Method for preparing food-grade amino acid ferrous chelate compound without interfering anions

A technology of ferrous amino acid and anion, which is applied in food preparation, food science, application, etc., can solve the problem that the chelation reaction of ferrous chloride and amino acid is difficult to carry out completely, and it is impossible to obtain ferrous glycine products with high iron content, sulfate ions and The problem of difficult separation of chloride ions, etc., achieves the effect of stable physical and chemical properties of the product, convenient for industrial scale production, and good stability of the aqueous solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

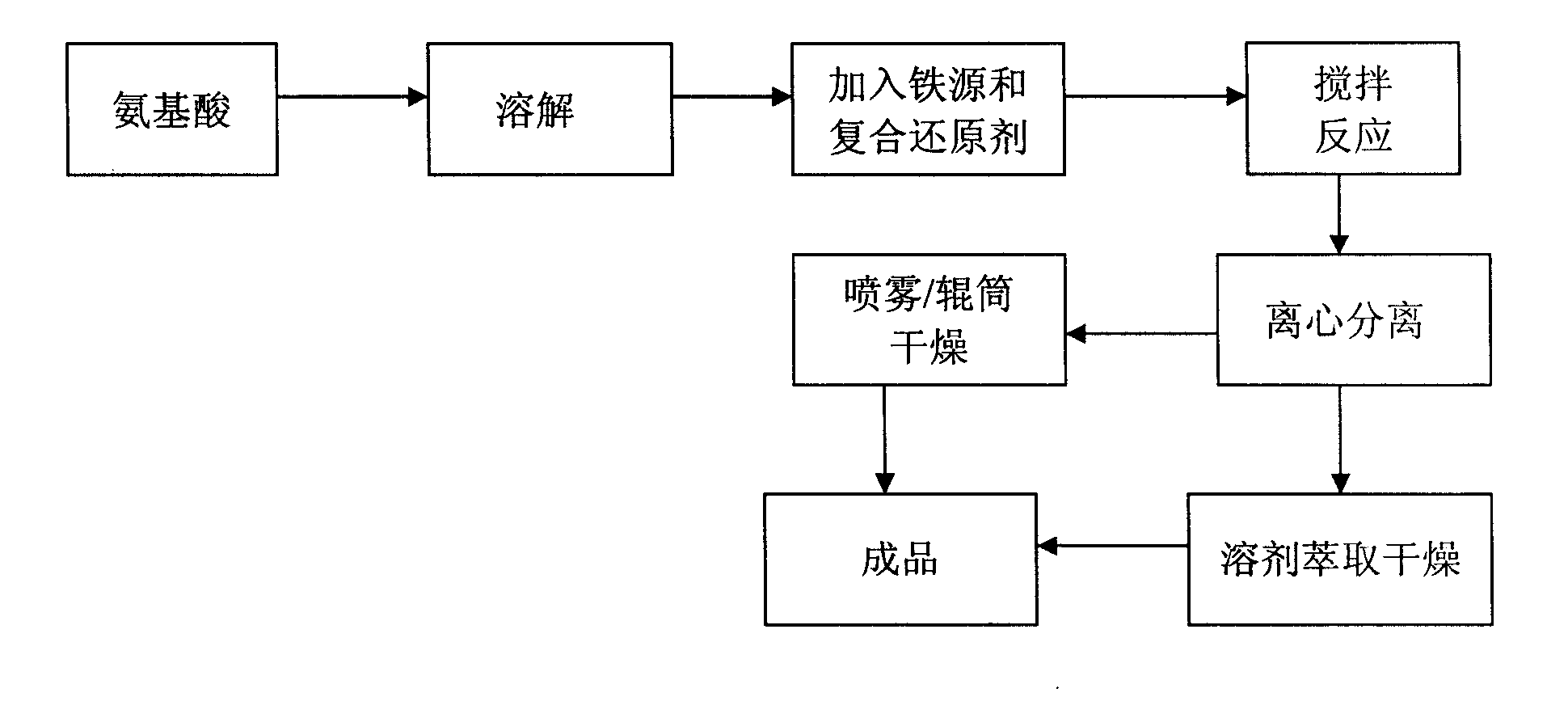

Method used

Image

Examples

Embodiment 1

[0012] Choose glycine and reduced iron powder as the main raw materials, the molar ratio is 1:1; first dissolve glycine in water, add reduced iron powder under nitrogen protection, adjust the pH value to 6 with citric acid; heat to 40°C in water bath, and react under stirring 24 hours; centrifugally separate the reduced iron powder, evaporate and concentrate, extract with a 90% aqueous ethanol solution, and dry to obtain a food-grade ferrous glycine chelate product with a ferrous content of 17%.

Embodiment 2

[0014] Glycine and ferrous hydroxide are selected as the main raw materials, and the molar ratio is 2:1; first, the glycine is dissolved in water, and fresh ferrous hydroxide is added under the protection of nitrogen, and the pH value is adjusted to 6 with ascorbic acid; heated to 60°C, stirred The reaction was carried out for 48 hours; after evaporating and concentrating until a small amount of solid precipitated out, it was extracted with a 70% ethanol aqueous solution and dried to obtain a food-grade ferrous glycinate chelate product with a ferrous content of 16%.

Embodiment 3

[0016] Choose methionine and ferrous carbonate as the main raw materials, and the molar ratio is 2:1; first dissolve glycine in water, add fresh ferrous carbonate under nitrogen protection, adjust the pH value to 5 with ascorbic acid, heat to 70 ° C, and stir Reacted for 18 hours; evaporated and concentrated, and roller dried to obtain a food-grade ferrous glycinate chelate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com