Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "FERROUS CARBONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron in ferrous sulfate had a higher biological availability than that in the ferrous carbonate; however, bioavailability of the ferrous carbonate iron appeared to be substantial and considerably more than that noted in previous studies in which a different source of ferrous carbonate was used.

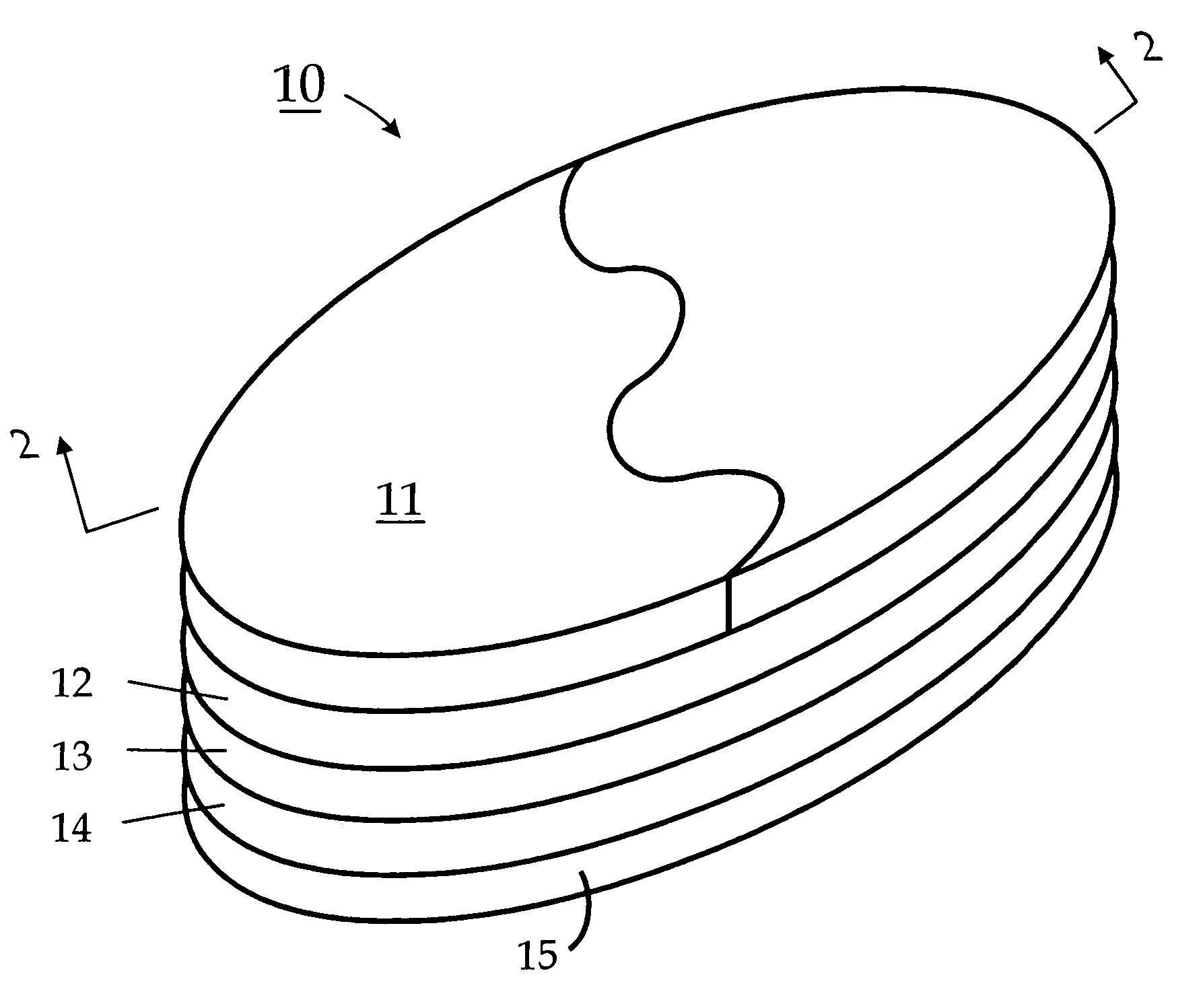

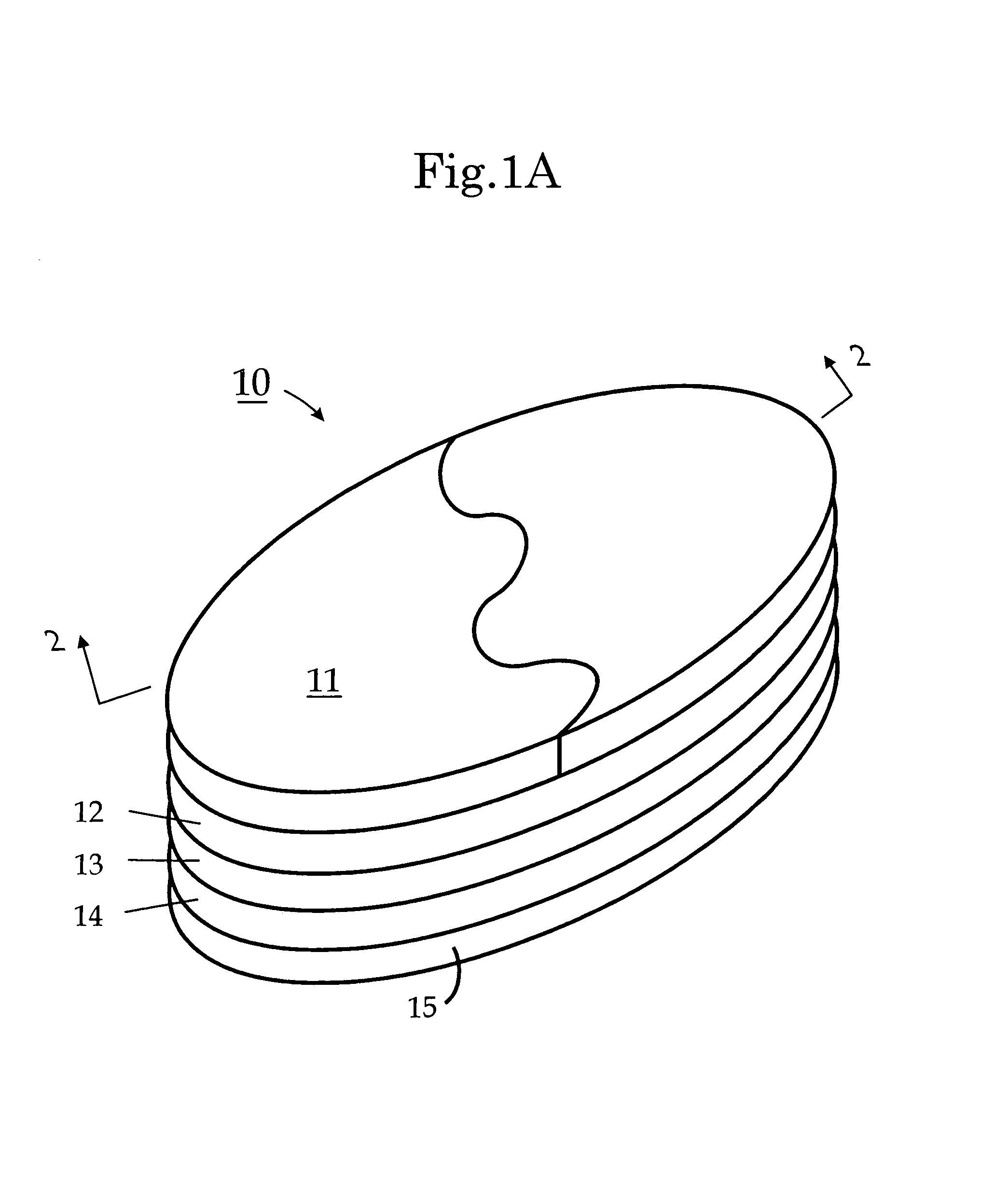

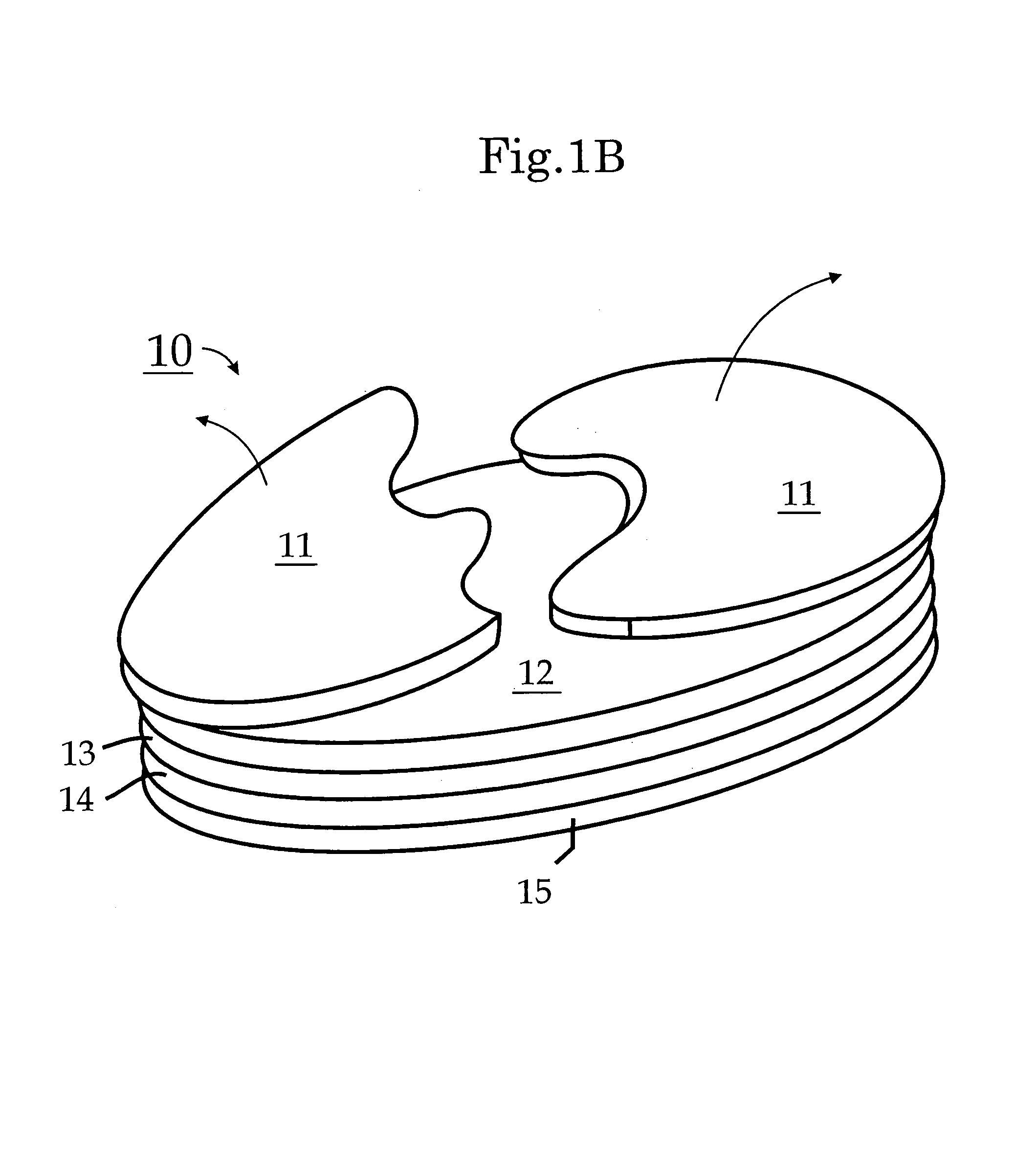

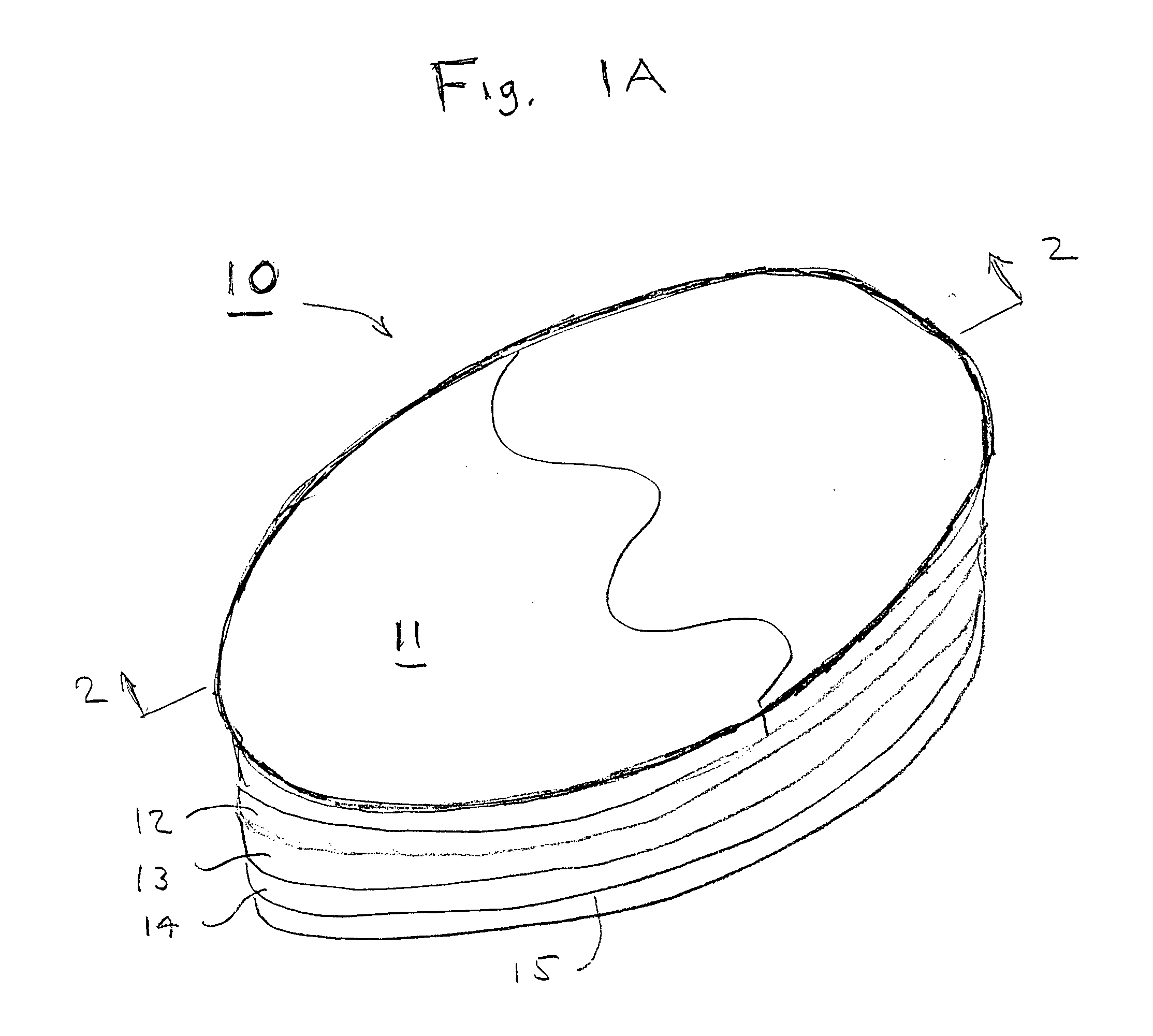

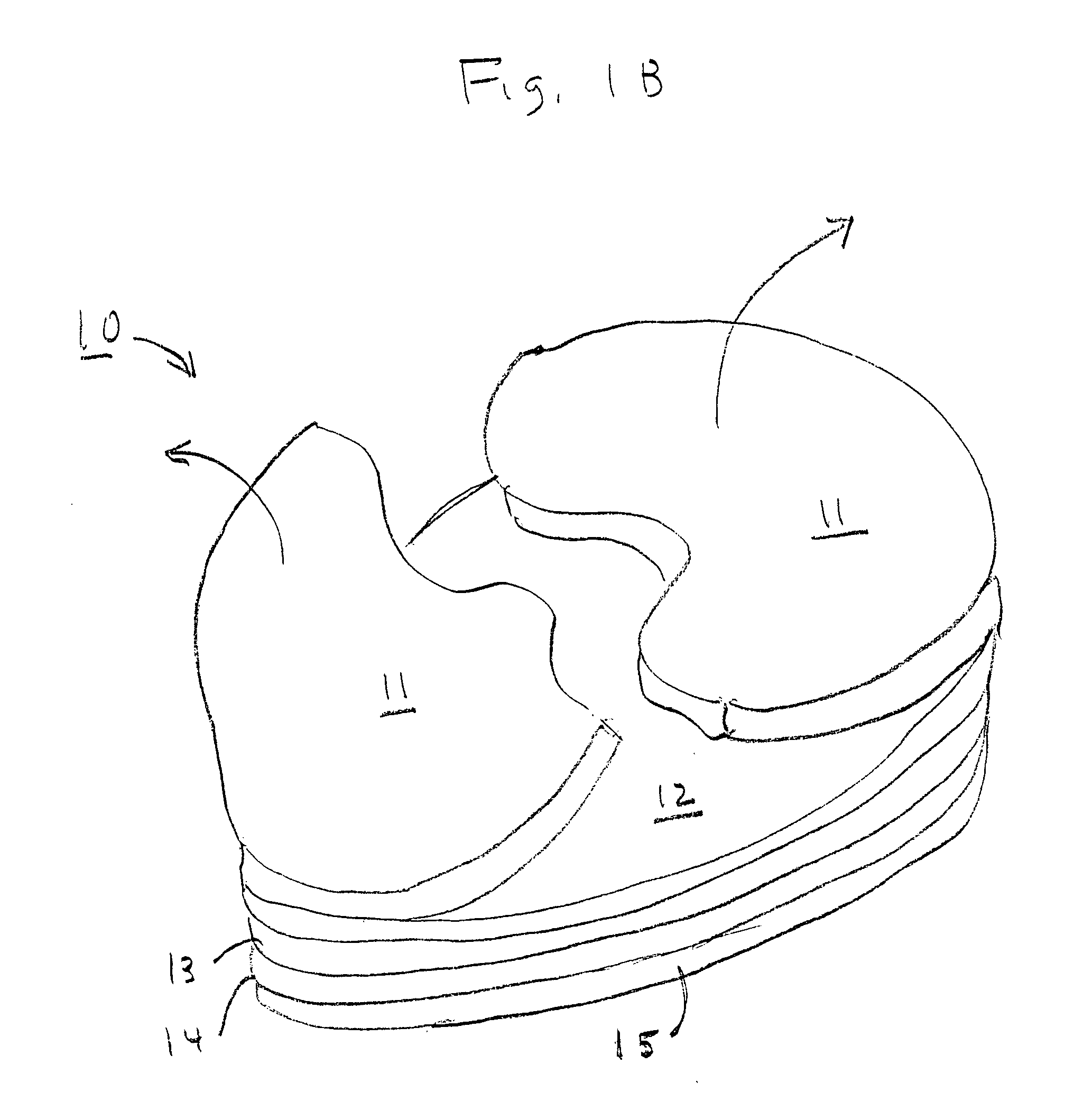

Transdermal method and apparatus

Owner:ALDRED KATHERINE M

Transdermal method and apparatus

A transdermal patch for the treatment of iron deficiency including a drug reservoir layer containing an hematinic substance; a rate-controlling membrane secured to said reservoir layer; and a contact adhesive secured to said rate-controlling membrane, wherein said hematinic substance is selected from the class consisting of ferrous sulfate, ferrous lactate, ferrous iodide, ferrous gluconate, ferrous fumarate, ferrous citrate, ferrous carbonate saccharated, ferrous carbonate mass, ferronascin, ferroglycine sulfate, and ferrocholinate.

