A kind of preparation method of high-purity nano ferric oxide

A ferric tetroxide and nanotechnology, which is applied in the field of preparation of high-purity nano ferric tetroxide, can solve the problems of low rate performance, volume change particle agglomeration, poor cycle stability of negative electrode materials, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

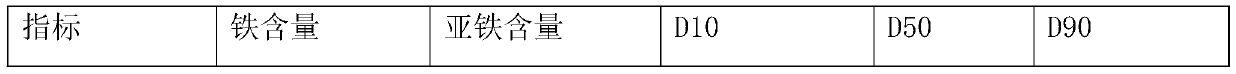

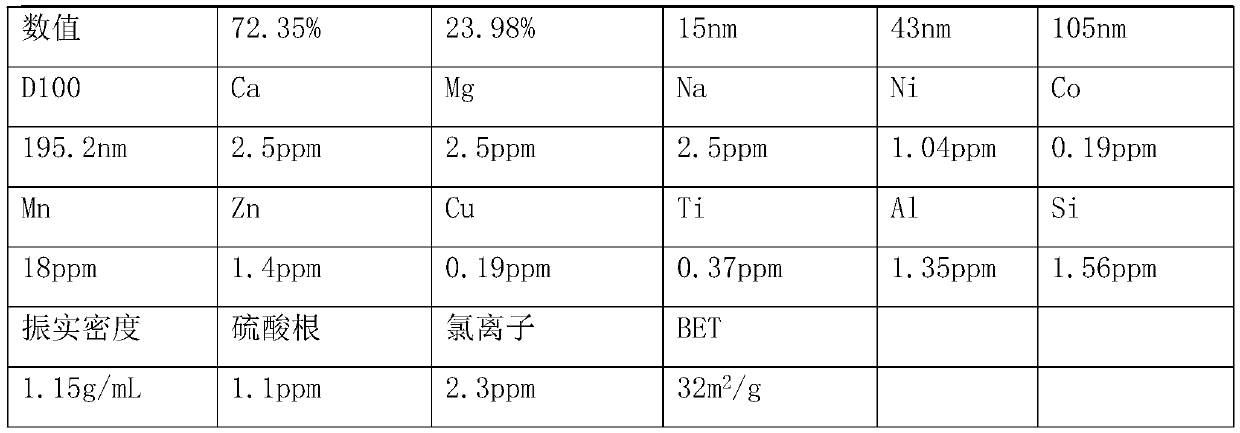

Image

Examples

Embodiment 1

[0043] A preparation method of high-purity nano ferric oxide, which comprises the following steps:

[0044] (1) Iron salt, ammoniacal liquor and oxidizing agent are joined in the reactor together, and at temperature is 235 ℃, and pressure is 1.8 atmospheres, and the pH of control reaction system is 7.55, and pH is the pH value under 25 ℃ of temperature, reacts An oxidation-reduction potential meter is installed on the kettle. When the ORP of the redox potential meter is 235mV, stop feeding, continue to react at high temperature for 2.5 hours, and observe the ORP value of the redox potential meter at the same time. When the ORP value is greater than 250mV, pass Inject hydrogen to reduce the ORP value to 235mV, then continue to increase the pressure to 3.2 atmospheres, maintain the pH of the reaction system at 8.03, the pH is the pH value at a temperature of 25°C, and the temperature is 168°C, and feed hydrogen to make the solution ORP value decreased to -25mV, and reacted for 2...

Embodiment 2

[0056] A preparation method of high-purity nano ferric oxide, which comprises the following steps:

[0057](1) Iron salt, ammoniacal liquor and oxidizing agent are joined in the reactor together, and at temperature is 245 ℃, and pressure is 1.89 atmospheric pressure, and the pH of control reaction system is 7.48, and pH is the pH value under 25 ℃ of temperature, reacts An oxidation-reduction potential meter is arranged on the kettle. When the ORP of the redox potential meter is 205mV, stop feeding, continue to react at high temperature for 2.5 hours, and observe the ORP value of the redox potential meter at the same time. When the ORP value is greater than 250mV, pass Inject hydrogen to reduce the ORP value to 205mV, then continue to increase the pressure to 3.68 atmospheres, maintain the pH of the reaction system at 7.99, the pH is the pH value at a temperature of 25°C, and the temperature is 168°C, and feed hydrogen to make the solution ORP value decreased to 25mV, and react...

Embodiment 3

[0068] A preparation method of high-purity nano ferric oxide, which comprises the following steps:

[0069] (1) Add iron salt, ammonia water and oxidant to the reaction kettle together, and control the pH of the reaction system to 7.55 at a temperature of 220-250°C and a pressure of 1.98 atmospheres, and the pH is the pH value at a temperature of 25°C , the reactor is equipped with an oxidation-reduction potential meter, when the ORP of the redox potential meter is 208mV, stop feeding, continue to react at high temperature for 2.3 hours, and observe the ORP value of the redox potential meter at the same time, when the ORP value is > 250mV , feed hydrogen to reduce the ORP value to 208mV, then continue to increase the pressure to 3.5 atmospheres, maintain the pH of the reaction system at 8.07, the pH is the pH value at a temperature of 25°C, and the temperature is 175°C, and feed hydrogen to make The ORP value of the solution was reduced to -10mV, and reacted for 23 minutes;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com