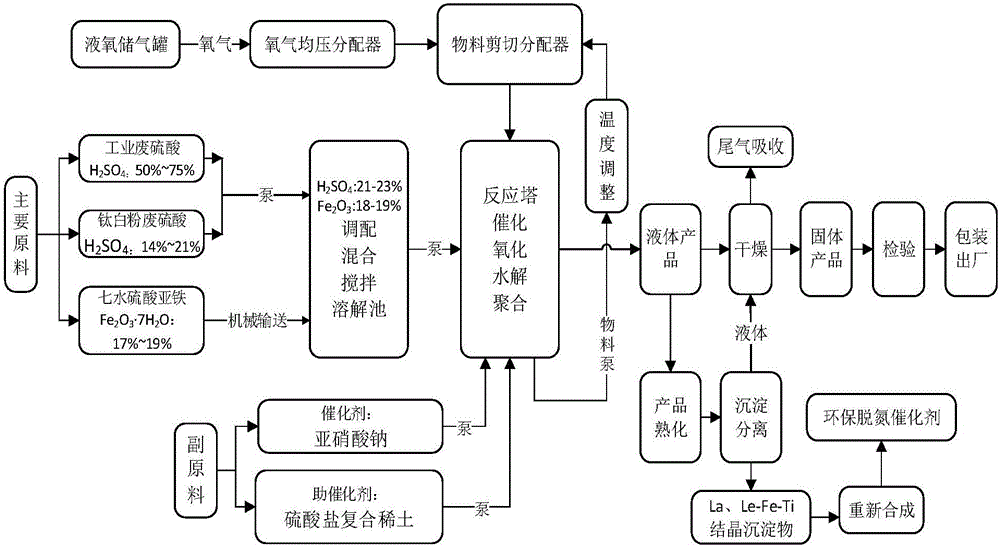

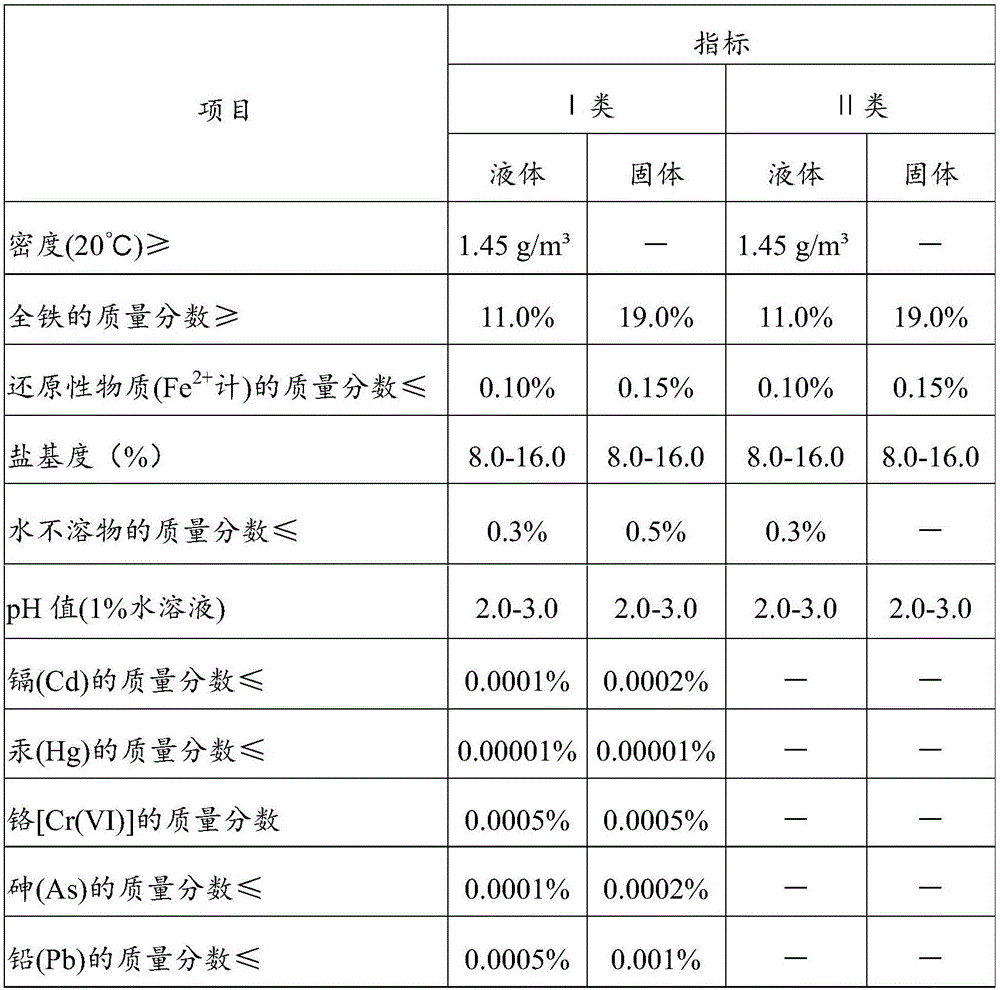

Polyferric sulfate and preparation method of polyferric sulfate

ActiveCN105692717AAdjust the reaction temperatureIncrease acidityIron sulfatesWater/sewage treatment by flocculation/precipitationRare earthIron(III) sulfate

The invention discloses polyferric sulfate as well as a preparation method and a preparation device of the polyferric sulfate. The preparation method comprises the following steps: conveying the following components into a mixing tank in percentage by weight: 40 percent to 50 percent of iron sulfate heptahydrate and 60 percent to 50 percent of titanium dioxide waste sulfuric acid, and blending the materials; adjusting the concentration range of the titanium dioxide waste sulfuric acid H2SO4 to be 21 percent to 23 percent to obtain mixed reaction materials; conveying the reaction materials into a reaction tower, and adding a sulfate composite rare-earth solution as a reaction cocatalyst when conveying the reaction materials into the reaction tower; controlling the temperature in the reaction tower to be 40 DEG C to 60 DEG C; after all the blended materials enter the reaction tower, adding a sodium nitrite solution as a reaction catalyst; continually introducing oxygen gas into the reaction tower so that the oxygen gas and the reaction materials make oxidization, hydrolysis and polymerization reactions under the action of the cocatalyst and the catalyst; after effectively converting Fe<2+> ions in the materials into Fe<3+> ions, obtaining liquid polyferric sulfate. With the adoption of the polyferric sulfate as well as the preparation method and the preparation device of the polyferric sulfate, the production efficiency can be greatly improved, environmental hazards are reduced, and a more prominent water purification and coagulation effect is realized.

Owner:广西继禹环保科技有限公司

Special biological fertilizer for camphor tree etiolation treatment, and application method thereof

InactiveCN105061000AYellowing control effect is obviousReduce alkalinityFertilising methodsFertilizer mixturesIron sulfateCinnamomum camphora

The invention discloses a special biological fertilizer for camphor tree etiolation treatment, and an application method thereof. The special biological fertilizer comprises 70-79wt% of a base fertilizer, 0.03-0.08wt% of chelated iron, 10-20wt% of an iron sulfate fertilizer, 3-8wt% of urea and 3-8wt% of a calcium magnesium phosphate fertilizer. The fertilizer has an obvious treatment effect on etiolation of camphor tree, and reduces the yellowed leaf rate of camphor to below 5% from original about 90%.

Owner:JIANGSU YINGFENG JIAYUAN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com