Owner:ALDRED KATHERINE M

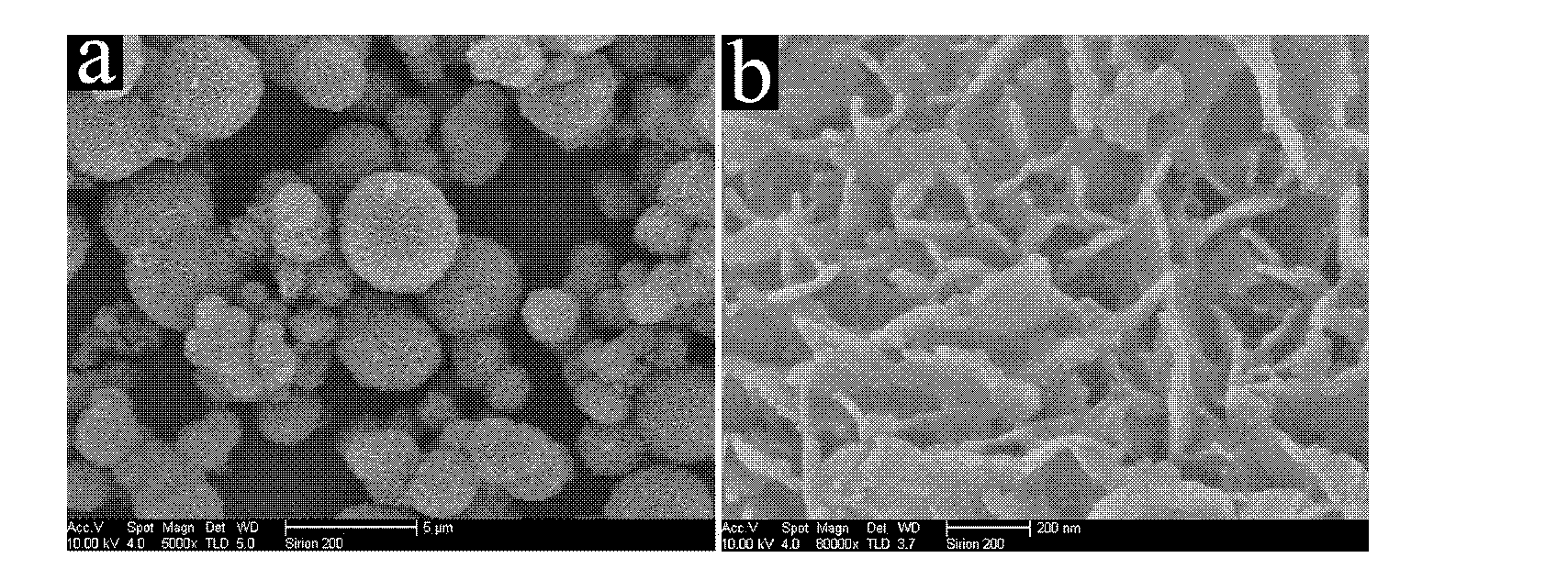

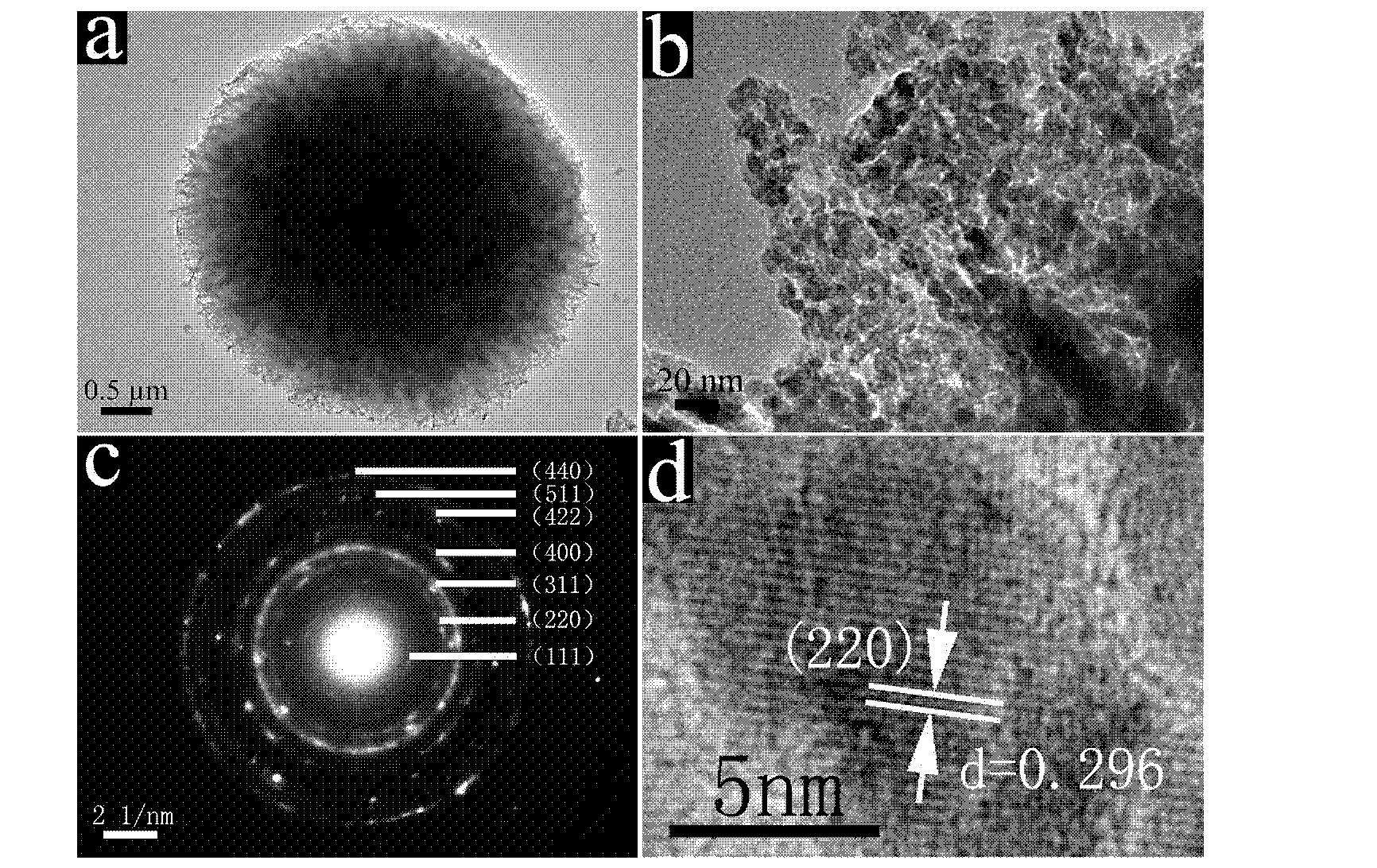

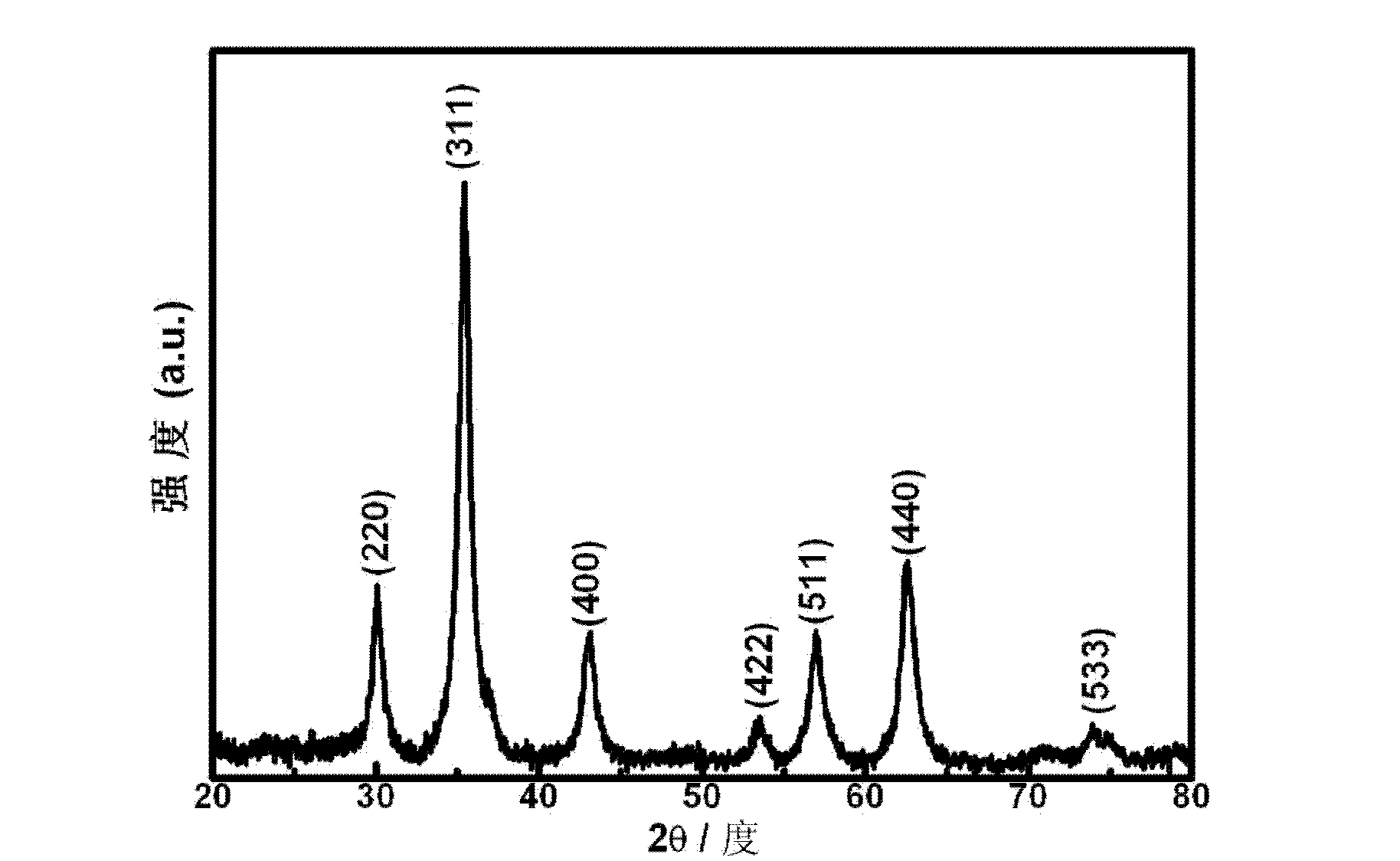

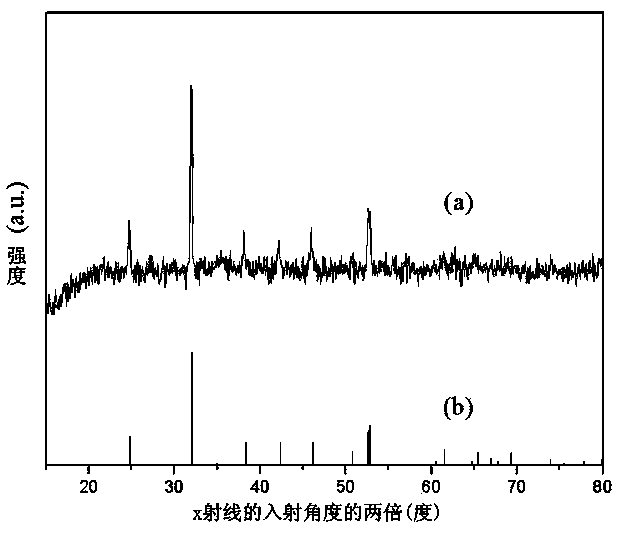

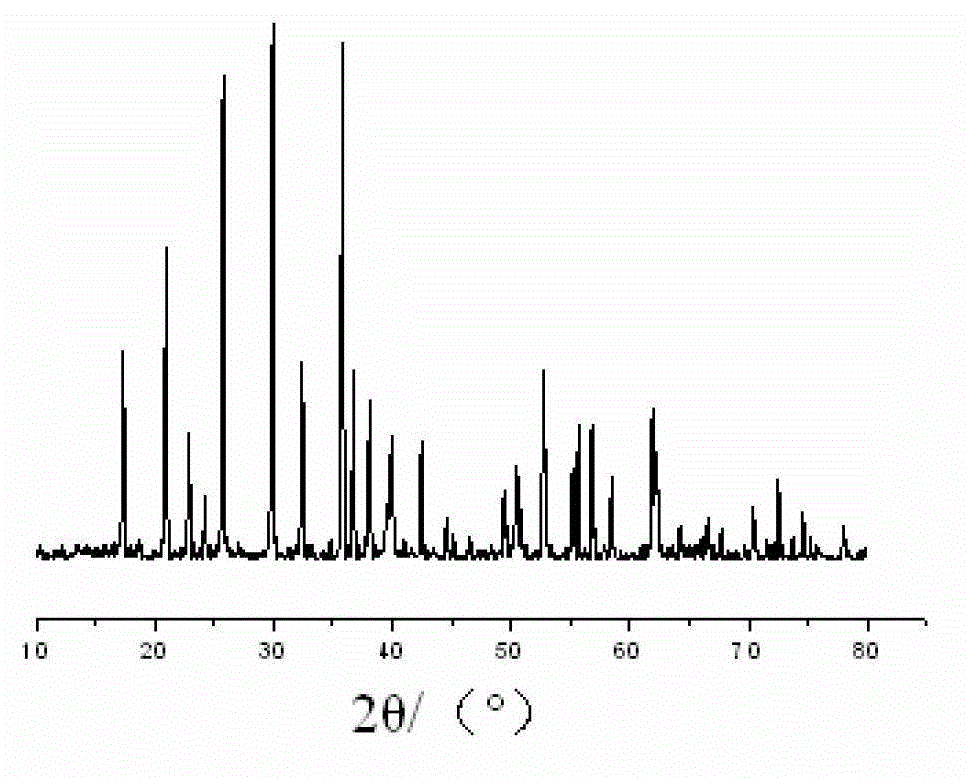

Ferroferric oxide porous ball having micro-nano structure, and preparation method of ferroferric oxide porous ball

InactiveCN102153151AHigh crystallinityActiveFerroso-ferric oxidesNanotechnologyMicro nanoReaction temperature

The invention discloses a ferroferric oxide porous ball having a micro-nano structure, and a preparation method of the ferroferric oxide porous ball. The ferroferric oxide porous ball having the micro-nano structure is prepared by annealing a ferrous carbonate porous ball having the micro-nano structure under the atmosphere of argon; the ferrous carbonate porous ball having the micro-nano structure is prepared by mixing ferric trichloride, urea and ascorbic acid; absorption and reduction of the synthesized ferroferric oxide porous ball having the micro-nano structure to heavy metal hexavalent chromium ion are tested. During preparation of ferrous carbonate by a hydrothermal process, a dispersing agent and a surfactant are not required; and substances such as a template are absent, so the ferroferric oxide porous ball having the micro-nano structure is environment-friendly, and aftertreatment is convenient; moreover, the reaction temperature is low and the process is simple; and due to a porous structure, the ferroferric oxide porous ball having the micro-nano structure prepared by the method has high specific surface and high activity of the nano structure, and can prevent gathering of particles effectively.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Deoxidizing preservative and preparation method thereof

The invention provides a deoxidizing preservative. The deoxidizing preservative comprises the following components in percentage by weight: 85 to 95 percent of oxygen absorbent and 5 to 15 percent of water; the oxygen absorbent is blocky solid and comprises the following components in percentage by weight: 40 to 90 percent of ultrahigh molecular weight polyethylene, 5 to 55 percent of oxygen absorbing substance and 5 to 20 percent of active carbon, wherein the oxygen absorbing substance is one or a mixture of reduced iron powder, ferrous chloride, ferrous carbonate, ferrous sulfate and zinc powder. The deoxidizing preservative not only prevents food pollution caused by powder leakage, but also prevents materials from adsorbing oxygen in the environment in the processes from mixing to packing so as to greatly lose oxygen absorption performance and reduce the production cost for manufacturers of the deoxidizing preservative.

Owner:GUANGDONG GUANGYI TECH IND

Method for preparing positive electrode material of LiFePO4 by phosphorous acid or salt thereof

InactiveCN101332987ALow costWide variety of sourcesCell electrodesPhosphorus compoundsPhosphorous acidPhosphate

The invention relates to a method for preparing lithium iron phosphate by phosphorous acid or phosphite; the preparation method is as follows: lithium salt, ferrous salt, phosphate and phosphorous acid or phosphite are blended, added with carbon-containing compound, and further added with wet milling liquid, processed by ball milling and mixing, and dried at normal atmosphere or vacuum; the dried powder is sintered to prepare lithium iron phosphate cathode material. The lithium is one of or the mixture of lithium carbonate, lithium hydroxide, lithium oxalate, lithium acetate, lithium nitrate, lithium fluoride and lithium phosphate; the ferrous salt is one of or the mixture of iron oxalate, iron acetate, iron dichloride, ferrous sulfate or ferrous carbonate; the phosphate is one of or the mixture of ammonium phosphate, diammonium phosphate of monoammonium phosphate; the molecular formula of phosphite is AH2PO3, A2HPO3, EHPO3, E(H2PO3)2 or G(H2PO3)3; the carbon-containing compound is one of or the mixture of polypropylene, polyacrylamide, polyvinyl alcohol, glucose, cane sugar or starch. The method of the invention has simple preparing process and short time consumed, and the materials have good cycling performance under the heavy current discharging condition.

Owner:FUJIAN NORMAL UNIV

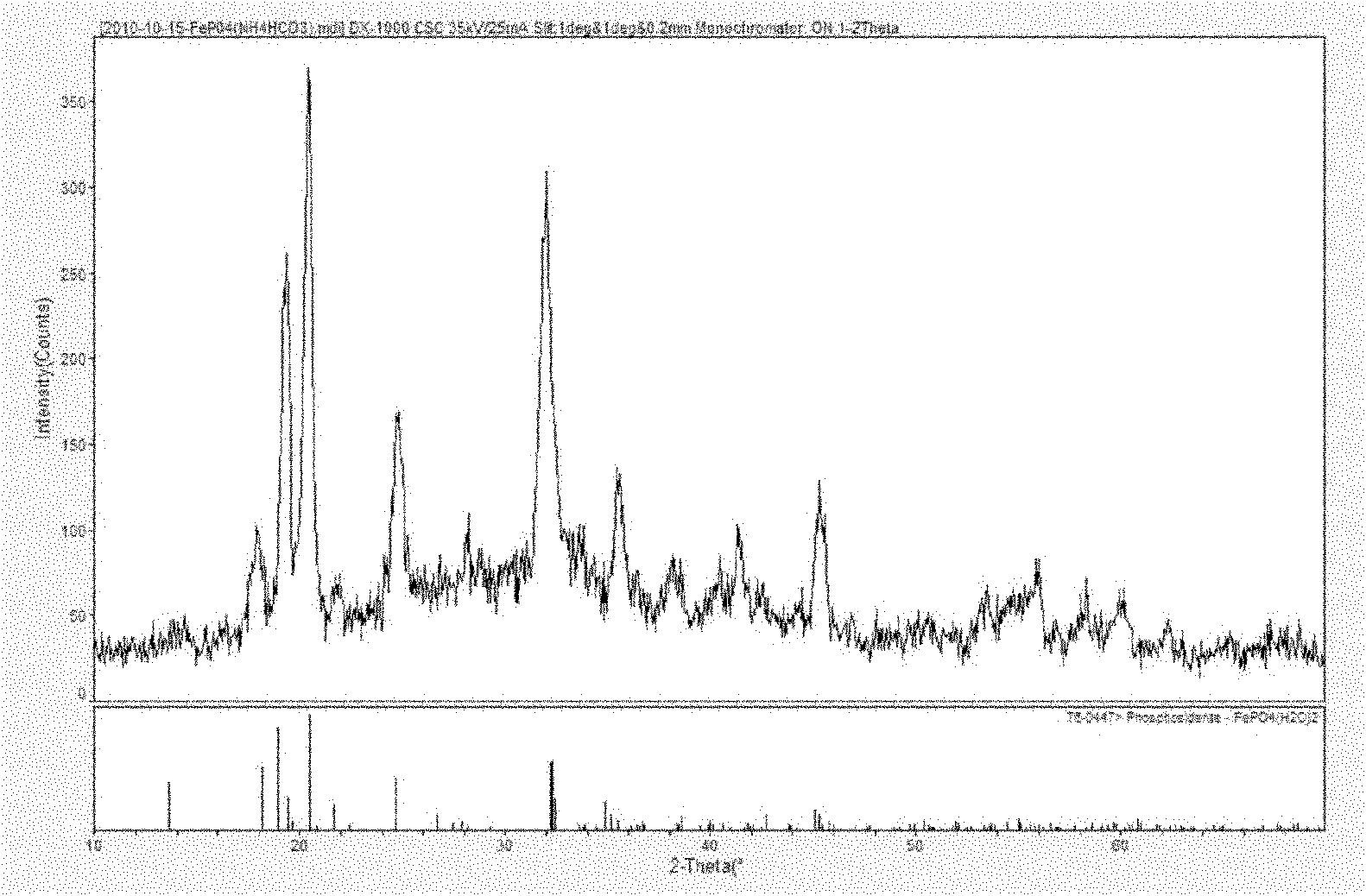

Humic acid fertilizer synergist with ammonia volatilization inhibition effect and preparation method thereof

ActiveCN104725141AReduce releaseReduce lossesBio-organic fraction processingOrganic fertiliser preparationNutritionBiology

Owner:QINGDAO HAILIYUAN BIOTECH

Method for preparing glycine iron(óÄ) chelate for fortified food

InactiveCN1634872AImprove oxidation stabilityEasy to separate and purifyOrganic compound preparationAmino-carboxyl compound preparationSolubilityNutrition

The invention relates to a method for preparing a food nutrition reinforcer glycine chelated iron(ó�), which belongs to the field of preparation of amino acid chelated iron(II). In the invention, glycine and ferrous chloride or ferrous carbonate are used as raw materials, antioxidant is added and nitrogen gas is passed for protection in process of chelation reaction, different organic solvents are employed for precipitating and eluting in separation and purification of products to separate chelated iron(II) and inorganic iron efficiently and remove impurity anion for producing products with excellent oxidation stability and water solubility. The content of glycine chelated iron(ó�) is over 80% in the synthetic products rehydration rate of glycine chelated iron(ó�) is above 95%, and the stability of glycine chelated iron(ó�) and aqueous solution are better than ferrous sulfate.

Owner:JIANGNAN UNIV

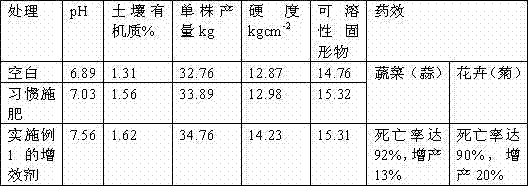

High-purity iron phosphate used for producing lithium ion battery positive-pole material and preparation method thereof

InactiveCN102126713ALow impurity contentImprove electrochemical performancePhosphorus compoundsFerrous saltsPhosphoric acid

The invention relates to high-purity iron phosphate used for producing a lithium ion battery positive-pole material and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking ferrous salt and carbonate as raw materials; reacting to generate intermediate product ferrous carbonate precipitation, wherein, the ferrous carbonate is easy to filter, and the foreign ions are easy to wash; filtering and recovering ammonium sulfate; dissolving the ferrous carbonate precipitation; adding oxidant for oxidizing; regulating the pH value of the solution; heating and preserving the temperature for a certain time to obtain the iron phosphate precipitation; filtering, drying and precipitating to obtain the high-purity iron phosphate; and mixing and calcining the high-purity iron phosphate, the lithium source and the carbon source to obtain the lithium ion battery positive-pole material with excellent electrochemistrical performance. By using the method provided by the invention, the impurity content in the iron phosphate is effectively lowered, the process time is shortened, the energy consumption is reduced, and the cost and the consumption of the raw materials are lowered; and the filter liquor is easy to recover, and the production cost is very low, thus being beneficial for large-scale production in scaled industry.

Owner:SICHUAN UNIV

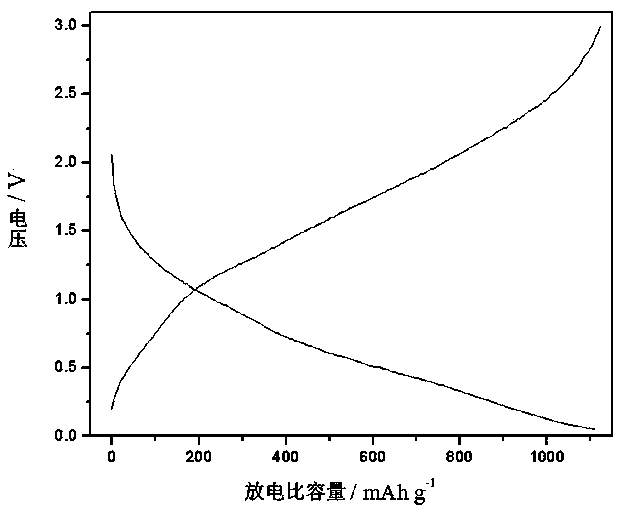

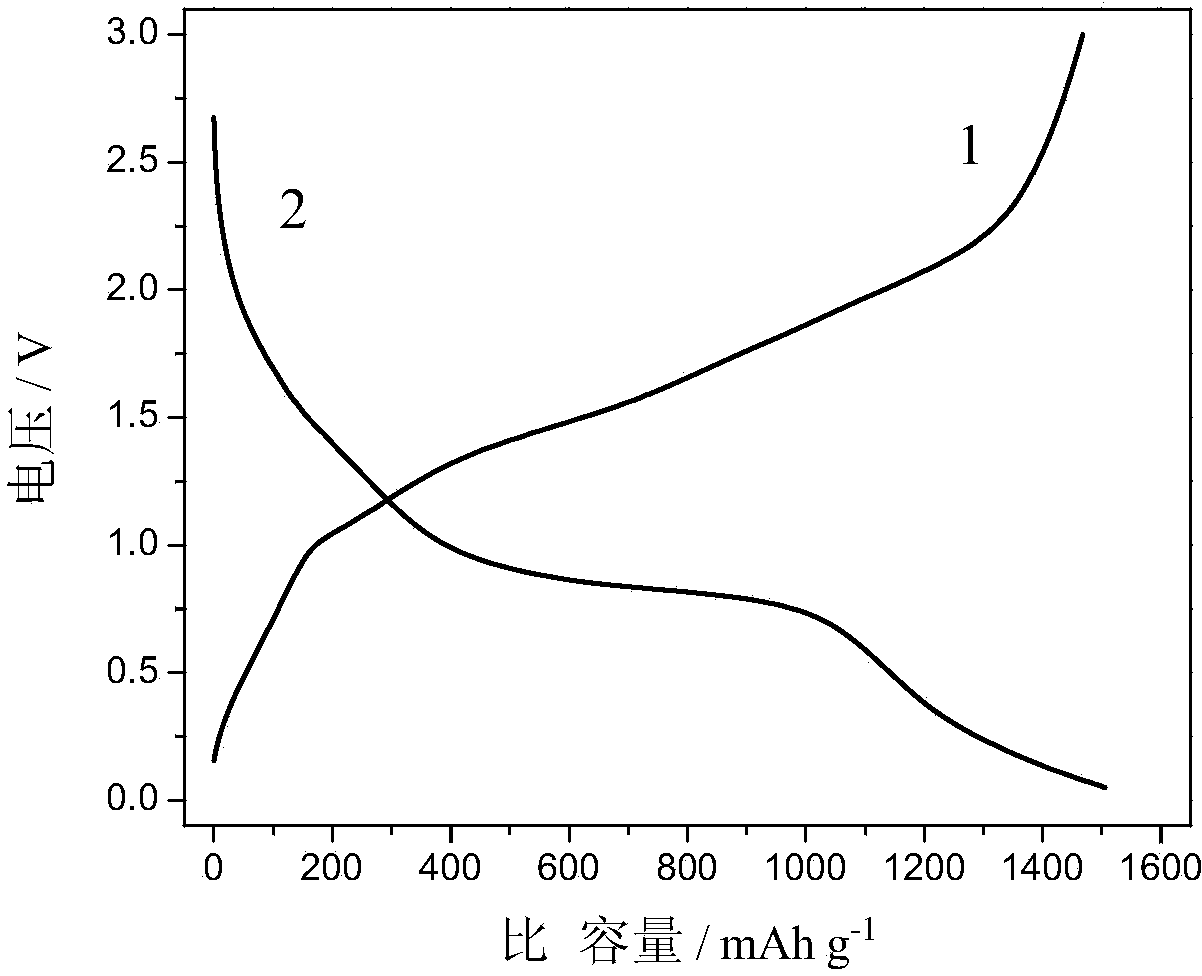

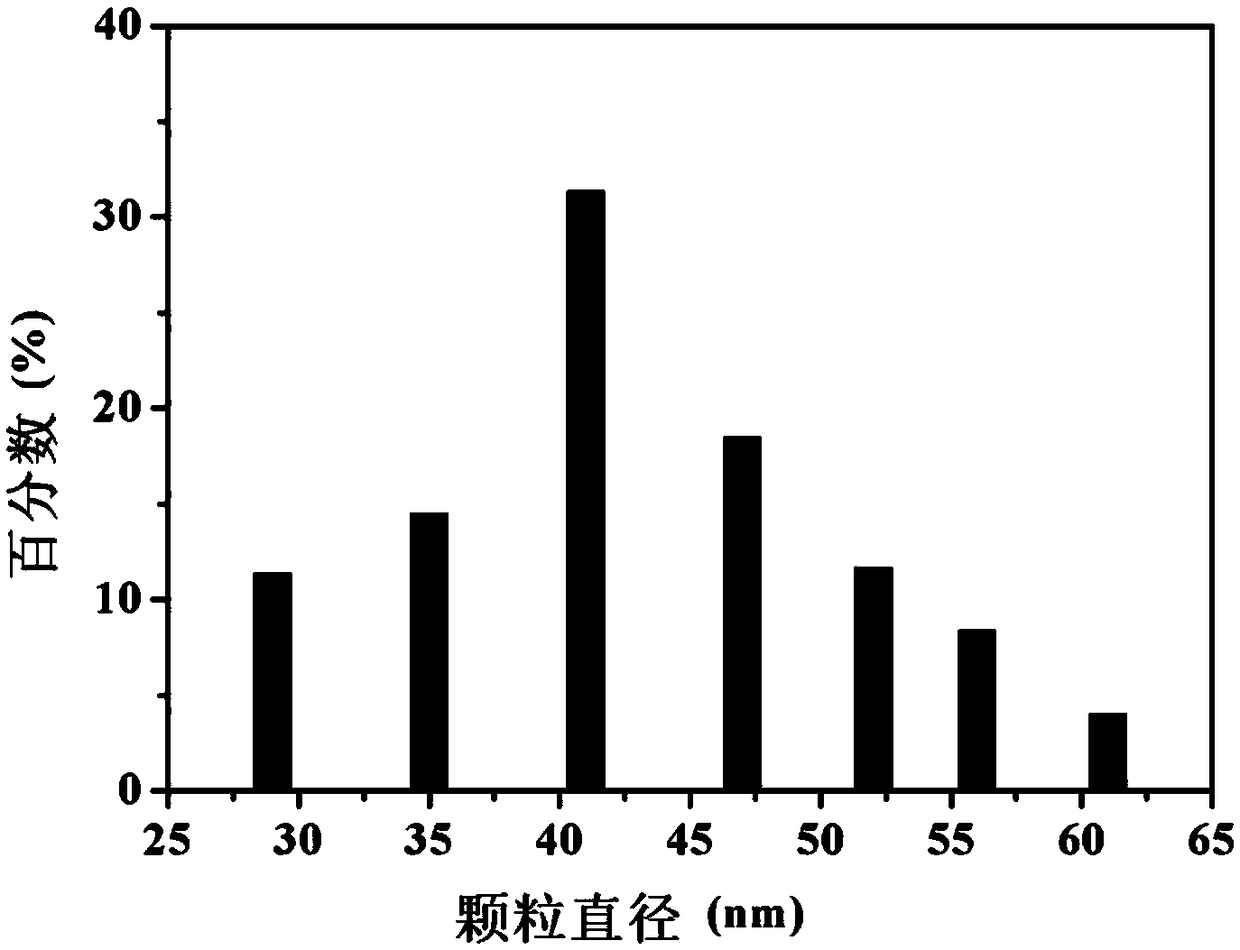

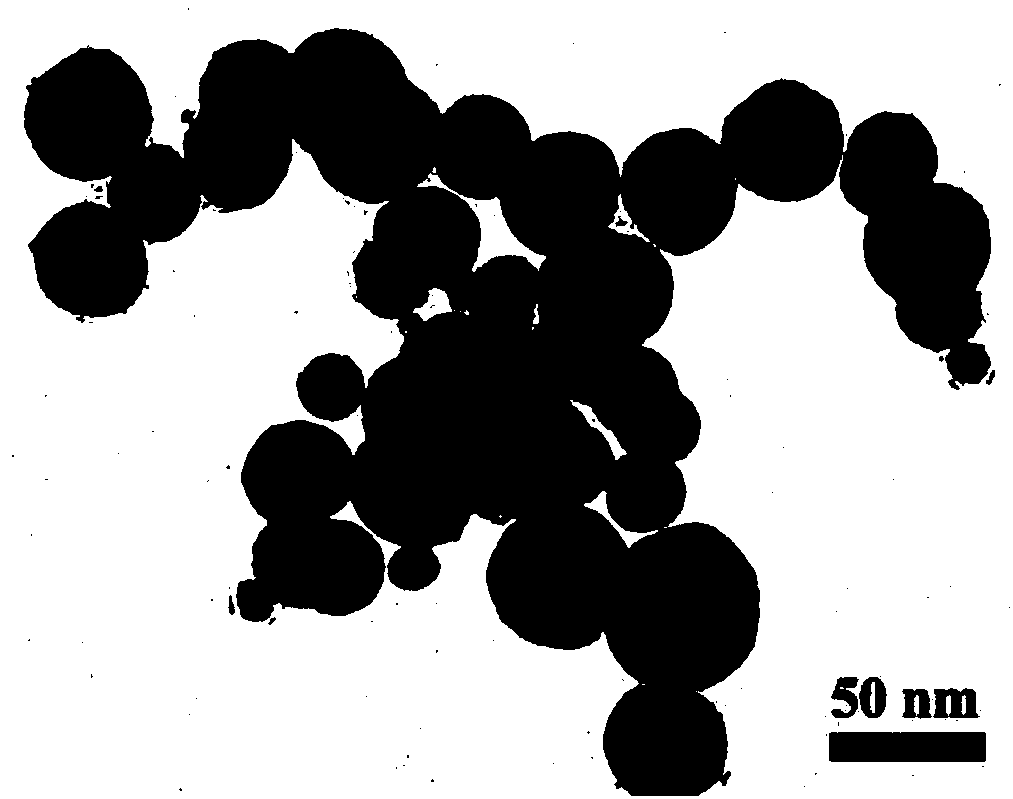

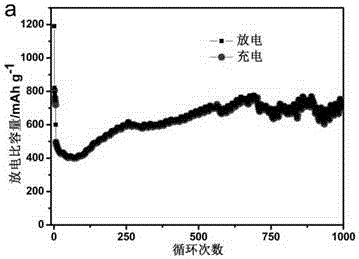

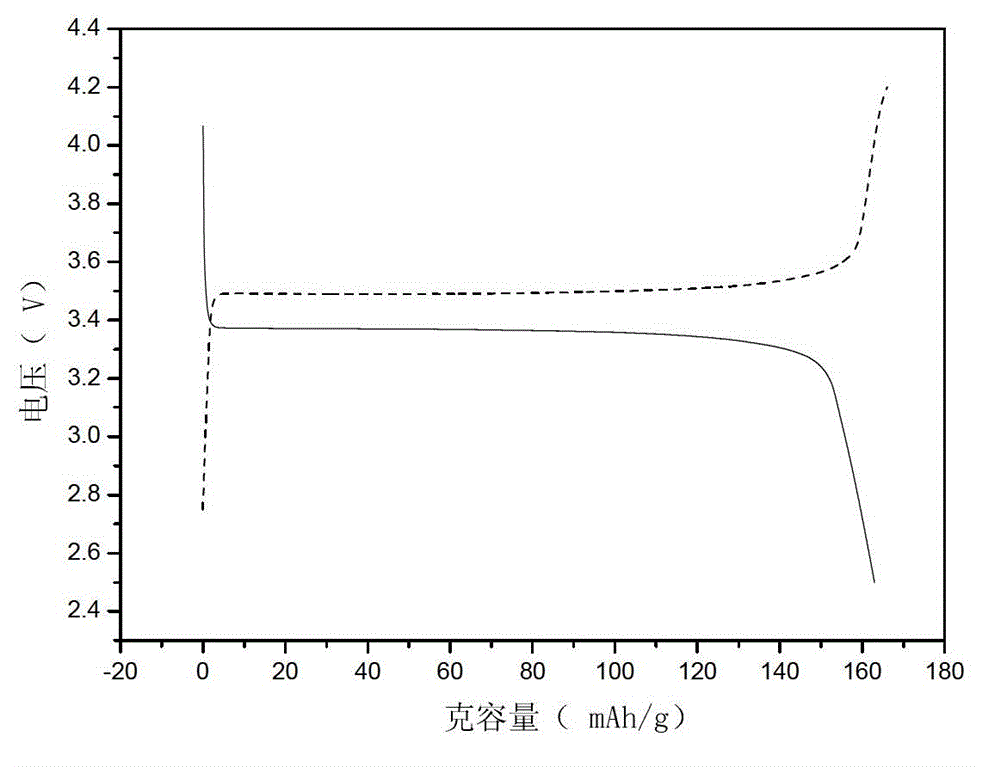

Lithium ion battery cathode material and preparation method thereof

ActiveCN103413941AHigh specific capacityImprove cycle performanceCell electrodesSecondary cellsMicro nanoFerrous salts

The invention discloses a lithium ion battery cathode material and a preparation method thereof. According to the preparation method of the lithium ion battery cathode material, low-temperature hydrothermal method is employed, sodium dodecyl sulfate is used as a surfactant, a soluble ferrous salt and urea are used as raw materials, and the micro-nano scale ferrous carbonate cathode material is prepared at a certain temperature and in a certain period of time. The ferrous carbonate cathode material is used for lithium ion batteries for the first time, initial discharge specific capacity can reach to 900 to 1110mAh / g when electric current density is 200mA / g and voltage is 0.05 to 3.0V, and the specific capacity is maintained at 585 to 640mAh / g after 100 cycles of discharge. The specific capacity of the ferrous carbonate cathode material is high, cycle performance and multiplying power performance are excellent, sources of the raw materials are wide, and cost of the raw materials is low. In addition, the application of hydrothermal method is capable of synthesizing the ferrous carbonate cathode material at a relatively low temperature, the preparation method is simple, operability and repeatability are high, and application and development prospect is promising.

Owner:HUNAN ZOOMWE NEW ENERGY TECH CO LTD

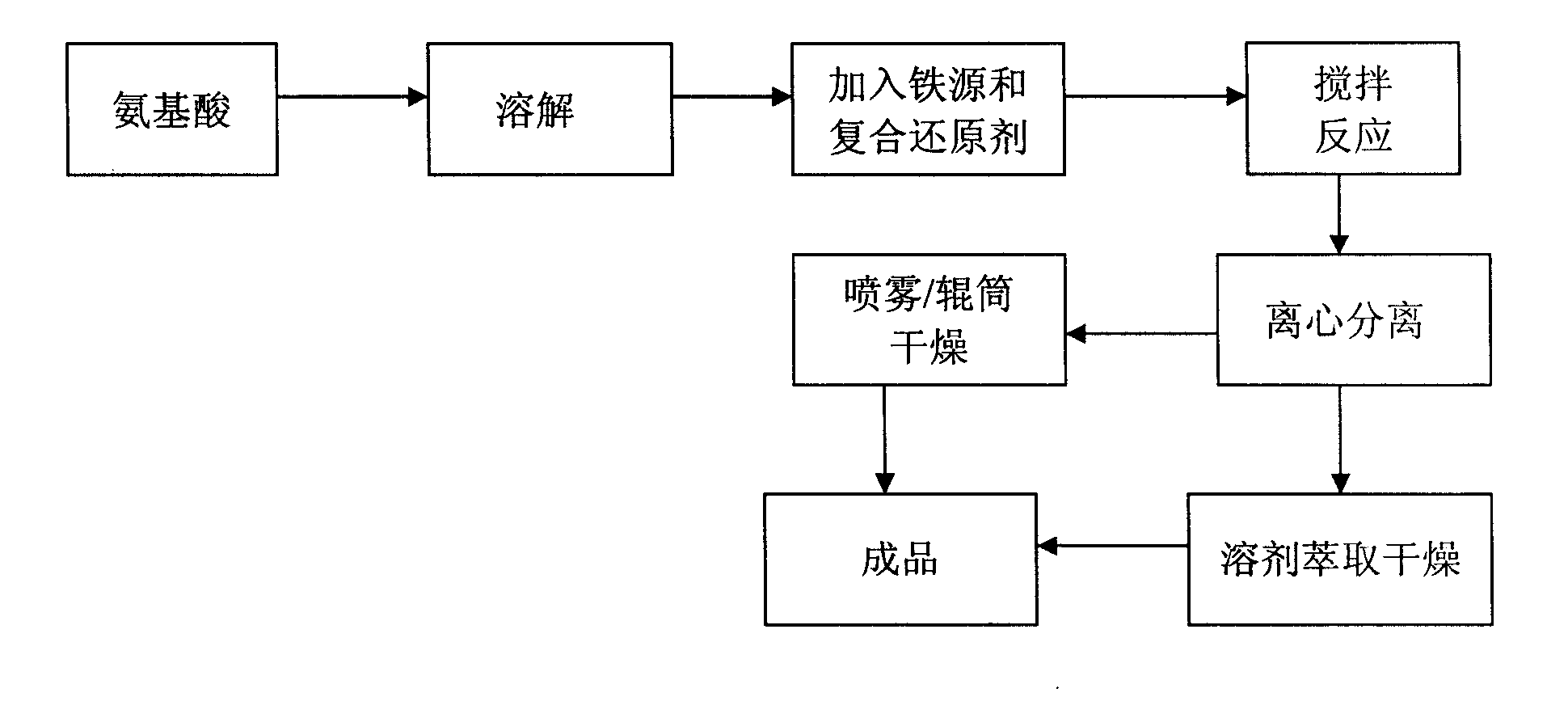

Method for preparing food-grade amino acid ferrous chelate compound without interfering anions

InactiveCN101606715AHigh ferrous contentImprove oxidation stabilityFood preparationEvaporationCyclodextrin

The invention relates to a method for preparing a food-grade amino acid ferrous chelate compound without interfering anions, which selects amino acid and an iron source as main raw materials and is characterized by comprising the following steps: selecting glycine, methionine, glutamic acid, lysine and the like as amino acid raw materials, and selecting pure iron elements, ferrous oxide, ferrous hydroxide, ferrous carbonate and the like as the iron source, wherein the reaction mol ratio of the amino acid to the iron source is 1:1-6:1; and dissolving the amino acid in water, adding the iron source, adding a non-interfering anionic reducing agent or a complex reducing agent such as citric acid, ascorbic acid, acetic acid, carbonic acid and the like, adjusting the pH value to between 3 and 8, heating the mixture to between 40 and 100 DEG C, stirring the mixture to react for 5 to 70 hours, performing evaporation concentration, and extracting the mixture with 50 to 100 percent aqueous solution of ethanol, or performing spray drying or roller drying directly to obtain the required product. The product can be added with auxiliary agents of maltodextrin, cyclodextrin and the like, thus the method has the characteristics that the product has no interfering anions, the ferrous content is high, the preparation process is simple, and the like.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process and Reagent for Removal of Oxygen from Hydrocarbon Streams

A method of using a sulfided iron reagent to remove oxygen from gaseous and liquid fluid streams such as natural gas, light hydrocarbon streams, crude oil, acid gas mixtures, carbon dioxide gas and liquid streams, anaerobic gas, landfill gas, geothermal gases and liquids, and the like is disclosed. In a preferred embodiment, the reagent is made by mixing, agglomerating and shaping finely powdered ferrous carbonate, preferably siderite which are used to remove oxygen from a hydrocarbon or carbon dioxide stream that also contains sulfur compounds such as hydrogen sulfide.

Owner:NEW TECH VENTURES

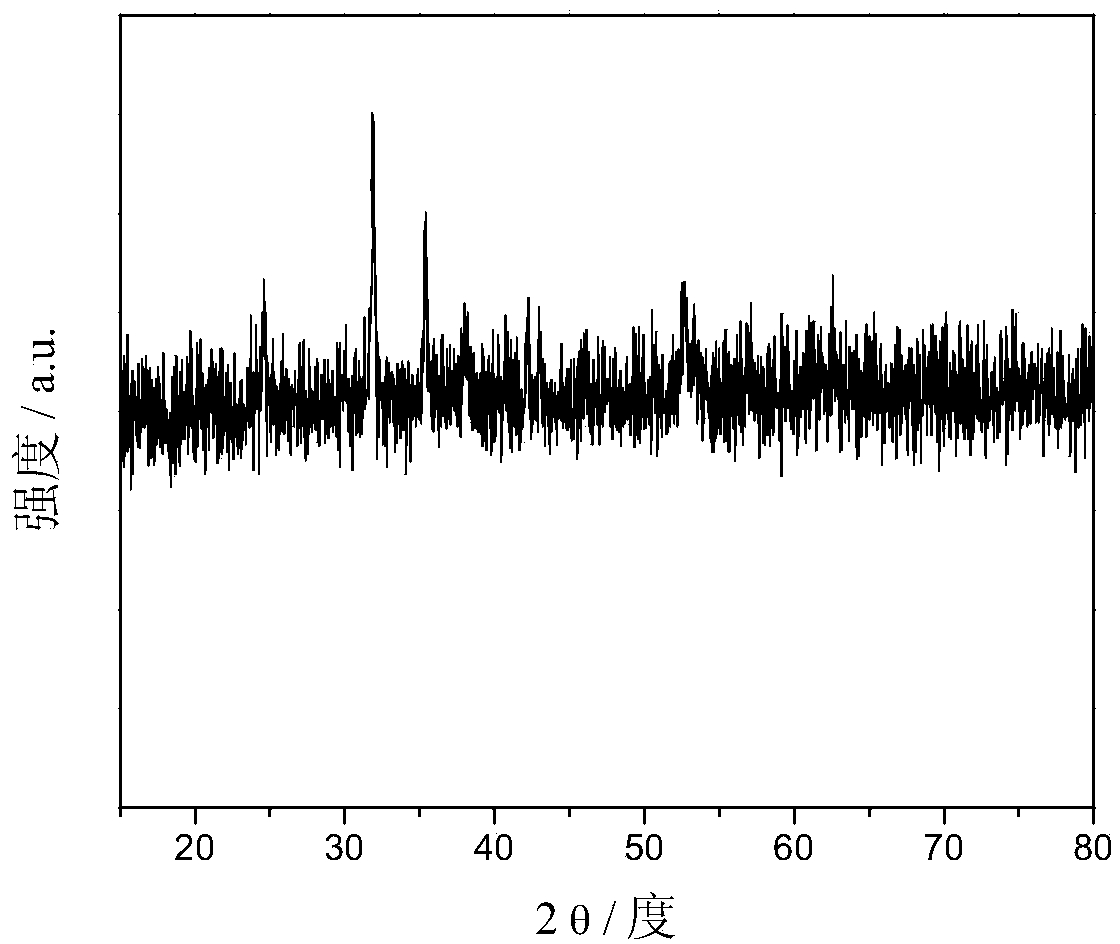

Method for synthesizing barium carbonate iron monocrystal at high temperature and under high pressure

InactiveCN108588835AHigh purityHigh crystallinityPolycrystalline material growthFrom solid stateIron powderSingle crystal

The invention discloses a method for synthesizing barium carbonate iron monocrystal at high temperature and under high pressure. The method comprises the following steps: grinding and uniformly mixingthe analytic pure barium carbonate and the synthetic ferrous carbonate according to the molar ratio of 1:1 to serve as a starting raw material, performing high-temperature and high-pressure reactionfor 12 hours at 500 to 800 DEG C and under the pressure of 1 to 3 GPa to obtain a barium carbonate iron powder crystal sample, grinding and mixing the barium carbonate iron powder crystal sample and anhydrous oxalic acid according to the molar ratio of 1:0.1 to prepare a sample, and performing high-temperature and high-pressure reaction for 100 hours at 700 to 900 DEG C and under the pressure of 3GPa to prepare a barium carbonate iron monocrystal sample. The high-temperature and high-pressure method has the advantages that the operation process is simple and the experimental condition is easyto control; the obtained barium carbonate iron sample has the characteristics of high purity, high crystallinity degree, chemical stability, insusceptibility to water absorption and the like; and thetechnical problem that the existing method for artificially synthesizing the barium carbonate iron and growing the monocrystal has defectiveness is solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

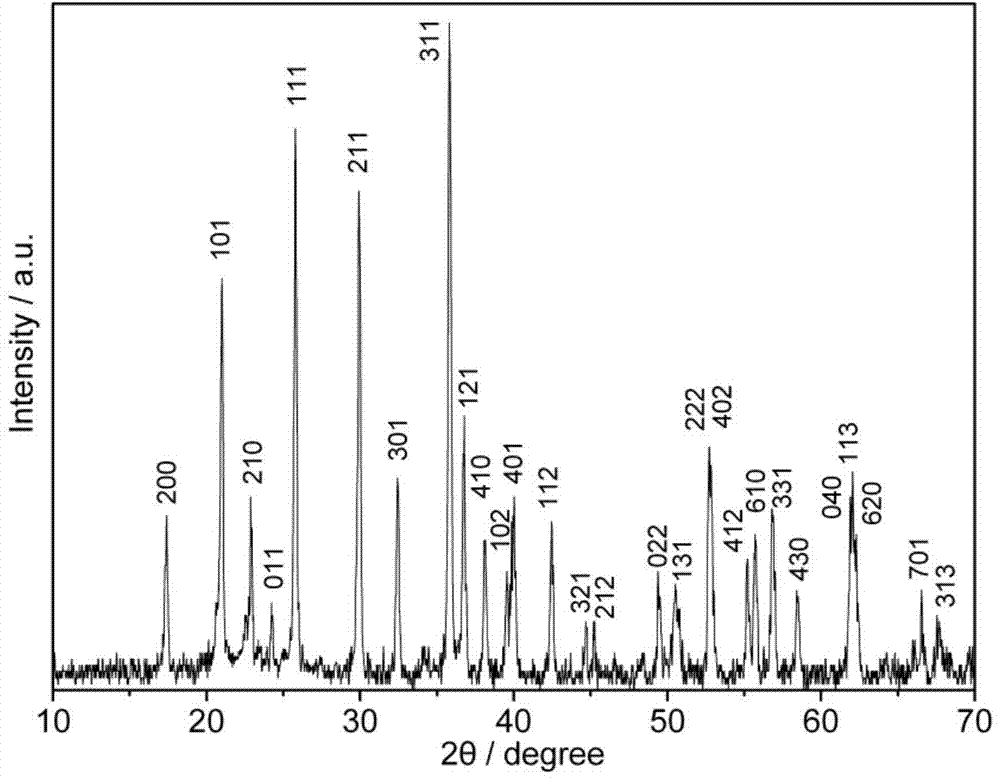

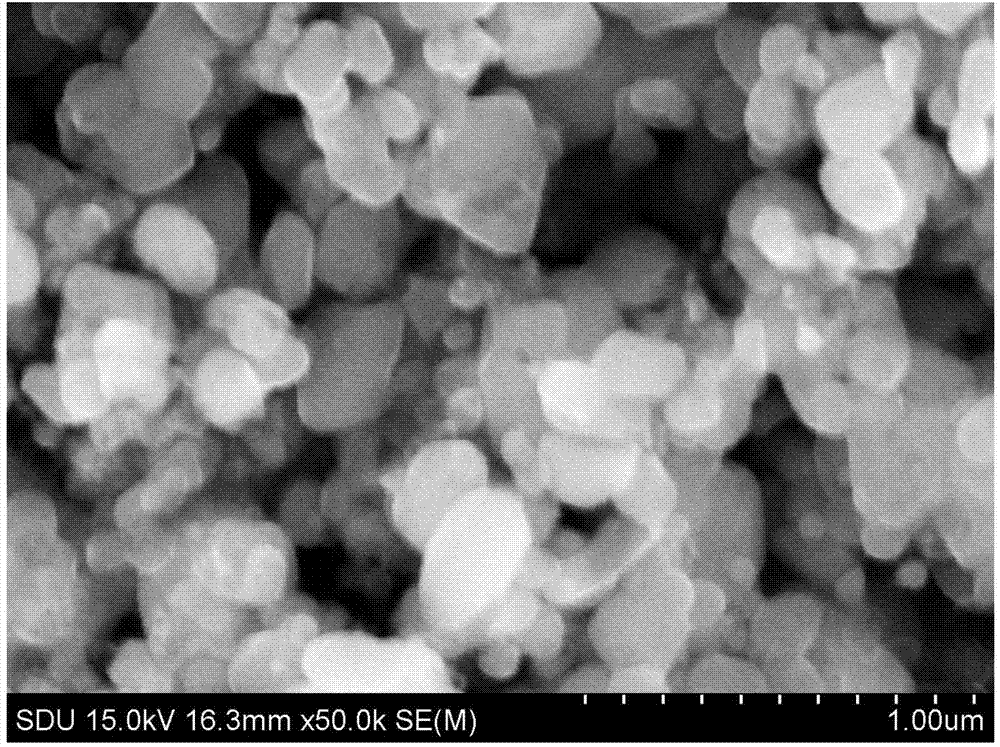

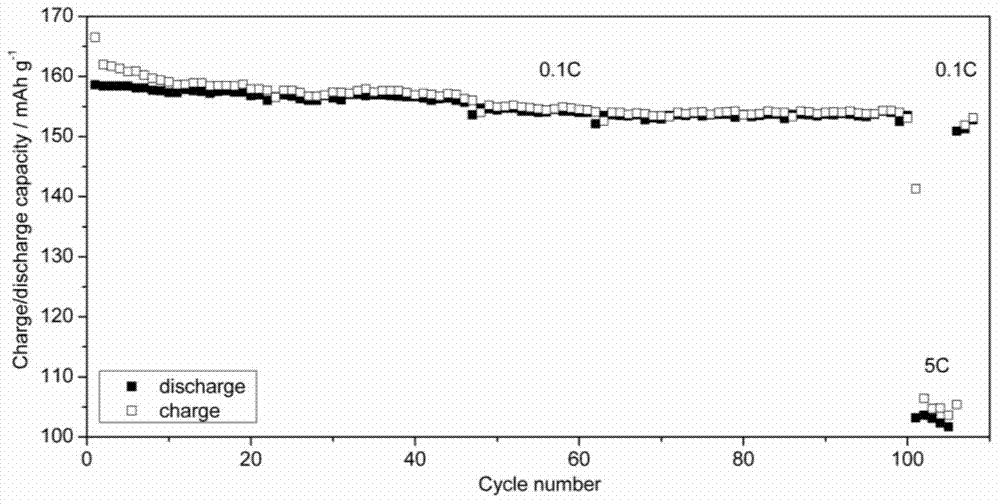

Method of preparing nanoscale lithium iron phosphate / carbon composite anode material

InactiveCN103500832AHigh purityReduce manufacturing costCell electrodesSecondary cellsCarbon compositesHigh energy

The invention relates to a method of preparing a nanoscale lithium iron phosphate / carbon composite anode material. A lithium source, a phosphorus source and ferrous carbonate are mixed with a carbon source according to a stoichiometric ratio to form a mixture A; the mixture A is subjected to high-energy wet ball-milling and dried to obtain a precursor B; the precursor B is pre-burned and sintered in a protective atmosphere to obtain the nanoscale lithium iron phosphate / carbon composite anode material. By means of the method, the ferrous carbonate low in price is successfully used as an iron source for replacing iron trioxide or ferrous oxalate frequently used in a traditional solid phase method, so that nanoscale pure-phase lithium iron phosphate is prepared, and the production cost per ton of the lithium iron phosphate is lowered by 18-37 percent points. The obtained compound is fine in particle with the grain size ranging from 20nm to 200nm, and has good electrical conductivity. The capacity is maintained higher than 150 mAh / g after 100 times of 0.1C circulation and higher than 100 mAh / g at the time of 5C discharge, and therefore the nanoscale lithium iron phosphate / carbon composite anode material is an ideal anode material for a lithium ion battery.

Owner:SHANDONG UNIV

Superfine cobalt alloy powder and preparation method thereof

The invention provides a superfine cobalt alloy powder and a preparation method thereof. The preparation method comprises the following steps: (1) stirring and ball milling: mixing raw materials including cobalt carbonate or cobalt oxalate, nickel carbonate or nickel oxalate, ferrous carbonate or ferrous oxalate and Al2O3, adding an oleic acid dispersant, feeding into a stirring ball mill, stirring and ball milling for a certain time period and obtaining mixed powder, wherein the raw materials contain 20 weight percent of Ni, 20 weight percent of Fe, 1 weight percent of Al2O3 and the balance of Co and other elements; and (2) powder reduction: reducing the mixed powder obtained by the step (1) in a hydrogen reduction furnace and obtaining superfine cobalt alloy powder. In the superfine cobalt powder of the invention, the use of nickel in place of part of cobalt saves cobalt resources considerably, a solid solution strengthening phase and a dispersion strengthening phase change the tendency that the conventional cobalt-containing powder material is susceptible to generating cobalt pool and alloy crystal aggregation and growth after being sintered, and the wear resistance, hardness, strength and fracture toughness are high.

Owner:GEM CO LTD

In-situ biogas desulfurizer

The invention discloses an in-situ biogas desulfurizer, which is added into a biogas fermentation device to make desulfurization and raw material fermentation carried out synchronously, and solves the problems of short service cycle, frequent and inconvenient replacement and the like of the conventional biogas desulfurizer. The in-situ biogas desulfurizer adopts the technical key points that: the desulfurizer is a ferric salt, and is one or more of ferric salts such as ferrous oxalate, ferrous chloride, ferrous sulphate, ferrous nitrate, ferrous carbonate, ferric chloride, ferric sulfate, ferric nitrate and ferric citrate; and a mass ratio of the desulfurizer to dried biogas fermentation raw materials is (1-30):1,000. The in-situ biogas desulfurizer is directly added into the biogas fermentation device to desulfurize the in-situ biogas, and has the advantages of abundant raw materials, obvious improvement on desulfurization efficiency, convenient operation, desulfurizing equipment cost conservation, low running cost and the like.

Owner:北京合百意可再生能源技术有限公司 +1

Ferrous carbonate/graphene composite material and preparation method and applications thereof

ActiveCN103840132AHigh specific capacityImprove cycle performanceSecondary cellsNegative electrodesMass ratioConcentration ratio

Owner:HUNAN YACHENG NEW MATERIAL CO LTD

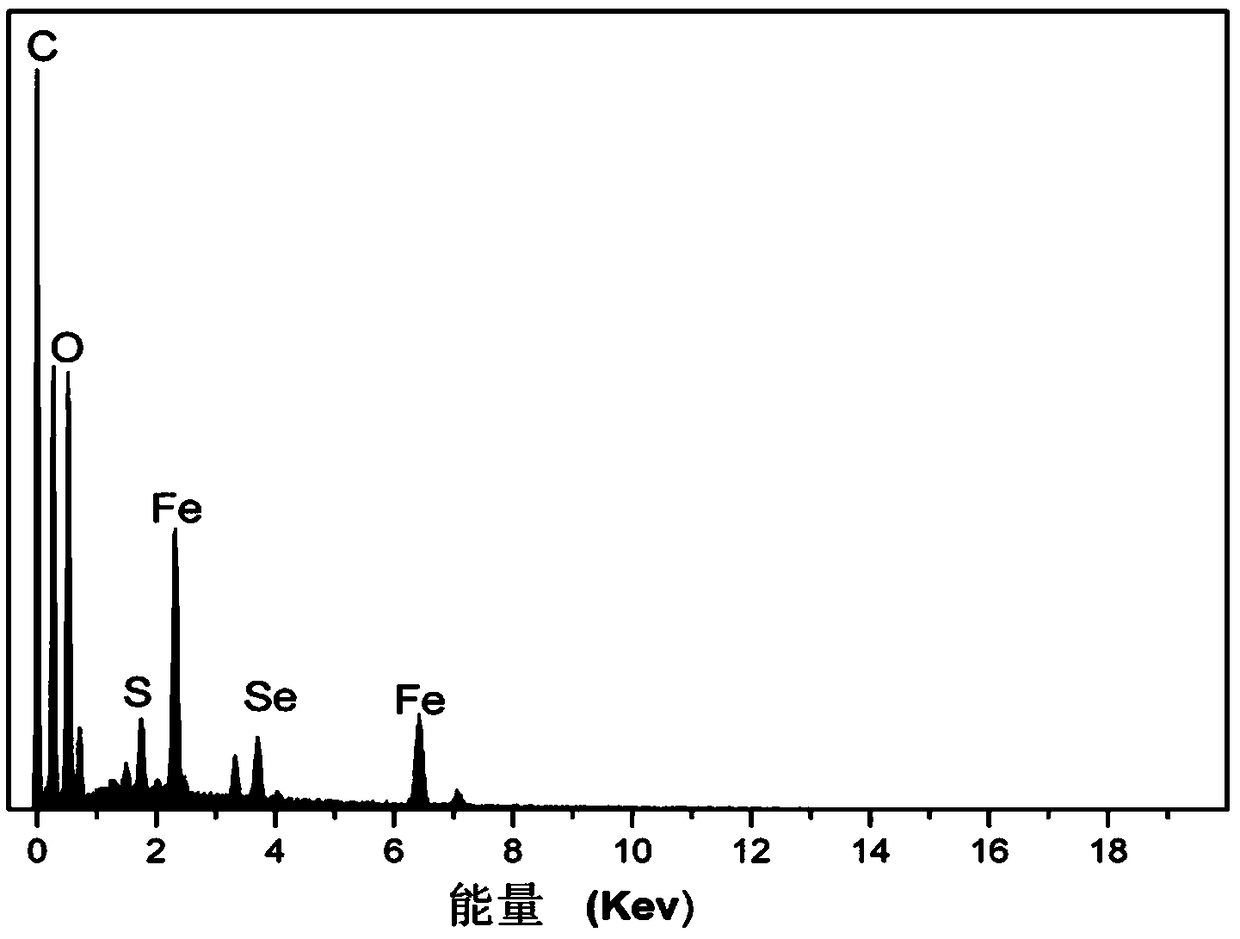

Ferrous modified selenium sol for inhibiting cadmium-arsenic accumulation of paddy rice as well as preparation method and application thereof

ActiveCN108967442ASimple preparation processCan be produced industrially on a large scaleBiocidePlant growth regulatorsSelenium CompoundCadmium Cation

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

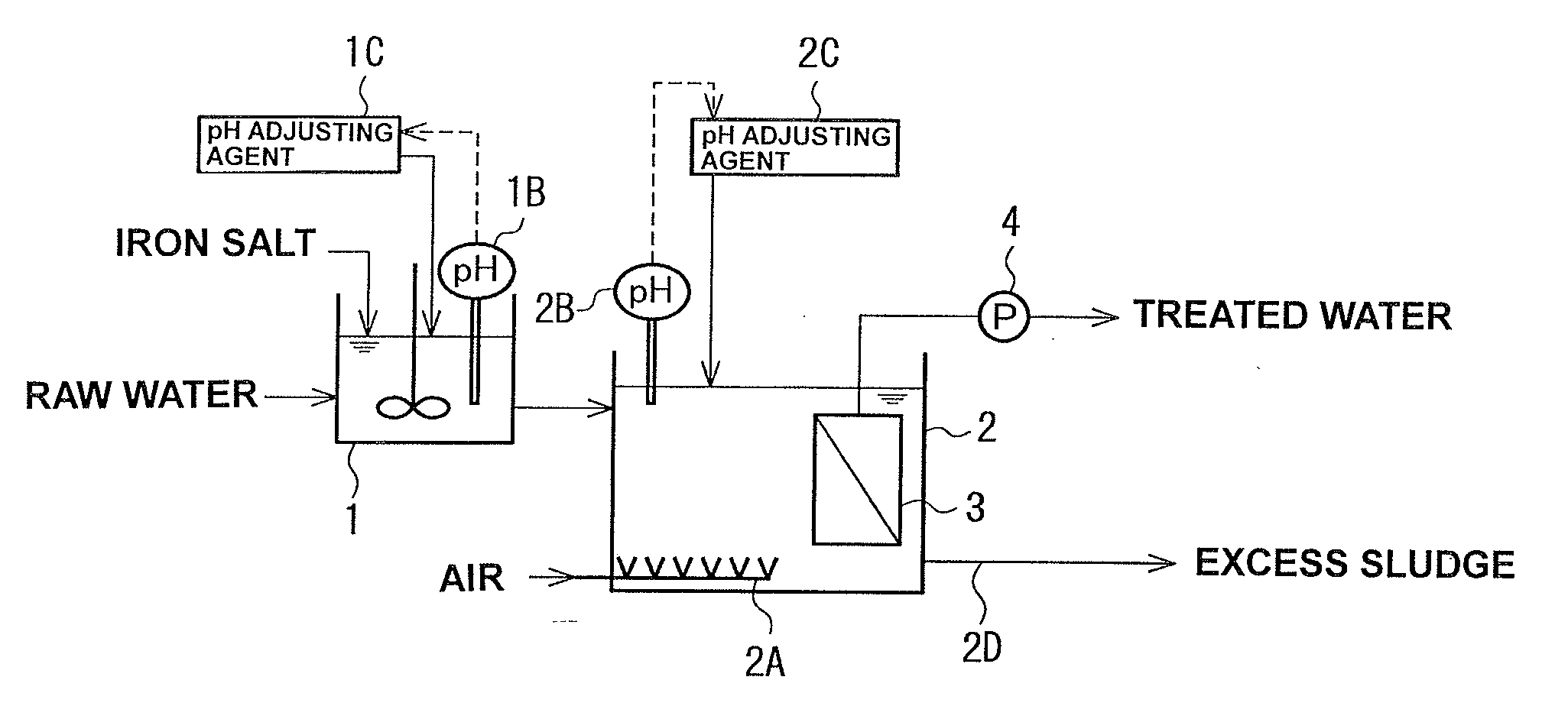

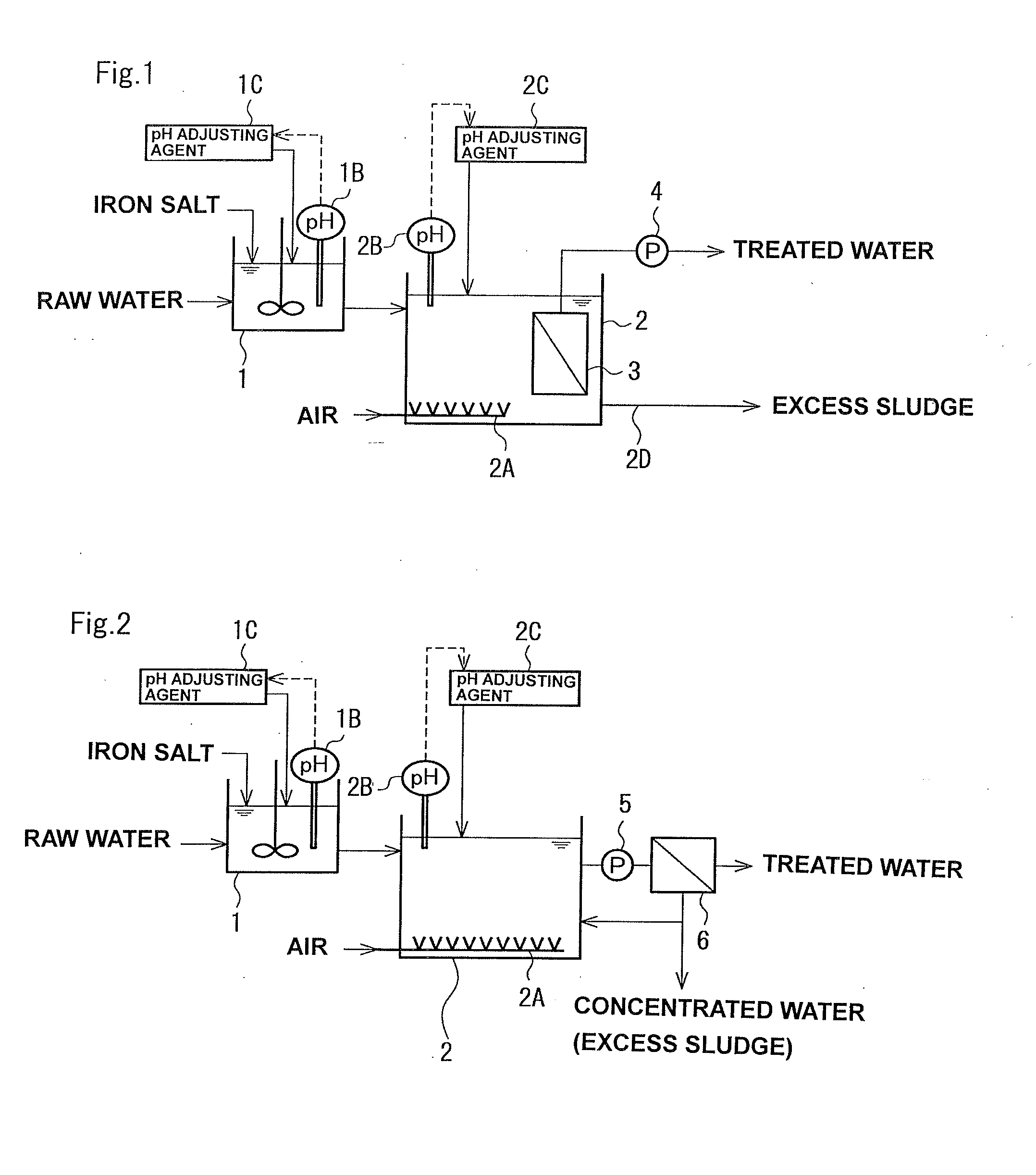

Organic-wastewater treatment method and organic-wastewater treatment apparatus

InactiveUS20120160768A1Easy to useImprove filtering effectTreatment using aerobic processesWater contaminantsFerric hydroxideActivated sludge

By adding an iron salt, the sedimentation property, the concentration property, and the filtration property of sludge in an activated-sludge mixed liquor in a biological treatment tank are effectively improved and treated water of high quality is efficiently provided. When an iron salt such as ferrous chloride, ferric chloride, or polyferric sulfate is added to organic wastewater and the organic wastewater is biologically treated, the iron salt is added to the organic wastewater and mixing is conducted; and the water mixture is mixed with activated sludge and biologically treated. By mixing organic wastewater and an iron salt at a pH close to an optimum pH for ferric hydroxide in advance, the turbidity of the treated water due to the formation of iron oxide or ferrous carbonate is suppressed.

Owner:KURITA WATER INDUSTRIES LTD

Production method of medical sodium iodide

A process for preparing medicinal sodium iodide from iodine, Fe powder and dicarbonate includes such steps as preparing ferrous iodide, reaction between ferrous iodide and dicarbonate to obtain ferrous carbonate, sodium iodide and water, separating sodium iodide, removing SO4 radicals, filtering, concentrating and crystallizing.

Owner:自贡市金典化工有限公司

Production method of ammonium iodide

ActiveCN1751998ALow requirements for production equipmentSimple production process controlAmmonium halidesDicarbonateIodine

A process for preparing ammonium iodide from iodine, Fe powder, and dicarbonate includes such steps as preparing ferrous iodide, reaction between ferrous iodide and dicarbonate to obtain ferrous carbonate, ammonium iodide, CO2 and water, separating ammonium iodide, removing SO4 radical, filtering, concentracting, and crystallizing. Its advantage is low corrosion to productive apparatus.

Owner:自贡市金典化工有限公司

Retarding water reducing agent

The present invention belongs to the technical field of water reducing agents, and particularly relates to a concrete retarding water reducing agent, which comprises a water reducing agent, a retarder and a reducing agent, wherein a weight ratio of the water reducing agent o the retarder is 9:1-7:3, the reducing agent accounts for 0.01-0.04% of the total weight of the water reducing agent and the retarder, the water reducing agent is a naphthalene sulfonic acid formaldehyde condensation water reducing agent, the reducing agent is SRA-3, and the retarder is one or a plurality of materials selected from ferrous sulfate, sodium fluorosilicate, ferrous carbonate, cellulose ether and cadmium sulfate. According to the present invention, with the efficient retarding water reducing agent, the cement particles can be dispersed, the workability of concrete can be improved, the water consumption per unit can be reduced, the strength of concrete can be increased, the durability of concrete can be improved, the cement consumption per unit can be reduced, and the concrete cost can be reduced; and the product has effects of concrete setting time delaying, early strength, water reducing and the like.

Owner:TIANJIN WANGJIU SCI & TECH DEV

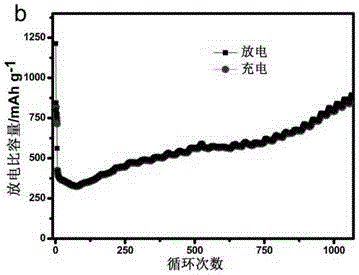

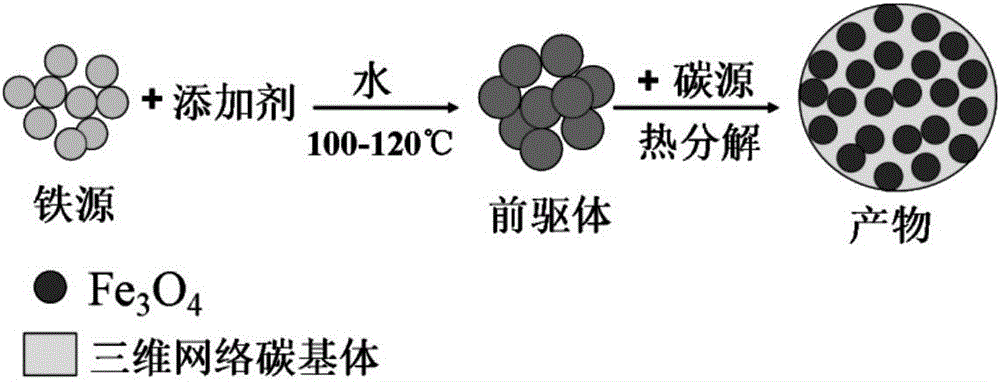

Preparation method of carbon/iron oxide composite and lithium-ion battery

ActiveCN106099077AImprove conductivityHigh magnificationCell electrodesSecondary cellsHigh rateSize change

The invention provides a preparation method of a carbon / iron oxide composite, comprising: mixing ferrous carbonate with a high-molecular organic matter, and heating and calcining in a protective atmosphere to obtain the carbon / iron oxide composite. Compared with the prior art, the method uses ferrous carbonate micro-particles as a raw material, the material may decompose into nano-scale iron oxide in subsequent high-temperature calcining, micro-structure of nanoparticles is accordingly obtained, the charge-discharge capacity is higher than that of solely nano-scale or micro-scale particles, and the structure is more stable; moreover, carbon material that is added may connect iron oxide active nanoparticles via three-dimensional network carbon, the carbon material can serve as a buffer and support, stress due to size changes of a substance is buffered, basic configuration of the substance is maintained, and the carbon material has high electrical conductivity so that the prepared carbon / iron oxide composite has high rate, high specific capacity and long cycle life.

Owner:SHANDONG SACRED SUN POWER SOURCES

Manufacture method of anode material of lithium ion battery

InactiveCN101546825AEasy to separateEasy to operateElectrode manufacturing processesPhosphorus compoundsLithium hydroxidePhosphate

The invention discloses a manufacture method of an anode material of a lithium ion battery, belonging to the manufacture method of battery anode materials. The method takes iron (Fe), sulfuric acid (H2SO4), sodium carbonate (Na2CO3), lithium hydroxide (LiOH) or lithium carbonate (LI2CO3) and phosphoric acid (H3PO4) as raw materials and comprises the steps of preparing ferrisulfas, preparing ferrous carbonate, preparing lithium orthoposphate monometallic and preparing ferrous phosphate lithium anode material. The invention has the advantages of simple manufacturing technique, convenient operation, safety, reliability, pure product, stable quality, low cost and no pollution to environment.

Owner:XUZHOU HAITIAN GREEN ENERGY TECH

Method for preparing composite enzyme of kudzu vine leaves and folium mori

ActiveCN105962344AQuality improvementFully retain active ingredientsFood ingredient functionsBlood vesselEnzyme method

The invention discloses a method for preparing composite enzyme of kudzu vine leaves and folium mori. The method comprises the following steps of: shredding kudzu vine leaves and folium mori, squeezing, collecting a leaf liquid, pouring the squeezed kudzu vine leaves, the folium mori and the leaf liquid into a fermentation container, adding a sodium hydrogen phosphate-citrate buffer solution which is cooled in advance, adding composite enzyme and ferrous carbonate, and performing enzyme method low-temperature extraction; and preparing primary fermentation broth from the extraction filtrate, inoculating the primary fermentation broth into lactobacillus plantarum so as to obtain secondary fermentation broth, and performing solid-liquid separation on the secondary fermentation broth, thereby obtaining the composite enzyme. Due to enzyme method low-temperature extraction, nutrient elements in kudzu vine leaves and folium mori can be sufficiently extracted, and thus the effects and eating security of the product can be greatly improved; the method disclosed by the invention is simple in process, effective components of kudzu vine leaves and folium mori can be sufficiently maintained, the quality is stable, multiple effects of reducing blood vessel resistance, improving heart and brain blood circulation, reducing myocardial oxygen consumption and the like can be achieved, and a nutrient healthcare function can be achieved.

Owner:JIANSU MAOBAO GEYE CO LTD

Method for preparing lithium ion battery anode material lithium iron phosphate

InactiveCN101355160ANo need to control moisture contentReduce energy consumptionCell electrodesPhosphorus compoundsIron saltsLithium iron phosphate

The invention relates to a method for preparing a LiFePO4 anode material for a lithium ion battery. The method comprises the following steps that a wet chemical method is adopted to synthesize ferrous carbonate by cheap and soluble bivalent iron salt and sodium carbonate; after cleaning, Li salt, a P source and a soluble C source are added and dried; and finally, after baked twice and ground once, dried powder is made into LiFePO4 with regular appearance, uniform grain size and excellent electrical property. The method has the advantages of simple technological process, low production cost of prepared product and stable and controllable product performance, and can be used in industrial production.

Owner:KINGRAY NEW MATERIALS SCI & TECH

Compound iron fertilizer special for fruit tree and forest tree branches and trunks and application method of compound iron fertilizer

ActiveCN107056469AAvoid fixationReduce releaseFertilising methodsNitrogenous fertilisersFruit treeIron powder

The invention discloses compound iron fertilizer special for fruit trees and forest tree branches and an application method of the compound iron fertilizer. A preparation method of the compound iron fertilizer is characterized by including: using saturated ferrous sulfate, saturated ammonium bicarbonate and iron powder to prepare ferrous carbonate containing the iron powder, adding the ferrous carbonate into a certain amount of compound amino acid and citric acid solution under 65-70 DEG C, performing immediate filtration after the reaction, concentrating filtrate, adding clay, kneading into long strips, cutting into cylinders, and airing or drying to obtain the compound iron fertilizer. The application method includes: drilling an inclined hole in a fruit tree or forest tree branch and trunk, placing the compound iron fertilizer into the hole in the trunk, injecting water, and sealing the hole. The compound iron fertilizer has the advantages that the problem that conventional iron fertilizer is prone to oxidation and low in fertilizer efficiency is solved, and the compound iron fertilizer is simple to apply, safe and capable of mildly providing iron nutrients for trees and keeping the absorption effectiveness of the iron nutrients for a long time.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

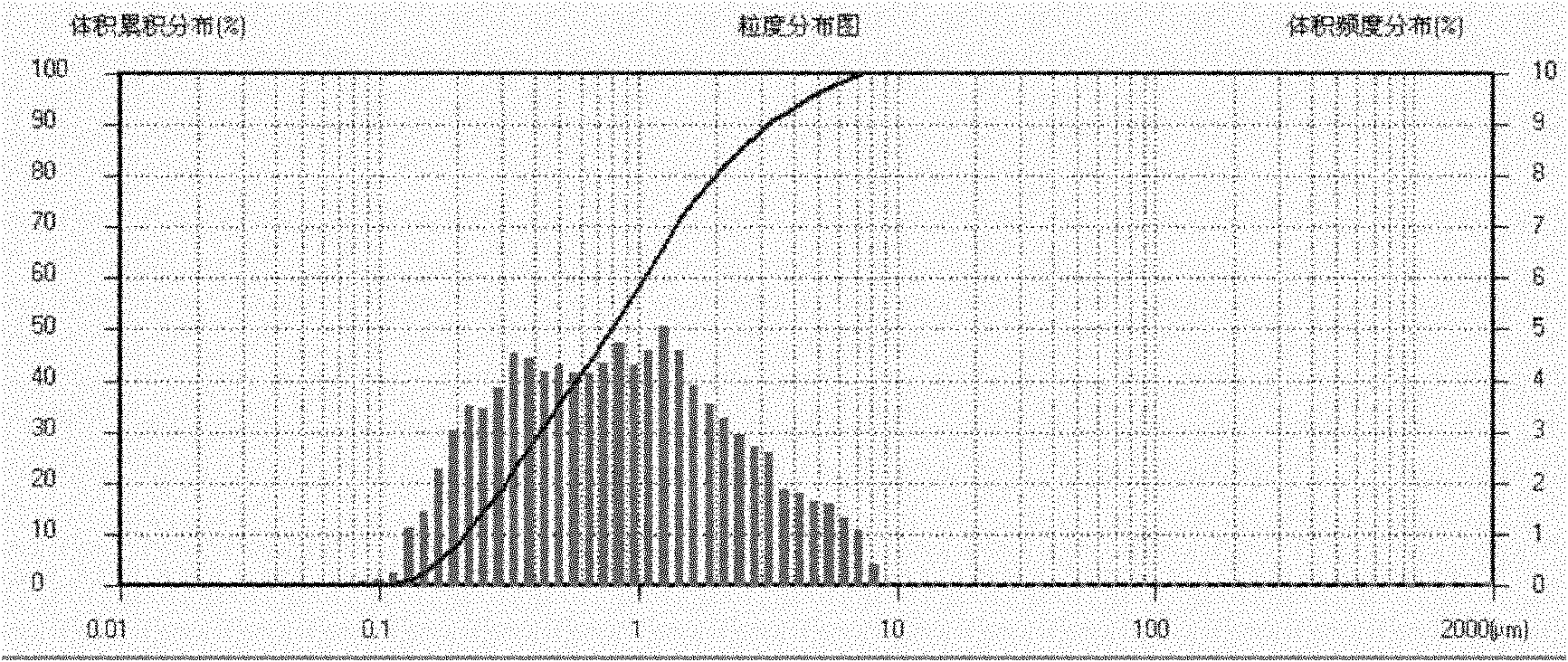

Liquid-phase co-precipitation preparation method of lithium iron phosphate cathode material

The invention discloses a liquid-phase co-precipitation preparation method of a lithium iron phosphate cathode material and belongs to the technical field of preparation of chemical materials. The method comprises the following steps of: using a controlled crystallization technology to prepare ferrous carbonate; with the newly prepared ferrous carbonate as an iron source, phosphoric acid as a phosphorus source and lithium hydroxide or lithium carbonate as a lithium source, preparing a lithium iron phosphate precursor by a liquid-phase co-precipitation method; drying, coating with carbon and sintering to obtain the lithium iron phosphate cathode material. The method disclosed by the invention better overcomes the shortcomings in the liquid-phase method that of Fe2<+> is oxidized easily and pH value of the solution is instable; and the prepared product is high in purity, uniform in distribution, and micron or nano-sized in granularity; the precursor which is small in granularity and contains various elements which are uniformly dispersed is more beneficial to the high-temperature solid-phase reaction, and is capable of shortening the sintering duration and reducing the energy consumption. The liquid-phase co-precipitation preparation method of the lithium iron phosphate cathode material has the advantages that used raw materials are simple and easily available, cost is low, and the preparation process can be controlled easily; therefore, the preparation method is applicable to massive industrial production.

Owner:TSINGHUA UNIV

Method for reducing oxygen content of fluid streams containing sulfur compounds

A method of using a sulfided iron reagent to remove oxygen from gaseous and liquid fluid streams such as natural gas, light hydrocarbon streams, crude oil, acid gas mixtures, carbon dioxide gas and liquid streams, anaerobic gas, landfill gas, geothermal gases and liquids, and the like is disclosed. In a preferred embodiment, the reagent is made by mixing, agglomerating and shaping finely powdered ferrous carbonate, preferably siderite which are used to remove oxygen from a hydrocarbon or carbon dioxide stream that also contains sulfur compounds such as hydrogen sulfide.

Owner:NEW TECH VENTURES

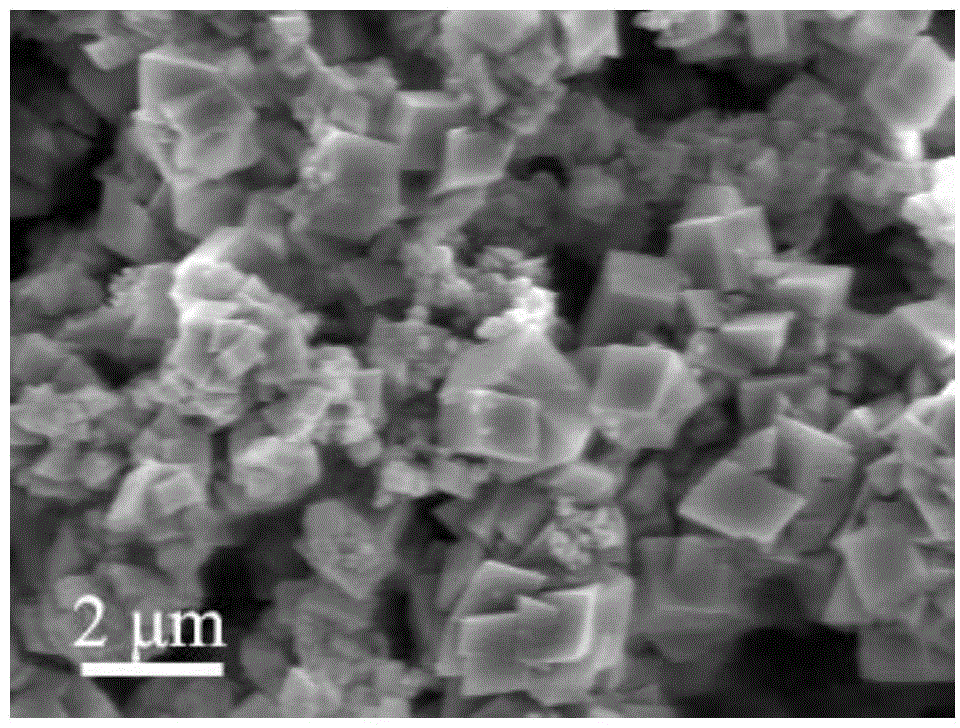

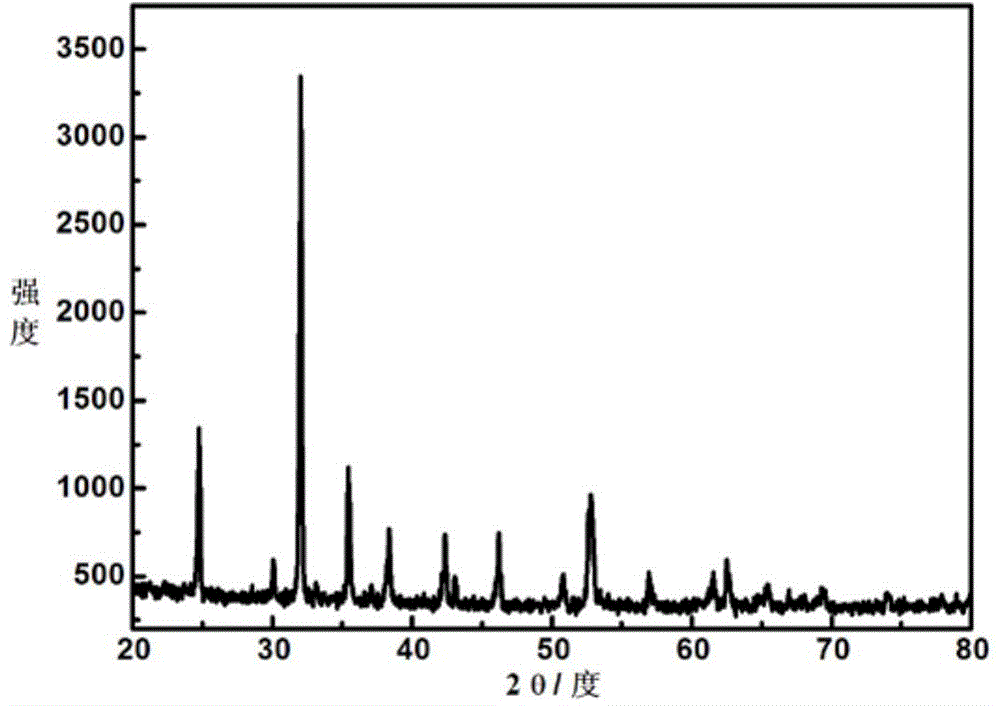

Ferrous carbonate hexahedron and preparation method thereof

The invention discloses a ferrous carbonate hexahedron and a preparation method thereof. The ferrous carbonate hexahedron is a FeCO3-phase hexahedron crystal structure, wherein the side length of the ferrous carbonate hexahedron is 500-5000nm. The preparation method comprises the following steps: uniformly stirring ferrous chloride tetrahydrate, urea and deionized water in a mole ratio of (1-5):(3-15):(2000-3000); adding the uniform solution into a high-pressure autoclave, putting the high-pressure autoclave into a drying oven, heating to 120-180 DEG C, and keeping the temperature for 3-18 hours; and naturally cooling the high-pressure autoclave to room temperature, taking out the reaction product, repeatedly washing the reaction product with deionized water and anhydrous ethanol until the water solution is neutral, centrifugating to obtain a precipitate, and drying the precipitate in a drying oven to obtain the ferrous carbonate hexahedron powder. The method does not need to add any dispersing agent or surfactant; the prepared ferrous carbonate hexahedron has high crystallinity; and the preparation process has the advantages of convenient after-treatment, low reaction temperature, short reaction time, simple reaction technique and low cost.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for synthesizing spherical siderite single crystal by using precursor at high temperature under high pressure

InactiveCN109989109ASolve problems that cannot be artificially synthesizedHave the characteristics of cleavagePolycrystalline material growthFrom solid stateIron powderRefractive index

The invention discloses a method for synthesizing a spherical siderite single crystal by using a precursor at high temperature under high pressure. The method comprises the following steps: firstly, uniformly grinding and mixing analytically pure barium carbonate and synthesized ferrous carbonate according to a molar ratio of 1:1, taking the mixture as an initial raw material to carry out a reaction at high temperature under high pressure to obtain a barium carbonate iron powder crystal precursor, then grinding and mixing the barium carbonate iron powder crystal precursor with anhydrous oxalicacid according to a molar ratio of 1:1, assembling the prepared sample in a high-pressure synthesis assembly block, and putting the sample into a huge cubic press to carry out a high-temperature high-pressure reaction to prepare the gold-yellow spherical siderite single-crystal sample. The invention solves the problem that the existing spherical siderite seed crystal cannot be artificially synthesized. The size of the spherical siderite single crystal obtained by the method is up to 200 microns, and a thick gold yellow color can be observed under a mineral phase mirror, so that requirements of spherical siderite gems to refractive index are met. In addition, the spherical siderite prepared by the method does not contain Ba impurities.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com